Production method and upsetting equipment of half-shell with high dimensional accuracy

A dimensional accuracy, half shell technology, applied in the field of high dimensional accuracy half shell production and upset forging equipment, can solve the problems of low dimensional accuracy, the half shell cannot be calibrated, and the local dimensional accuracy is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

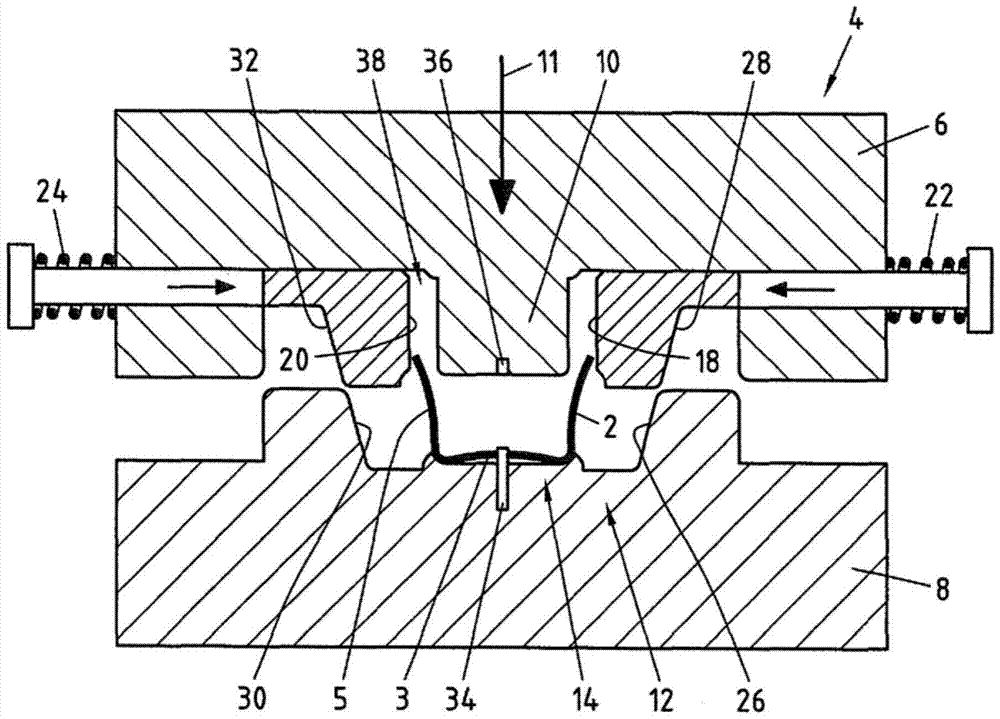

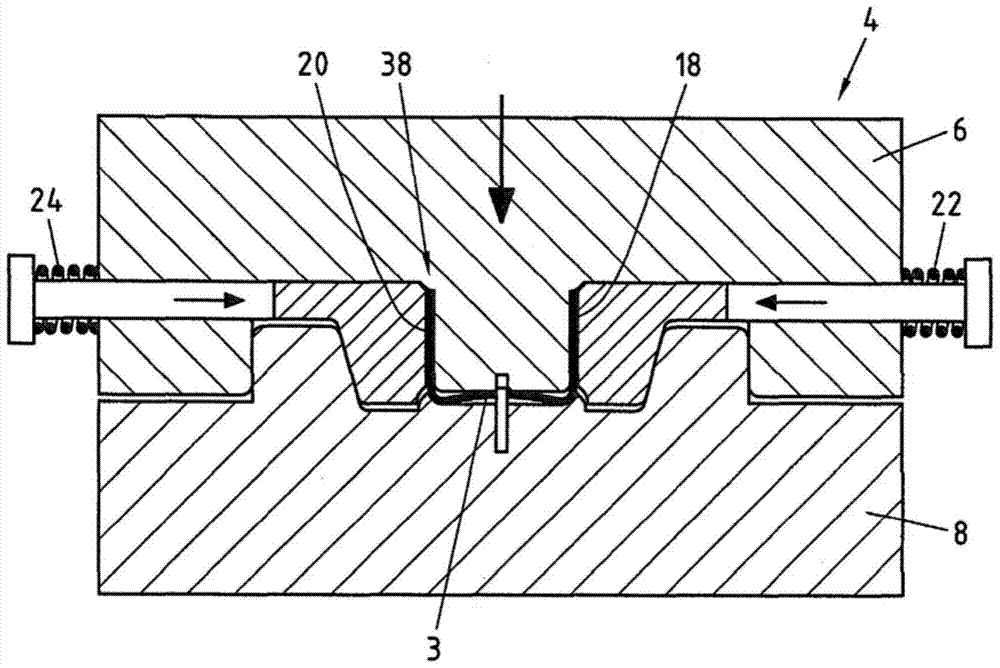

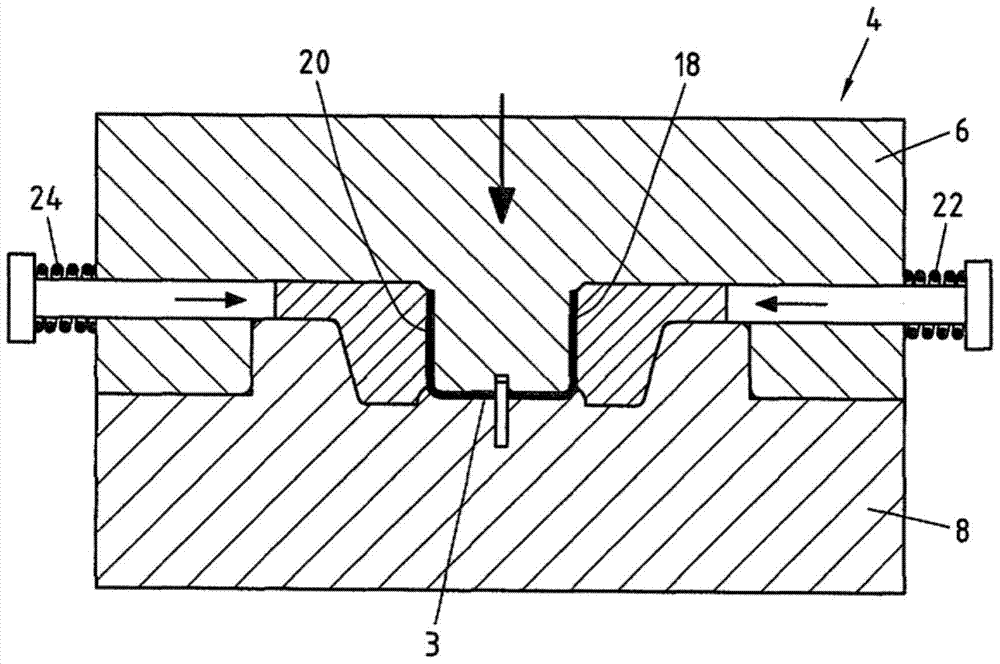

[0026] Figure 1a to Figure 1c A method for the production of deep-drawn half-shells 2 with high dimensional accuracy according to a first exemplary embodiment of the invention is shown, which is carried out by using a first exemplary embodiment of an upsetting installation 4 according to the invention . The prefabricated half-shell 2 with the base area 3 and the side frames 5 is arranged in an upsetting device 4 . Furthermore, the prefabricated half-shell 2 has a blank allowance due to its geometry, so that the prefabricated half-shell 2 passes through the Figure 1b and Figure 1c The forging process shown is up forged into the finished shape. In the illustrated exemplary embodiment of the half-shell 2 , the blank allowance is distributed approximately in the base area 3 of the prefabricated half-shell 2 . The base area 3 of the prefabricated half-shell 2 is therefore slightly curved. The upsetting device 4 has a first device half 6 and a second device half 8 , the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com