A kind of Hastelloy alloy and carbon steel composite plate and its manufacturing method

A technology of Hastelloy alloy and clad plate, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., to prevent contact, improve crevice corrosion resistance, and avoid the generation of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

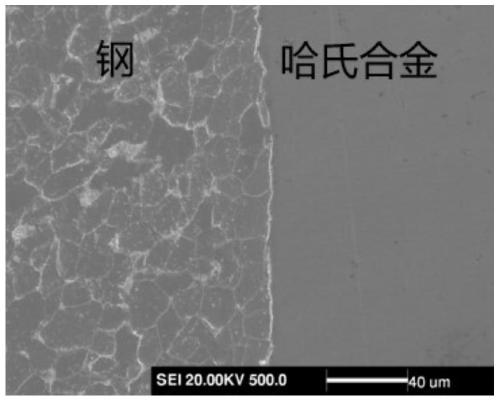

[0023] A method for manufacturing a Hastelloy and carbon steel clad plate, comprising the following steps:

[0024] 1) Polish the surface of the C-276 Hastelloy alloy with a size of 100mm×120mm×4mm and the carbon steel with a size of 100mm×120mm×8m and wash them with acid to remove surface impurities; wherein, the mass percentage content of the carbon steel is C≤0.22%Mn ≤1.8%Si≤0.6%S≤0.050P≤0.045, the balance is Fe and unavoidable impurity elements; Hastelloy mass percentage content is C≤0.02%, 10%≤Cr≤21%, 13%≤Mo≤ 20%, 3%≤Fe≤9%, 3%≤W≤6%, Si≤0.10%, Co≤3.5%, the balance is Ni and unavoidable impurity elements.

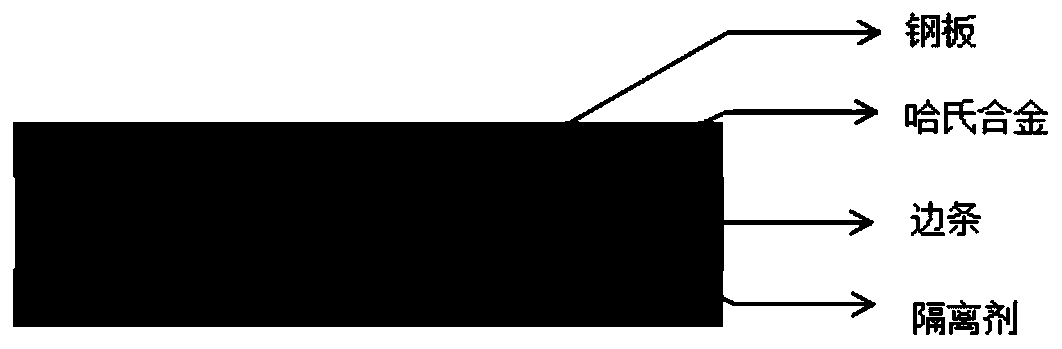

[0025] 2) Apply a release agent between the contact surfaces of the two layers of Hastelloy to make a symmetrical combination of billets, and place the steel plate or billet on the outermost side.

[0026] 3) Add side strips to the combined Hastelloy and carbon steel combined steel billet, use vacuum electron beam welding method to vacuum the combined steel billet with ...

Embodiment 2

[0033] A method for manufacturing a Hastelloy and carbon steel clad plate, comprising the following steps:

[0034] 1) Polish the surface of the C-276 Hastelloy alloy with a size of 150mm×150mm×3mm and the carbon steel with a size of 150mm×150mm×9m, and wash the surface impurities with acid; the mass percentage of the carbon steel is C≤0.22%Mn≤ 1.8%Si≤0.6%S≤0.050P≤0.045, the balance is Fe and unavoidable impurity elements; Hastelloy mass percentage content is C≤0.02%, 10%≤Cr≤21%, 13%≤Mo≤20 %, 3%≤Fe≤9%, 3%≤W≤6%, Si≤0.10%, Co≤3.5%, and the balance is Ni and unavoidable impurity elements.

[0035] 2) Apply a release agent between the contact surfaces of the two layers of Hastelloy to make a symmetrical combination of billets, and place the steel plate or billet on the outermost side.

[0036] 3) Add side strips to the combined Hastelloy and carbon steel combined steel billet, use vacuum electron beam welding method to vacuum the combined steel billet with a mechanical pump, and th...

Embodiment 3

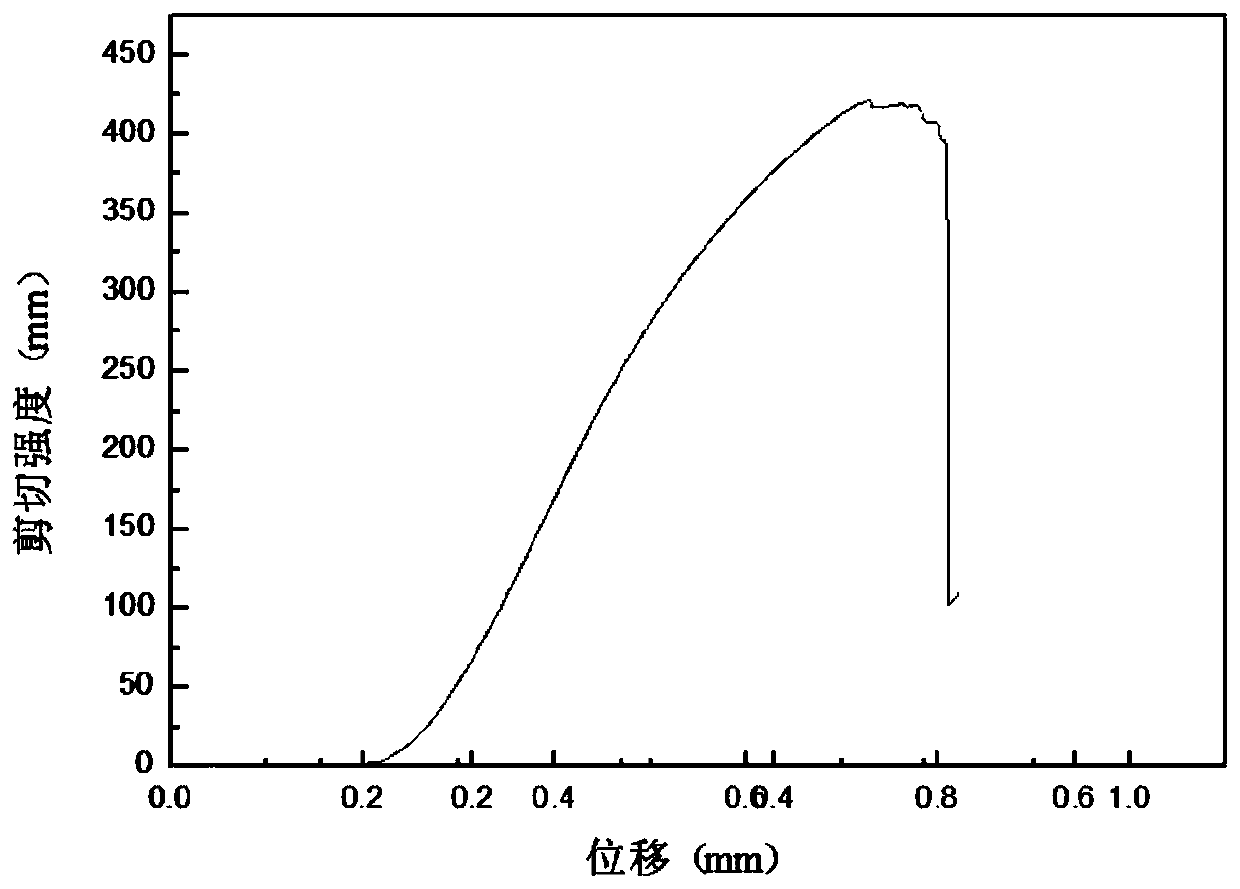

[0039] The present invention also sets up a control experiment for the influence of the rolling temperature on the bonding strength of the manufacturing method of Hastelloy and carbon steel clad plate, and the concrete experimental steps are as follows:

[0040] 1) Polish the surface of the C-276 Hastelloy alloy with a size of 150mm*125mm*4mm and the Q235 low carbon steel with a size of 150mm*125mm*8mm, and wash the surface impurities with acid. The Hastelloy composition is shown in Table 2:

[0041] Table 2 Hastelloy composition (wt%)

[0042]

[0043] 2) Apply a release agent between the contact surfaces of the two layers of Hastelloy to make a symmetrical combination of billets, and place the steel plate or billet on the outermost side.

[0044] 3) Add side strips to the combined Hastelloy and carbon steel combined steel billet, use vacuum electron beam welding method to vacuum the combined steel billet with a mechanical pump, and the vacuum degree reaches 10 -2 After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com