Cu-Zn-Sn-S photovoltaic material, and preparation method and preparation device thereof

A photovoltaic material, copper-zinc-tin-sulfur technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve problems such as easy to cause safety accidents, highly toxic steam, high consumption of S, etc., to avoid safety problems, Solve the energy crisis and avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

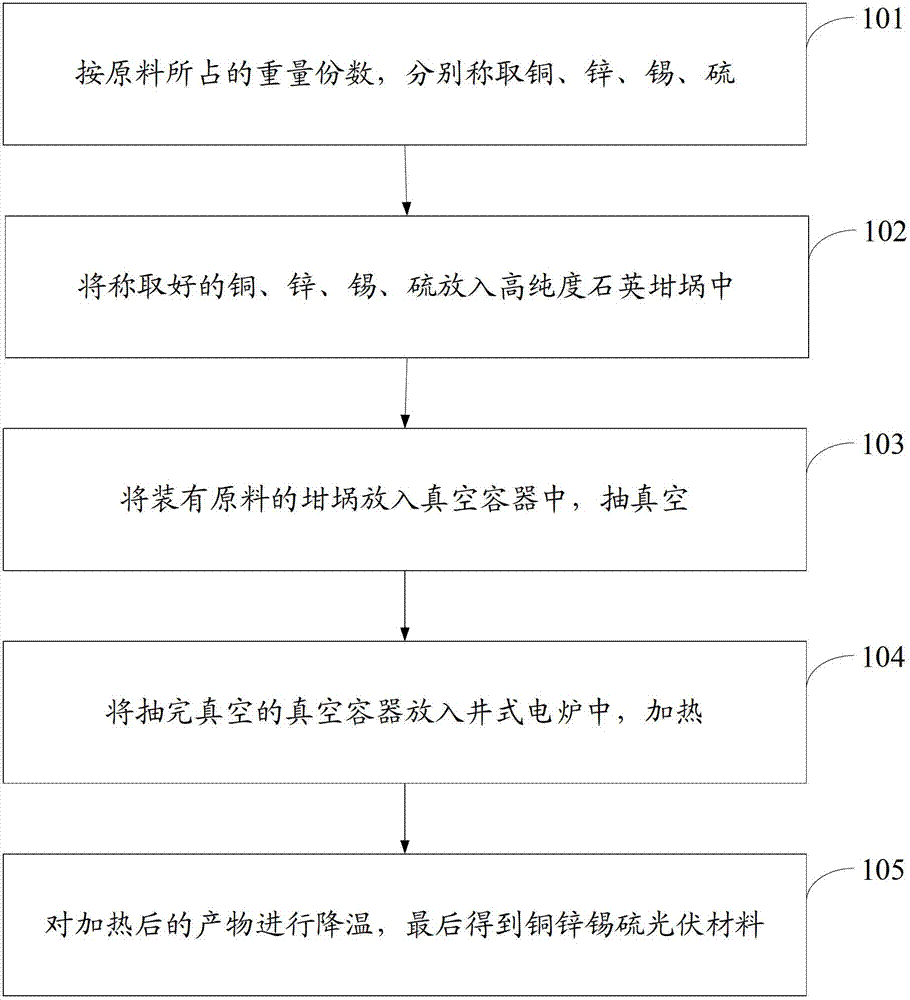

[0068] The present invention also provides a method for preparing the copper-zinc-tin-sulfur photovoltaic material described above, the method is a smelting method, comprising:

[0069] A. take copper, zinc, tin, sulfur respectively by the parts by weight of raw materials;

[0070] B. Mix the copper, zinc, tin and sulfur that have been weighed and package, and vacuumize;

[0071] C. Heating copper, zinc, tin and sulfur in a vacuum environment;

[0072] D. Lowering the temperature to obtain the copper-zinc-tin-sulfur photovoltaic material.

[0073] Since it is prepared by smelting for any of the above-mentioned copper-zinc-tin-sulfur photovoltaic materials, the raw materials include: in parts by weight, 18-35 parts of copper, 5-30 parts of zinc, 5-30 parts of 30 parts of tin, 25 to 45 parts of sulfur.

[0074] The specific content of the raw materials of the copper-zinc-tin-sulfur photovoltaic material is preferably: in parts by weight,

[0075] 18~35 parts of copper, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com