Magnesium alloy polyhedral circulation rolling method

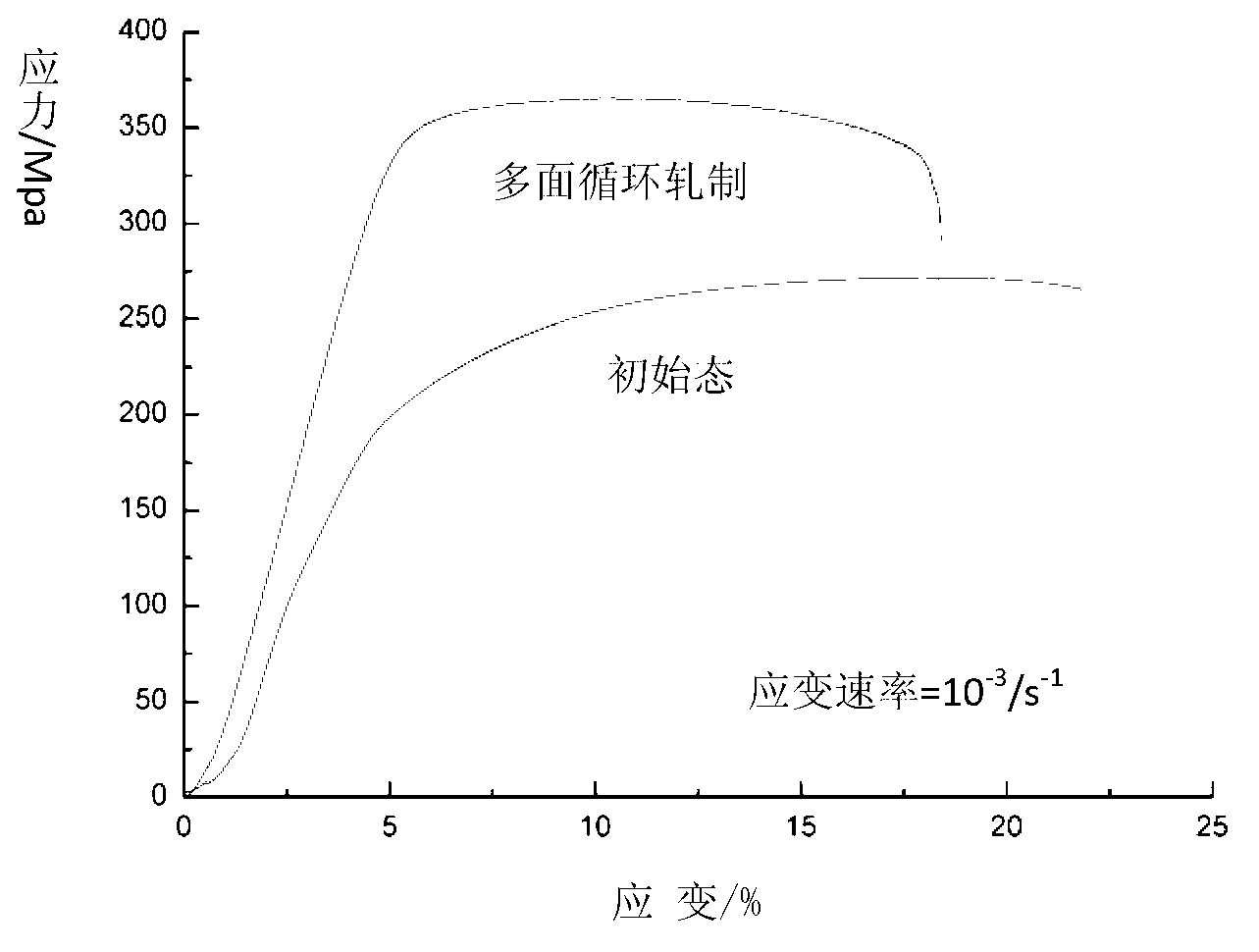

A magnesium alloy and alloy technology, applied in the field of ultra-fine-grain metal material preparation, can solve the problems of reducing the application value of materials, uneven grain distribution, poor material uniformity, etc., and achieves easy industrial production, simple preparation method, and improved yield strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

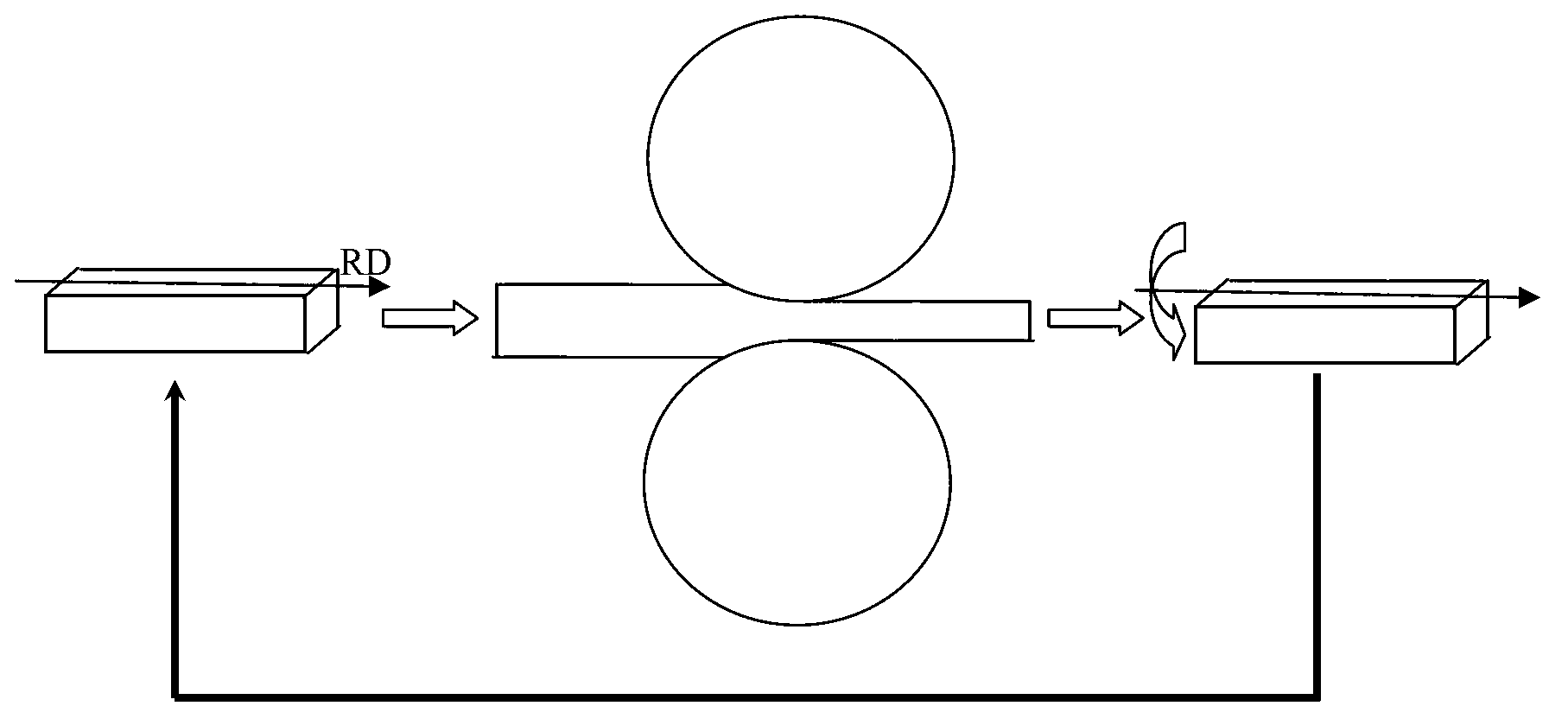

[0030] 1. Use wire cutting to cut AZ31 magnesium alloy plate with a square cross section. The plate size is 25mm long and the cross section size is 10mm×10mm, and the coordinates of the alloy are calibrated;

[0031] 2. The alloy is rolled for the first time by using a two-roll rolling mill, and the downforce is 1mm. The temperature of the roll is set at room temperature, and the temperature of the rolled bar is set at 300°C;

[0032] 3. The rolling direction of the previous pass is the axis, and after the sample is rotated 90° clockwise, the alloy is rolled for the second time, with the same amount of pressure, wherein the temperature of the roll is set at room temperature, and the temperature of the rolled bar is Set to 300°C;

[0033] The second step and the third step constitute a rolling cycle, and the number of completed rolling cycles is set to 15 passes, and the rolling process is completed.

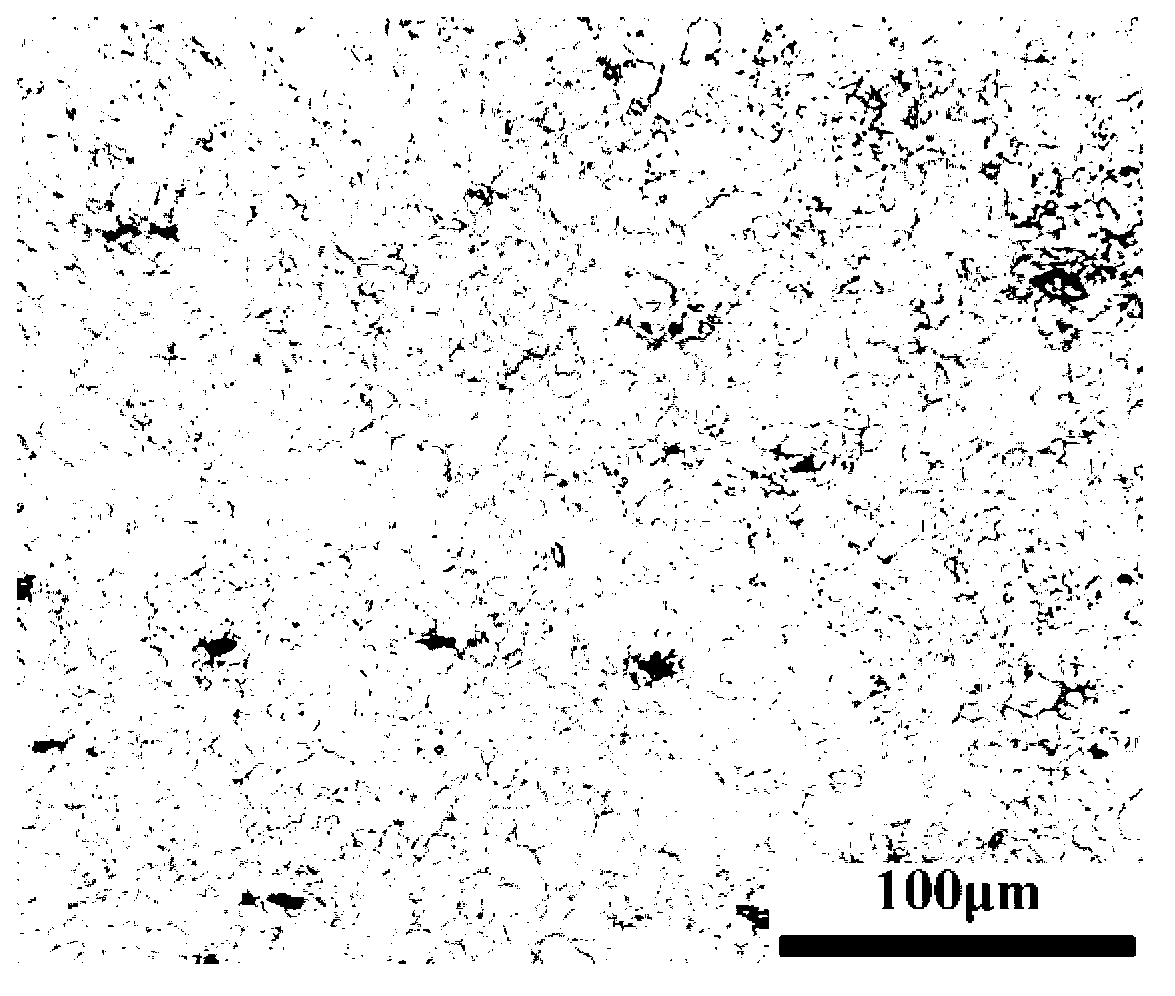

[0034] Optical microscopy observations show that there are a large number o...

Embodiment 2

[0036] 1. Use wire cutting to cut AZ31 magnesium alloy plate with a square cross section. The plate size is 30mm long and the cross section size is 12mm×12mm, and the coordinates of the alloy are calibrated;

[0037] 2. The alloy is rolled for the first time with a two-roll rolling mill, and the downforce is about 1.2mm. Among them, the temperature of the roll is set at room temperature, and the temperature of the rolled bar is set at 350°C;

[0038] 3. The rolling direction of the previous pass is the axis, and after the sample is rotated 90° clockwise, the alloy is rolled for the second time, with the same amount of pressure, wherein the temperature of the roll is set at room temperature, and the temperature of the rolled bar is Set to 350°C;

[0039] The second step and the third step constitute a rolling cycle, and the number of completed rolling cycles is set to 18 passes, and the rolling process is completed.

[0040] Optical microscope observations show that there are ...

Embodiment 3

[0042] 1. Use wire cutting to cut AZ31 magnesium alloy plate with a square cross section. The plate size is 35mm long and the cross section size is 15mm×15mm, and the coordinates of the alloy are calibrated;

[0043] 2. The alloy is rolled for the first time by using a two-roll rolling mill, and the downforce is 1.5mm. The temperature of the roll is set at room temperature, and the temperature of the rolled bar is set at 450°C;

[0044] 3. The rolling direction of the previous pass is the axis, and after the sample is rotated 90° clockwise, the alloy is rolled for the second time, with the same amount of pressure, wherein the temperature of the roll is set at room temperature, and the temperature of the rolled bar is Set to 450°C;

[0045] The second step and the third step constitute a rolling cycle, and the number of completed rolling cycles is set to 20 passes, and the rolling process is completed.

[0046]Optical microscope observations show that there are still a large n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com