Oversized thin plate rolling device and molybdenum thin plate rolling method

A technology of super-large specifications and rolling equipment, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as large safety risks and potential safety hazards, rising production costs, and increased heating furnace specifications, and achieve improvement Effects of mass, scale-up, and avoidance of constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

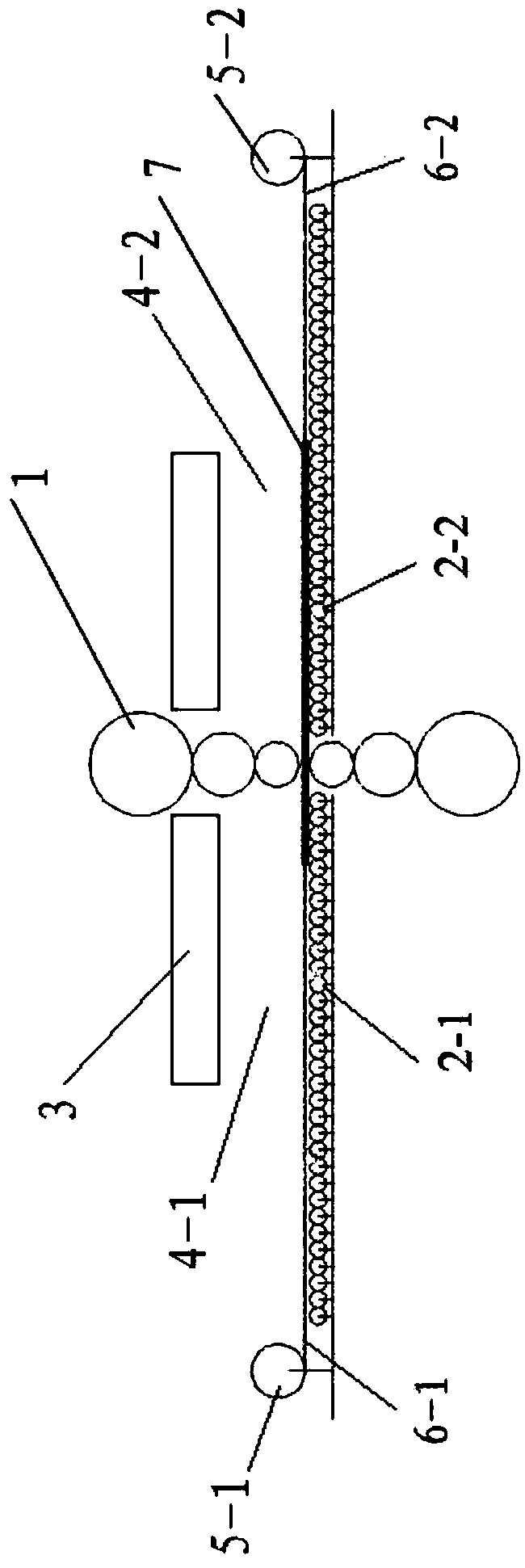

[0027] Such as figure 1 An ultra-large-size sheet rolling equipment is shown. The equipment includes a six-high reversible rolling mill 1. The entrance side and the exit side of the six-high reversible rolling mill 1 are respectively provided with first transport roller tables 2-1 for transporting plates 7 And the second transport roller table 2-2, the first transport roller table 2-1 near the entrance side of the six-high reversible rolling mill 1 is provided with a first heating zone 4-1, and the first transport roller table 2-1 close to the exit side of the six-high reversible rolling mill 1 A second heating zone 4-2 is provided on the second transportation roller 2-2, and a heating device 3 for heating the plate 7 is installed directly above the first heating zone 4-1 and the second heating zone 4-2, The first coiler 5-1 is installed at a position close to the first transport roller 2-1, the second coiler 5-2 is installed at a position close to the second transport roller 2...

Embodiment 2

[0031] Step 1. Place the molybdenum sheet on the first transportation roller 2-1, and then weld the two ends of the molybdenum sheet with the first lead 6-1 and the second lead 6-2 respectively; the molybdenum sheet The length is 3.8m, the thickness is 4.8mm, and the mass is 208kg;

[0032] Step 2: Turn on the heating device and adjust the heating temperature to 400°C, and then turn on the first coiler 5-1 and the second coiler 5-2 at the same time to make the second coiler wound on the second coiler 5-2 Belt 6-2 pulls the molybdenum sheet through the first transport roller 2-1 into the first heating zone 4-1 for heating. The heated molybdenum sheet enters the six-high reversible rolling mill 1 for rolling, and then enters the second heating zone 4- 2 Heating to complete one rolling; the rotation direction and rotation speed of the first coiler 5-1 and the second coiler 5-2 during the one-time rolling process and the rolling direction of the six-high reversible rolling mill 1, T...

Embodiment 3

[0036] Step 1. Place the molybdenum sheet on the first transportation roller 2-1, and then weld the two ends of the molybdenum sheet with the first lead 6-1 and the second lead 6-2 respectively; the molybdenum sheet The length is 3.6m, the thickness is 4.65mm, and the mass is 212kg;

[0037] Step 2. Turn on the heating device and adjust the heating temperature to 450°C, and then turn on the first coiler 5-1 and the second coiler 5-2 at the same time, so that the second coiler wound on the second coiler 5-2 Belt 6-2 pulls the molybdenum sheet through the first transport roller 2-1 into the first heating zone 4-1 for heating. The heated molybdenum sheet enters the six-high reversible rolling mill 1 for rolling, and then enters the second heating zone 4- 2 Heating to complete one rolling; the rotation direction and rotation speed of the first coiler 5-1 and the second coiler 5-2 during the one-time rolling process and the rolling direction of the six-high reversible rolling mill 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com