Patents

Literature

36results about How to "Plastic enough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

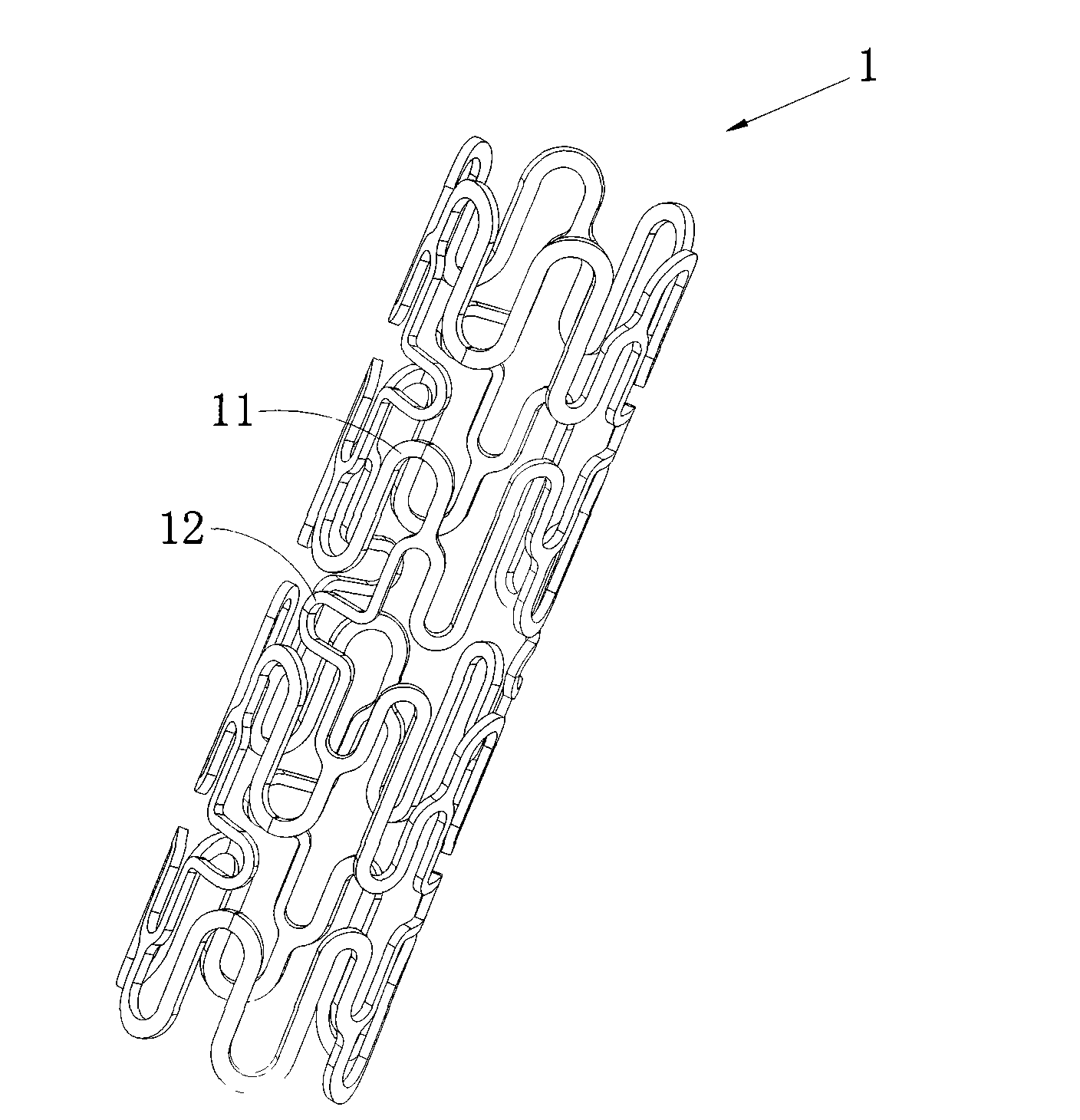

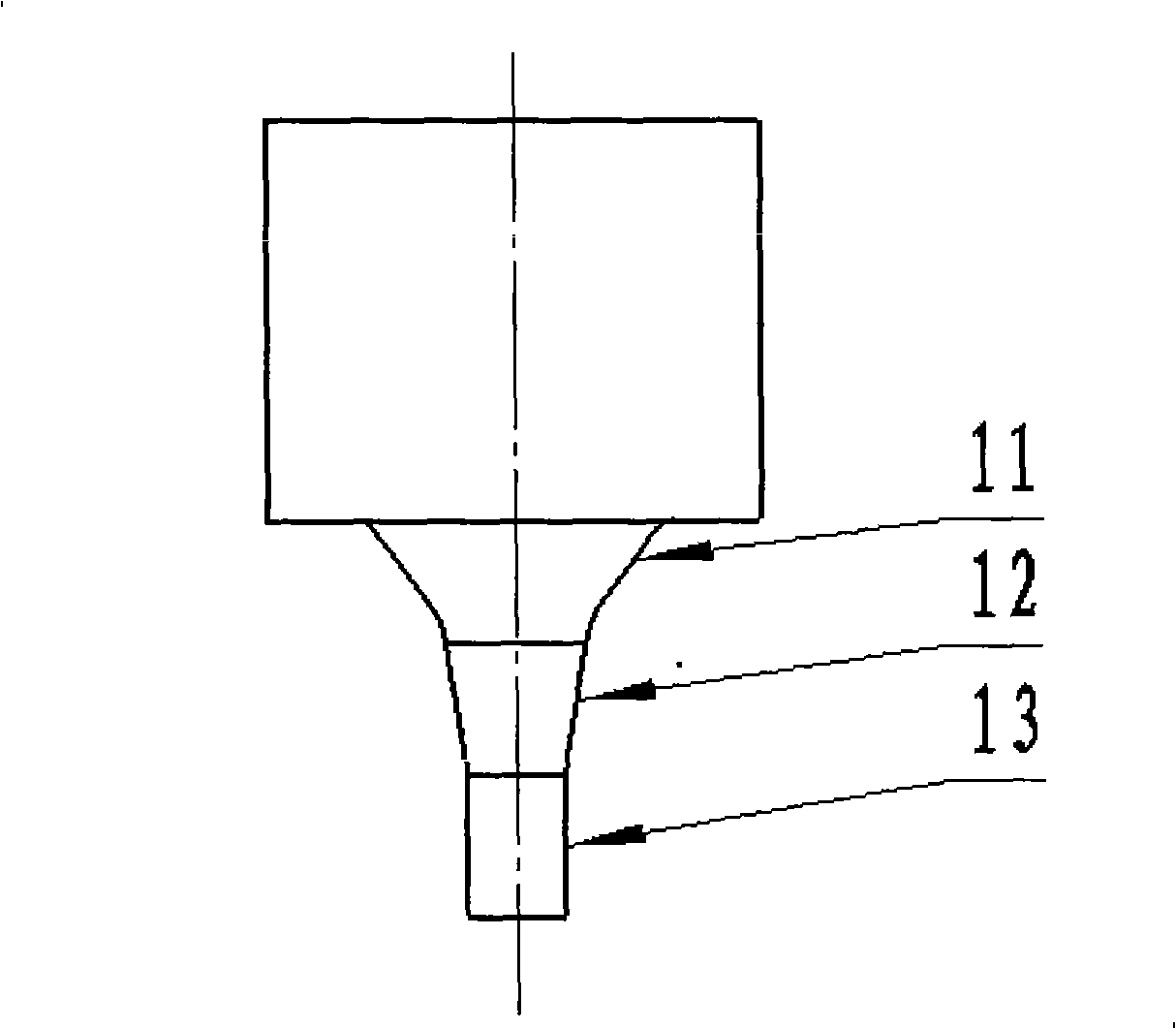

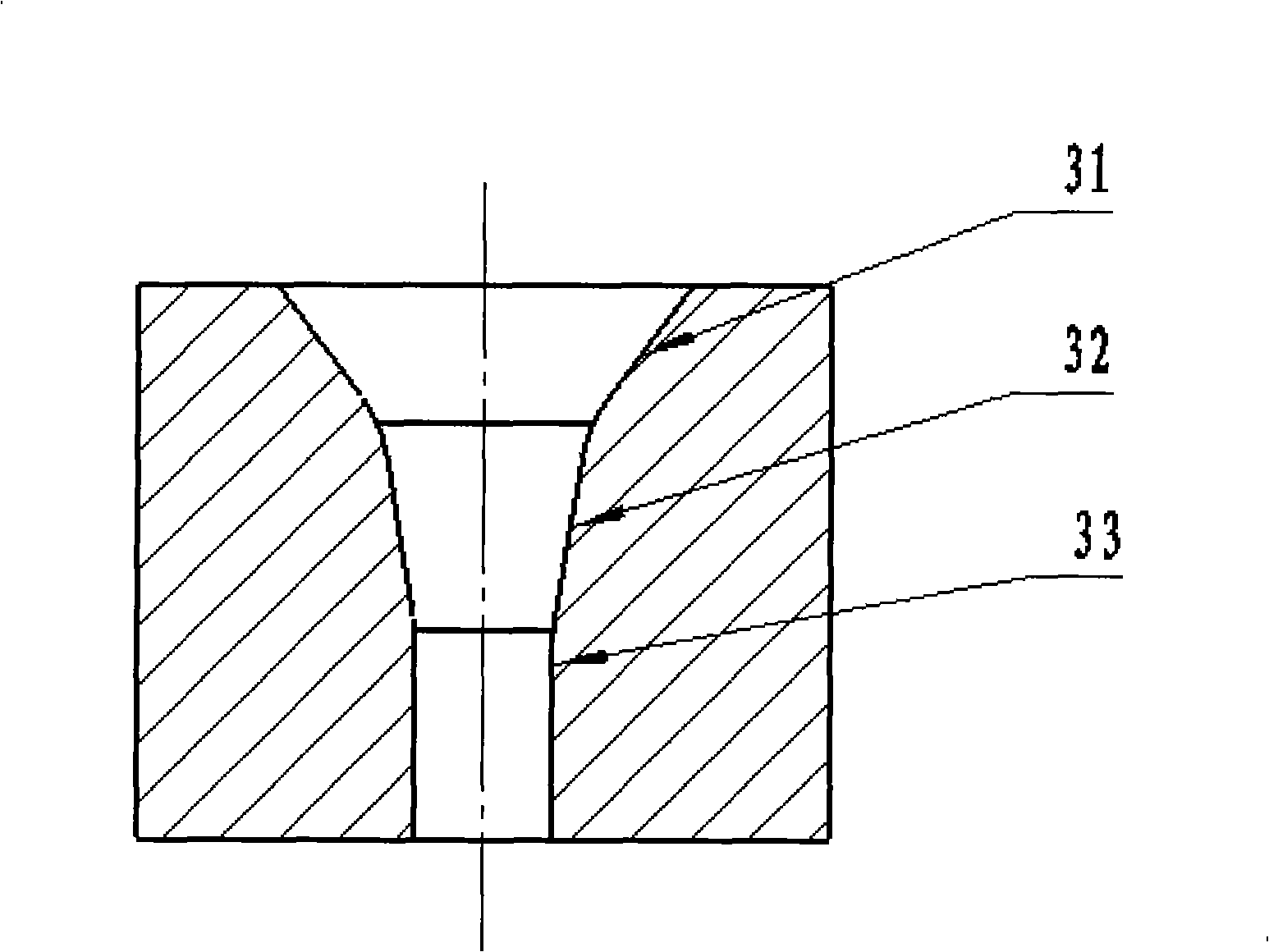

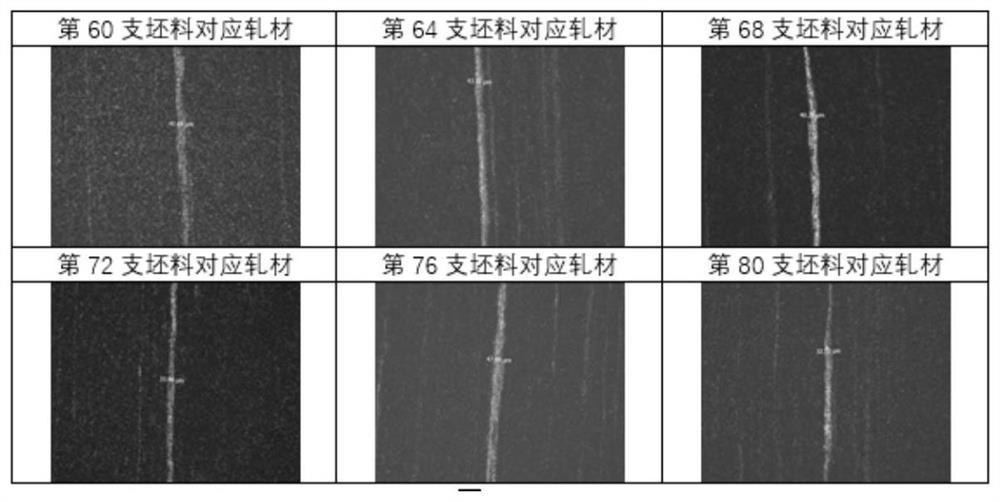

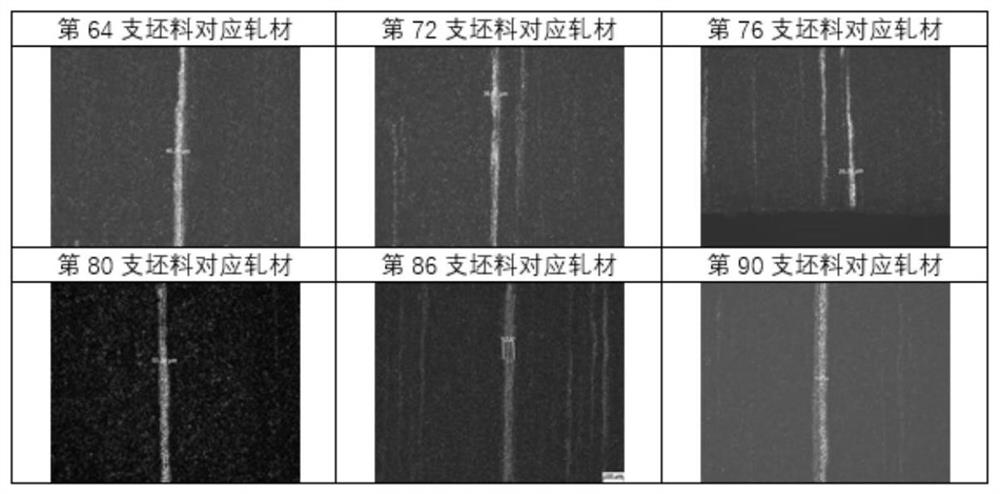

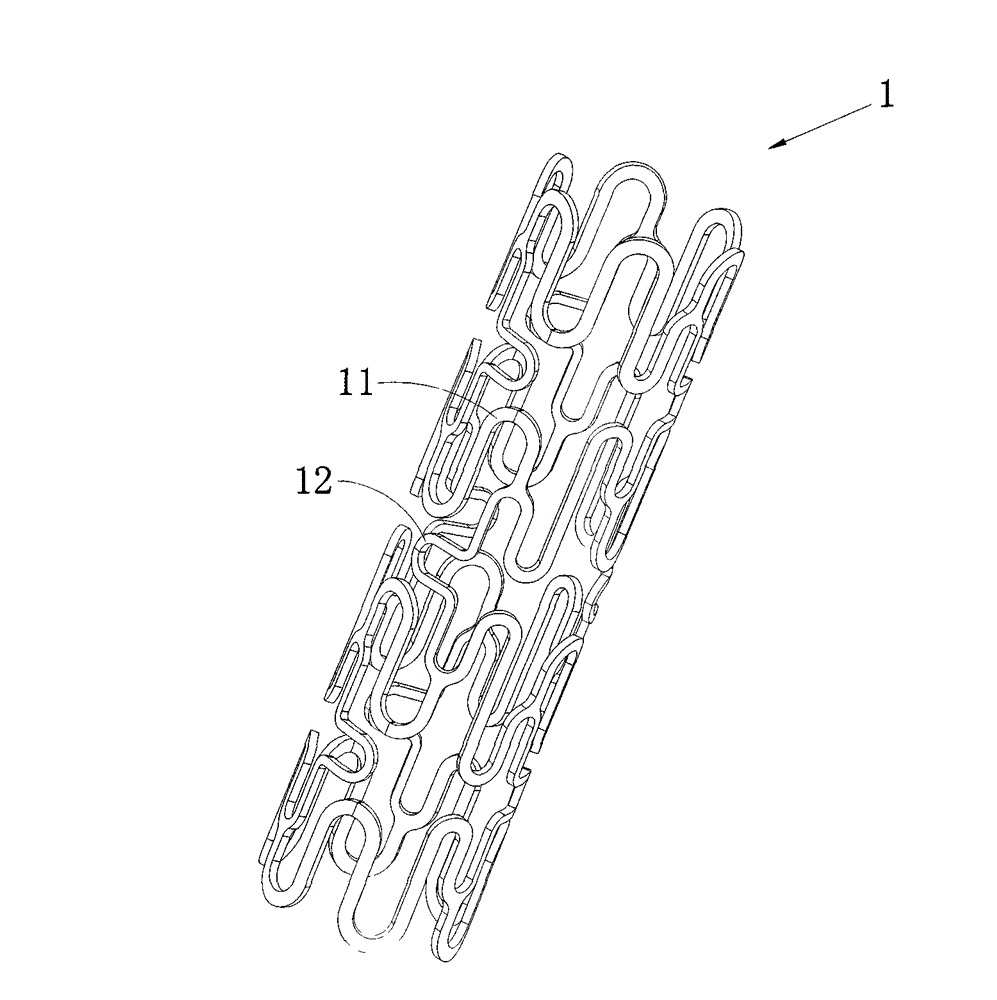

Human body absorbable blood vessel support and its manufacturing method

ActiveCN101549170AHigh strengthFast absorptionStentsSolid state diffusion coatingHuman bodyUltimate tensile strength

The present invention provides a method for manufacturing human body absorbable blood vessel support, including the following steps: (1) support forming; (2) cleaning and pre-polishing the support; (3) performing surface alloying treatment to the support; (4) performing fine finish to the support after surface treatment. The invention also provides a human body absorbable blood vessel support, theinvention adopts a surface alloying technique so that the support has a compound diffusion layer with adjustable penetration depth, thereby improving the support intensity and simultaneously quickening the corrosion speed of the support and shortening the support absorption cycle. The yield strength and elongation rate can be modulated in a prodigious scope by controlling the distribution, shapeand depth of the composite diffusion layer, to reach the intensity and absorption cycle required by the support.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

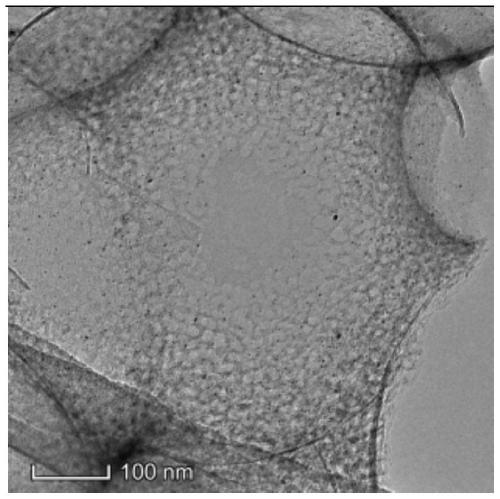

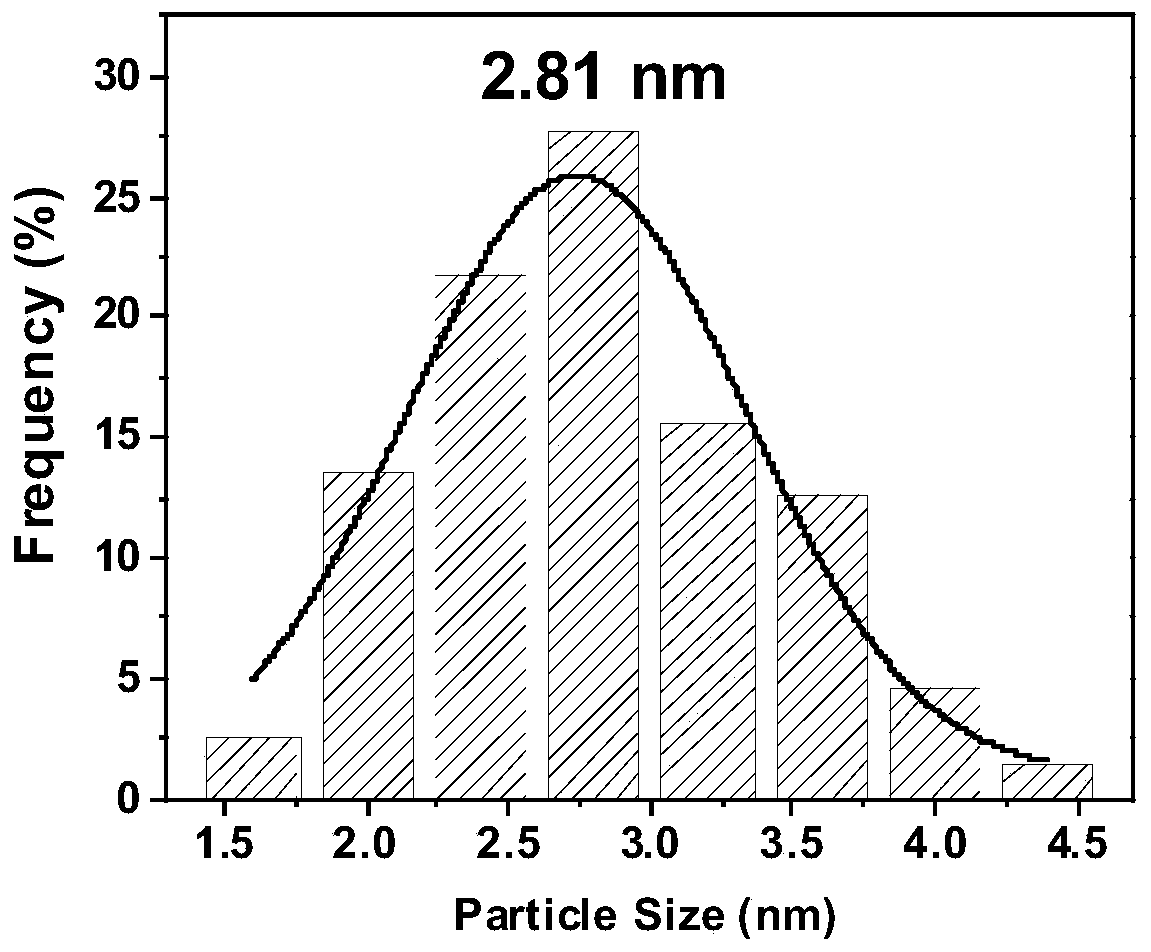

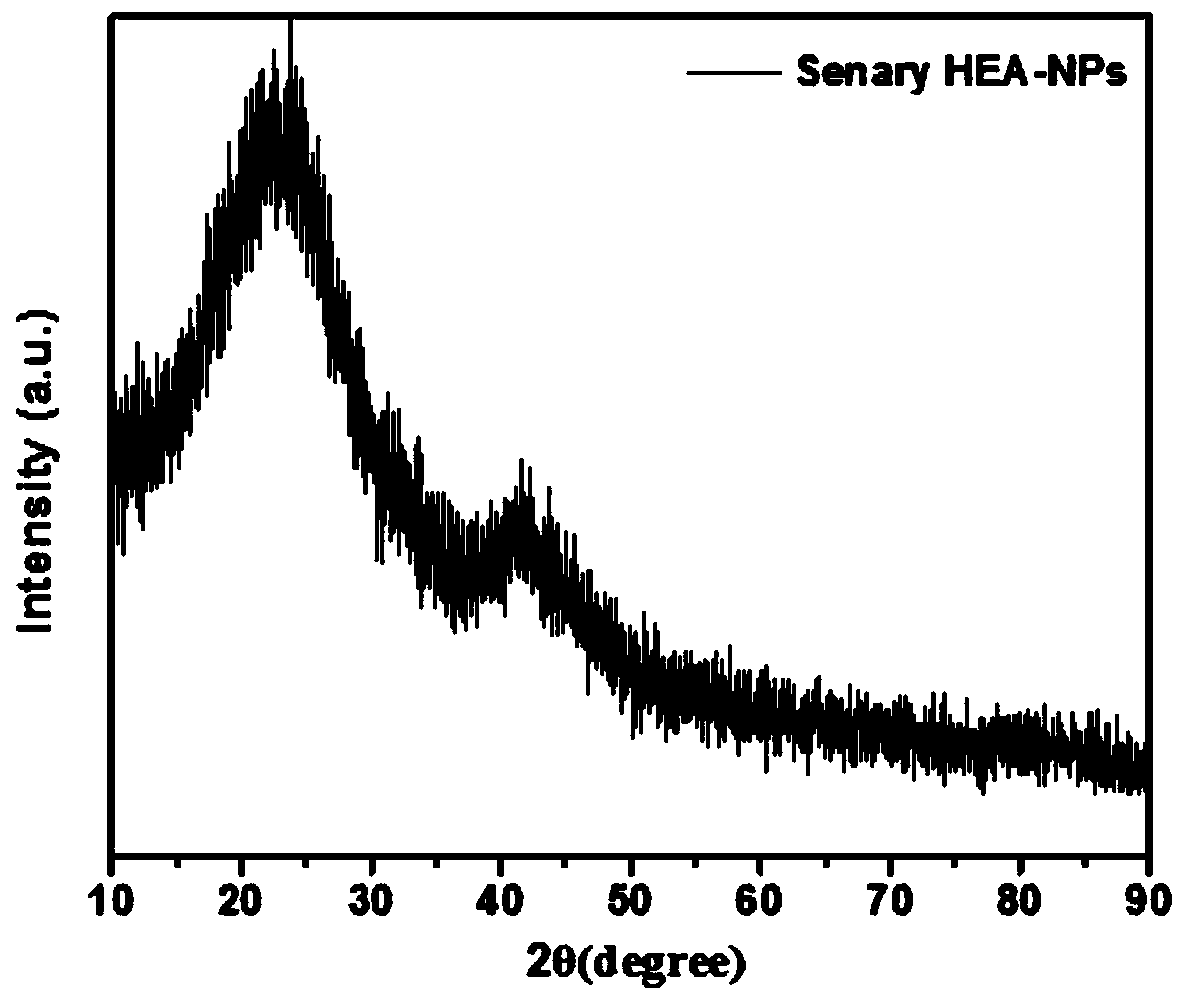

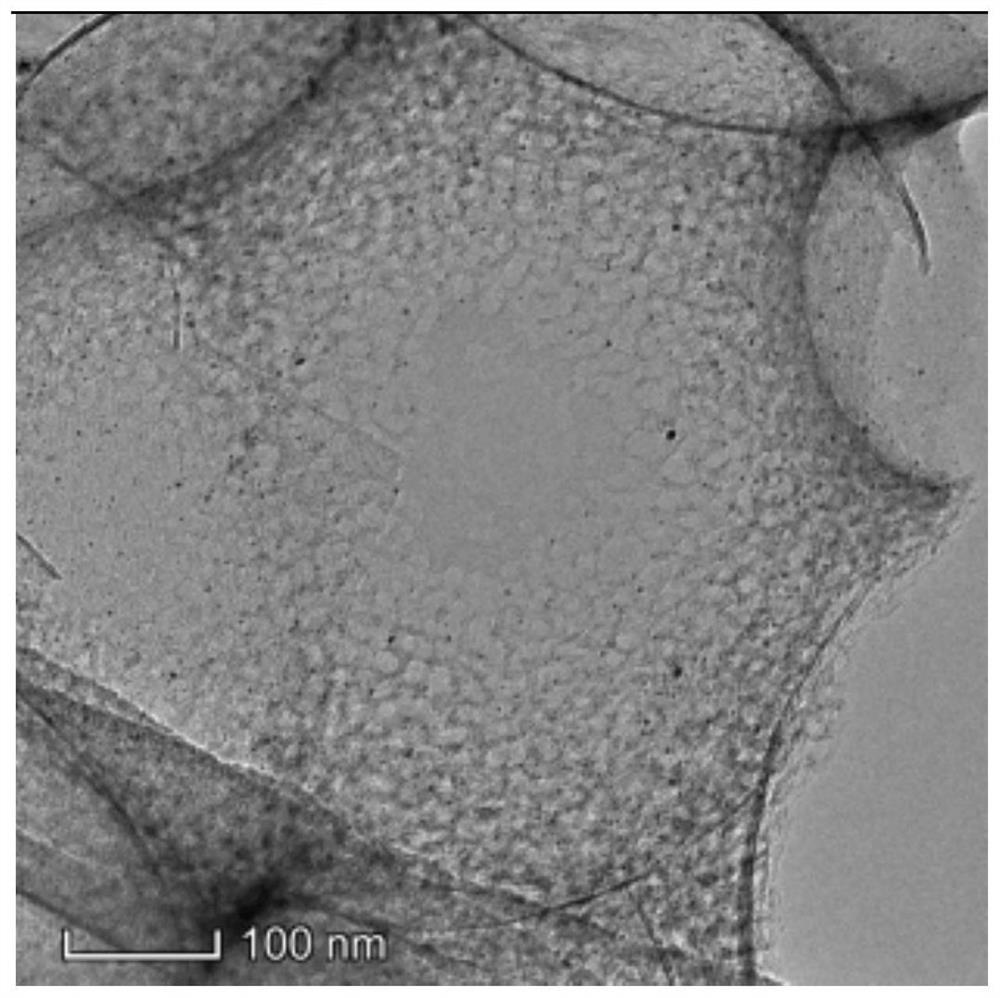

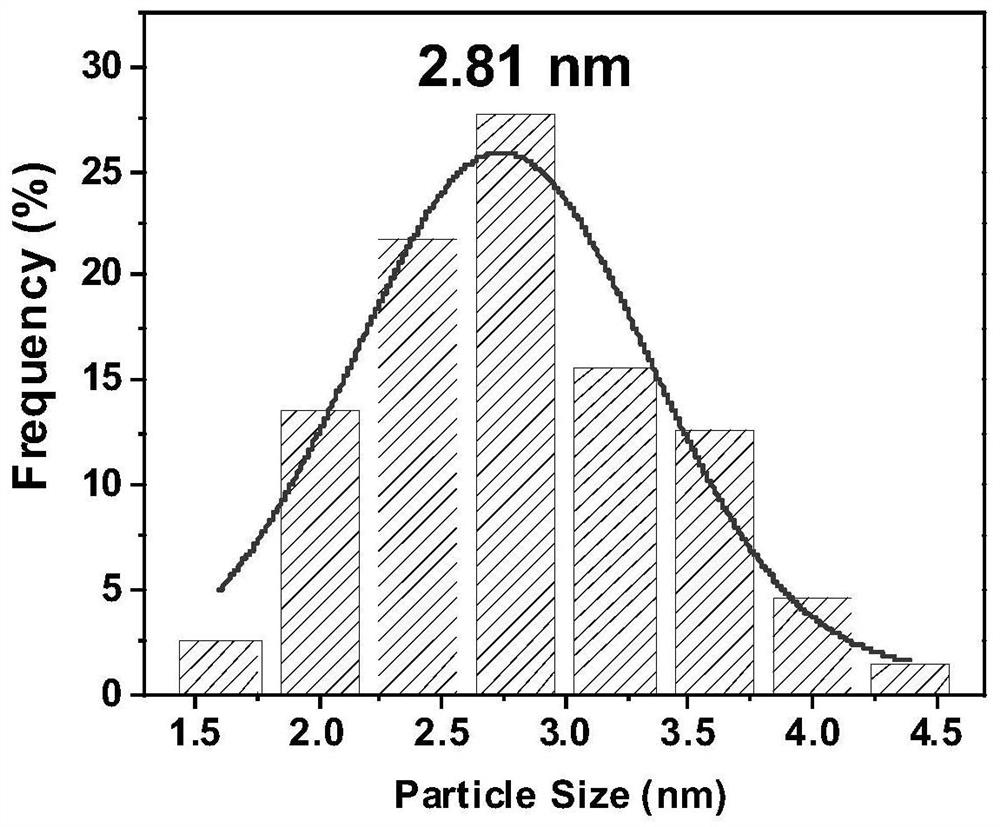

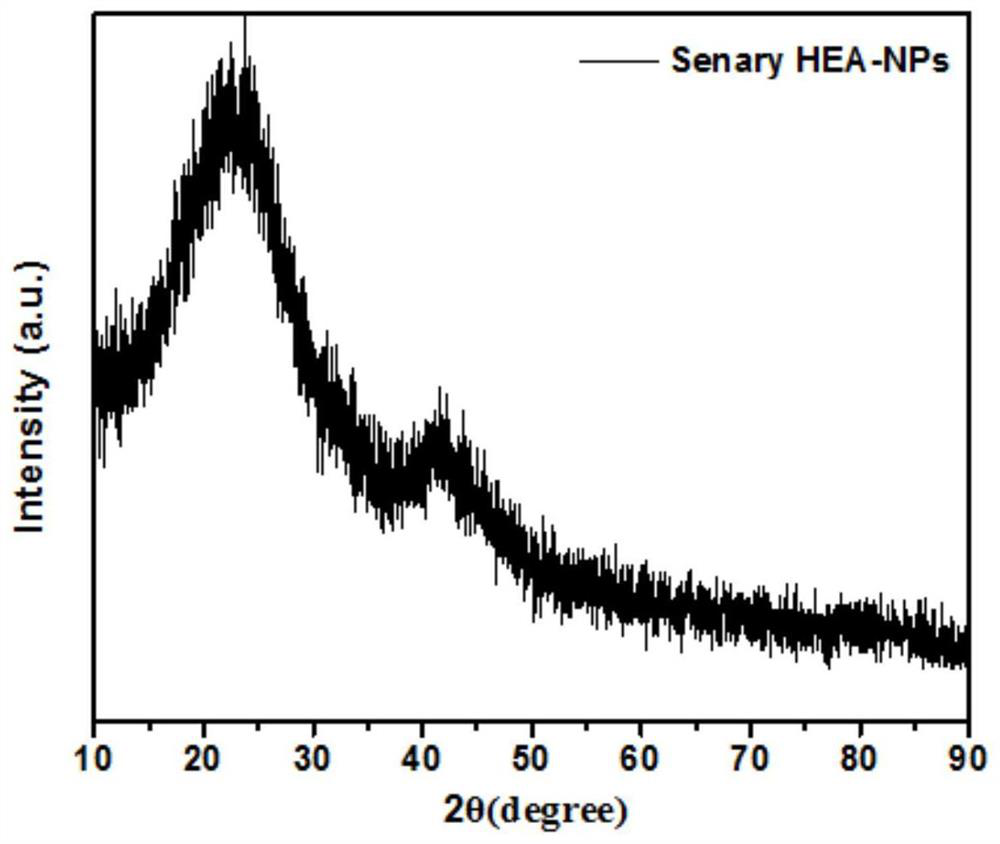

Preparation method of monodisperse platinum-series high-entropy alloy nanoparticle catalyst

ActiveCN111111693AHigh Pt utilizationEasy to prepareMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHigh entropy alloys

The invention relates to the technical field of material chemistry, and particularly discloses a preparation method of a monodisperse platinum-series high-entropy alloy nanoparticle catalyst. The preparation method comprises the steps: preparing a silicon dioxide photonic crystal template, preparing a carbon precursor solution, and dissolving a platinum precursor and at least four other metal precursors in THF and CHCl3 to obtain a mixed solution; mixing a block copolymer F127, a carbon precursor solution and tetraethyl orthosilicate, respectively adding the mixture and a protonic acid solution into the mixed solution, and stirring to obtain a transparent solution; adding the transparent solution into the silicon dioxide photonic crystal template, drying, heating and curing to obtain a purple brown solid; calcining the purple brown solid to obtain a gray solid; and etching the gray solid by adopting strong base or strong acid, filtering and drying. The monodisperse platinum-series high-entropy alloy nanoparticle catalyst with the advantages of controllable particle size, good dispersity, excellent performance and the like is obtained by adopting the preparation method disclosed bythe invention.

Owner:CHONGQING UNIV

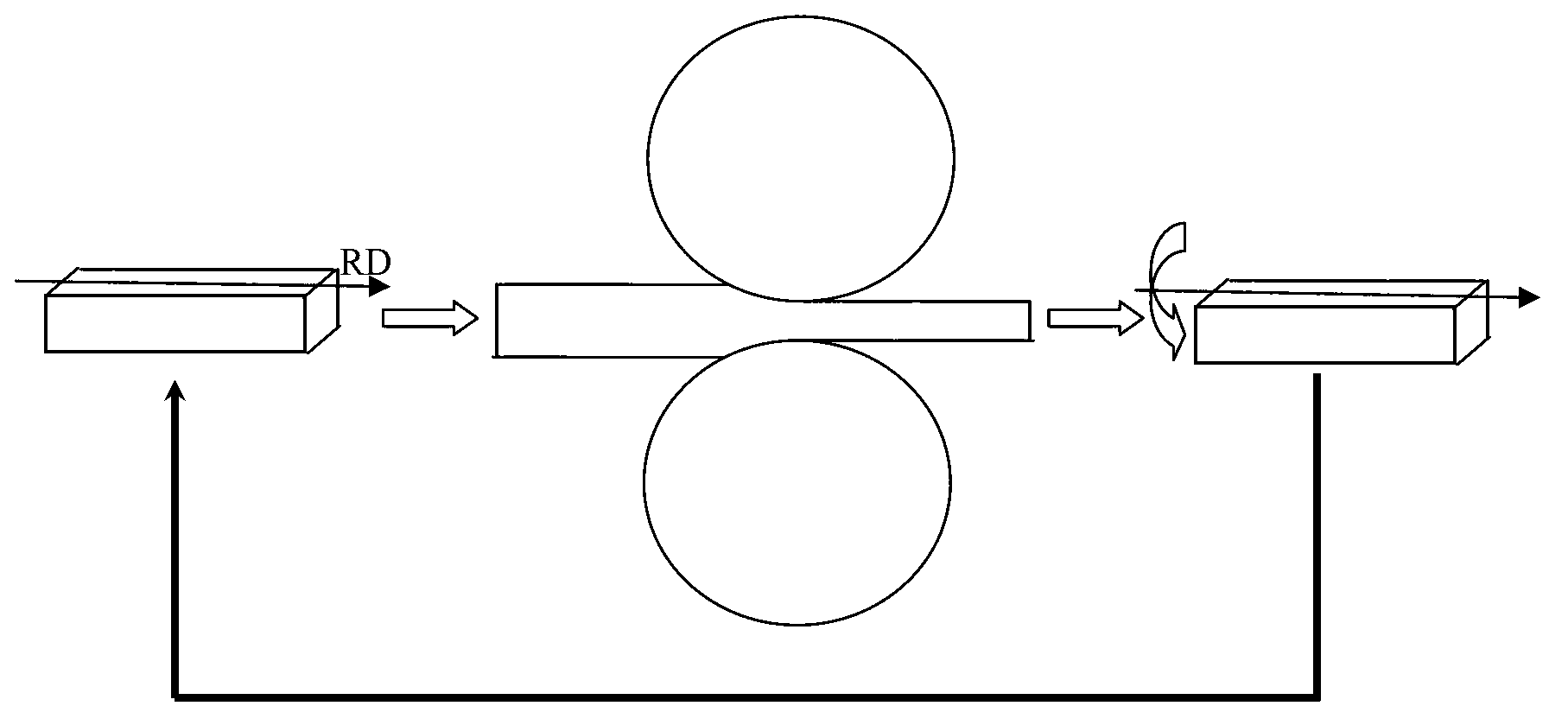

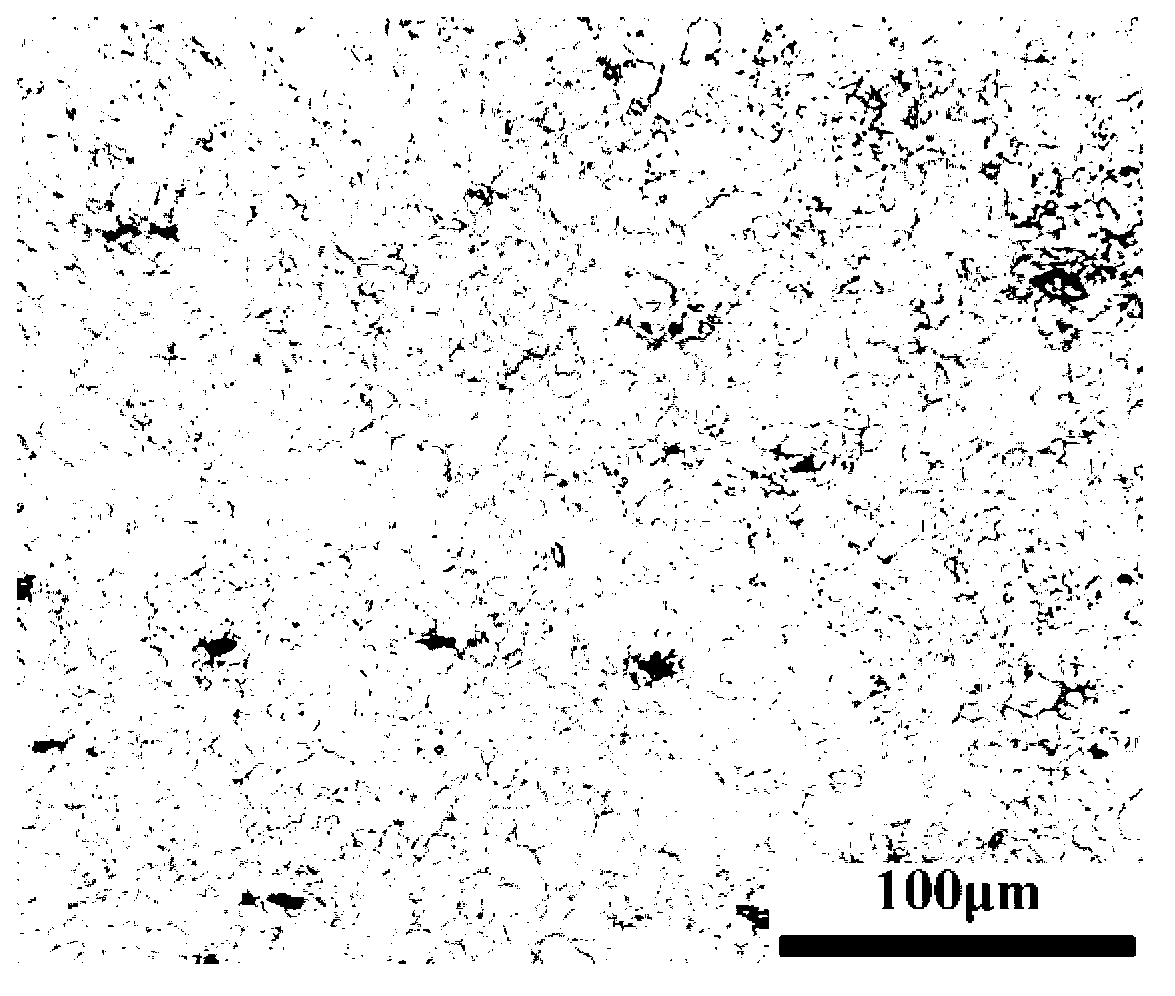

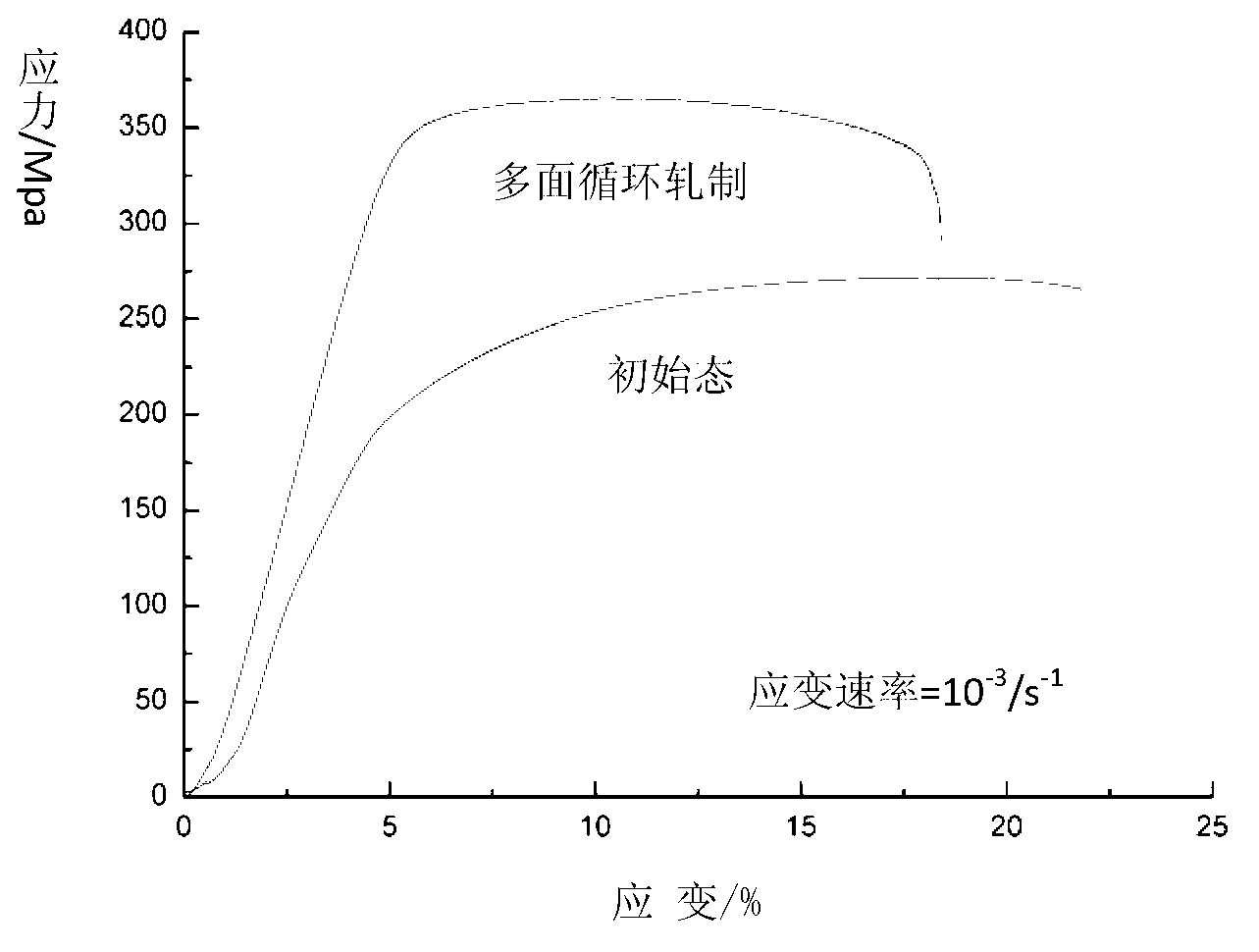

Magnesium alloy polyhedral circulation rolling method

InactiveCN103008346AHigh yield strengthImprove performanceMetal rolling arrangementsCrystal twinningMultiple pass

The invention provides a magnesium alloy polyhedral circulation rolling method, so that magnesium alloy grains obtained by rolling are finer, smaller, higher in strength and higher in ductility, and the tissue refinement and mechanical property of the magnesium alloy are improved. The solution scheme adopted by the invention is as follows: performing primary rolling on a well cut magnesium alloy plate and then clockwise rotating the magnesium alloy plate for 90 degrees along a rolling shaft, performing secondary rolling on the alloy and forming a rolling circulation; or after performing primary rolling on the well cut magnesium alloy plate, performing multiple passes of rolling, clockwise rolling the plate for 90 degrees along the rolling shaft and then performing multiple passes of rolling. Compared with the prior art, the magnesium alloy polyhedral circulation rolling method has the following beneficial effects: under the pressure effects of different acting surfaces, crystal twin is excited to the greatest extent, crystal twin interface strengthening is introduced, the yield strength of the magnesium alloy is greatly improved, and the preparation method is simple.

Owner:NANJING UNIV OF SCI & TECH

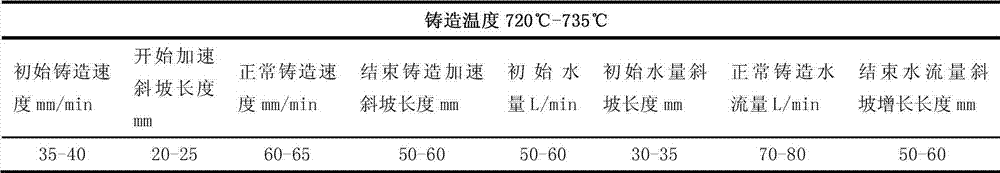

Aluminum alloy cast ingot for automotive bumper and production process thereof

InactiveCN102965553AStrong age hardening effectImproves resistance to stress corrosionSlagThermal deformation

The invention relates to an aluminum alloy cast ingot for an automotive bumper and a production process thereof and belongs to the technical fields of aluminum alloy and processing technique. The processing of the aluminum alloy cast ingot for the automotive bumper is finished by the following steps of: material proportioning, smelting, permanent magnetism stirring, temperature measurement, sampling, adjustment of ingredient and temperature, turning down, refining (first purification), standing, online adding of Al, Ti and B wires, online degassing and slag removal (secondary purification), double filtering, equal-level hot top casting, cast ingot homogenization, machining of the cast ingot, inspection of the cast ingot and heating of the cast ingot by an induction furnace. The hard aluminum alloy cast ingot, machined in the invention, has excellent thermal deformation performance and higher strength after being subjected to online quenching in extrusion process, the welding property and corrosion resistance of a product are excellent, and the product has certain stress-corrosion resistance and particularly has stronger shock absorption capacity and folding resistance.

Owner:CONGLIN GROUP

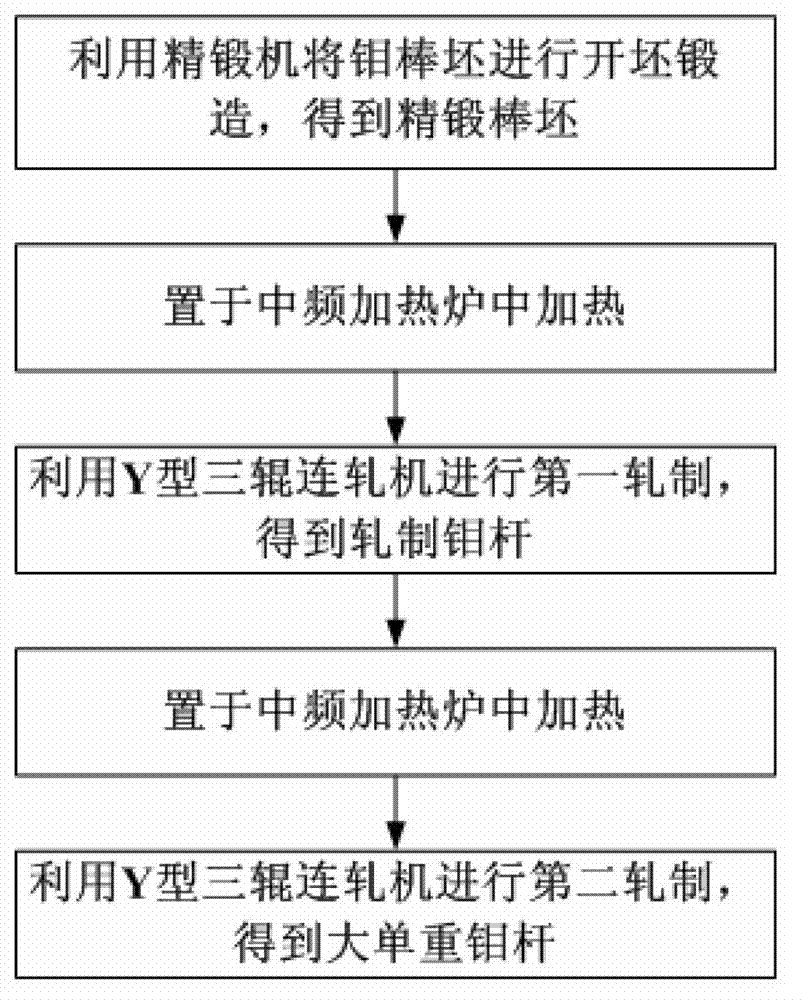

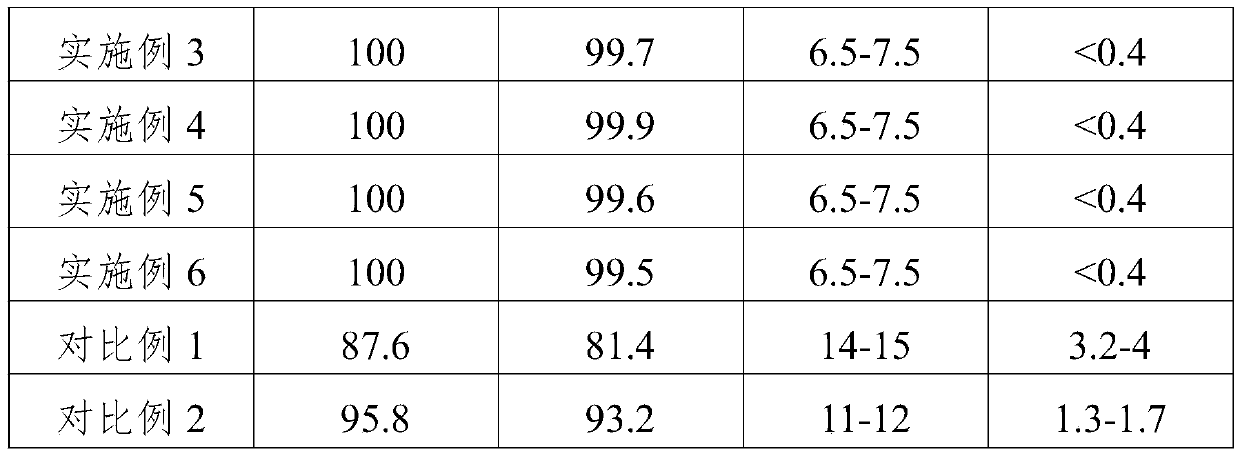

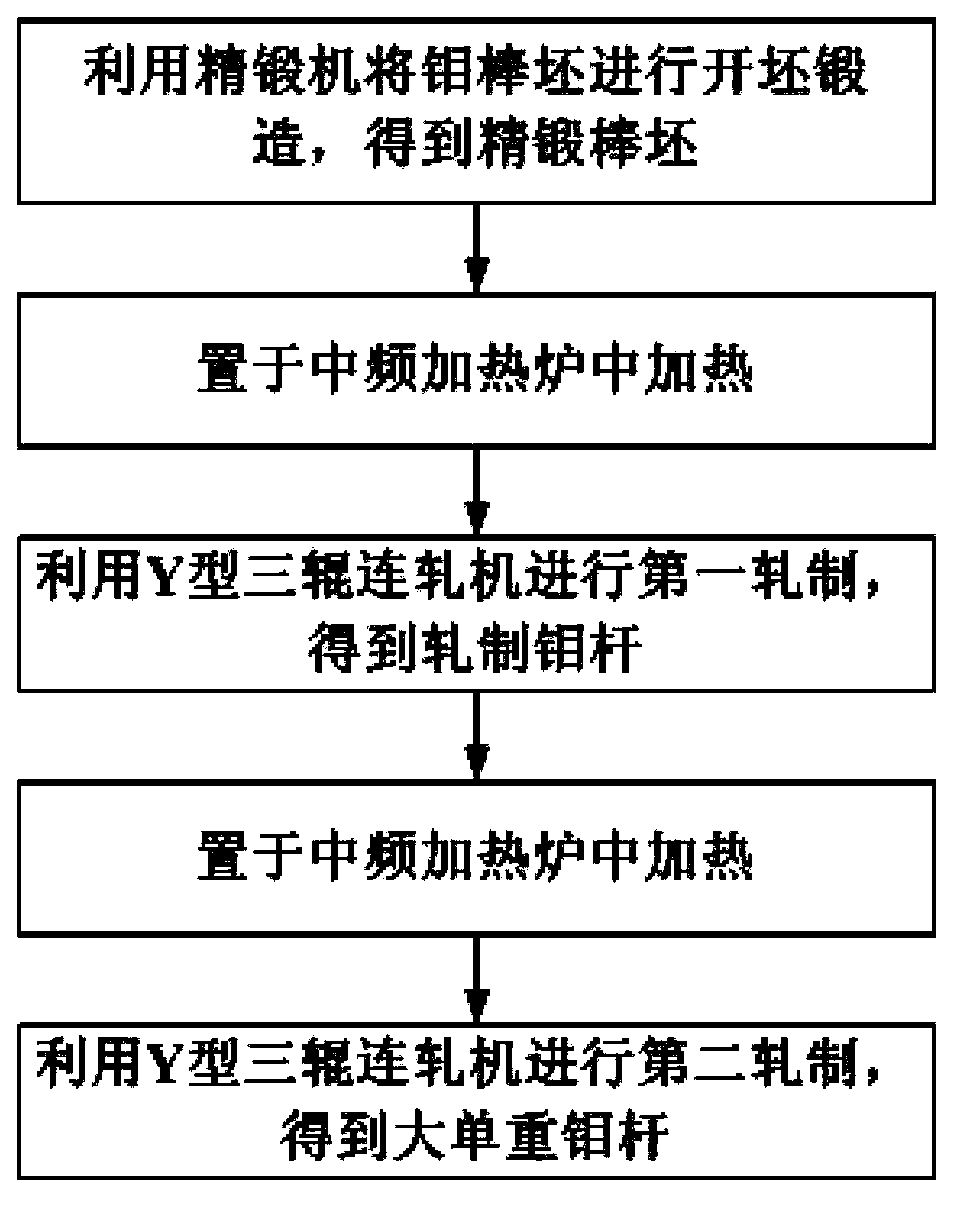

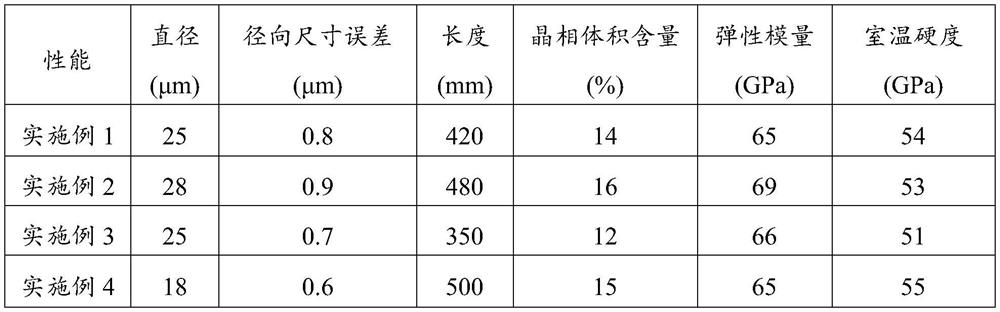

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389ARealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

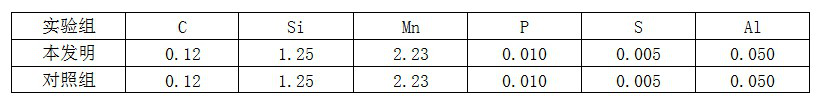

Preparation method of non-quenched and tempered steel for automobile chassis

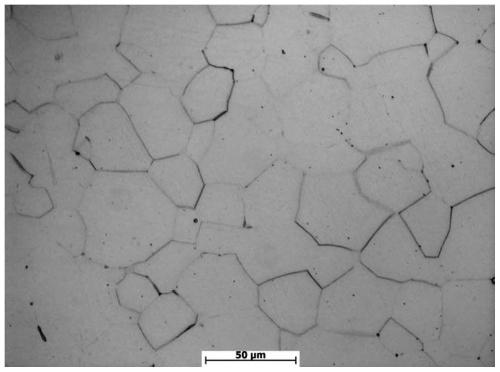

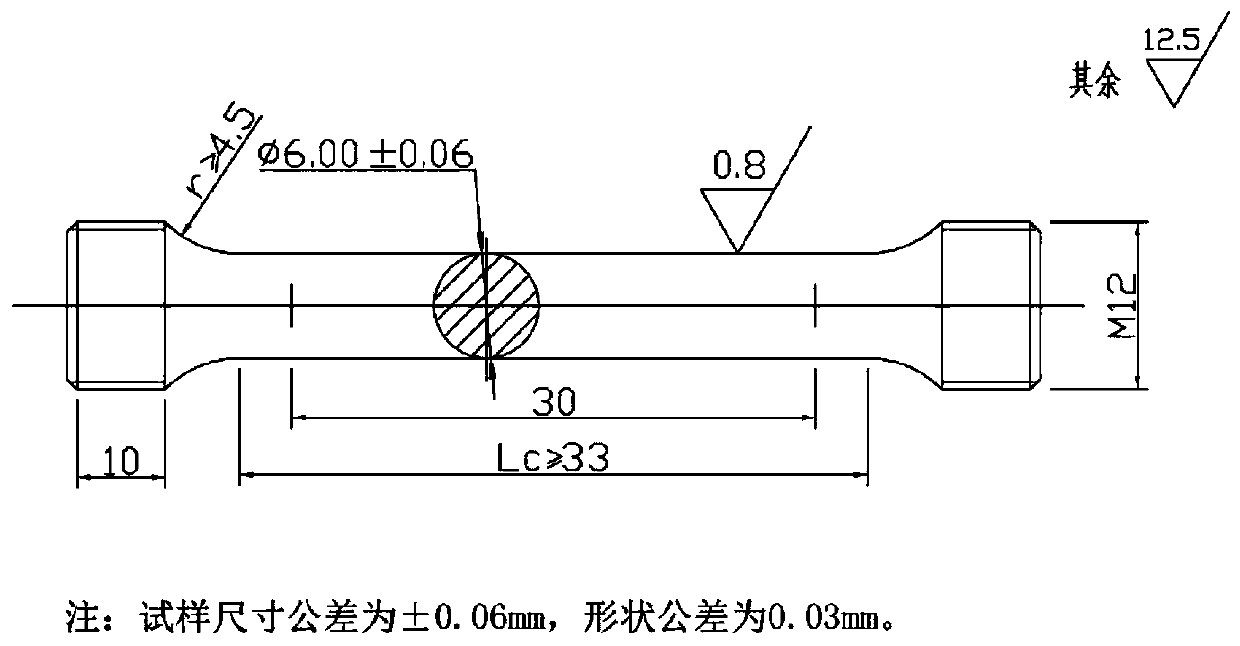

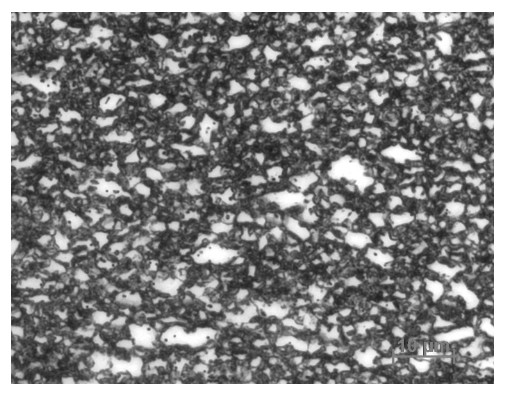

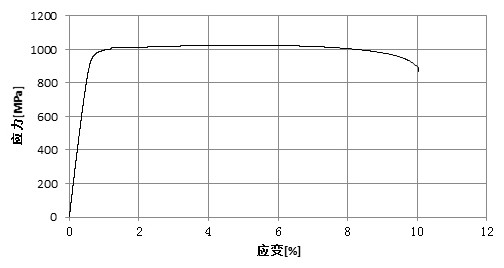

ActiveCN111906153AAvoid growing upReduce composition segregationTemperature control deviceWork cooling devicesWater coolingMaterials science

The invention discloses a preparation method of non-quenched and tempered steel for an automobile chassis. The preparation method comprises the following production steps of a square billet heating process, a controlled rolling and controlled cooling step, a reducing and sizing step and a cooling step. Square billet heating comprises a preheating section and a three-section heating process; and the controlled rolling and controlled cooling step comprises the processes of primary rolling, intermediate rolling, primary intensive pressure water cooling, finish rolling and secondary intensive pressure water cooling. The non-quenched and tempered steel,produced by the preparation method disclosed by the invention, for the automobile chassis has a ferrite and pearlitic structure, the grain sizereaches 7.5 grade or above, the tensile strength reaches 940-990Mpa, the yield strength is 600-650Mpa, and the impact toughness is 41-48J. The strength, toughness and other mechanical properties of the steel are improved, the fatigue resistance and tensile strength are improved, and the technical and quality requirements of the non-quenched and tempered steel for automobile chassis parts are completely met.

Owner:JIANGSU YONGGANG GROUP CO LTD

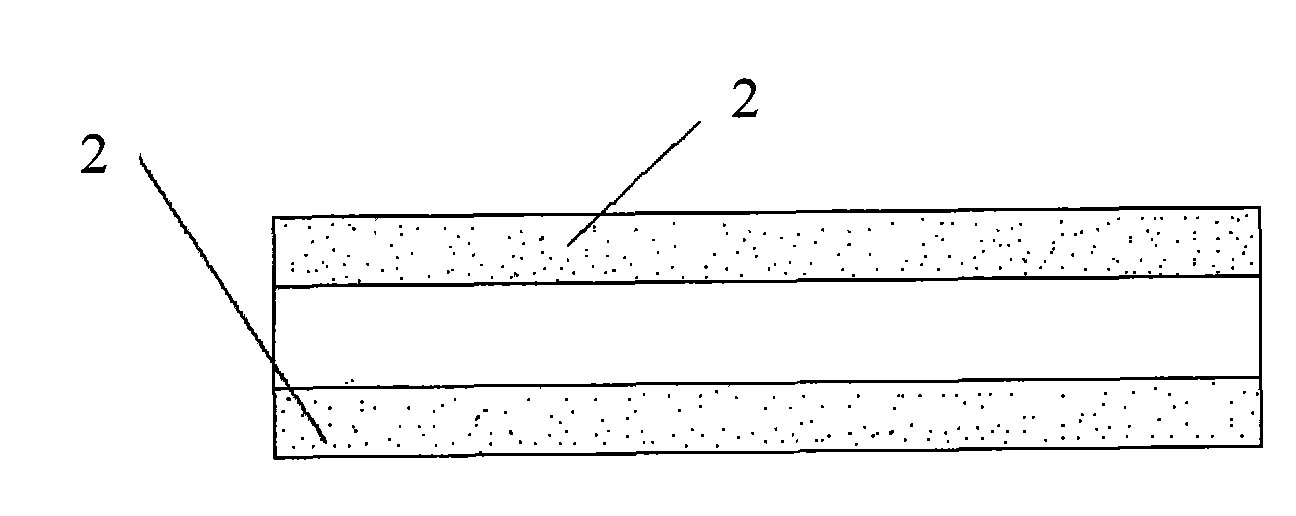

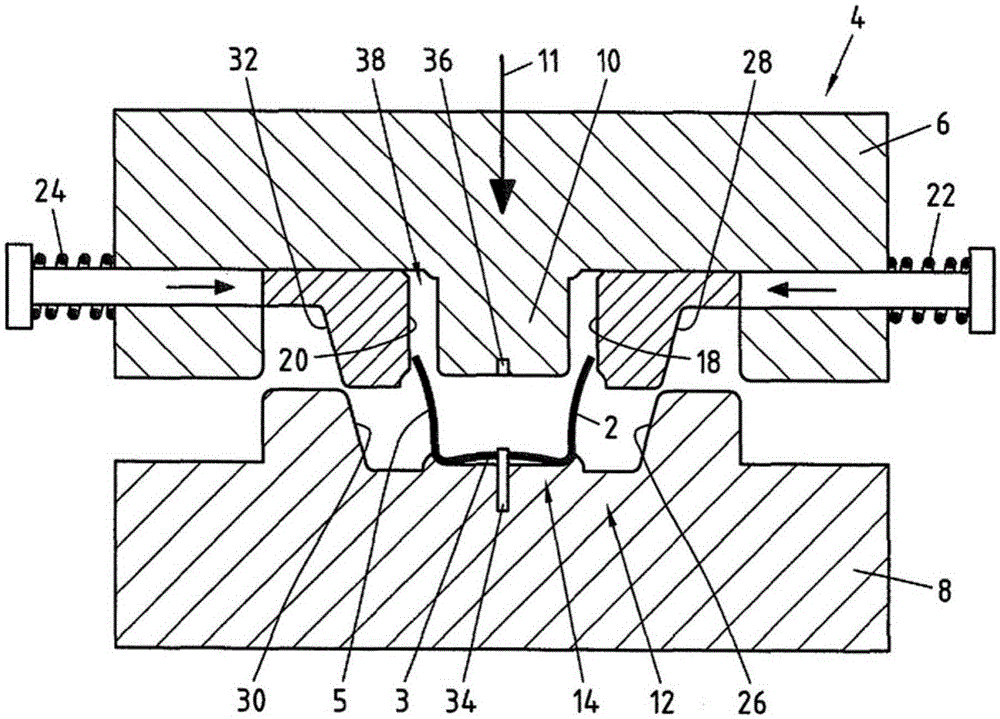

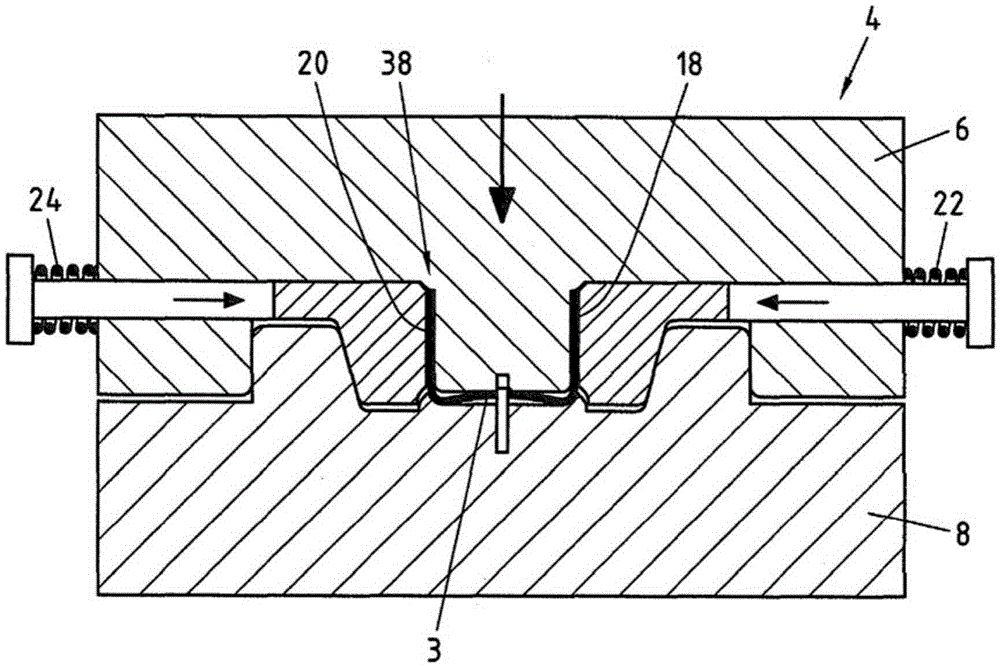

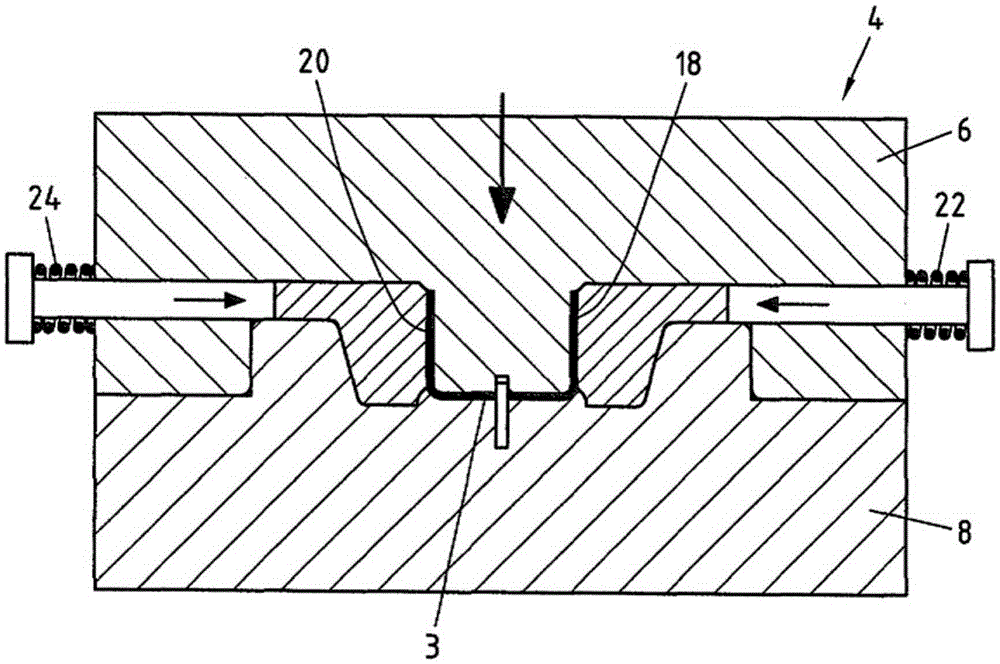

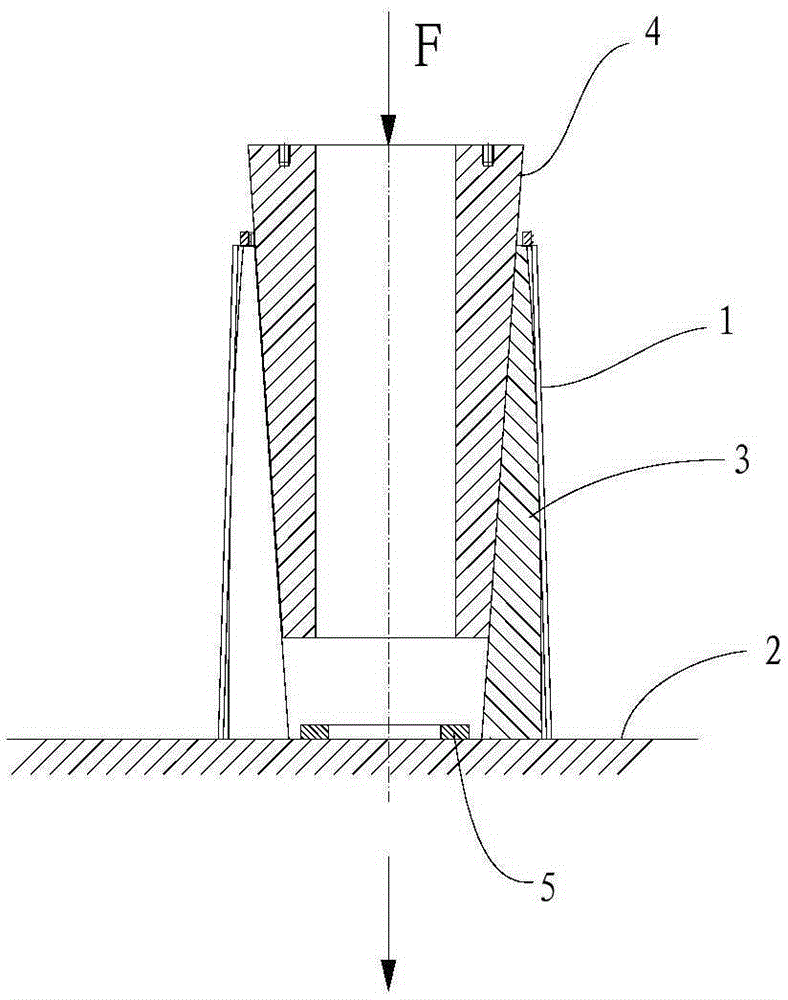

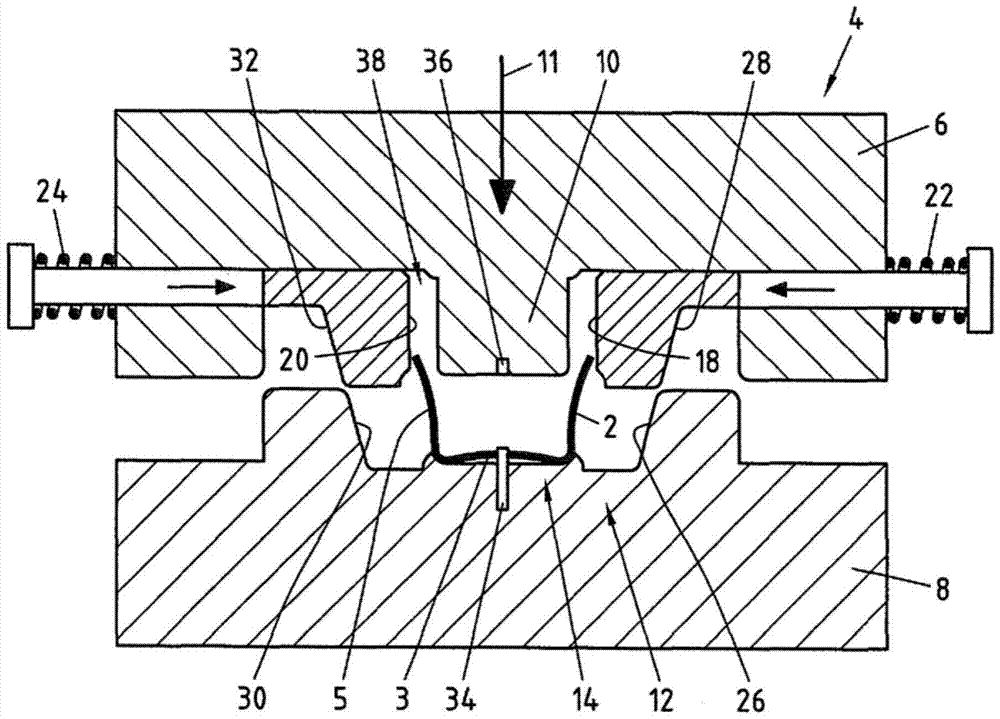

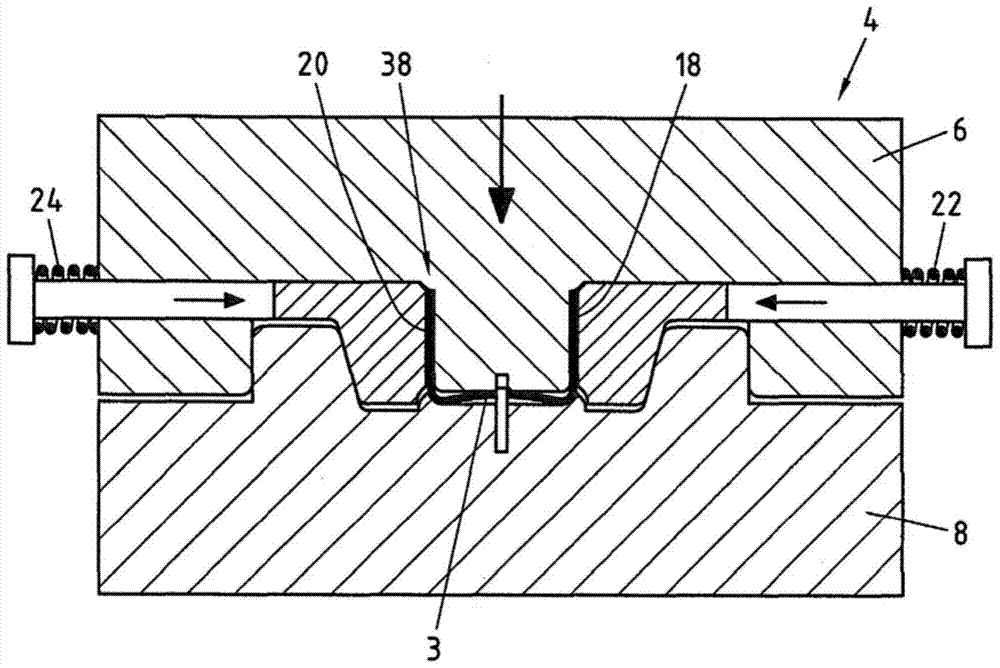

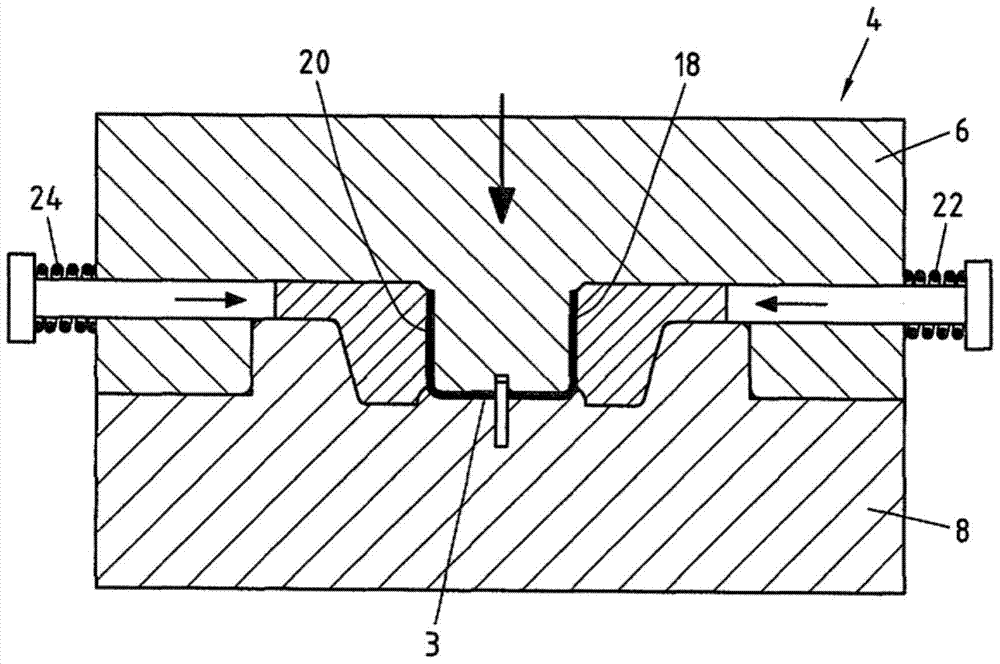

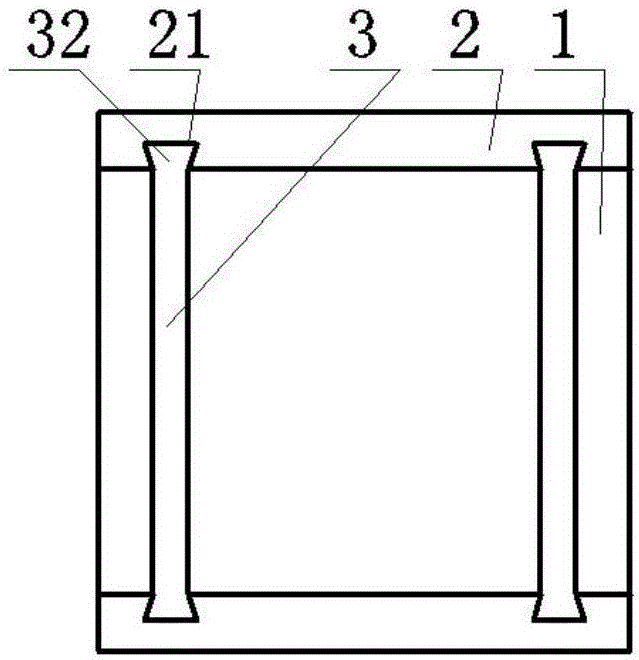

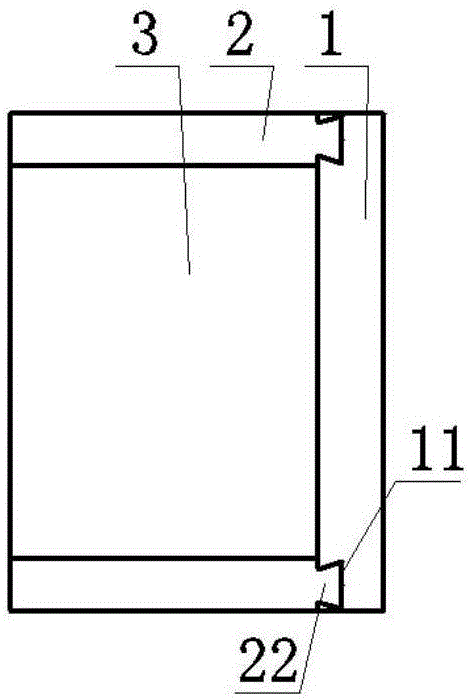

Method and compression tool for producing highly dimensionally stable half shells

The invention relates to a method for producing highly dimensionally stable, deep-drawn half shells (2, 42), which have a bottom region (3), a jacket (5), and optionally a flange (44), wherein a half shell (2, 42) pre-formed from a blank is shaped into a finished half shell, wherein the pre-formed half shell (2, 42) has excess blank material because of the geometric shape of the pre-formed half shell and wherein, because of the excess blank material, the half shell (2, 42) is compressed into the finally formed half shell in a compression tool during the shaping of the pre-formed half-shell into the final form of the half shell by means of at least one pressing process. The problem addressed by the invention is that of specifying a method and a device, by means of which the process reliability during the production of a half shell can be increased. The problem is solved by the previously mentioned method in that the size of the compression gap (38, 76) is reduced during the closing of the compression tool (4, 40) to the actual wall thickness of the jacket (5) of the pre-formed half shell. In addition, the problem is solved by a compression tool according to the invention in that two side walls (18, 20, 56, 58, 80, 82) are provided, which side walls form a die together with the bottom region (14, 54) of the mold (12, 52) of the second tool half (8, 48) and which side walls (18, 20, 56, 58, 80, 82) can be moved perpendicularly or obliquely to the direction of motion of the punch (10, 50).

Owner:THYSSENKRUPP STEEL EURO AG

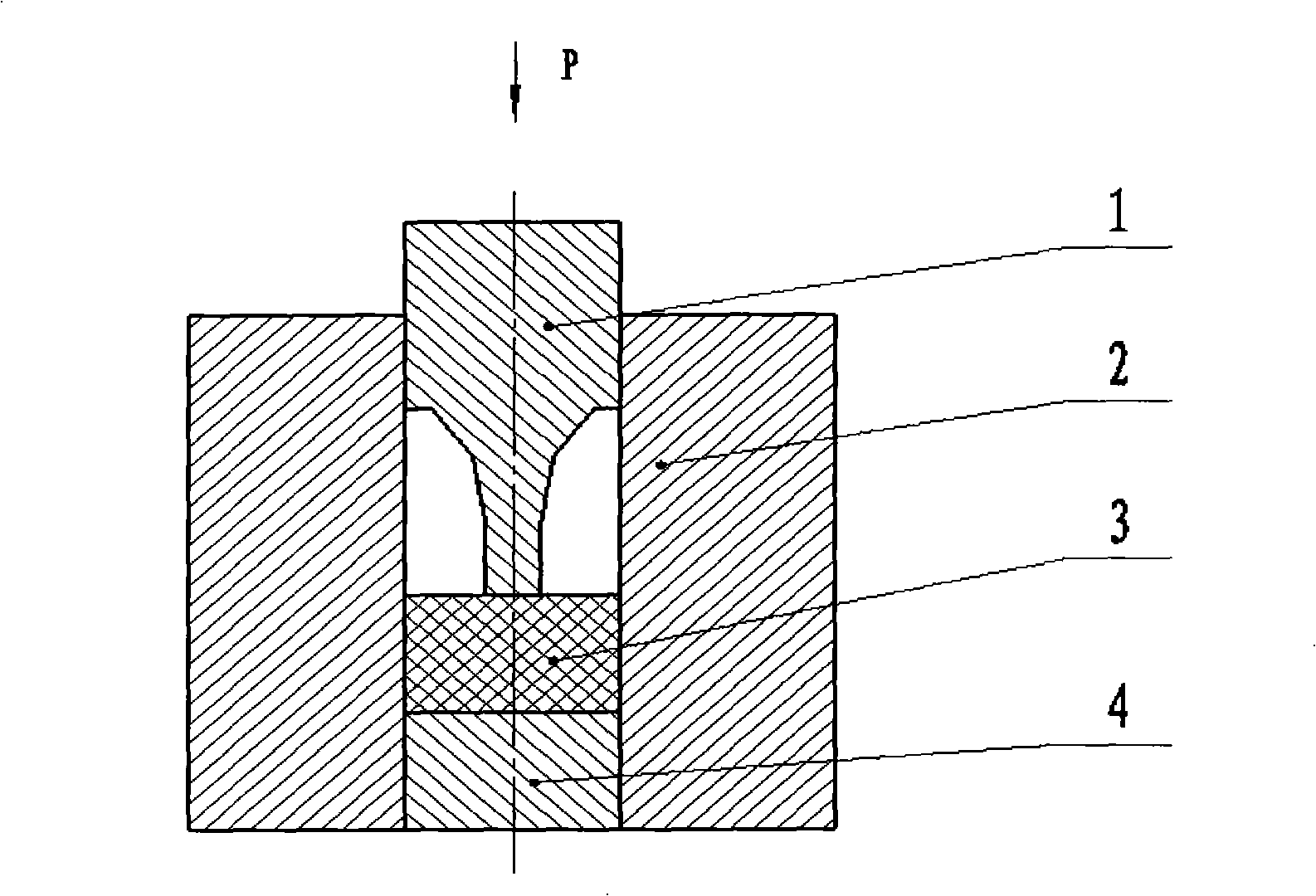

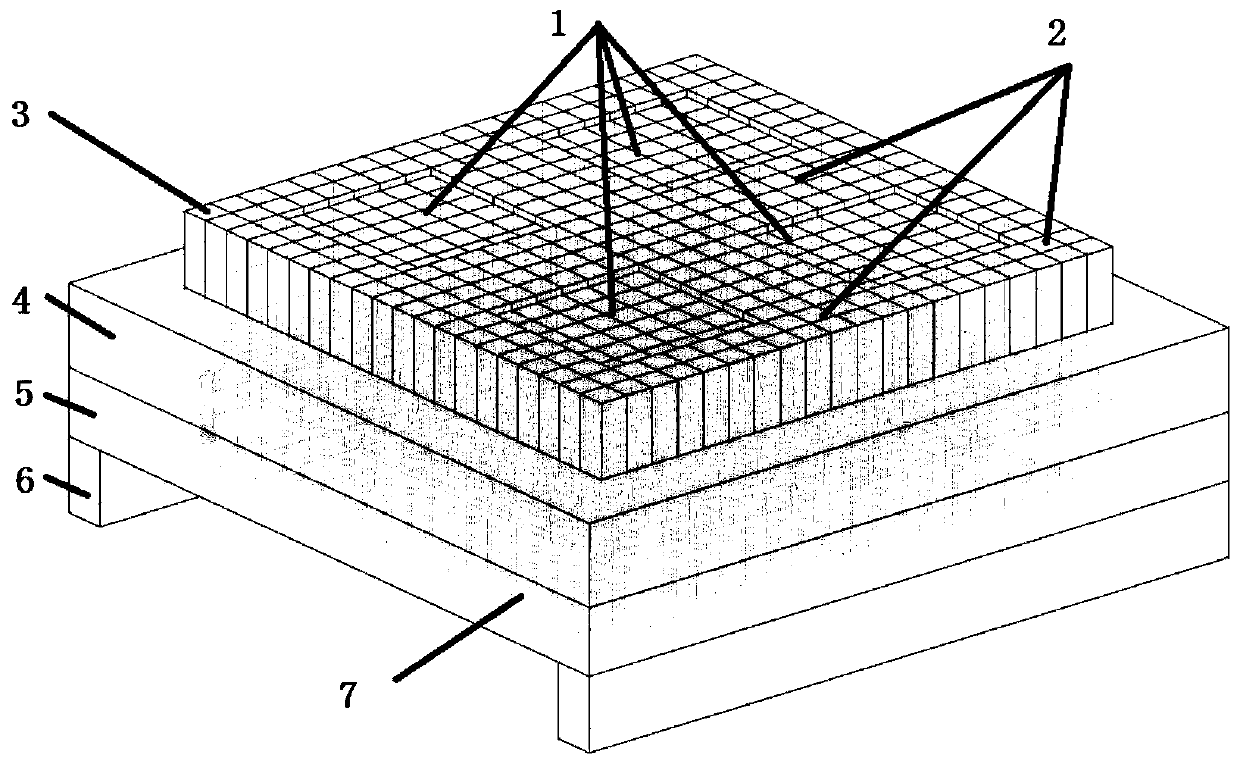

Aluminum oxide based nano complex phase ceramic bull block and method for preparing same

ActiveCN101289313AImprove mechanical propertiesImprove high temperature stabilityDrawing diesCeramic sinteringMechanical property

The invention discloses an alumina base nanometer complex phase ceramics die and a preparation method thereof. The alumina base nanometer complex phase ceramics is adopted to prepare the die, the matrix component of the nanometer complex phase ceramics die is Al2O3, and a second phase is ZrO2(3Y) and MgAl2O4. The preparation method of the nanometer complex phase ceramics die is that an alumina base nanometer complex phase ceramics sintered body of a certain shape is first obtained as the stock for preparing the die; then the hole shape of the die is formed by the method of superplastic pressing; after a slight accurate grinding process, the alumina base nanometer complex phase ceramics die is obtained. The alumina base nanometer complex phase ceramics die has the advantages of good mechanical property, a slight amount of machining and being suitable for mass production.

Owner:ZHENJIANG NAISI ADVANCE MATERIALS

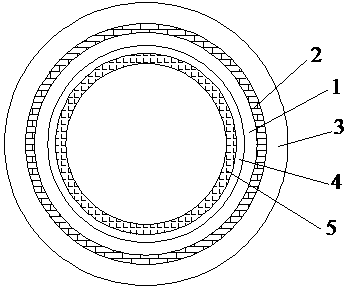

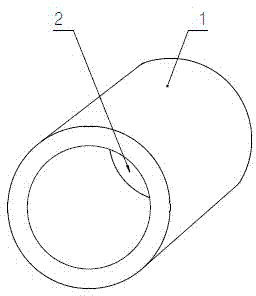

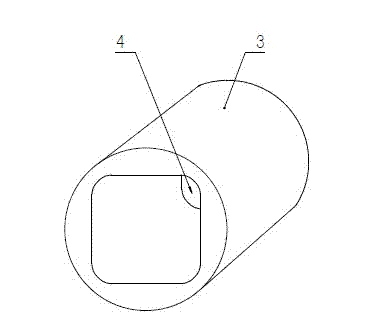

Seamless steel pipe used for petrochemical engineering

InactiveCN104180081AFulfil requirementsImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationPetrochemicalToughness

The invention discloses a seamless steel pipe used for petrochemical engineering. The seamless steel pipe comprises a steel pipe body, an Ni56Cr22Mo13Cu alloy layer, an Nb-TiAl alloy layer, an Mg-Zn-Nd-Cd-Zr alloy layer and a high-corrosion-resistant Fe-(Cr, Ni)-Mo-P-C-B bulk amorphous alloy layer, wherein the outer surface of the steel pipe body is covered with the Ni56Cr22Mo13Cu alloy layer and the Nb-TiAl alloy layer in sequence; the Mg-Zn-Nd-Cd-Zr alloy layer and the high-corrosion-resistant Fe-(Cr, Ni)-Mo-P-C-B bulk amorphous alloy layer are arranged on the inner surface of the steel pipe body in sequence. According to the invention, through the adoption of the scheme, the seamless steel pipe has sufficient plasticity and toughness as well as high corrosion resistance, and can meet the requirements of the conventional petrochemical industry for seamless steel pipes.

Owner:WUXI HAOHAO STEEL PIPE

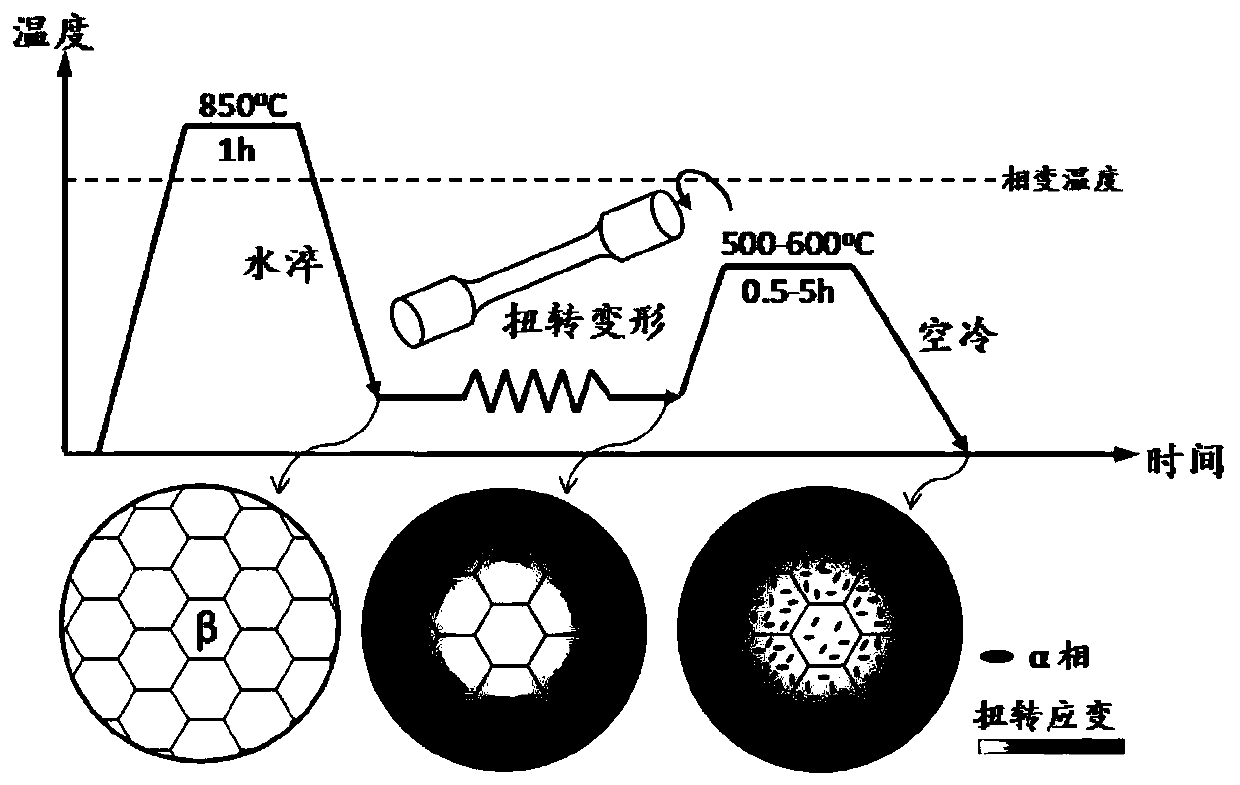

Technology for carrying out toughening treatment on stable Beta titanium alloy

The invention discloses a technology for carrying out toughening treatment on stable Beta titanium alloy. According to the technology for carrying out toughening treatment on the stable Beta titaniumalloy, the stable Beta titanium alloy with a gradient organizational structure is prepared by adopting pre-torsional deformation and aging treatment, the strength of the stable Beta titanium alloy isdistributed in a gradient manner from the surface to the center, and then high strength and high toughness are achieved at the same time.

Owner:HUANGHUAI UNIV

Flame-retardant rubber leather product

The invention belongs to the field of leather production, and specifically relates to a flame-retardant rubber leather product which is characterized by being prepared from the following raw materials in parts by weight: 20-30 parts of butyl rubber, 15-25 parts of chloroprene rubber, 15-25 parts of natural rubber, 8-10 parts of carbon black, 2-4 parts of zinc oxide, 10-14 parts of a flame retardant, 1-3 parts of stearic acid, 0.5-1.5 parts of a softener, 1-3 parts of sulfur, 1-3 parts of an accelerant, and 0.5-1.5 parts of an anti-aging agent. The flame-retardant rubber leather product can maintain the hardness and also has excellent resistance to crack and resistance to deformation crack growth. The flame-retardant rubber leather product has the hardness range of 20-50, is non flammable, and has excellent flame retardant effect.

Owner:烟台鑫海耐磨胶业有限公司

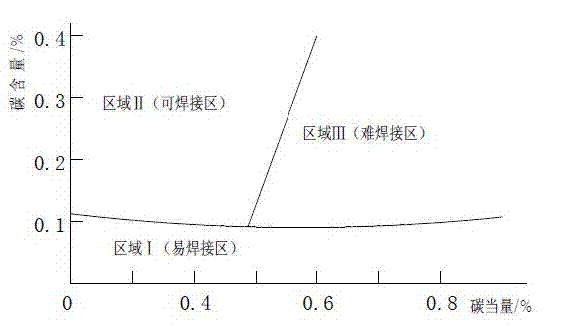

Ultrahigh-yield-ratio steel and production process thereof

The invention provides ultrahigh-yield-ratio steel and a production process thereof. After strip steel is rapidly cooled, a dislocation source is provided through pre-strain treatment, and dislocationpinning strengthening treatment is adopted after pre-strain treatment, wherein the steel subjected to dislocation pinning strengthening is low-alloyed steel, and the carbon content is 0.02%-0.77%. The production process of the ultrahigh-yield-ratio steel comprises the steps of strip steel cold rolling, continuous annealing, rapid cooling, pre-strain treatment and dislocation pinning strengtheningtreatment. According to the scheme, the ultrahigh-yield-ratio steel has enough plasticity and good welding performance. The method can be used for manufacturing parts with high shape stability, highdeformation resistance and high reaming requirements, such as battery protection plates, bumpers, seat guide rails, reinforcers, and measuring tools of automobiles. The production process can also beused for manufacturing spring steel requiring high elastic limit.

Owner:VALIN ARCELORMITTAL AUTOMOTIVE STEEL CO LTD

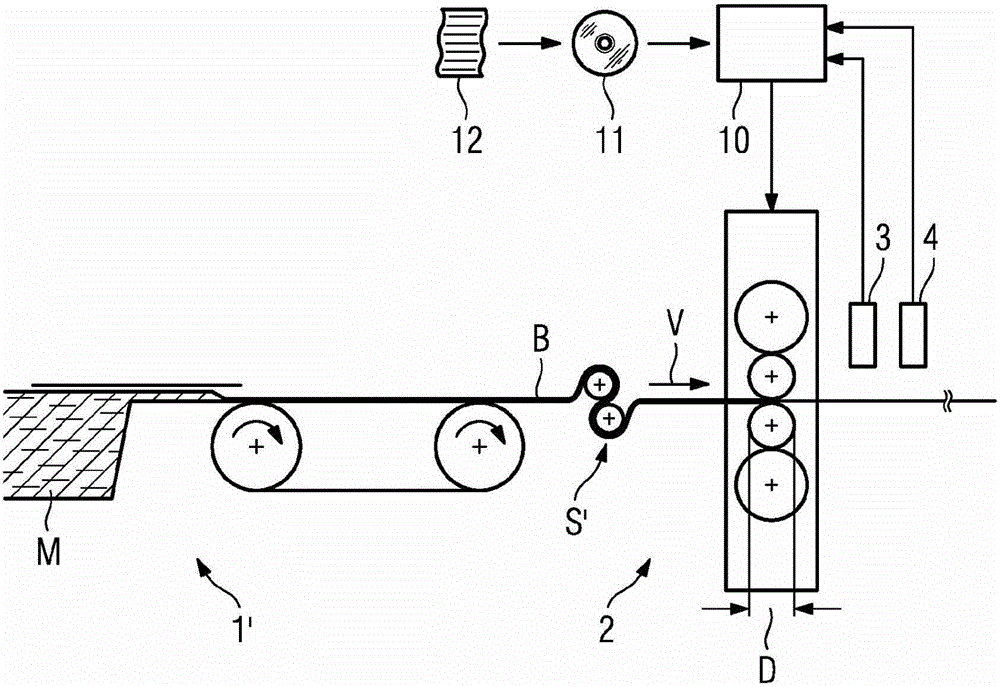

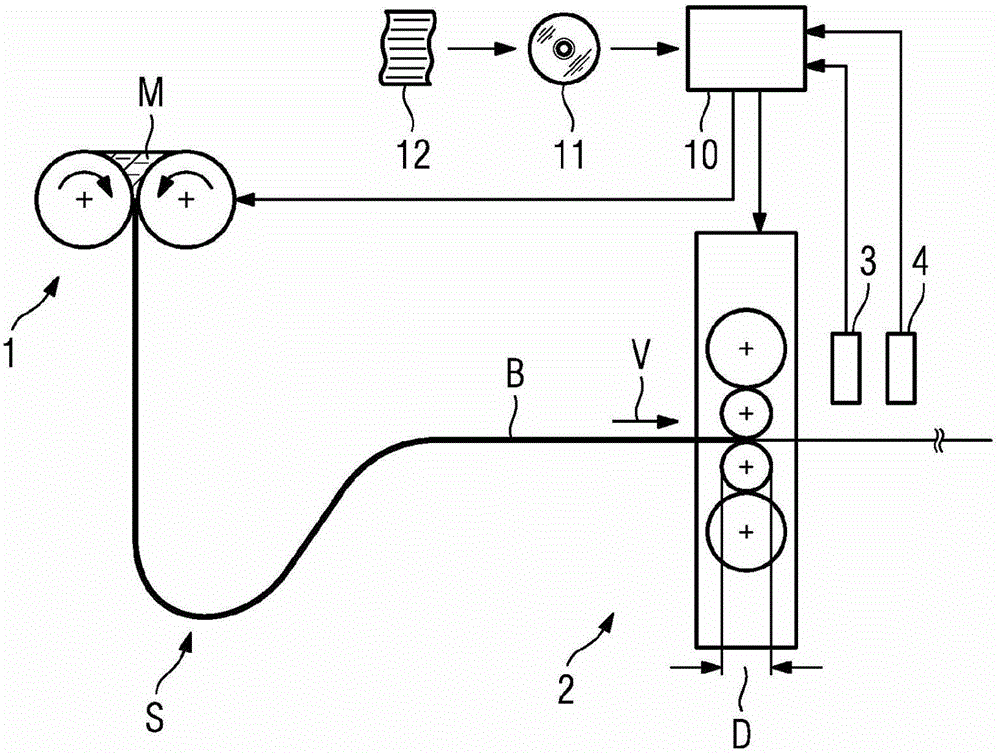

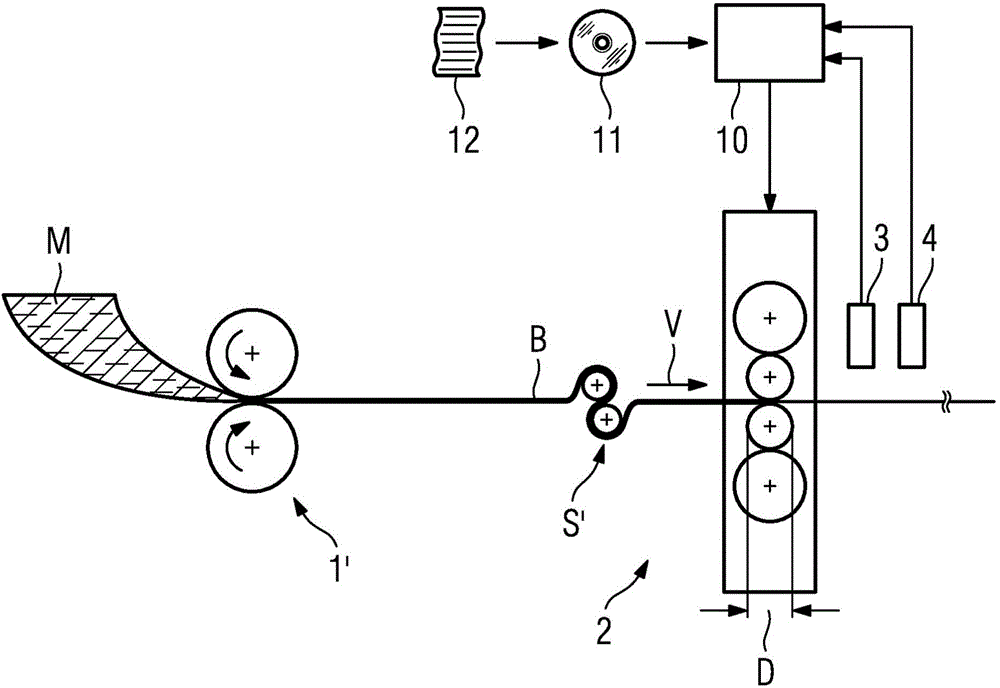

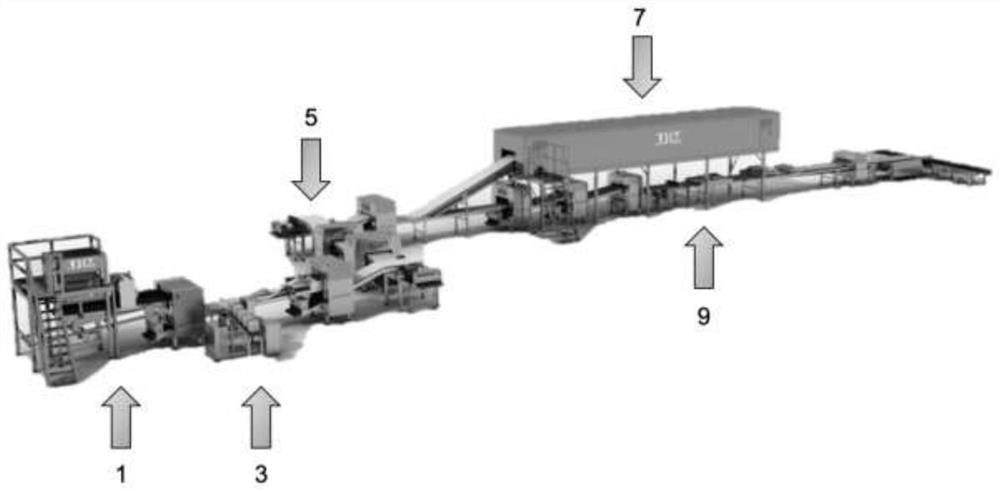

Method for producing a metal strip using a casting rolling assembly and control and/or regulating device for a compound casting rolling assembly

InactiveCN103068502AMeet thickness range requirementsImprove manufacturing precisionRoll mill control devicesMetal rolling arrangementsMetal stripsStrip mill

Producing a metal band using a casting roller composite plant, comprises casting a metal by a casting device (1, 1'), and hot forming the metal bands by at least one rolling mill (2). The casting roller composite plant is operated so that the metal band extends continuously between the casting device and the rolling mill. The metal band is continuously supplied to the rolling mill. The rolling mill has a desired thickness profile, according to which the rolling mill rolls the metal band. The thickness profile exhibits at least two different target thicknesses for different band sections. Producing a metal band using a casting roller composite plant, comprises casting a metal by a casting device (1, 1') and hot forming the metal bands by at least one rolling mill (2). The casting roller composite plant is operated so that the metal band extends continuously between the casting device and the rolling mill. The metal band is continuously supplied to the rolling mill. The rolling mill has a desired thickness profile, according to which the rolling mill rolls the metal band. The thickness profile exhibits at least two different target thicknesses for different band sections in the longitudinal direction of the metal band. The thickness profile is designed so that the first and / or the second target thickness are adjusted at least twice. Independent claims are also included for: (1) a control and / or regulating device (10) for a casting roller composite plant to produce longitudinally thick profiled metal strip, comprising a machine readable program code, which includes control commands and causes the control and / or regulating device to perform the method mentioned above; and (2) the casting roller composite plant to manufacture metal strip thick profiled in its longitudinal direction, comprising the casting device and the rolling mill, where the control and regulating device is operatively connected with the rolling mill.

Owner:PRIMETALS TECH GERMANY

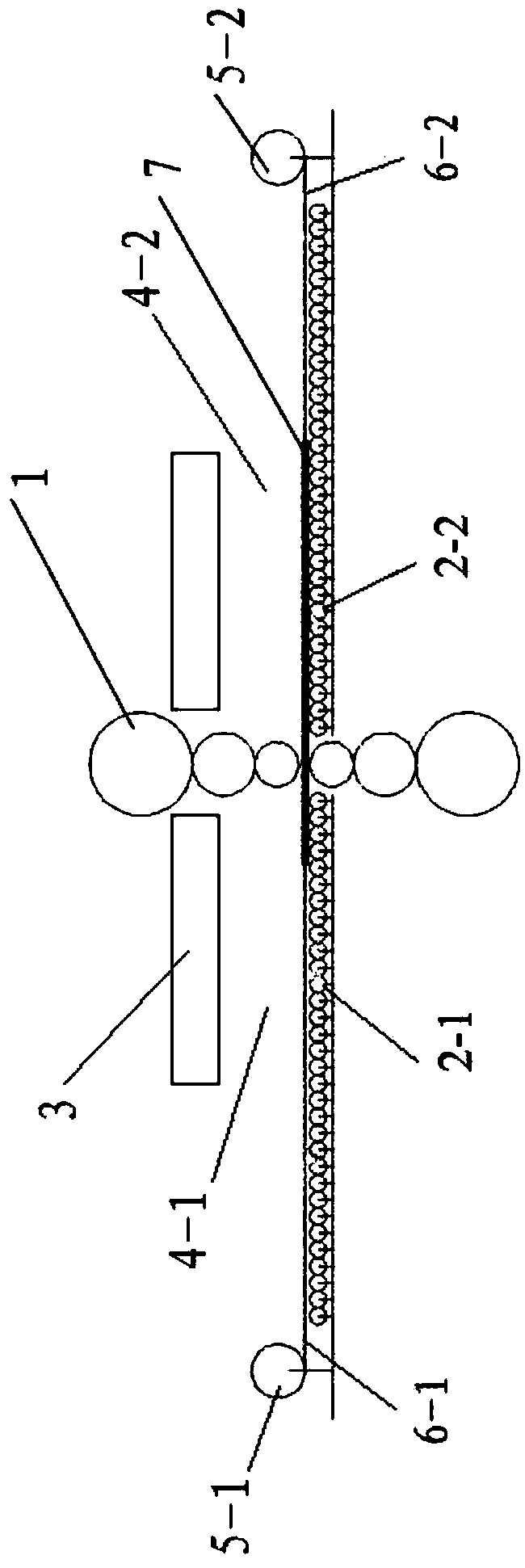

Oversized thin plate rolling device and molybdenum thin plate rolling method

The invention discloses an oversized thin plate rolling device, which comprises a six-roller reversible mill; an inlet side and an outlet side of the a six-roller reversible mill are evenly distributed with transporting roller paths, and heating zones are arranged on the transporting roller paths; upper parts of the heating zones are equipped with heating devices, and a recoiling machine is installed at the position closing to the transporting roller paths, and a leading tape is coiled on the recoiling machine; the heating zones are arranged on the transporting roller paths at inside and outsides of the six-roller reversible mill. The device solves the problem of limited plate dimension by the heating furnace dimension in annealing after rolling the plate, and is suitable for rolling the oversized thin plate. The invention provides an oversized molybdenum thin plate rolling method. By using the recoiling machine, a molybdenum plate is moved between the heating zones and the six-rollerreversible mill through the transporting roller paths, so as to heat, roll and anneal; through changing the rotating direction of the recoiling machine and the rolling direction of the six-roller reversible mill, the repeat heating, rolling and annealing are realized, the plasticity of the molybdenum plate is improved, and the specification of the molybdenum plate after being rolled is enlarged.

Owner:JINDUICHENG MOLYBDENUM CO LTD

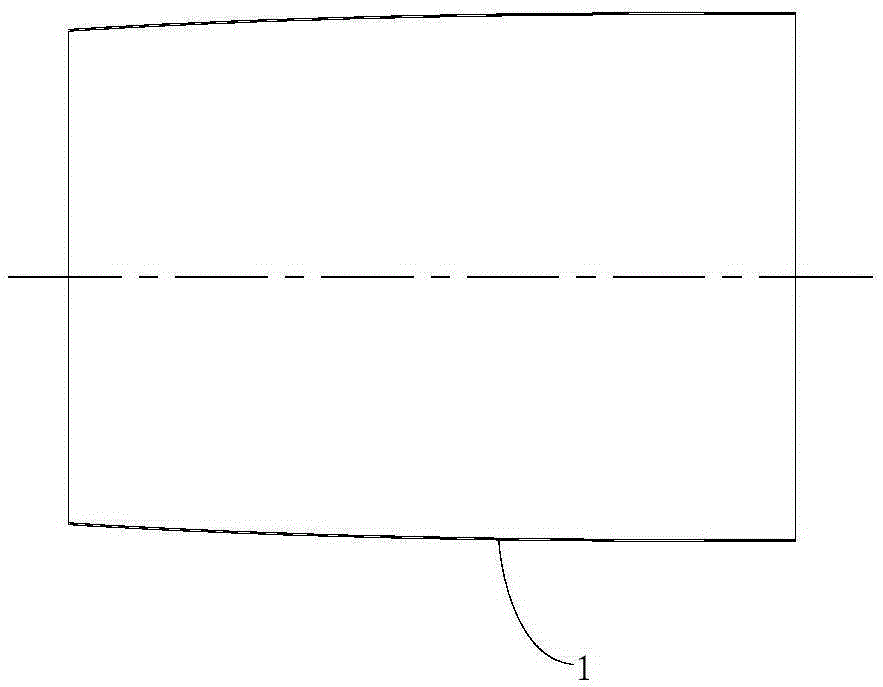

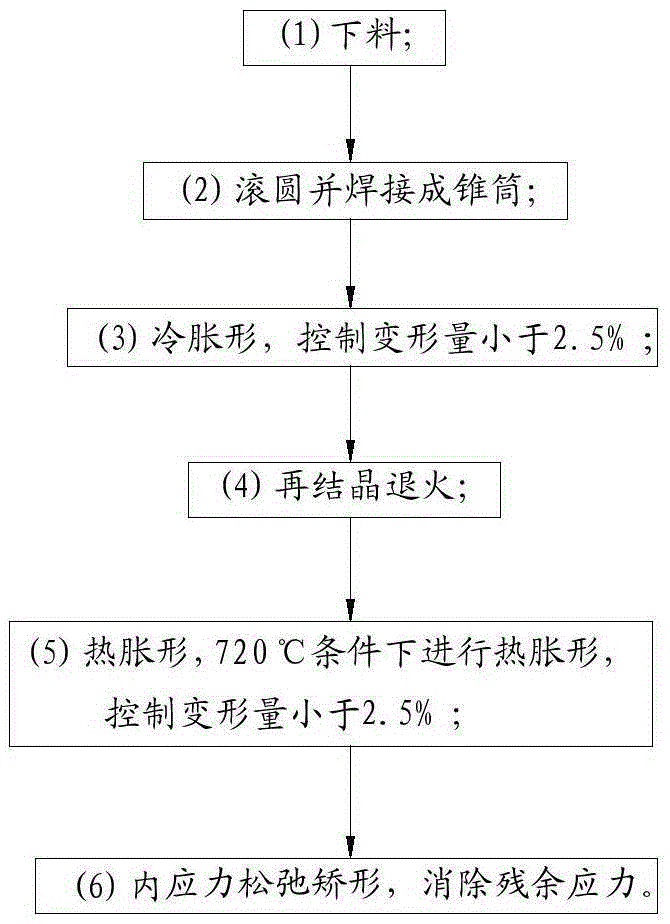

Processing method of titanium alloy double curvature rotary cylinder

The invention belongs to the field of metal forming and processing and in particular relates to a processing method of a titanium alloy double-curvature rotary drum. The method comprises the following steps of (1) feeding materials; (2) rolling the materials and forming a conical drum through welding; (3) performing cold bulging and controlling the deformation quantity to be less than 25%; (4) performing recrystalization annealing; (5) performing hot bulging under the condition of 720 DEG C and controlling the deformation quantity to be less than 2.5%; (6) performing internal stress relaxed shaping to eliminate residual stress. The processing method of the titanium alloy double-curvature rotary drum ensures the maximum deformation rate to be approximate to and less than 6% to guarantee the strength of the titanium alloy double-curvature rotary drum and eliminates the residual stress after bulging as well as under stress removal temperature and time conditions to guarantee the dimensional accuracy of the titanium alloy double-curvature rotary drum and the uniformity of products.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

Production method and upsetting equipment of half-shell with high dimensional accuracy

The invention relates to a method for the production of deep-drawn half-shells (2, 42) with high dimensional accuracy, which have a bottom area (3) and side frames (5) and optionally have convex rim (44), wherein the half-shells (2, 42) prefabricated from blank sheets are formed into finished half-shells, wherein the prefabricated half-shells have a stock allowance due to their geometry, and the prefabricated half-shells (2, 42) , 42) In the process of forming the finished half-shell, due to the blank margin, the half-shell (2, 42) is upset in the upsetting equipment through at least one forging process to form the finished half-shell. Since the size of the upsetting gap (38, 76) is reduced to the actual wall thickness of the side frame of the prefabricated half-shell when the upsetting device (4, 40) is closed, it is achieved by the method described above. The object of the method and the device which can improve the reliability of the process in the production process. In addition, since two side walls (18, 20, 56, 58, 80, 82) are provided, the two side walls (18, 20, 56, 58, 80, 82) and the second device half (8, 48 ) The bottom area (14, 54) of the forging die (12, 52) forms the corresponding die together and the two side walls (18, 20, 56, 58, 80, 82) can be along relative to the forging punch The moving direction of (10, 50) moves in a vertical or oblique direction, so the upsetting equipment according to the present invention achieves the above object.

Owner:THYSSENKRUPP STEEL EURO AG

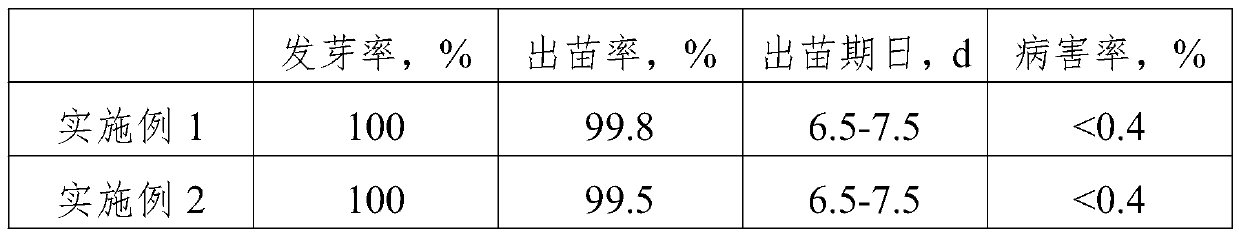

High-seedling-rate cotton seedling raising nutrition pot and seedling raising method thereof

InactiveCN111084073AImprove germination rateImprove the survival rate of plantingGrowth substratesCotton cultivationPlant regulatorsGrowth promotion

The invention provides a high-seedling-rate cotton seedling raising nutrition pot and a seedling raising method thereof. The cotton seedling raising nutrition pot is prepared from, by weight, 13-16 parts of biomass base, 4-7 parts of modified attapulgite, 1-3 parts of mushroom bran, 8-12 parts of river mud, 0.1-0.25 part of plant regulator and 0.5-1.5 parts of compound medicine mixed liquid. Through reasonable raw material selection and matching, nutritional requirements and growth promotion in the seedling growing and budding period are effectively guaranteed, meanwhile, cotton seedling growing tracking treatment is conducted in a targeted mode, the germination rate and the emergence rate of cotton are greatly increased, the seedling rate reaches 99.9%, the growth vigor is excellent, thedisease resistance is good, transplanting is conducted in a field, the overall plant growth vigor is 1-2 cm high, the roots and stems are much and thick and strong. The planting survival rate of the cotton is greatly increased, the disease and pest damage rate is obviously reduced, and the economic benefit is good.

Owner:安徽驰讯网络科技有限公司

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389BRealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Blowout preventer shell

InactiveCN105422039AExtended service lifeImprove abilitiesSealing/packingEconomic benefitsBlowout preventer

The invention discloses a blowout preventer shell which is characterized by being a rectangular ultrahigh-pressure blowout preventer shell, wherein a plurality of side holes are formed in the shell; the shell is of a double-shell material structure made of 25CrNiMo low-carbon alloy steel and is forged in a quenching and tempering heat treatment way; weight-reduced reinforcing ribs are cast outside the shell; and an anticorrosive paint layer is smeared inside the shell. The blowout preventer shell disclosed by the invention has relatively high yield strength, tensile strength and fatigue strength because of being made of 25CrNiMo low-carbon alloy steel and also has plasticity and toughness; the side holes formed in the shell can be used for throttling and releasing pressure, so that the safety performance is high; and an anticorrosion paint is smeared on the surface of the shell, so that the service life of the blowout preventer is favorably prolonged, and the blowout preventer is high in comprehensive performance and very high in economic benefit.

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

Alloy steel, seamless steel pipe and heat treatment technology of shaped steel pipe

The invention discloses alloy steel with high tensile strength and yield strength, high hardness, low thermal expansion coefficient, good corrosion resistance, oxidation resistance and weldability. The alloy steel contains the following components of: by weight, 0.12-0.17% of carbon, 0.25-0.40% of silicon, 1.2-1.39% of manganese, 0.02-0.04% of niobium, 0.04-0.06% of vanadium, 0.02-0.04% of titanium, 0.02-0.04% of aluminium, 0.0005-0.0035% of boron, chromium being less than or equal to 0.1%, nickel being less than or equal to 0.05%, copper being less than or equal to 0.05%, phosphor being lessthan or equal to 0.025%, sulfur being less than or equal to 0.025%, and the balance being iron. The invention also discloses a seamless steel pipe prepared by the alloy steel and a heat treatment technology of a shaped steel pipe molded based on the seamless steel pipe. The technology is to successively carry out step heating quenching treatment and temper heat treatment on the molded shaped steel pipe. The alloy steel provided by the invention and the shaped steel pipe obtained by the alloy steel and the heat treatment technology are mainly used in fire-fighting equipment.

Owner:苏州华创特材股份有限公司

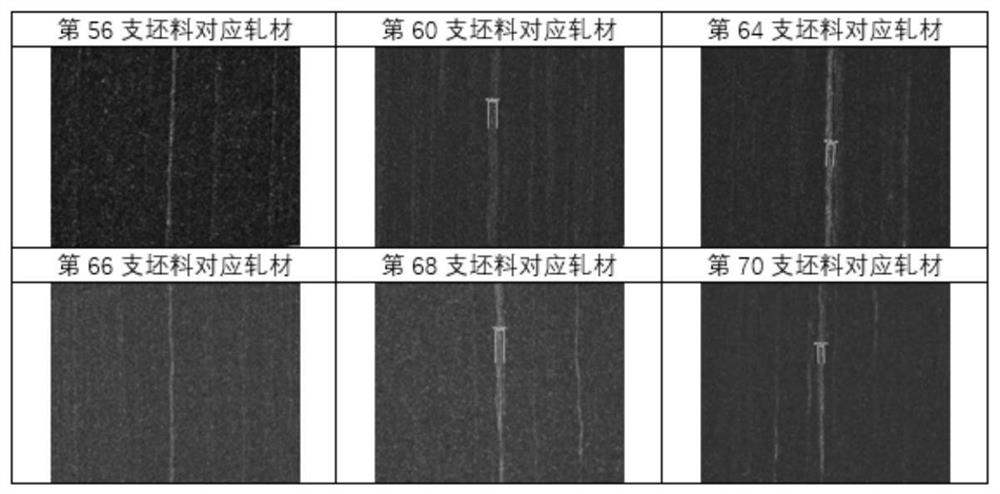

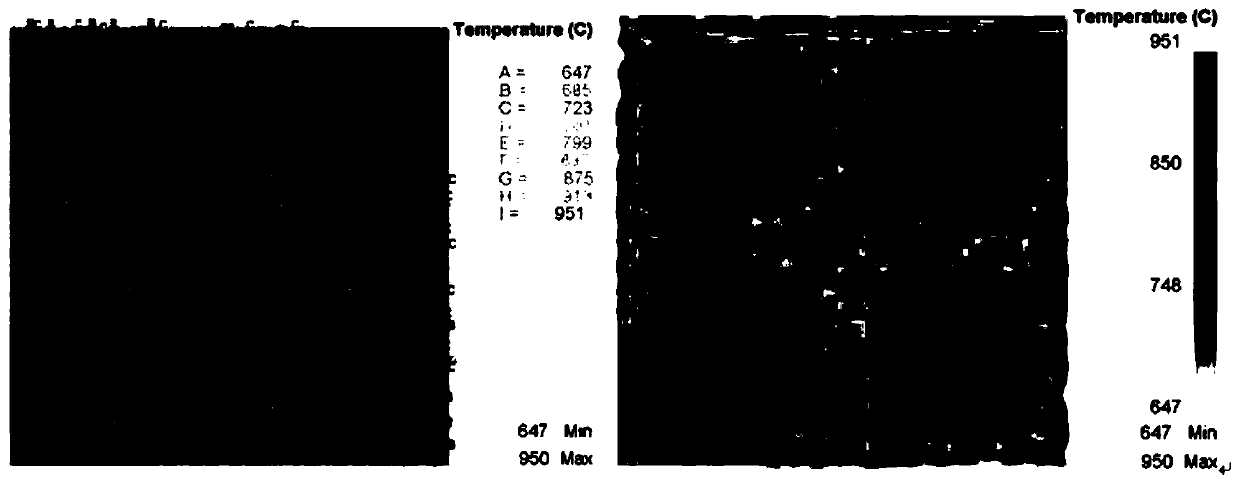

Process for improving heating production efficiency of high-carbon chromium bearing steel

PendingCN114164329AIncrease the number of tappingIncreased heating productivityFurnace typesHeat treatment furnacesChromiumEnergy load

The invention discloses a process for improving the heating production efficiency of high-carbon chromium bearing steel, and relates to the technical field of steel production, the process comprises the following steps: S1, charging: adopting a hot delivery and hot charging process for 320 * 480 rectangular billets, and increasing the temperature of hot delivery billets; s2, preheating of a non-heat-supply section: adjusting through a burner of an adjacent preheating section, and controlling the temperature to be 750-850 DEG C; s3, material distribution, wherein the distance between steel billets in the furnace is adjusted; and S4, heat supply section: carrying out heat balance calculation on the high-carbon-chromium bearing billet again, adjusting the heat supply energy load of each section, and rolling the high-carbon-chromium bearing billet into round steel with the specification of phi 50-100mm after discharging. On the premise of meeting relevant product standards and technical protocol requirements, the heating production efficiency of the high-carbon-chromium bearing steel with the requirement for the high-temperature diffusion time is improved.

Owner:NANJING IRON & STEEL CO LTD

Human body absorbable blood vessel support and its manufacturing method

The present invention provides a method for manufacturing human body absorbable blood vessel support, including the following steps: (1) support forming; (2) cleaning and pre-polishing the support; (3) performing surface alloying treatment to the support; (4) performing fine finish to the support after surface treatment. The invention also provides a human body absorbable blood vessel support, theinvention adopts a surface alloying technique so that the support has a compound diffusion layer with adjustable penetration depth, thereby improving the support intensity and simultaneously quickening the corrosion speed of the support and shortening the support absorption cycle. The yield strength and elongation rate can be modulated in a prodigious scope by controlling the distribution, shapeand depth of the composite diffusion layer, to reach the intensity and absorption cycle required by the support.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

A kind of preparation method of monodisperse platinum series high entropy alloy nano particle catalyst

ActiveCN111111693BHigh Pt utilizationEasy to prepareMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHigh entropy alloys

The invention relates to the technical field of material chemistry, and specifically discloses a method for preparing a monodispersed platinum-based high-entropy alloy nanoparticle catalyst, which includes the preparation of a silicon dioxide photonic crystal template and the preparation of a carbon precursor solution. The platinum precursor and a lot of In four other metal precursors dissolved in THF and CHCl 3 to obtain a mixed solution; mix the block copolymer F127, carbon precursor solution and tetraethyl orthosilicate, and add the protonic acid solution to the mixed solution respectively, and stir to obtain a transparent solution; add the transparent solution to the silica photon In the crystal template, it is dried and then heated and solidified to obtain a purple-brown solid; the purple-brown solid is calcined to obtain a gray solid; the gray solid is etched with strong alkali or strong acid, and then filtered and dried. The preparation method in this patent is used to obtain a monodisperse platinum-based high-entropy alloy nanoparticle catalyst with the advantages of controllable particle size, good dispersion and excellent performance.

Owner:CHONGQING UNIV

A kind of preparation method of non-quenched and tempered steel for automobile chassis

ActiveCN111906153BAvoid growing upReduce composition segregationTemperature control deviceWork cooling devicesMaterials scienceImpact toughness

A method for preparing non-quenched and tempered steel for automobile chassis, comprising the following production steps: a billet heating process, a controlled rolling and controlled cooling step, a sizing step, and a cooling step; wherein, the billet heating includes a preheating section and a three-stage heating The process; the controlled rolling and controlled cooling steps include preliminary rolling, intermediate rolling, primary water cooling, finish rolling, and secondary water cooling; the non-quenched and tempered steel for automobile chassis produced by the preparation method of the present invention has ferrite+ Pearlite structure, grain size above 7.5, tensile strength 940-990Mpa, yield strength 600-650Mpa, impact toughness 41-48J; mechanical properties such as strength and toughness of steel are improved, fatigue resistance and tensile strength are improved. The tensile strength fully meets the technical and quality requirements of non-quenched and tempered steel for automobile chassis parts.

Owner:JIANGSU YONGGANG GROUP CO LTD

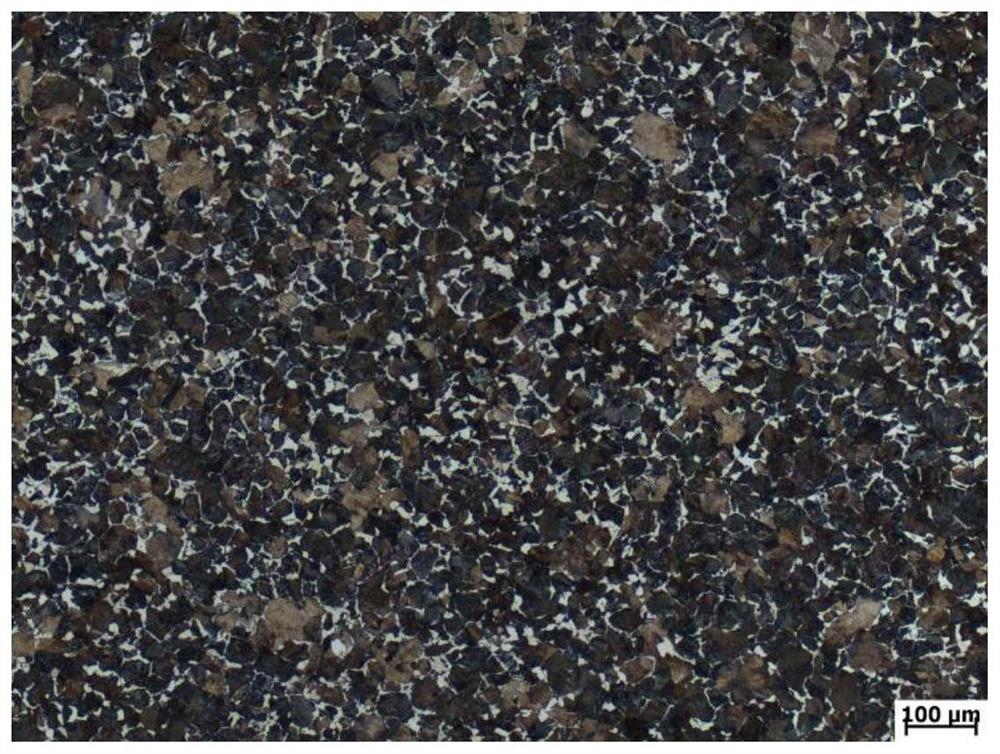

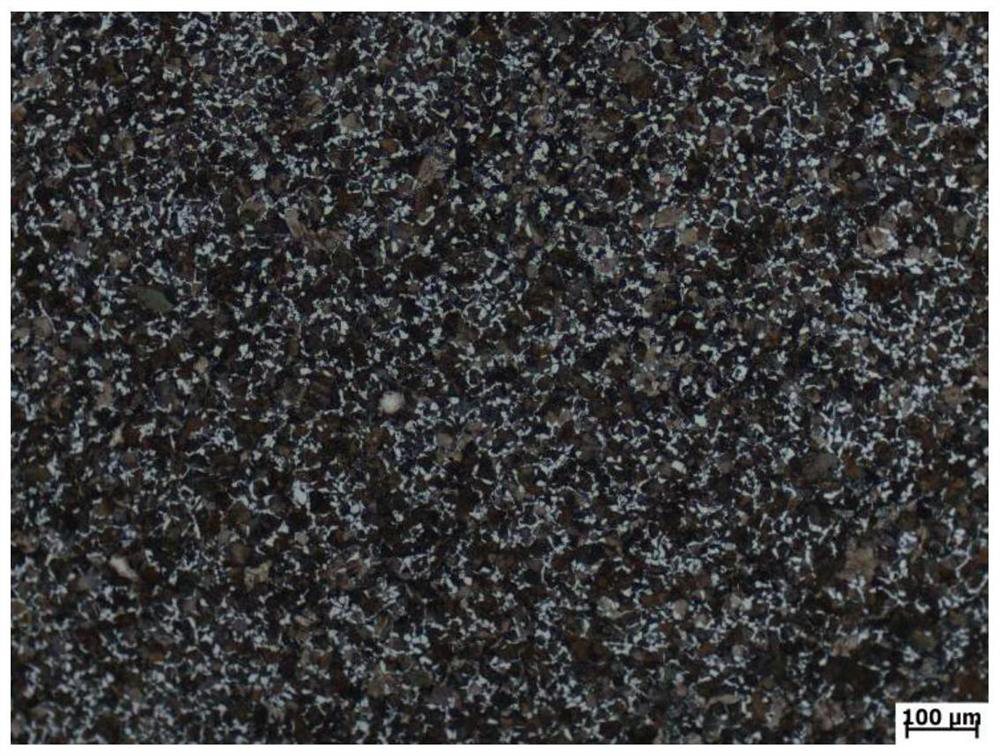

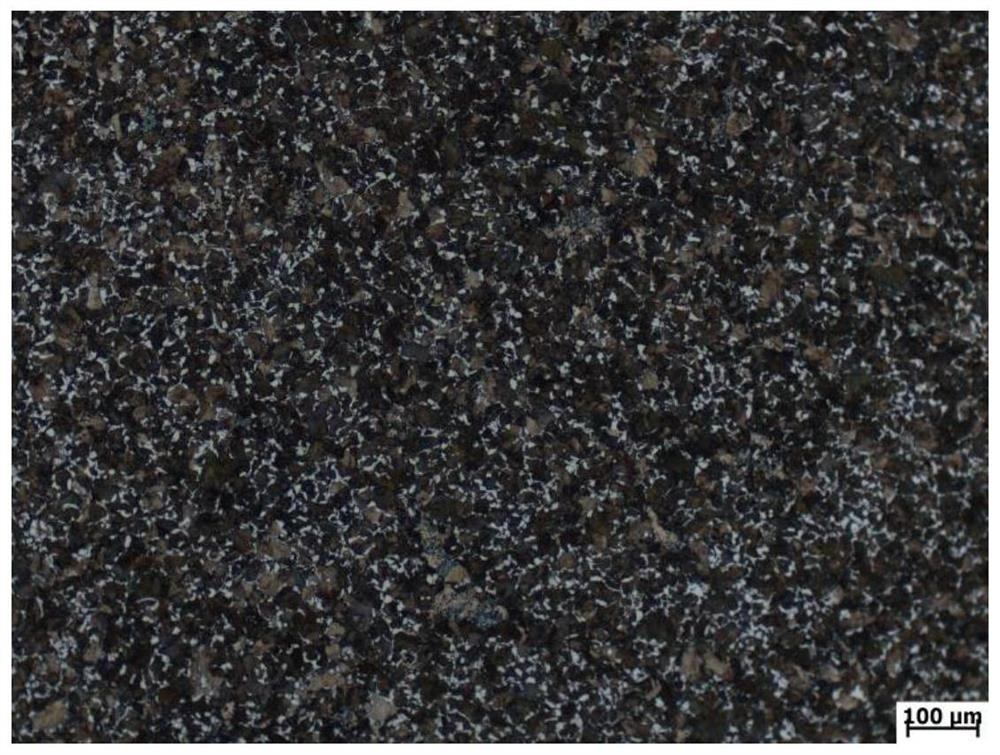

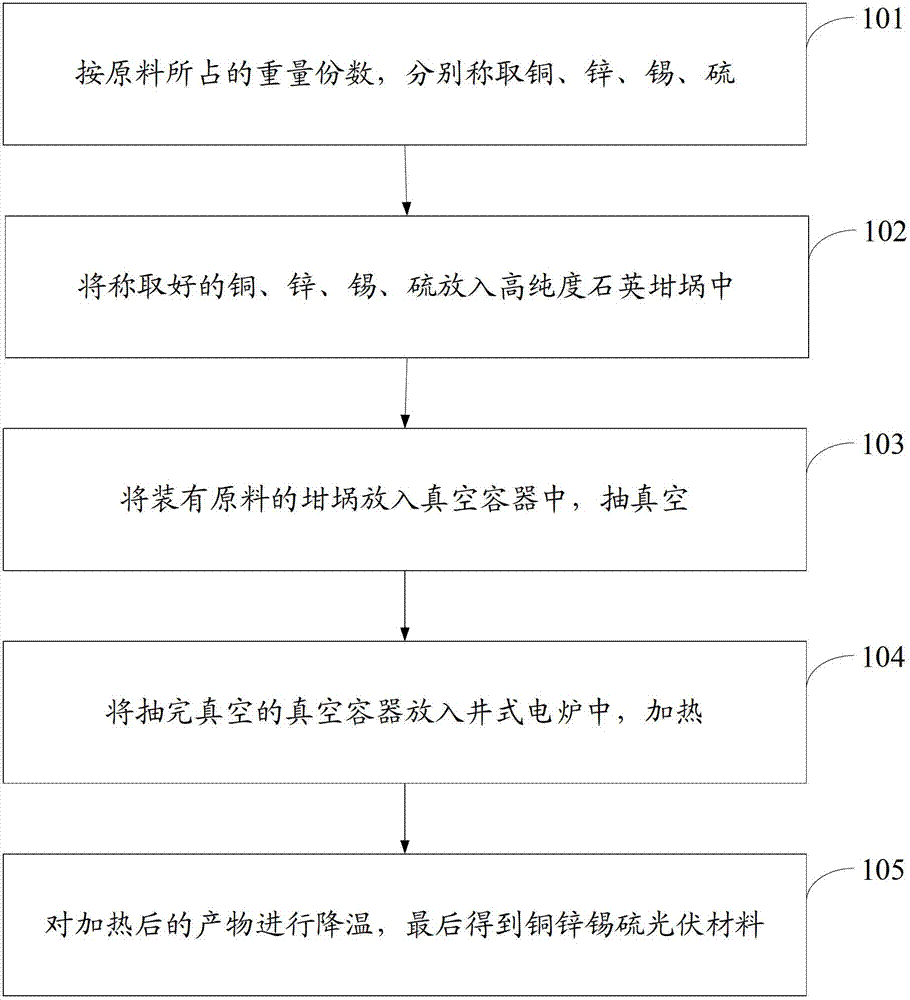

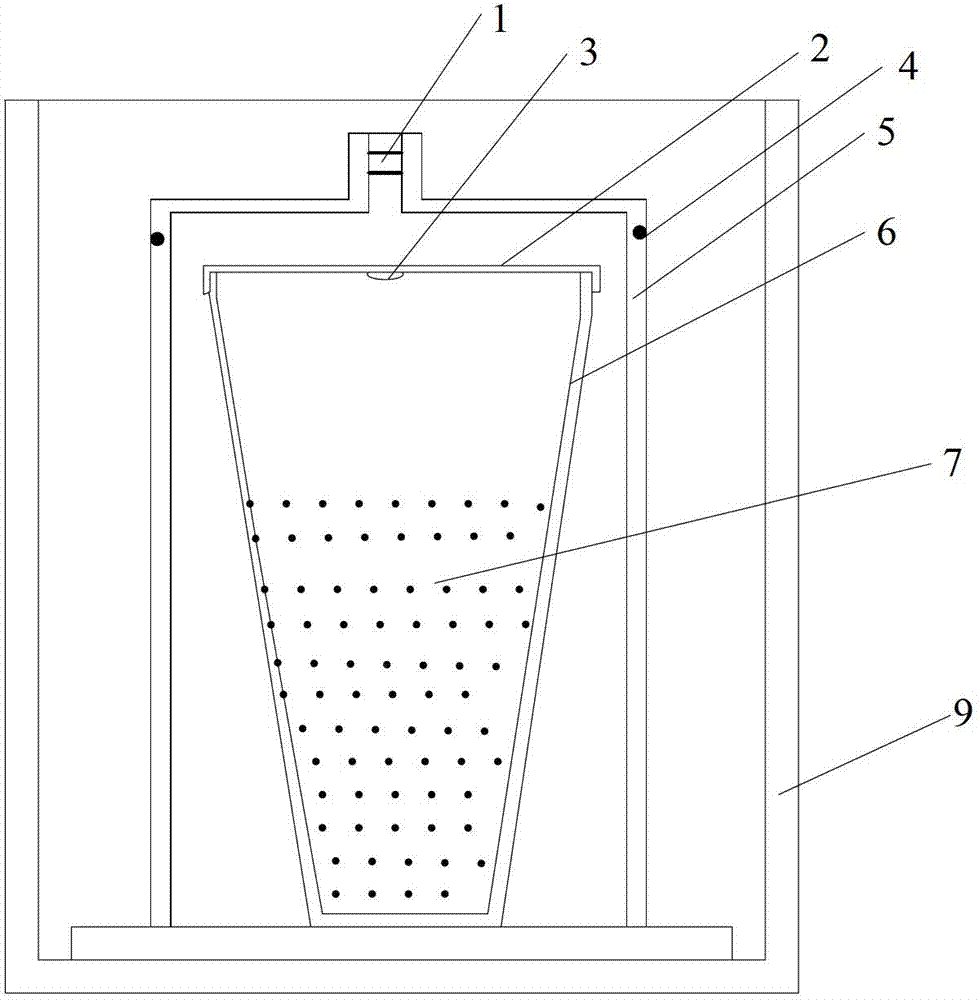

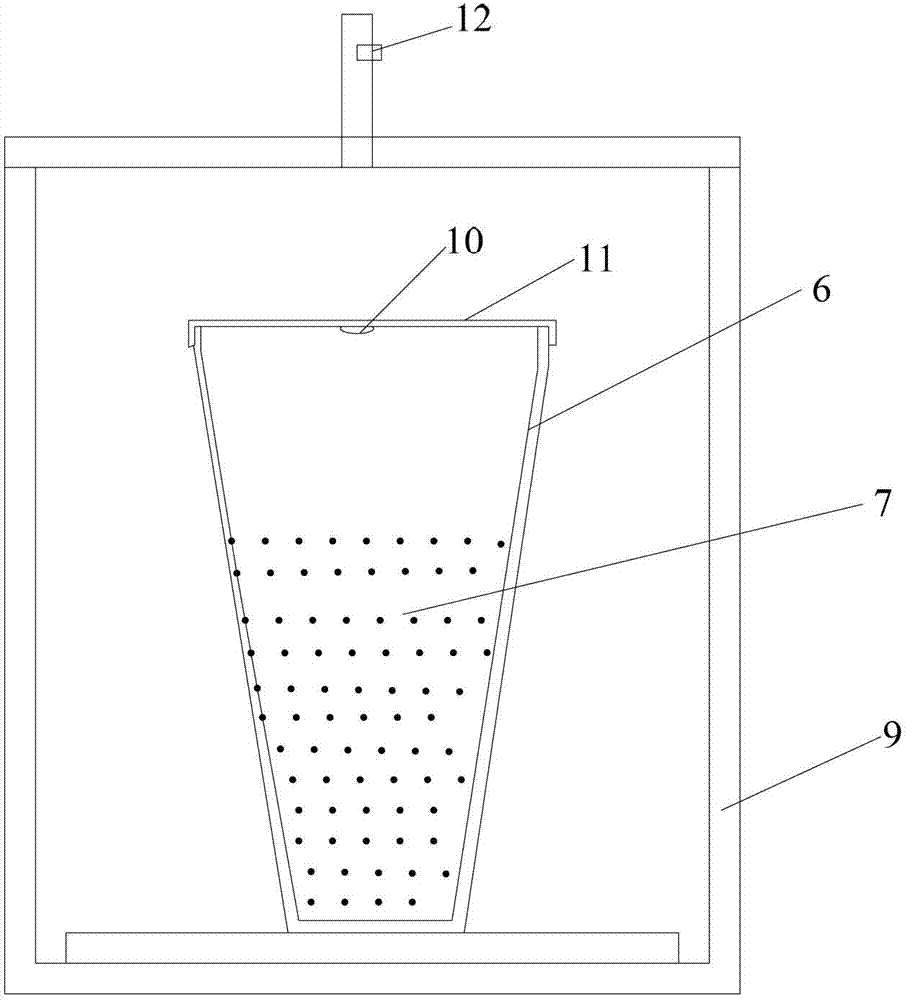

Cu-Zn-Sn-S photovoltaic material, and preparation method and preparation device thereof

InactiveCN102730751AStrong enoughPlastic enoughTin compoundsSemiconductor devicesChemical industryVacuum pumping

The invention relates to the field of chemical industry, particularly relates to a Cu-Zn-Sn-S photovoltaic material, and a preparation method and a preparation device thereof. The photovoltaic material comprises 18-35 weight parts of Cu, 5-30 weight parts of Zn, 5-30 weight parts of Sn, and 25-45 weight parts of S. The preparation method comprises the following steps: A, respectively weighing Cu, Zn, Sn, and S according to the weight parts; B, mixing the weighed Cu, Zn, Sn and S and encapsulating, and conducting vacuum pumping; C, heating Cu, Zn, Sn and S in a vacuum; and D, cooling to obtain the Cu-Zn-Sn-S photovoltaic material. The preparation device comprises an encapsulation container, a vacuum container and a heating unit, wherein the encapsulation container is arranged in the vacuum container, and the vacuum container is arranged in the heating unit. According to the invention, the Cu-Zn-Sn-S photovoltaic material can be prepared by smelting process.

Owner:PIONEER MATERIALS INC CHENGDU

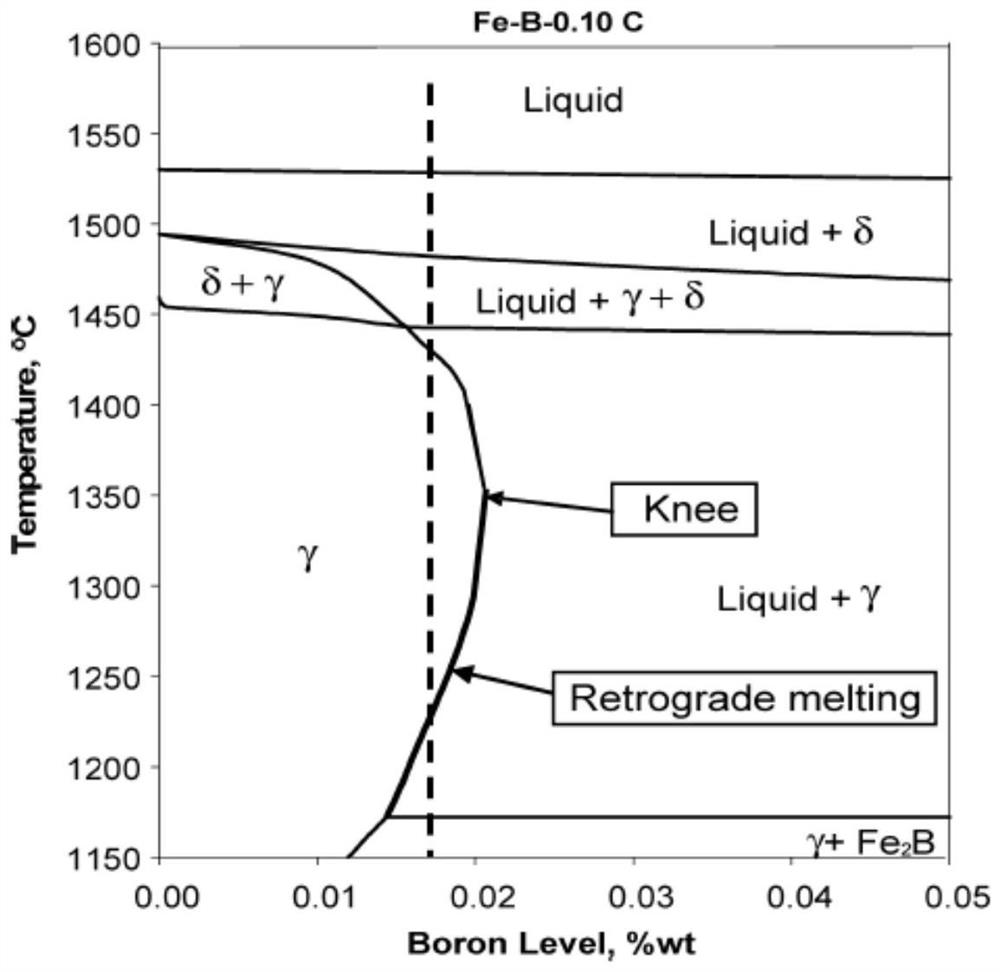

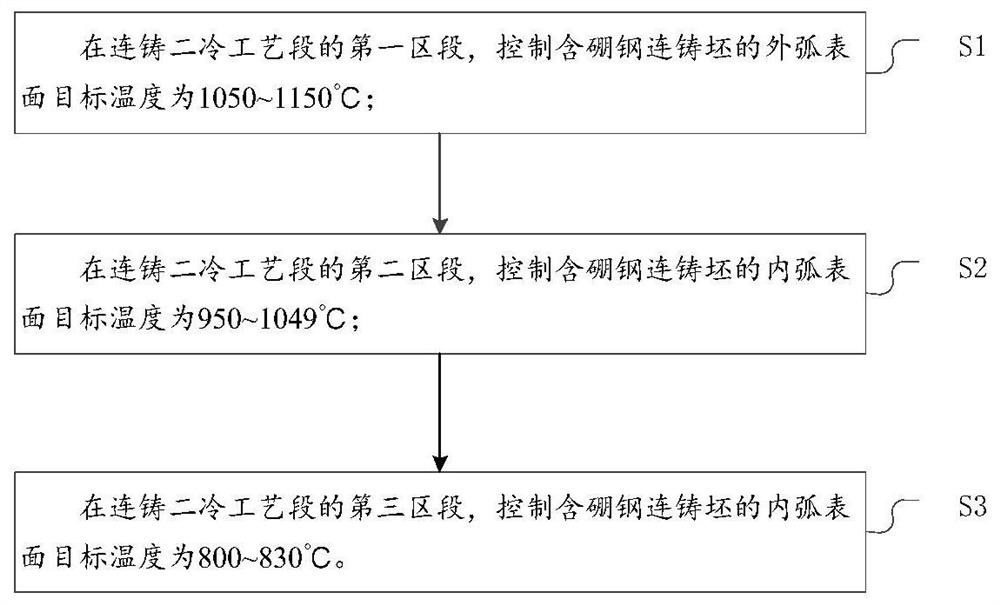

Secondary cooling control method, system and device for boron-containing steel continuous casting billet and storage medium

The invention discloses a secondary cooling control method for a boron-containing steel continuous casting billet. The secondary cooling control method comprises the steps that in a first section of a continuous casting secondary cooling process section, the target temperature of the outer arc surface of the boron-containing steel continuous casting billet is controlled to 1050-1150 DEG C; in the second section of the continuous casting secondary cooling process section, the target temperature of the inner arc surface of the boron-containing steel continuous casting billet is controlled to 950-1049 DEG C; and in the third section of the continuous casting secondary cooling process section, the target temperature of the inner arc surface of the boron-containing steel continuous casting billet is controlled to 800-830 DEG C. Through the combination of the means, the surface quality of the boron-containing steel continuous casting billet can be remarkably improved, the occurrence rate of cracks of the casting billet is decreased, and the secondary cooling control method is suitable for continuous casting process control of boron-containing steel.

Owner:SHOUGANG CORPORATION

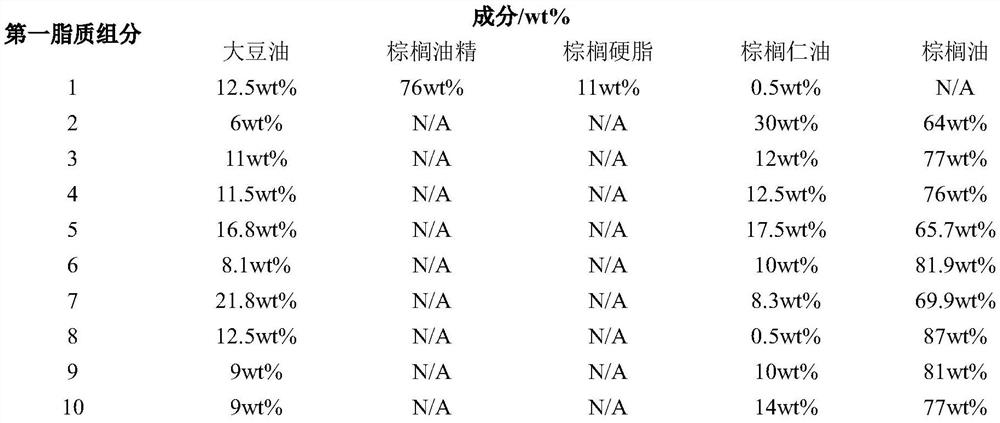

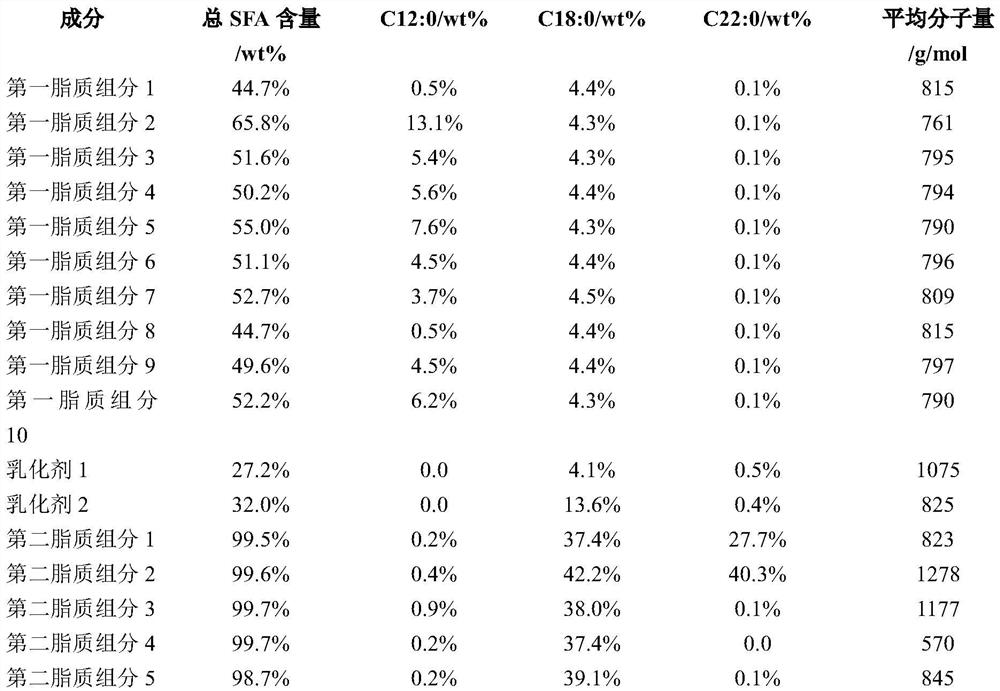

Lipid composition for baked products

A lipid composition comprising, by weight of the lipid composition: from 30 wt% to 70 wt% of a first lipid component; 10 wt% to 40 wt% of a sweet substance; from 5 wt% to 20 wt% of water; 0.1 wt% to 1.2 wt% of an emulsifier; and from 1.5 wt% to 11 wt% of a second lipid component. The emulsifier has an SFA content of less than 90 wt%. The second lipid component has an SFA content of at least 90 wt%, and a fully saturated fatty acid having a carbon chain of more than 16 carbons comprises C22: 0 and comprises at least 33.3 wt% of the SFA content of the second lipid component by weight. The lipid composition has an SFA content of at least 40 wt%, and fully saturated fatty acids having a carbon chain of more than 16 carbons comprise at least 12.5 wt% of the SFA content of the lipid composition by weight. The lipid composition has a C12: 0 content of from 0.35 wt% to 12 wt%. The lipid composition provides a hardness of from 500 g to 2000 g at 5 DEG C to 15 DEG C as measured by texture analysis using a 5 mm cylindrical probe penetrating 75% of the original height of the lipid composition at 2 mm / s. The lipid composition contains less than 2 wt% of TFA.

Owner:CARGILL INC

Universal self-closing wear-resisting erosion-resisting soil sample press station

InactiveCN107525704AImprove "short board effect"Improve the "short board effect"Preparing sample for investigationEngineeringCadmium Cation

The invention relates to a universal self-closing wear-resisting erosion-resisting soil sample press station; the resisting soil sample press station comprises a bottom plate, two first side plates, two second side plates and a cuboid top block, wherein two first trapezoid dovetail grooves and another two rectangular grooves are arranged on the bottom plate; the first trapezoid dovetail grooves are crossly symmetrical linear grooves of which openings are narrower than the bottom parts and the dip angle of oblique side is 20 degrees; the bottom parts of the first side plates are trapezoid wedges, and the matching gap between the first trapezoid dovetail groove and the trapezoid groove is lateral-sided 0.05 mm-0.07 mm; the side faces of the first side plates are further provided with two second trapezoid dovetail grooves of which dip angle of the oblique side is 15 degrees; the bottom parts of the second side plates are rectangular wedges adapted to the rectangular grooves, both ends of the side faces are provided with trapezoid wedges, and the matching gap between the second trapezoid dovetail groove and the trapezoid wedges is lateral-sided 0.05 mm-0.07 mm; the whole station is treated by cadmium plating; a neodymium iron boron magnetic block is further arranged on the bottom plate. The universal self-closing wear-resisting erosion-resisting soil sample press station is strong in university, self-closing, self-wear-resisting, and acid and alkali corrosion resisting.

Owner:LANZHOU UNIVERSITY

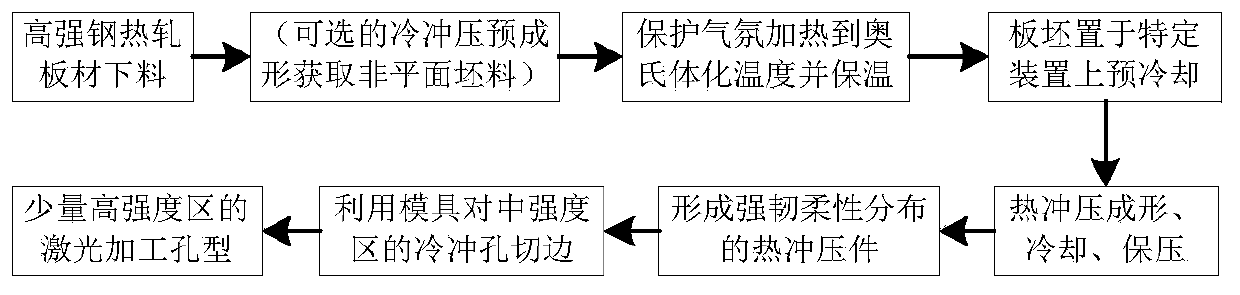

Hot stamping formation method and pre-cooling device

PendingCN111014398AIncrease resistanceLower resistanceShaping toolsQuenching devicesHot stampingPearlite

The invention discloses a hot stamping formation method. The method comprises the following steps of heating, wherein a high-strength steel plate is heated and subjected to heat preservation, so thatthe whole steel plate is turned into an austenite structure; pre-cooling, wherein a first area in the heated steel plate is in contact pressurization and is pre-cooled to the preset temperature range;hot stamping formation, wherein the pre-cooled steel plate is placed in a stamping die for stamping formation; and cooling and quenching, wherein pressure maintaining is performed until the temperature of the surface of the steel plate reaches to the preset range, and the steel plate is taken out from the stamping die and cooled to the room temperature. The first area inside the steel plate is turned into a mixed structure of martensite, bainite and pearlite, so that the steel plate outside the first area is turned into a martensite structure. According to the method, different parts of a hotstamping part have different structures and strengths, and the technology is simple, flexible and adjustable.

Owner:NANJING INST OF TECH

Method for preparing microcrystalline glass fiber from blast furnace slag powder and microcrystalline glass fiber

The invention provides a method for preparing microcrystalline glass fiber from blast furnace slag powder and microcrystalline glass fiber, and belongs to the technical field of glass fiber materials. The method comprises the following steps: melting waste glass to form molten glass; the blast furnace slag powder is fed into the molten glass, so that the blast furnace slag powder can be quickly laid on the liquid surface, the melting of the blast furnace slag powder is promoted, and the feeding mode can provide viscosity reduction time for a mixture formed by the molten glass and the blast furnace slag powder, so that the melting of the blast furnace slag powder in the melting process is further accelerated; then, bubbles and refractory components in the melt are removed through clarification, and the density of the melt is homogenized through homogenization; high-temperature spinning treatment is adopted, so that on one hand, sufficient plasticity of glass ceramic liquid is guaranteed, drawing is facilitated, and on the other hand, fiber breakage or large residual thermal stress caused by rapid cooling in the drawing process is prevented; and finally, heat treatment is performed to eliminate a small amount of internal stress remained in the microcrystalline glass fibers and improve the mechanical properties of the fibers.

Owner:SHAANXI SCI TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com