Lithium-sodium-cobalt-oxygen thermoelectric ceramic and preparation method thereof

A sodium cobalt oxygen and thermoelectric technology, applied in the field of lithium sodium cobalt oxygen thermoelectric ceramics and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Lithium carbonate (Li carbonate with a purity higher than 99%) 2 CO 3 ): sodium carbonate (Na 2 CO 3 ): cobalt tetroxide (Co 3 o 4 )=0.72:0.675:1 molar ratio proportioning Weigh raw materials and evenly mix, grind, carry out punching and pressing under the pressure of 100MPa to obtain compressed tablet then;

[0017] 2) Put the above-mentioned compressed tablet in a tube furnace with flowing oxygen, rapidly heat up to the calcination temperature, the calcination temperature is 1173K, and the calcination time is 30 hours, and then rapidly cool to room temperature to obtain Li 0.48 Na 0.45 CoO 2 blocks.

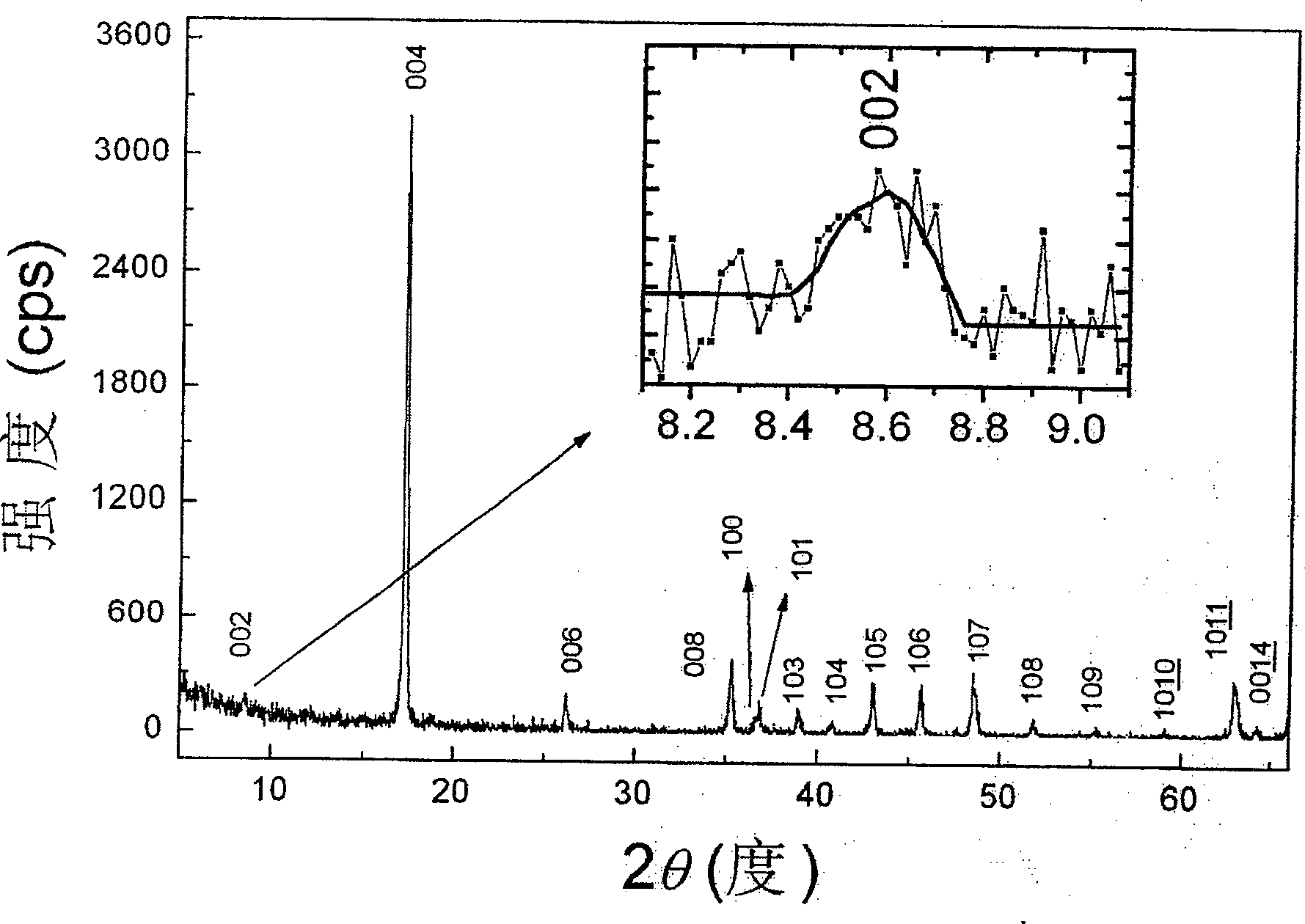

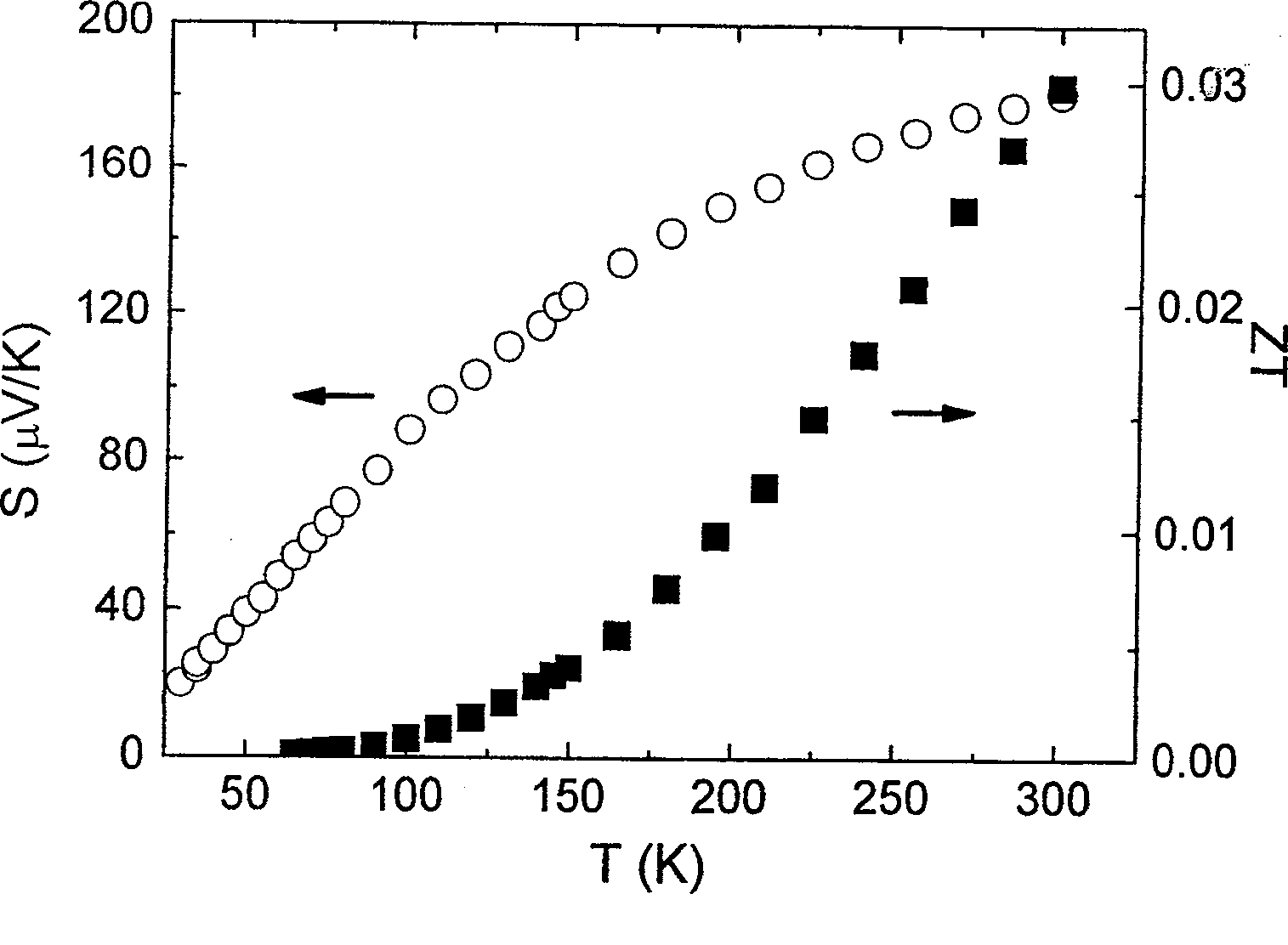

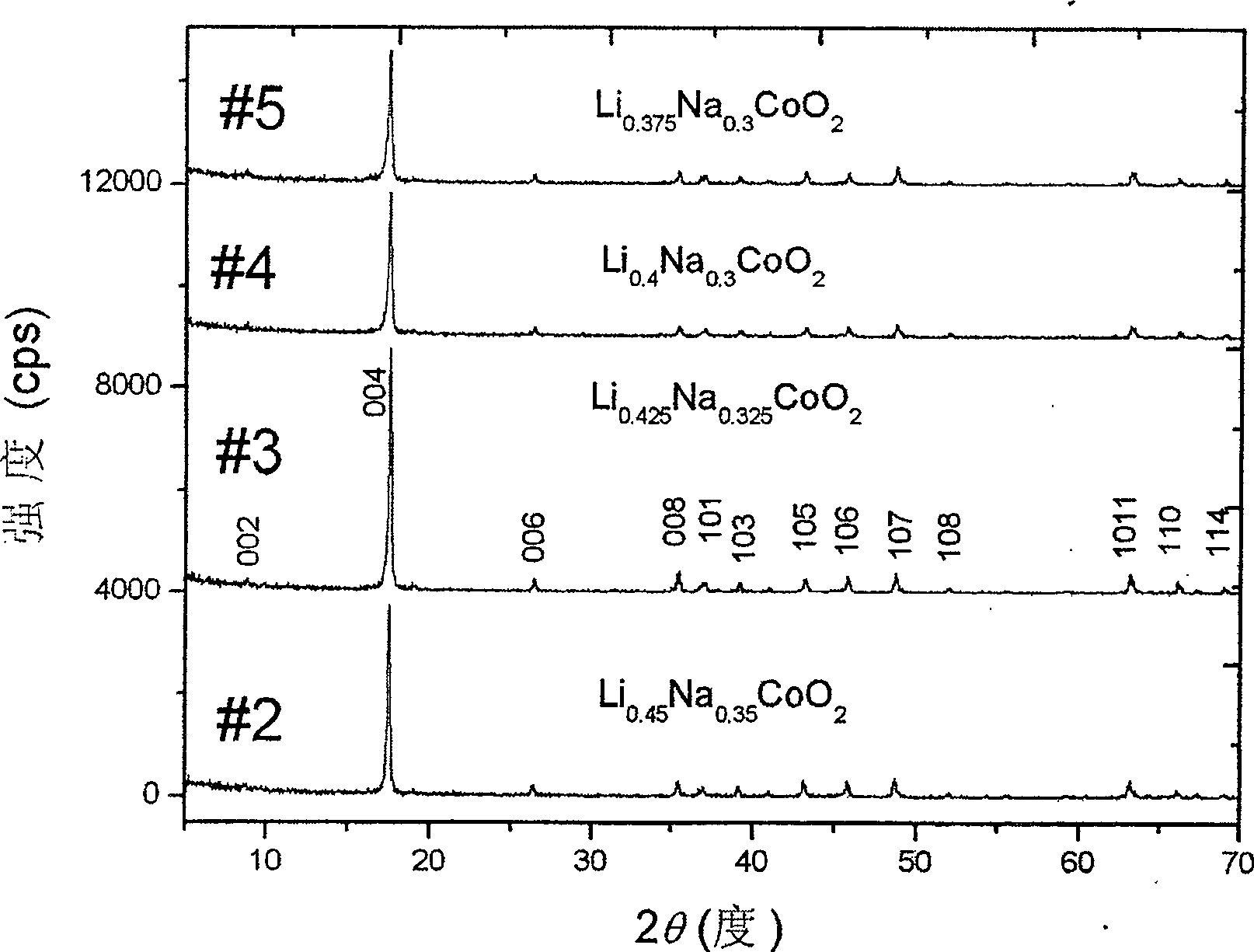

[0018] From figure 1 It can be seen that the lithium sodium cobalt oxide obtained by the above process has good single-phase property, and all X-ray diffraction peaks can be used as good indicators. The unit cell parameters of the sample are shown in Table 1; from figure 2 It can be seen that the synthesized lithium sodium cobalt oxide ceramics have good the...

Embodiment 2

[0020] 1) will Li 2 CO 3 :Na 2 CO 3 :Co 3 o 4 Raw materials with a molar ratio of 0.675:0.525:1 are fully mixed, ground, and then punched under a pressure of 80 MPa to obtain compressed tablets;

[0021] 2) Put the above-mentioned compressed tablet in a tube furnace with flowing oxygen, rapidly heat up to the calcination temperature, the calcination temperature is 1173K, and the calcination time is 24 hours, and then rapidly cool to room temperature to obtain Li 0.45 Na 0.35 CoO 2 blocks.

Embodiment 3

[0023] 1) will Li 2 CO 3 :Na 2 CO 3 :Co 3 o 4 Raw materials with a molar ratio of 0.6375:0.4875:1 are fully mixed, ground, and then punched under a pressure of 100 MPa to obtain compressed tablets;

[0024] 2) Put the above-mentioned compressed tablet in a tube furnace with flowing oxygen, rapidly heat up to the calcination temperature, the calcination temperature is 1153K, the calcination time is 36 hours, and then rapidly cool to room temperature. 0.425 Na 0.3255 CoO 2 blocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com