High-seedling-rate cotton seedling raising nutrition pot and seedling raising method thereof

The technology of seedling growth rate and nutrition bowl is applied in the field of cotton seedling raising nutrition bowl with high seedling growth rate and the field of raising seedlings, which can solve the problems of weakening nutrition bowl raising seedlings, transplanting, increasing yield, not adapting to cotton production in the new century, and extensive manual management, etc. Good protection and antibacterial effect, the effect of promoting division growth and function exertion, and improving the emergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

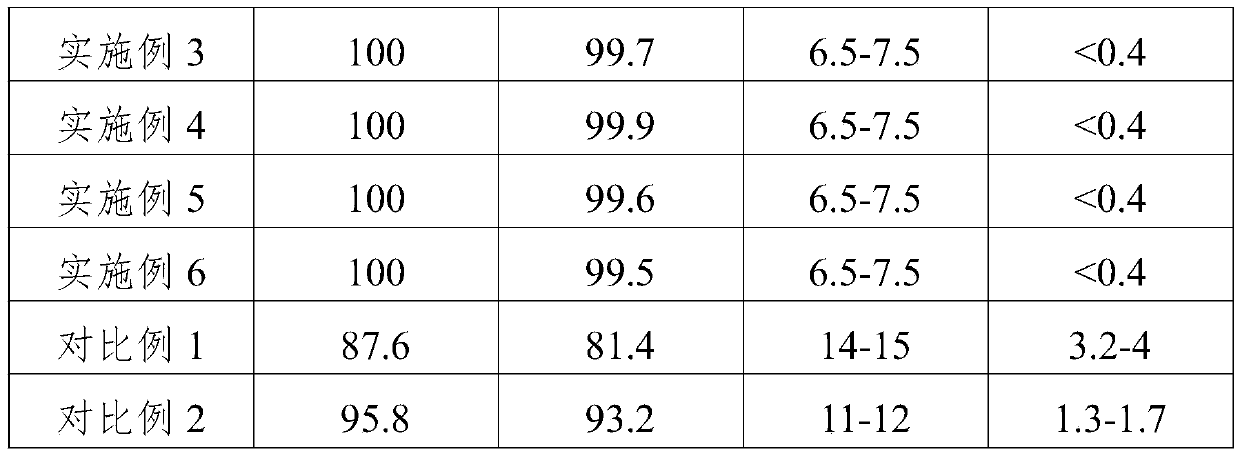

Embodiment 1

[0034] A nutritional pot for cotton seedling raising with a high seedling rate, comprising the following components in parts by weight: 15 parts of biomass base, 6 parts of modified attapulgite, 2 parts of fungus chaff, 10 parts of river mud, 0.15 parts of plant regulator, and compound drug Mixed solution 0.5 part.

[0035] in:

[0036] The biomass base includes humic acid, plant pulp, and shellac in a mass ratio of 0.8:0.3:0.2. The plant pulp raw materials include straw, Ulva, and tung oil, and the mass ratio of the three is 10:1:1.

[0037]The preparation method of modified attapulgite is as follows: first take attapulgite, wet grind it with 5% polyvinyl alcohol aqueous solution as a reagent for 5 hours, and then dry it at 80°C for 60 minutes under nitrogen atmosphere. After taking it out, add fulvic acid loaded with trace elements , then add distilled water with a total solid mass of 400% to it, mix and stir at 70°C and 400rpm for 5-10min, then ultrasonically treat at 45°C...

Embodiment 2

[0052] A nutritional pot for raising seedlings of cotton with a high seedling rate, comprising the following components in parts by weight: 16 parts of biomass base, 5 parts of modified attapulgite, 3 parts of fungus chaff, 12 parts of river mud, 0.25 parts of plant regulator, and compound medicine 0.8 parts of the mixed solution.

[0053] in:

[0054] The biomass base includes humic acid, plant pulp, and shellac in a mass ratio of 0.5:0.4:0.15. The plant pulp raw materials include straw, Ulva, and tung oil, and the mass ratio of the three is 10:1:2.

[0055] The preparation method of modified attapulgite is as follows: first take attapulgite, wet grind it with 5% polyvinyl alcohol aqueous solution as a reagent for 5 hours, and then dry it at 80°C for 60 minutes under nitrogen atmosphere. After taking it out, add fulvic acid loaded with trace elements , then add distilled water with a total solid mass of 300% to it, mix and stir at 70°C and 400rpm for 5-10min, then ultrasonic...

Embodiment 3

[0070] A nutritional pot for cotton seedlings with high seedling growth rate, comprising the following components in parts by weight: 15 parts of biomass base, 4 parts of modified attapulgite, 3 parts of fungus chaff, 10 parts of river mud, 0.15 parts of plant regulator, and compound medicine Mixed solution 1.2 parts.

[0071] in:

[0072] The biomass base includes humic acid, plant pulp, and shellac in a mass ratio of 1:0.4:0.15. The plant pulp raw materials include straw, Ulva, and tung oil, and the mass ratio of the three is 10:1:0.5.

[0073] The preparation method of modified attapulgite is as follows: first take attapulgite, wet grind it with 5% polyvinyl alcohol aqueous solution as reagent for 6 hours, then dry it at 80°C for 60 minutes under nitrogen atmosphere, after taking it out, add fulvic acid loaded with trace elements to it , then add distilled water with a total solid mass of 400% to it, mix and stir at 70°C and 400rpm for 5-10min, then ultrasonically treat at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com