Hard aluminum alloy ingot

A hard aluminum alloy and ingot casting technology, which is applied in the field of aluminum alloy, can solve the problems of increased cooling strength, reduce the tendency of thermal cracks, improve temperature and stress corrosion resistance, and improve stress corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

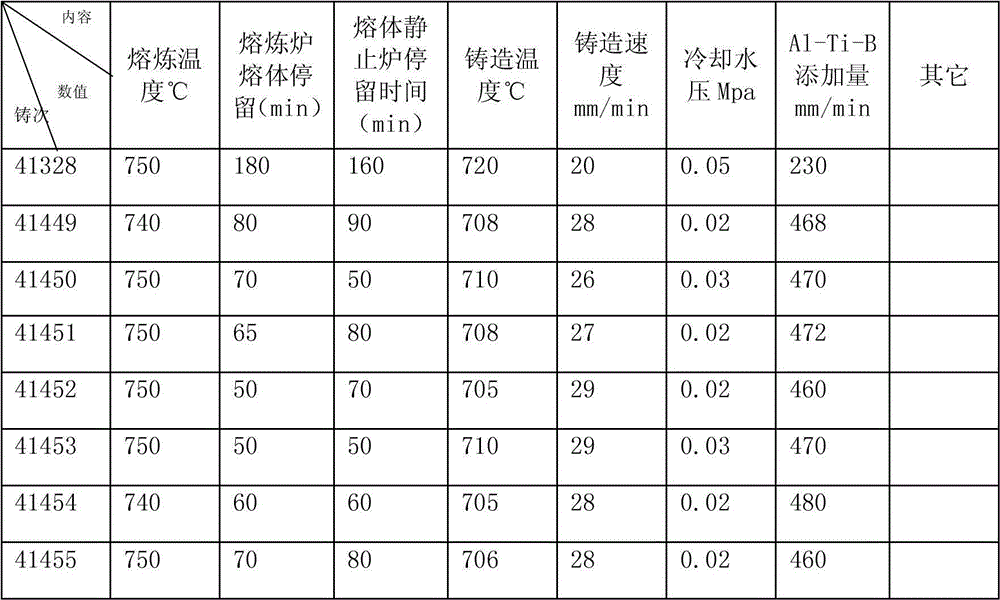

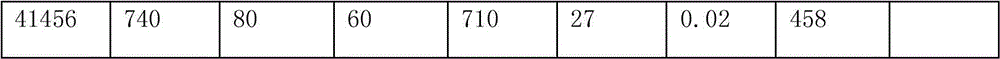

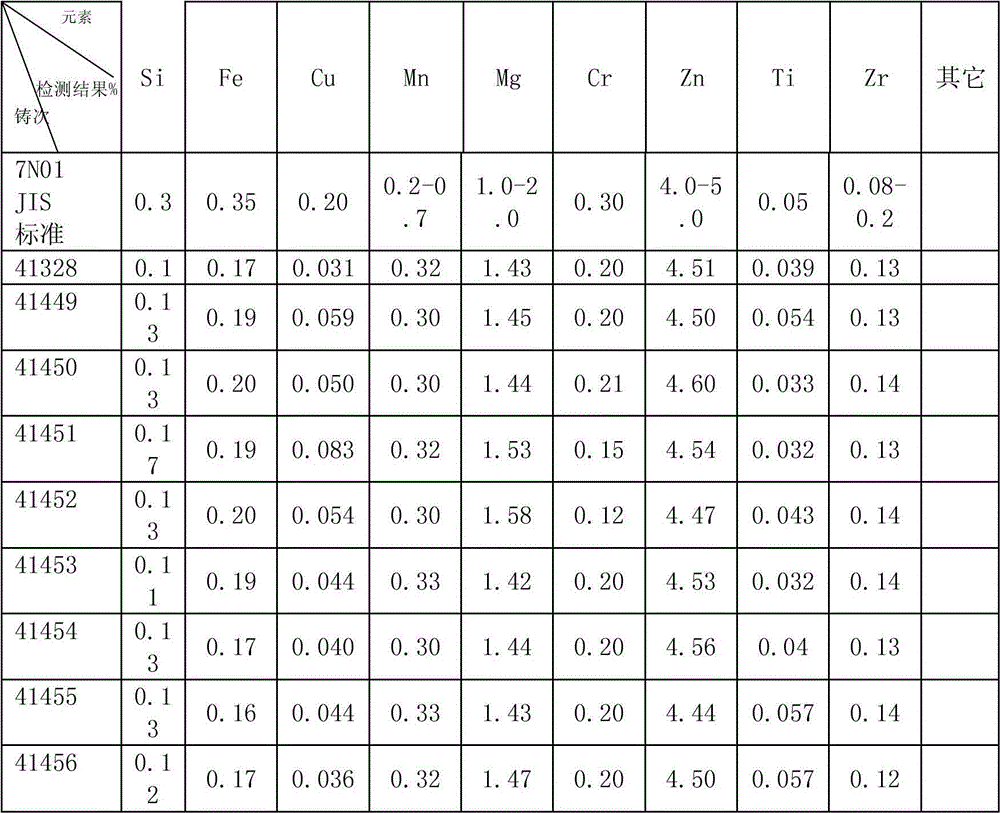

Examples

Embodiment 1

[0007] Example 1 In the hard aluminum alloy casting ingot of the present invention, its non-aluminum alloying elements are: the mass percentage of Si is 0.12%, the mass percentage of Fe is 0.18%, and the mass percentage of Mg is 1.44%. The mass percentage of Mn is 0.30%, the mass percentage of Cu is 0.15%, the mass percentage of Cr is 0.21%, the mass percentage of Zn is 4.60%, and the mass percentage of Zr is 0.14%, The individual mass percentage content of non-detectable impurities is 0.05%, and the total is 0.15%.

[0008] The fine-grained and refined processing technology of the hard aluminum alloy ingot comprises the following steps;

[0009] (1) Dosing first: the base of the alloy is made of 99.85 grade aluminum ingot, and Mg and Zn elements are added in the form of pure metals. Considering that Cu, Cr, Ti, and Zr elements have high melting points and low content in the alloy, the middle added in the form of an alloy;

[0010] (2) Afterwards, the regenerative gas furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com