Universal self-closing wear-resisting erosion-resisting soil sample press station

A kind of stamping machine, self-fixing technology, applied in the field of agricultural tools, can solve the problems of chipping and wear, poor corrosion resistance, steel plate deformation, etc., to enhance the impact resistance and stability, reduce instability, high surface integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

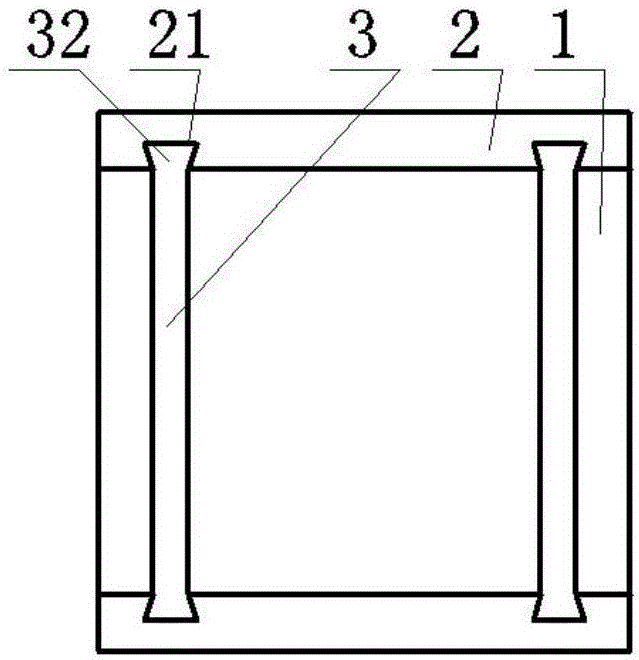

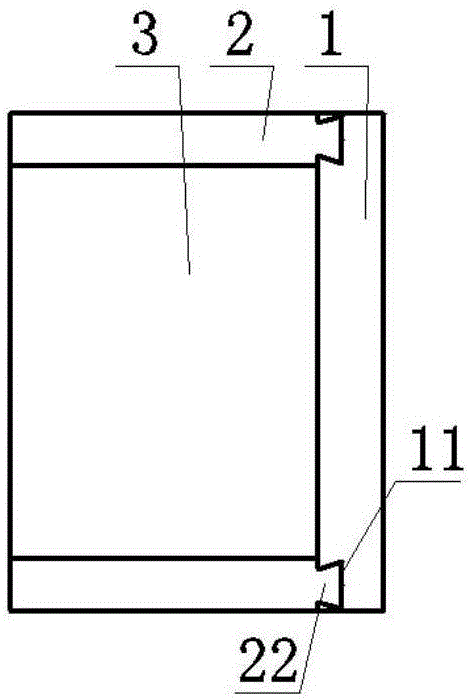

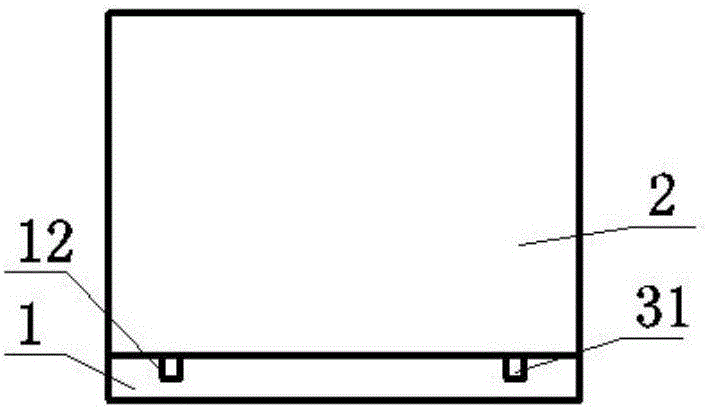

[0014] A universal self-locking wear-resistant and anti-corrosion soil sample press station, including a bottom plate 1, two first side plates 2, two second side plates 3, and a base plate 1 and two first side plates 2. A rectangular parallelepiped top block suitable for the space enclosed by the two second side plates 3. The bottom plate 1 is provided with two first trapezoidal dovetail grooves 11 parallel to each other and the other two parallel to each other and aligned with the first dovetail grooves. A rectangular groove 12 with a vertical center line, the first trapezoidal dovetail groove 11 is specifically a linear groove with an opening narrower than the bottom, left and right symmetrical, and a hypotenuse angle of 20°; the bottom of the first side plate 2 is the first trapezoidal dovetail groove 11 is adapted to the first trapezoidal wedge 22 with a matching gap of 0.05mm-0.07mm on one side, and two second trapezoidal dovetail grooves 21 parallel to each other and with...

Embodiment 2

[0016] The whole is consistent with Example 1, the difference is:

[0017] The bottom plate 1, the first side plate 2, the second side plate 3 and the top block are all made of T8 steel, after quenching and tempering and stress relief treatment, the hardness of the rear surface is not lower than 60HRC; the bottom plate 1 is not provided with neodymium Iron boron magnetic block4.

Embodiment 3

[0019] The whole is consistent with Example 1, the difference is:

[0020] The bottom plate 1, the first side plate 2, the second side plate 3 and the top block are all made of T8 steel. After quenching and tempering and stress relief treatment, the hardness of the rear surface is not less than 60HRC; the first dovetail set on the bottom plate 1 Both the slot 11 and the second dovetail slot 21 provided on the first side plate 2 have not undergone local high-frequency induction annealing treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com