Technology for carrying out toughening treatment on stable Beta titanium alloy

A titanium alloy, strengthening and toughening technology, applied in the field of heat treatment of titanium alloys, can solve problems such as plastic loss, and achieve the effect of improving strength, simple process flow, and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

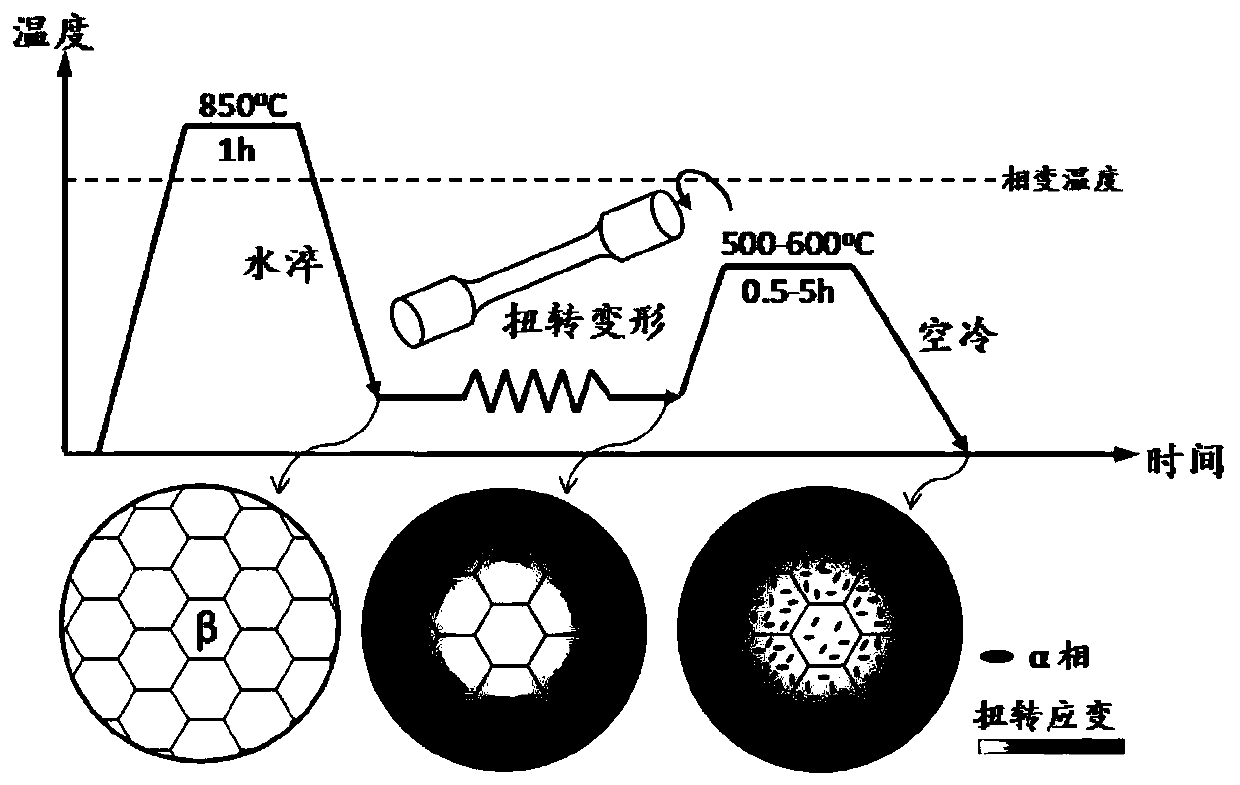

[0019] A process for strengthening and toughening stable Beta titanium alloys. It adopts gradient structure design, and prepares gradient structure stable Beta titanium alloys by pre-torsional deformation and aging treatment of stable Beta, so that the strength of the alloy can be increased from the surface to the surface. The heart has a gradient distribution.

[0020] A kind of technology that stable Beta titanium alloy is carried out toughening treatment, its concrete steps are as follows:

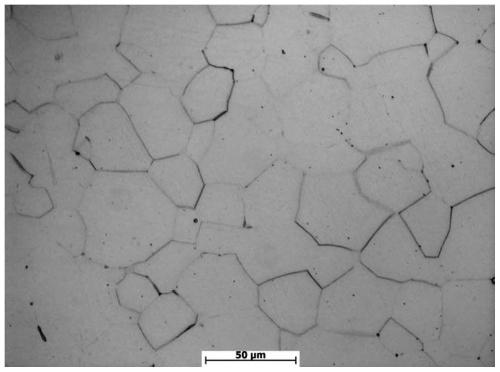

[0021] 1) Perform solution treatment and quenching treatment on the stable Beta titanium alloy to obtain a single-phase β structure, the solution temperature is 10-20°C above the α→β phase transition temperature, and the holding time is selected according to the thickness of the sample at 1min / mm , the quenching method is water quenching;

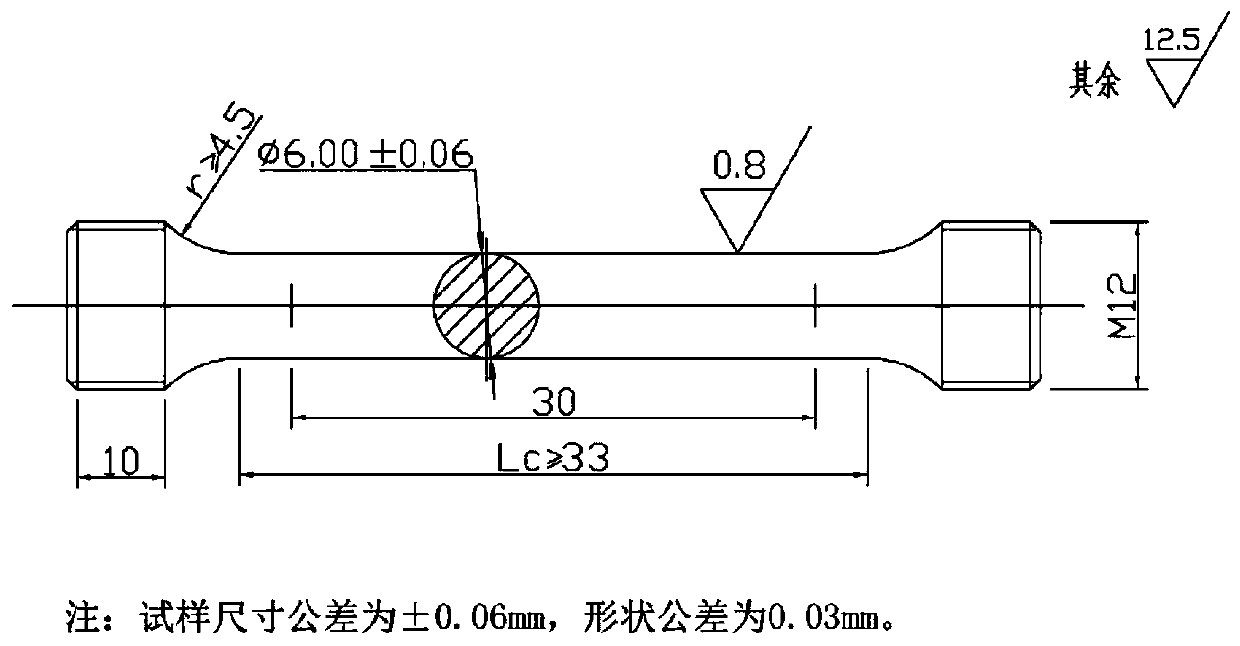

[0022] 2) Use a torsion testing machine to perform torsional deformation on the solid solution quenched state stable Beta titanium alloy, the torsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com