Process for improving heating production efficiency of high-carbon chromium bearing steel

A high-carbon chromium bearing steel and production efficiency technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve problems such as waste of resources, dissatisfaction of material distribution in the second heating section and soaking section, loss of efficiency, etc., to increase tapping The effect of improving the number of counts and heating production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

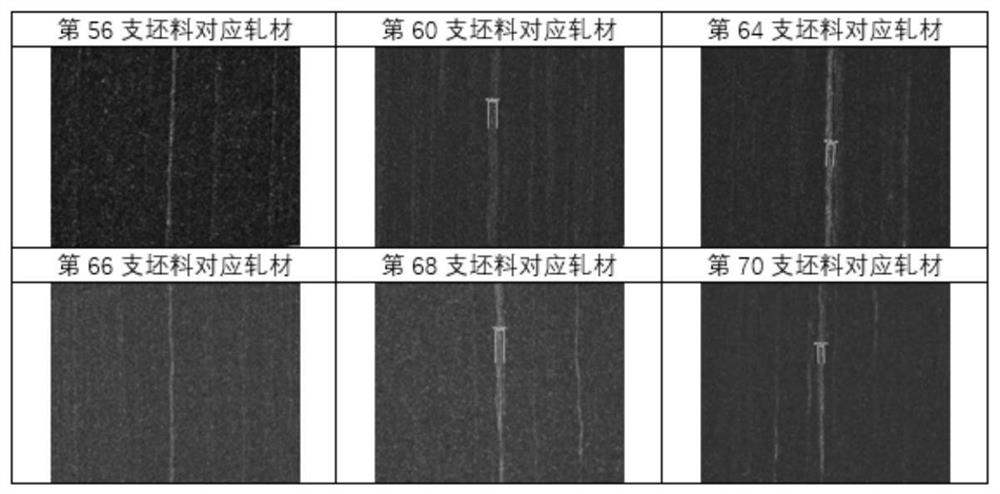

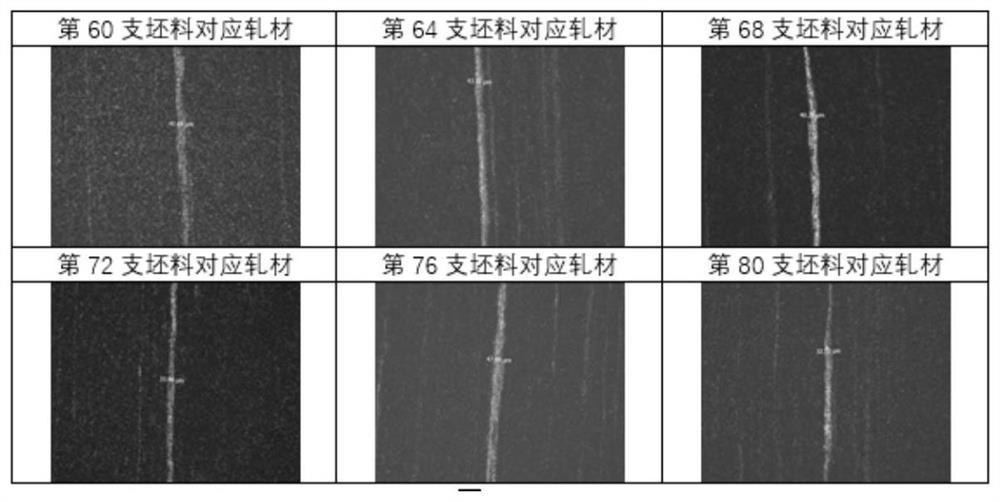

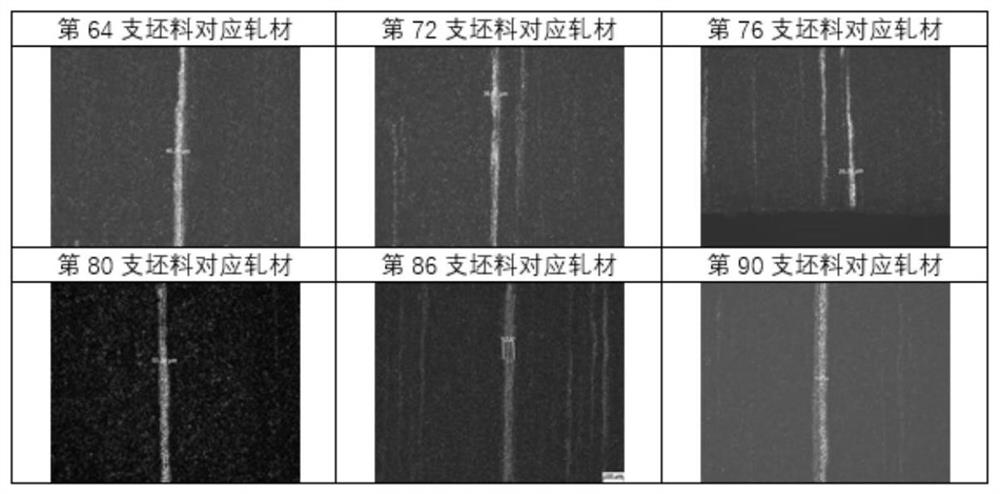

Image

Examples

Embodiment 1

[0033] This embodiment provides a process for improving the production efficiency of high-carbon chromium bearing steel heating. A high-carbon chromium bearing steel continuous casting slab of 320 (thickness)×480 (width)×5400mm (length) is selected, and its chemical composition and quality are 100%. The content is: C: 0.98%, Si: 0.23%, Mn: 0.33%, Cr: 1.45%, Mo: 0.003%, P: 0.008%, S: 0.001%, Al: 0.012%, and the balance is iron.

[0034] Include the following steps:

[0035] The steel billet is transferred to the rolling mill by an insulated car, and the surface temperature of the steel billet on the side entering the furnace is detected as 612-647 °C;

[0036] When loading steel, all six burners in the preheating section are turned on, and the furnace temperature in the non-heating section is actually controlled at 750-850°C, with a target temperature of 800°C;

[0037] After entering the furnace, the distance between billets should be 100mm, the temperature in the preheating ...

Embodiment 2

[0042] This embodiment provides a process for improving the heating production efficiency of high carbon chromium bearing steel. The continuous casting billet of high carbon chromium bearing steel of 320 (thickness) × 480 (width) × 5400 mm (length) is selected, and its chemical composition and quality are 100%. The contents are: C: 0.98%, Si: 0.23%, Mn: 0.33%, Cr: 1.45%, Mo: 0.003%, P: 0.008%, S: 0.001%, Al: 0.012%, and the balance is iron.

[0043] Include the following steps:

[0044] The billet is transported to the rolling mill by the heat preservation truck, and the surface temperature of the billet on the furnace side is detected as 605-651℃;

[0045] When loading steel, all 6 burners in the preheating section are turned on, the furnace temperature in the non-heating section is actually controlled at 750-850 °C, and the target temperature is 810 °C;

[0046] After entering the furnace, the billet spacing shall be 100mm, the temperature of the preheating section shall be...

Embodiment 3

[0051] This embodiment provides a process for improving the heating production efficiency of high carbon chromium bearing steel. The continuous casting billet of high carbon chromium bearing steel of 320 (thickness) × 480 (width) × 5400 mm (length) is selected, and its chemical composition and quality are 100%. The contents are: C: 0.98%, Si: 0.23%, Mn: 0.33%, Cr: 1.45%, Mo: 0.003%, P: 0.008%, S: 0.001%, Al: 0.012%, and the balance is iron.

[0052] Include the following steps:

[0053] The billet is transported to the rolling mill by the heat preservation truck, and the surface temperature of the billet on the furnace side is detected as 602-646℃;

[0054] When loading steel, all 6 burners in the preheating section are turned on, and the furnace temperature in the non-heating section is actually controlled at 750-850 °C, and the target temperature is 830 °C;

[0055] After entering the furnace, the billet spacing shall be 100mm, the temperature of the preheating section shal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com