A kind of preparation method of monodisperse platinum series high entropy alloy nano particle catalyst

A high-entropy alloy and nano-particle technology, applied in the field of material chemistry, can solve the problems that the element distribution does not reach the chemical distribution of the elements, the particle size of the high-entropy alloy is uneven, and the synthesis temperature is high, and achieves low cost, simple preparation method, and element distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

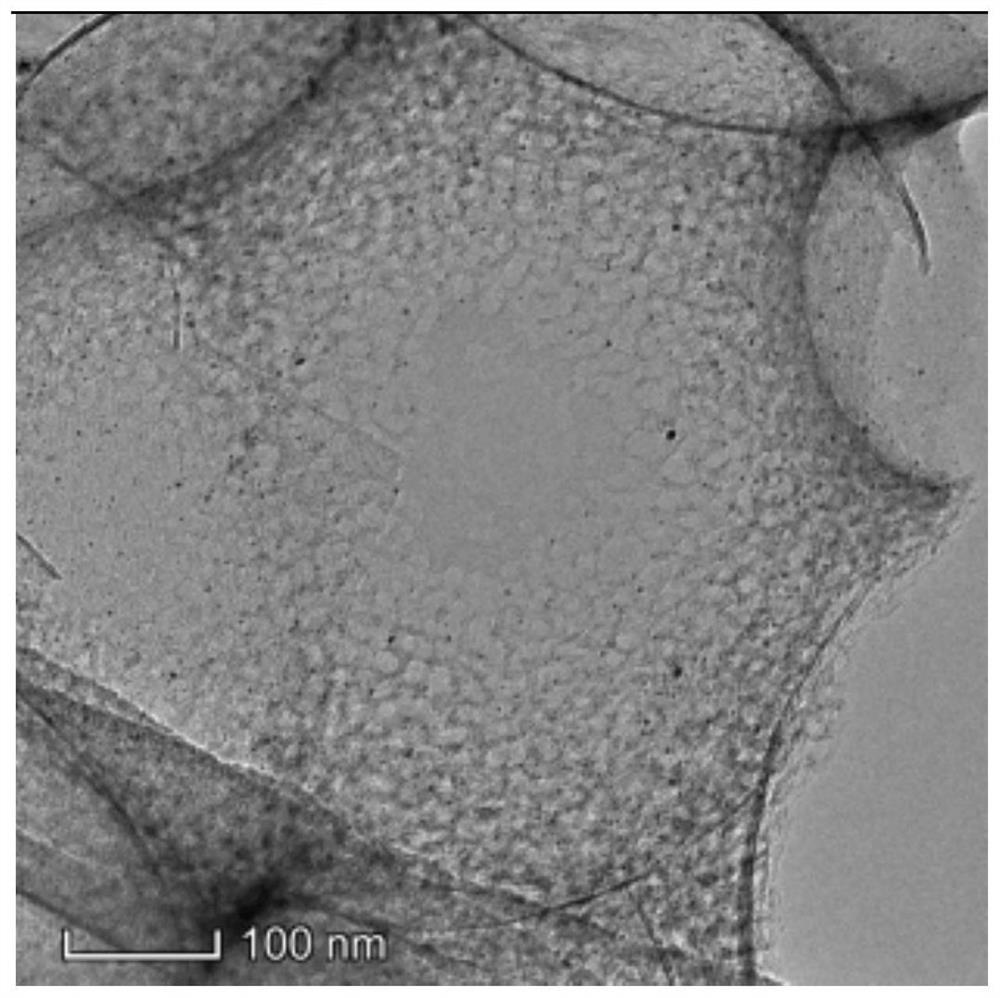

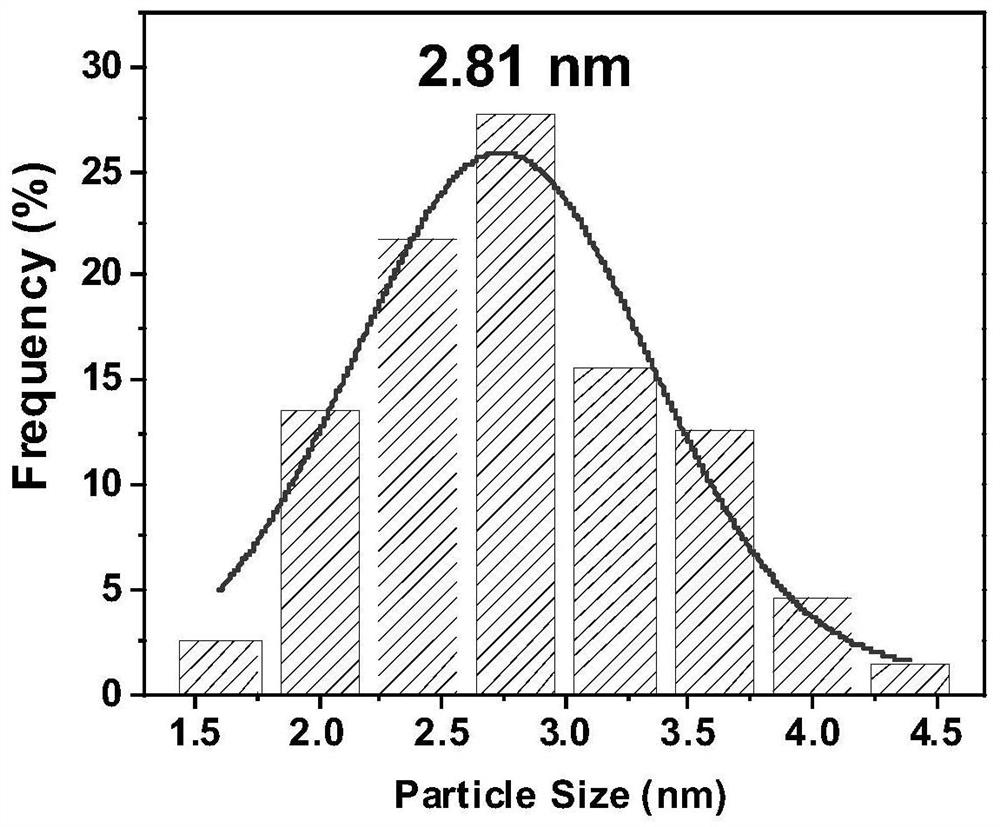

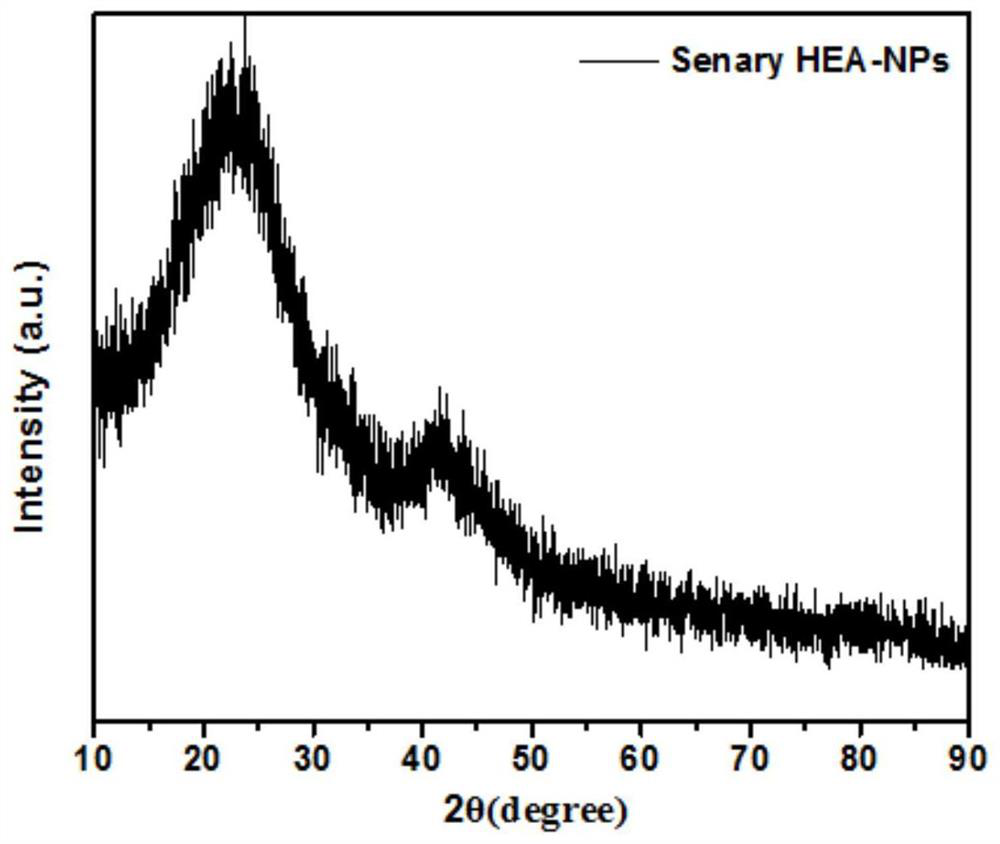

Image

Examples

preparation example Construction

[0047] Wherein the preparation method of hard template silicon dioxide photonic crystal is as follows:

[0048] Mix deionized water and ethanol at a volume ratio of 1:6 in a round-bottomed flask, and add ammonia solution with a volume ratio of 1:0.5 to water, and continuously stir the resulting solution at 30°C for 30 min. Subsequently, tetraethyl orthosilicate with a volume ratio of 1:1 to water was added to the above mixed solution and continued to stir for 12 hours to obtain a milky white solution.

[0049] Take tetraethyl orthosilicate and ethanol with a volume ratio of 1:1, mix and transfer it to a constant pressure dropping funnel, and control the mixed solution to slowly drip into the above milky white solution at a rate of one drop every 3 seconds, and then further continuously Stir for 12 hours, and finally centrifuge wash the obtained product with a mixed solution of water and ethanol at a speed of 7000r for 7 minutes. After washing three times, disperse in the ethan...

Embodiment 1

[0054] A method for preparing a monodisperse platinum-based high-entropy alloy nanoparticle catalyst, comprising the following steps:

[0055] Step 1: According to the mass ratio of platinum acetylacetonate, nickel acetylacetonate, bis(iron dicarbonylcyclopentadienyl), copper stearate, zinc zirdene, and ethyl cobalt bis-salicylamido is 5:4:4:4:3 :3 Weigh and dissolve in tetrahydrofuran (THF) and CHCl 3 in the mixed solution.

[0056] Step 2: Weigh the block copolymer F127 with a mass ratio of 1:1:1, the carbon precursor solution and tetraethyl orthosilicate, prepare a hydrochloric acid solution with a substance amount of 0.7 mmol, and then add the obtained in step 1 in sequence The mixed solution was stirred for 30 min to obtain a transparent solution.

[0057] Step 3: Pour the transparent solution obtained in step 2 into a silica photonic crystal template, then place it in a vacuum oven at 30°C for 24 hours, then raise the temperature to 110°C for 11 hours, and then raise t...

Embodiment 2~8

[0061] The preparation methods of Examples 2-8 are the same as those of Example 1, except that, as shown in Table 1, the platinum precursors, other metal precursors, protonic acid solutions and process parameters used are different.

[0062] Wherein in embodiment 2, the mass ratio of platinum acetylacetonate, ruthenium acetylacetonate, iridium acetylacetonate, nickel acetylacetonate, two (iron dicarbonyl cyclopentadienyl), copper stearate, zinc zirdene, bis-salicylamidoethyl cobalt 5:2:3:3:4:4:4:3.

[0063] Platinum acetylacetonate, ruthenium acetylacetonate, iridium acetylacetonate, rhodium acetylacetonate, tin chloride acetylacetonate, nickel acetylacetonate, bis(iron dicarbonyl cyclopentadienyl), copper stearate, zinc zirdene, bis The mass ratio of ethyl cobalt salicylamide is 4:4:3:3:2:3:6:3:6:4.

[0064] Table 1

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com