Human body absorbable blood vessel support and its manufacturing method

A vascular stent and a manufacturing method technology, applied in the field of medical devices, can solve the problems that the stent cannot be used, the elongation rate of the ferroalloy is not high enough, etc., and achieve the effects of shortening the absorption period, accelerating the absorption speed, and improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

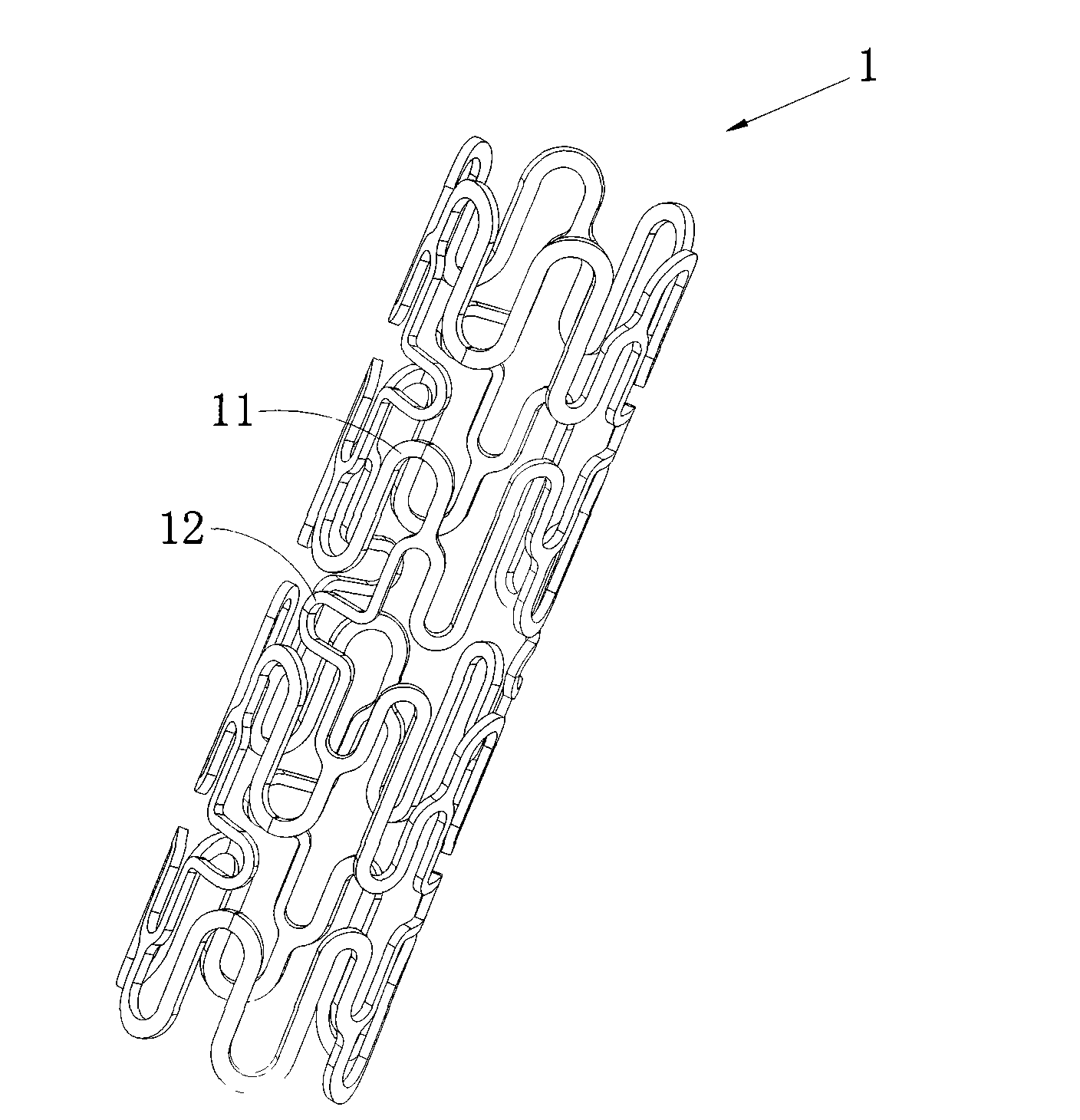

[0053] The pure iron pipe (outer diameter 2.8mm, wall thickness 0.2mm) that meets the requirements of GB / T9971-2004 is laser cut into a hollow tubular structure according to the preset pattern. The cut stent was ultrasonically cleaned with water for 10 minutes, followed by ultrasonic cleaning with absolute ethanol for 10 minutes, and then ultrasonic cleaning with acidic solution for 2 minutes. The cleaned stent was clamped on an electrochemical polishing device, and polished in an iron polishing solution for 2 minutes at a polishing voltage of 16 volts. Reverse the orientation of the stent at regular intervals during electrochemical polishing.

[0054] The pre-polished stent was ionized with N. After cleaning the pure iron bracket, put it into the cathode disk of the glow ion furnace and make full contact with the temperature measuring workpiece, and close the vacuum chamber. Start the vacuum pump to evacuate to below 6 Pa, turn on the bias power supply, and adjust the volta...

specific Embodiment 2

[0058] The pure iron pipe (outer diameter 2.8mm, wall thickness 0.2mm) that meets the requirements of GB / T9971-2004 is laser cut into a hollow tubular structure according to the preset pattern. The cut stent was ultrasonically cleaned with water for 10 minutes, followed by ultrasonic cleaning with absolute ethanol for 10 minutes, and then ultrasonic cleaning with acidic solution for 2 minutes. The cleaned stent was clamped on an electrochemical polishing device, and polished in an iron polishing solution for 2 minutes at a polishing voltage of 16 volts. Reverse the orientation of the stent at regular intervals during electrochemical polishing.

[0059] The pre-polished support is ionized: clean the pure iron support and put it on the cathode plate of the glow ion furnace to completely contact the temperature measuring workpiece, and close the vacuum chamber. Start the vacuum pump to evacuate to below 6 Pa, turn on the bias power supply, and adjust the voltage to 450V to gener...

specific Embodiment 3

[0063] The pure iron pipe (outer diameter 2.8mm, wall thickness 0.2mm) that meets the requirements of GB / T9971-2004 is laser cut into a hollow tubular structure according to the preset pattern. The cut stent was ultrasonically cleaned with water for 10 minutes, followed by ultrasonic cleaning with absolute ethanol for 10 minutes, and then ultrasonic cleaning with acidic solution for 2 minutes. The cleaned stent was clamped on an electrochemical polishing device, and polished in an iron polishing solution for 2 minutes at a polishing voltage of 16 volts. Reverse the orientation of the stent at regular intervals during electrochemical polishing.

[0064] Ion infiltration C+N on the pre-polished support: clean the pure iron support and put it into the cathode disk of the glow ion furnace to make full contact with the temperature measuring workpiece, and close the vacuum chamber. Start the vacuum pump to evacuate to below 6 Pa, turn on the bias power supply, and adjust the voltag...

PUM

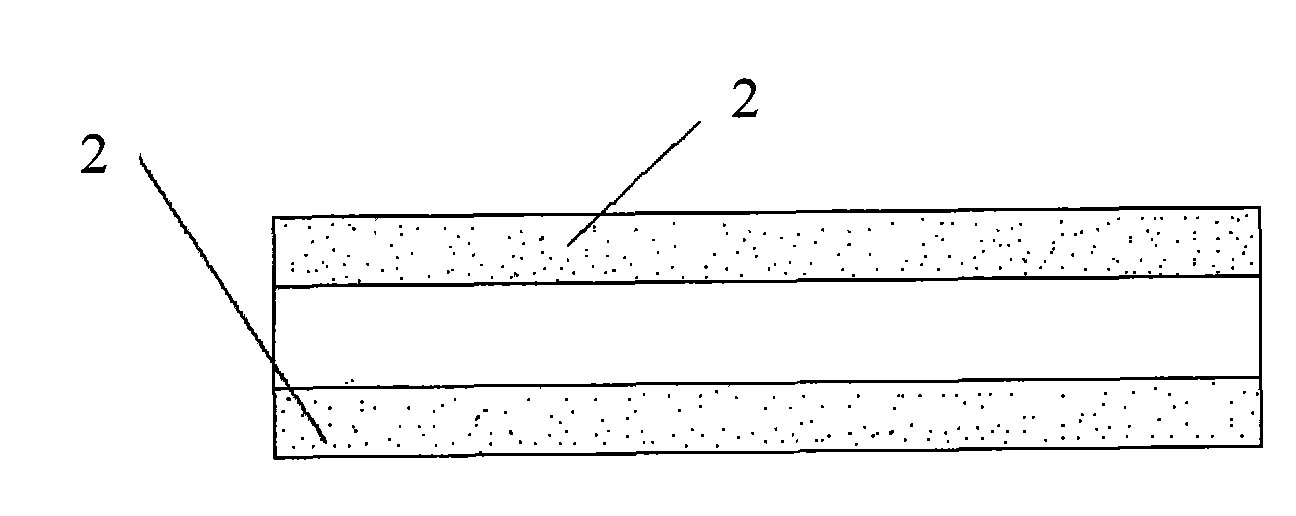

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com