Heat treatment method for improving stress corrosion resistance of 7-series aluminum alloy

A heat treatment method and technology for corrosion performance, applied in heat treatment furnaces, heat treatment equipment, energy efficiency improvement and other directions, can solve the problems of manual feeding and poor corrosion resistance, and achieve the effect of improving strength, better corrosion resistance and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

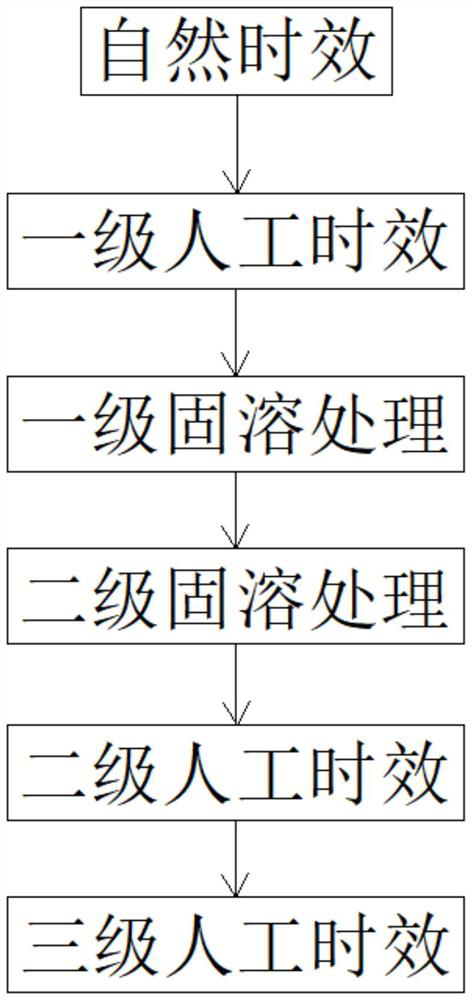

[0052] Example 1 discloses a heat treatment method for improving the stress corrosion resistance of 7-series aluminum alloys, refer to the attached figure 1 , which includes the following six heat treatment steps:

[0053] 1) Natural aging: After the extruded material is cooled to room temperature, it is naturally aged for 48~72h at room temperature, and the room temperature is 10℃~45℃.

[0054] 2) First-level artificial aging: keep the extruded material treated in step 1 at a temperature of 110°C~130°C for 18~24h, and cool it with strong wind after it is released from the furnace. The cooling rate of the strong wind cooling in step 2 is controlled at 10~ 30°C / min.

[0055] 3) Primary solution treatment: The extruded material treated in step 2 is subjected to primary solution treatment at a temperature of 430°C to 450°C for 0.5 to 2 hours, and cooled in the furnace for 1 hour.

[0056] 4) Secondary solid solution treatment: The extruded material treated in step 3 is subjecte...

Embodiment 2

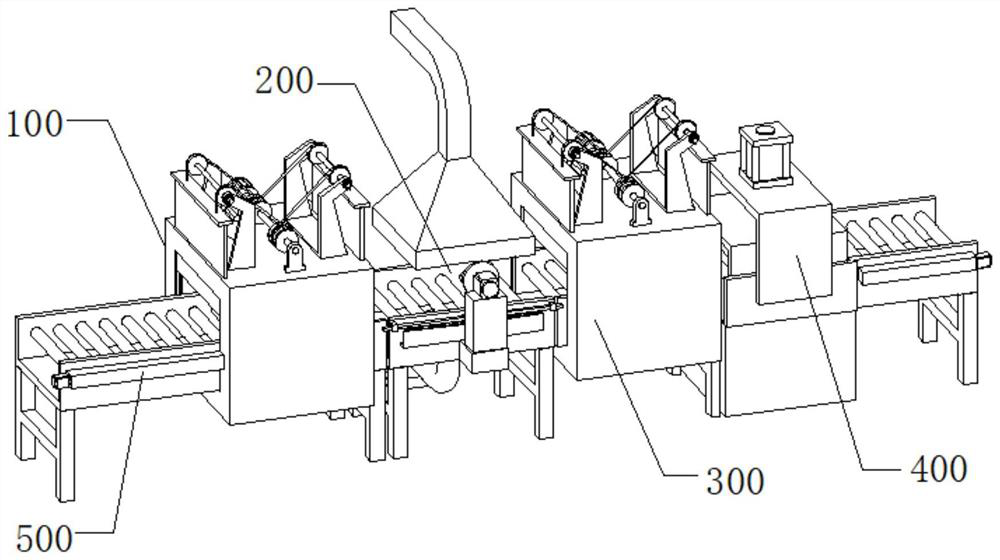

[0060] This Example 2 discloses a heat treatment device for improving the stress corrosion resistance of the 7-series aluminum alloy mentioned above. figure 2 , the heat treatment device includes an aging treatment chamber 100, a strong wind cooling device 200, a solution treatment chamber 300 and a quenching device 400 arranged in sequence from left to right, and the aging treatment chamber 100, the strong wind cooling device 200, the solution treatment chamber 300 and the quenching The four devices 400 are connected end to end.

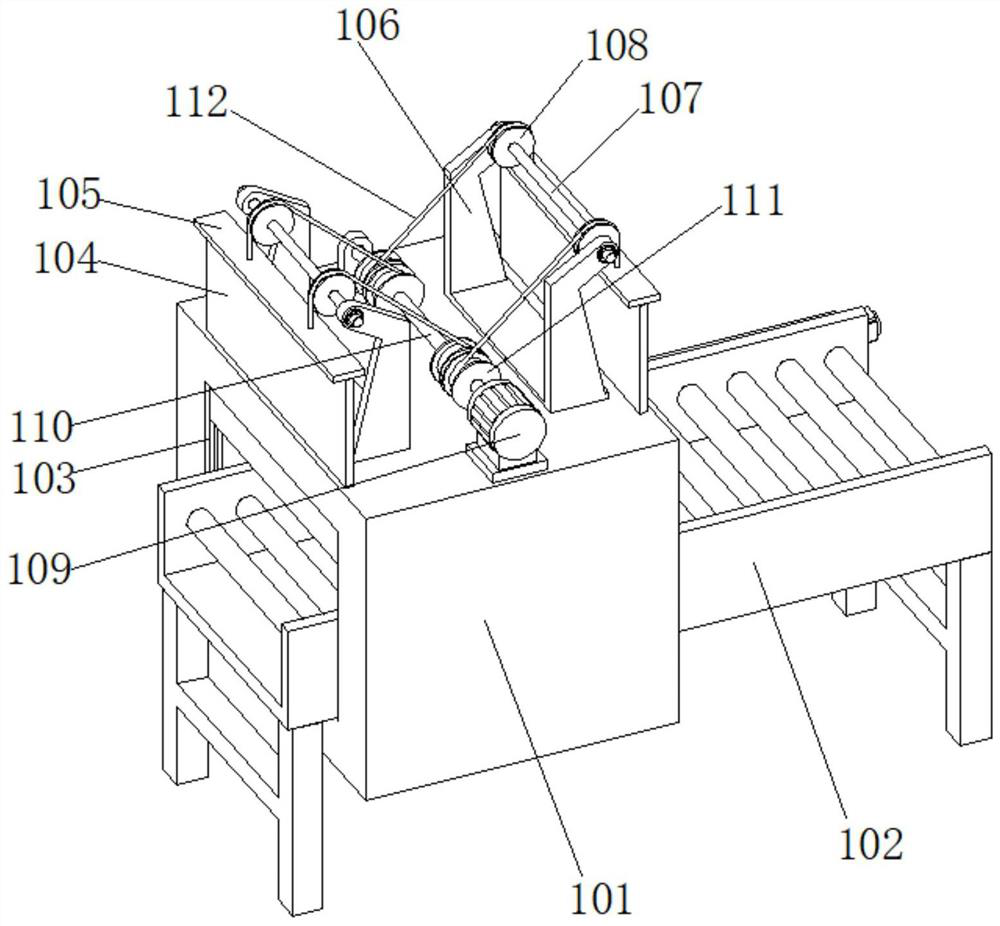

[0061] Reference attached image 3 And attached Figure 4 , wherein the aging treatment chamber 100 and the solid solution treatment chamber 300 have basically the same structure, both of which include a heating cabinet 101 and a first conveyor 102 disposed through the heating cabinet. And the heating cabinet 101 is all made of a high-temperature-resistant inner bag and an external thermal insulation layer.

[0062] A gate 103 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com