Method for preparing microcrystalline glass fiber from blast furnace slag powder and microcrystalline glass fiber

A technology of blast furnace slag powder and glass fiber, which is applied in the field of glass fiber materials, can solve the problems of low quality, poor mechanical properties, and restrictions on the application of high-quality glass-ceramic fiber of blast furnace slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

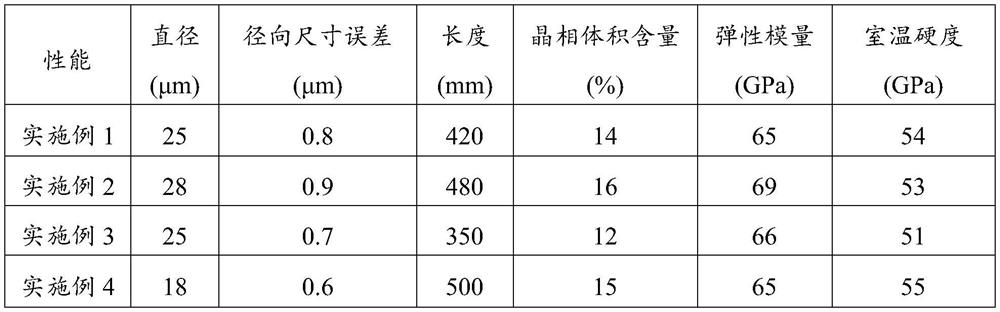

Embodiment 1

[0055] A method for preparing glass-ceramic fiber by utilizing blast furnace slag powder comprises the following steps:

[0056] (1) put the broken block-shaped construction waste glass with an average particle size of 23mm into the glass melting tank kiln device for melting to obtain glass liquid; wherein, the feeding rate of the waste glass is 86g / s, and the melting temperature is 765 ℃;

[0057] (2) throwing blast furnace slag powder into the molten glass obtained in the step (1), then sequentially melting, clarifying and homogenizing to obtain a glass-ceramic fiber precursor;

[0058] Among them, the mass ratio of waste glass and blast furnace slag powder is 86:128; the feeding rate of blast furnace slag powder is 128g / s, and the input position of blast furnace slag powder is 17cm away from the melting place of waste glass along the flow direction of molten glass; The position is 74cm away from the melting place of the waste glass along the flow direction of the molten gla...

Embodiment 2

[0062] A method for preparing glass-ceramic fiber by utilizing blast furnace slag powder comprises the following steps:

[0063] (1) The broken block-shaped construction waste glass with an average particle size of 21mm is put into the glass melting tank kiln device for melting, and the glass liquid is obtained; wherein, the feeding amount of the waste glass is 93g / s, and the melting temperature is 819 ℃;

[0064] (2) throwing blast furnace slag powder into the molten glass obtained in the step (1), then sequentially melting, clarifying and homogenizing to obtain a glass-ceramic fiber precursor;

[0065] Among them, the mass ratio of waste glass to blast furnace slag powder is 93:141; the feeding rate of blast furnace slag powder is 141g / s, and the input position of blast furnace slag powder is 24cm away from the melting place of waste glass along the flow direction of glass liquid; The position is 82cm away from the melting place of the waste glass along the flow direction of...

Embodiment 3

[0069] A method for preparing glass-ceramic fiber by utilizing blast furnace slag powder comprises the following steps:

[0070] (1) put the powdered construction waste glass with an average particle size of 56 μm into the glass melting tank kiln device for melting to obtain glass liquid; wherein, the feeding amount of the waste glass is 88 g / s, and the melting temperature is 789 ° C;

[0071] (2) throwing blast furnace slag powder into the molten glass obtained in the step (1), then sequentially melting, clarifying and homogenizing to obtain a glass-ceramic fiber precursor;

[0072] Among them, the mass ratio of waste glass and blast furnace slag powder is 88:131; the feeding rate of blast furnace slag powder is 131g / s, and the input position of blast furnace slag powder is 19cm away from the melting place of waste glass along the flow direction of molten glass; The position is 76cm away from the melting place of the waste glass along the flow direction of the molten glass, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com