Alloy steel, seamless steel pipe and heat treatment technology of shaped steel pipe

A technology for special-shaped steel pipes and seamless steel pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., and can solve the problem of low flexural strength, twist resistance, tensile strength, yield strength and hardness of fire-fighting equipment. , can not adapt to the temperature difference change rescue environment and other problems, to achieve the effect of improving oxidation resistance and corrosion resistance, weak overheating sensitivity, and strong temperature difference resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention are described in detail below.

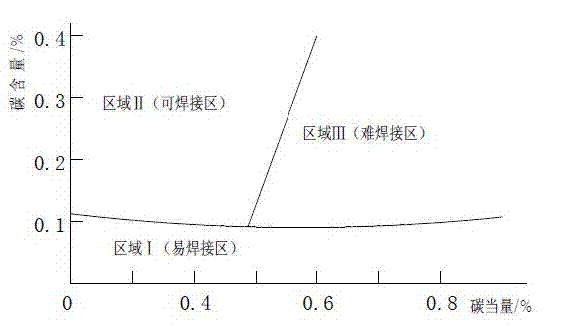

[0042] An alloy steel according to the present invention contains the following components in mass percent: 0.12-0.17 carbon, 0.25-0.40 silicon, 1.2-1.39 manganese, 0.02-0.04 niobium, 0.04-0.06 vanadium, 0.02-0.04 0.02~0.04 of titanium, 0.02~0.04 of aluminum, 0.0005~0.0035 of boron, ≤0.1 of chromium, ≤0.05 of nickel and ≤0.05 of copper, and the content of phosphorus and sulfur is ≤0.025, and the rest is iron.

[0043]In practical application, the strength and toughness of the alloy steel are improved by controlling the content of copper in the alloy steel between 0.02 and 0.05 (mass percentage), and the alloy steel has excellent corrosion resistance. By controlling the content of nickel in the alloy steel The content of nickel is between 0.02~0.05 (mass percentage) to increase the strength of alloy steel and make alloy steel have good plasticity and toughness. At the same time, because nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com