Aluminum alloy cast ingot for automotive bumper and production process thereof

A technology for aluminum alloy ingots and automobile bumpers, which is applied in the field of aluminum alloy ingots and its production technology, can solve the problems of low toughness and impact resistance, high price, feather crystals, etc., to improve stress corrosion resistance, improve Stress corrosion resistance and the effect of reducing the tendency of hot cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

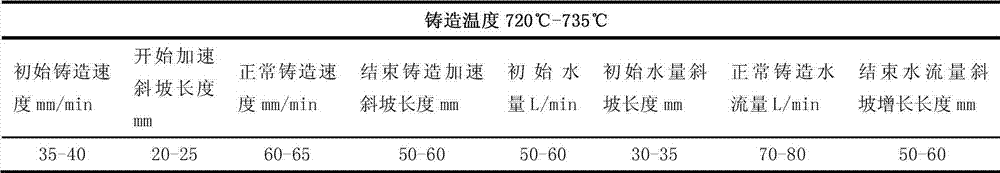

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The present invention is used for the aluminum alloy casting ingot of automobile bumper, and its non-aluminum alloying element is: the mass percent of Si is 0.095%, the mass percent of Fe is 0.163%, the mass percent of Mg The content is 1.23%, the mass percentage of Mn is 0.011%, the mass percentage of Cu is 0.219%, the mass percentage of Cr is 0.0023%, the mass percentage of Zn is 6.64%, the mass percentage of Zr The content is 0.156%, the mass percentage of Ti is 0.031%, the individual mass percentage of non-detectable impurities is 0.03%, and the total is 0.09%.

[0022] The production process for processing the aluminum alloy ingot comprises the following steps;

[0023] (1) Ingredients: Aluminum ingot of 99.85 grade is selected as the base of the alloy. Mg and Zn elements are added in the form of pure metals. Considering that Cu, Cr, Ti, and Zr elements have high melting points and low content in the alloy, they are added in the form of master alloys...

Embodiment 2

[0032] Example 2 The aluminum alloy casting ingot used for automobile bumper of the present invention, its non-aluminum alloying elements are: the mass percentage of Si is 0.089%, the mass percentage of Fe is 0.168%, and the mass percentage of Mg 1.21%, the mass percentage of Mn is 0.011%, the mass percentage of Cu is 0.213%, the mass percentage of Cr is 0.0022%, the mass percentage of Zn is 6.69%, the mass percentage of Zr is 0.158%, the mass percentage of Ti is 0.036%, the single mass percentage of non-detectable impurities is 0.03%, and the total is 0.09%. The aluminum alloy casting ingot production process of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com