Aluminum oxide based nano complex phase ceramic bull block and method for preparing same

A technology of multiphase ceramics and wire drawing dies, applied in the direction of wire drawing dies, etc., can solve the problems of producing ceramic wire drawing dies without using superplastic forming technology, etc., and achieves improved material utilization, high toughness and surface finish, and good comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

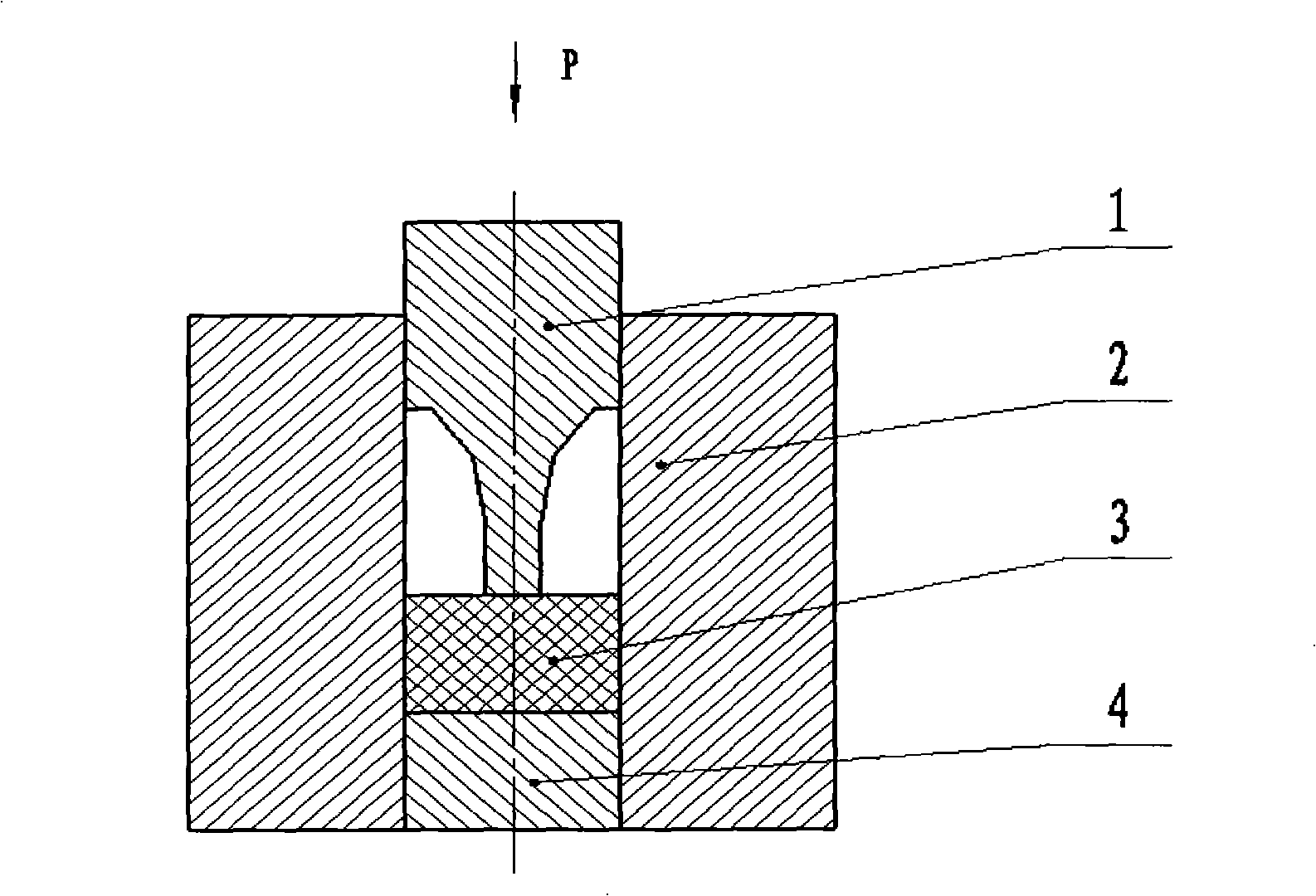

[0027] This embodiment provides an alumina-based nanocomposite ceramic wire drawing die and a preparation method thereof. Using commercially available Al 2 o 3 , ZrO 2 (3Y) and MgO nano-powder, the ratio of which meets the sintered composition of the sintered body obtained by Al 2 o 3 : ZrO 2 (3Y):MgAl 2 o 4 =60:20:20, the proportions are all molar ratios, and the three powders are mixed evenly in proportion to obtain the alumina-based composite powder. The obtained composite powder was sintered by vacuum hot pressing in a ZRY-55 vacuum hot pressing sintering furnace. During the sintering process, high-strength graphite was used as the mold material. The sintering temperature was 1500 ° C, the sintering pressure was 25 MPa, and the holding time of hot pressing sintering was 60 minutes. That is, a cylindrical nanocomposite ceramic sintered body is obtained as a ceramic blank (3) for preparing a wire drawing die.

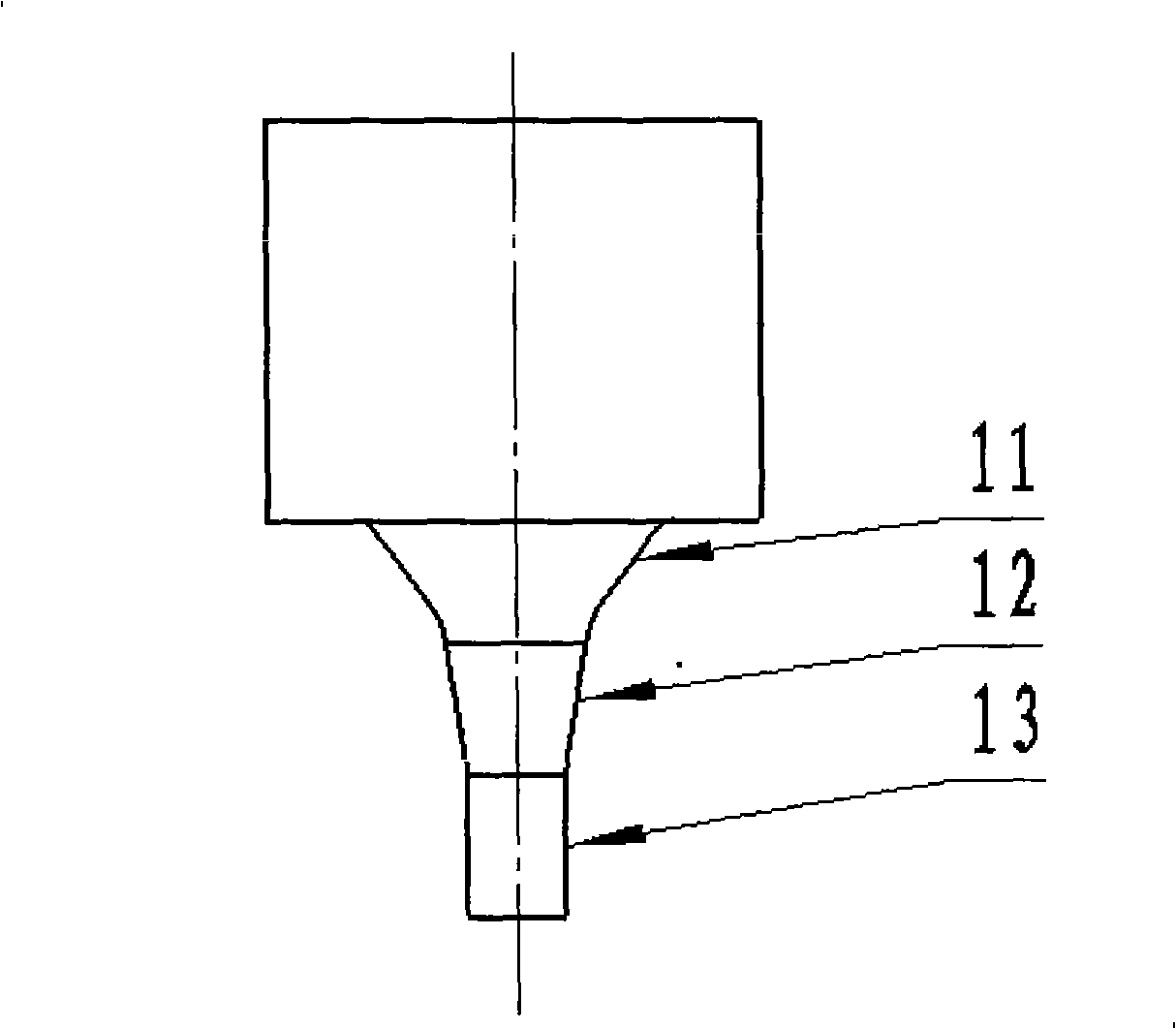

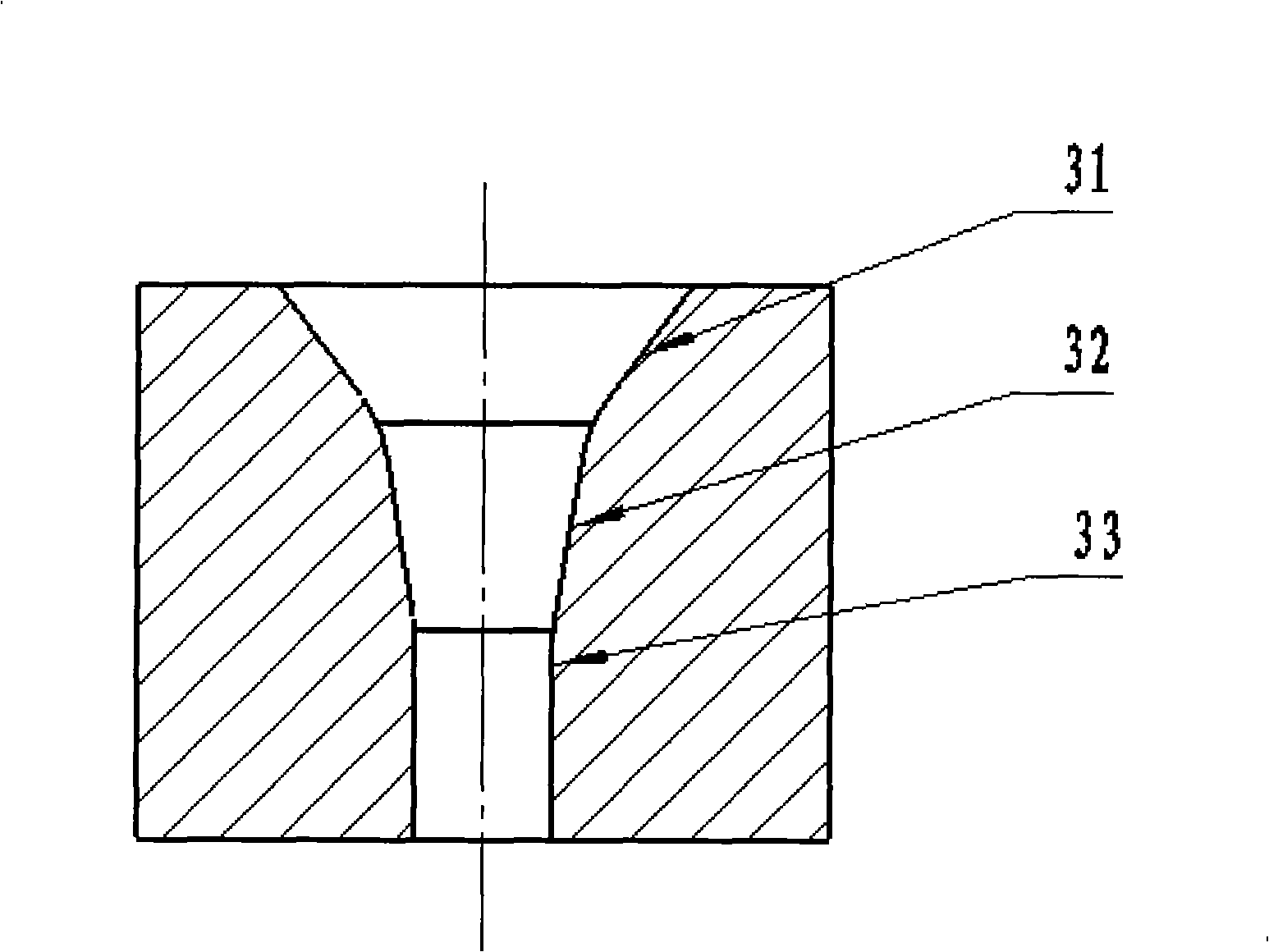

[0028] The superplastic extrusion forming process provid...

Embodiment 2

[0030] This embodiment provides an alumina-based nanocomposite ceramic wire drawing die and a preparation method thereof. Using commercially available Al 2 o 3 , ZrO 2 (3Y) and MgO nano-powder, the ratio of which satisfies the composition of the sintered body after sintering is Al 2 o 3 : ZrO 2 (3Y):MgAl 2 o 4 =80:10:10, and the proportioning ratios are all molar ratios. The three powders are uniformly mixed in proportion, and then dried and ground to obtain an alumina-based nanocomposite powder. The obtained composite powder was subjected to cold isostatic pressing treatment in a cold isostatic pressing machine, the pressure of the isostatic pressing treatment was 200MPa, and the holding time was 5min; then it was sintered without pressure in a box furnace at a sintering temperature of 1550°C. The holding time is 60min. That is, a cylindrical nanocomposite ceramic sintered body is obtained as a ceramic blank for preparing a wire drawing die.

[0031] as attached fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com