Ultrahigh-yield-ratio steel and production process thereof

A production process and yield-strength ratio technology, applied in the field of ultra-high yield-strength ratio steel and its production process, can solve the problems of complex production process, high cost, and insufficient strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

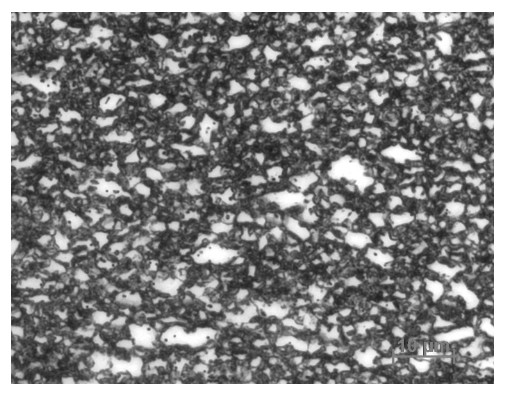

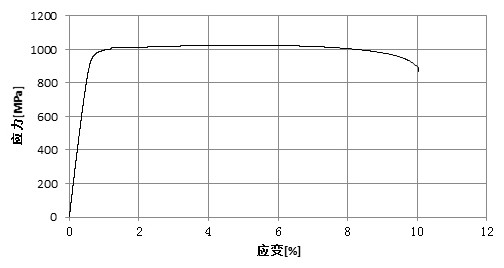

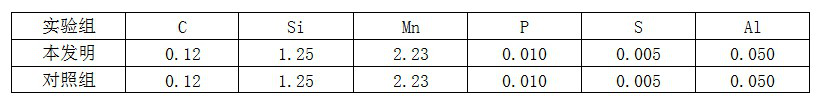

[0024] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 4 , the ultra-high yield strength ratio steel described in this embodiment has sufficient plasticity and good welding performance, and at the same time has a high resistance to plastic deformation, which can be used to maintain shape stability under high stress, and is not prone to Plastically deformed parts, or safety structures. Compared with DP, CP and other steels with the same composition and quenching process, the plasticity of the present invention is slightly lowered, but the yield strength is higher, and even the tensile strength is also increased. Therefore, the production method provided by the invention has low cost, and the produced product has stable and reliable performance.

[0025] In 1949, Cottrell and Bilby proposed the Coriolis air mass theory, which explai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com