Method for producing a metal strip using a casting rolling assembly and control and/or regulating device for a compound casting rolling assembly

A combined device and control device technology, which is applied in the field of manufacturing rolled pieces, can solve the problems of inaccurate thickness adjustment, difficulty in control, and insufficient thickness range, so as to avoid cracks in metal strips and improve manufacturing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

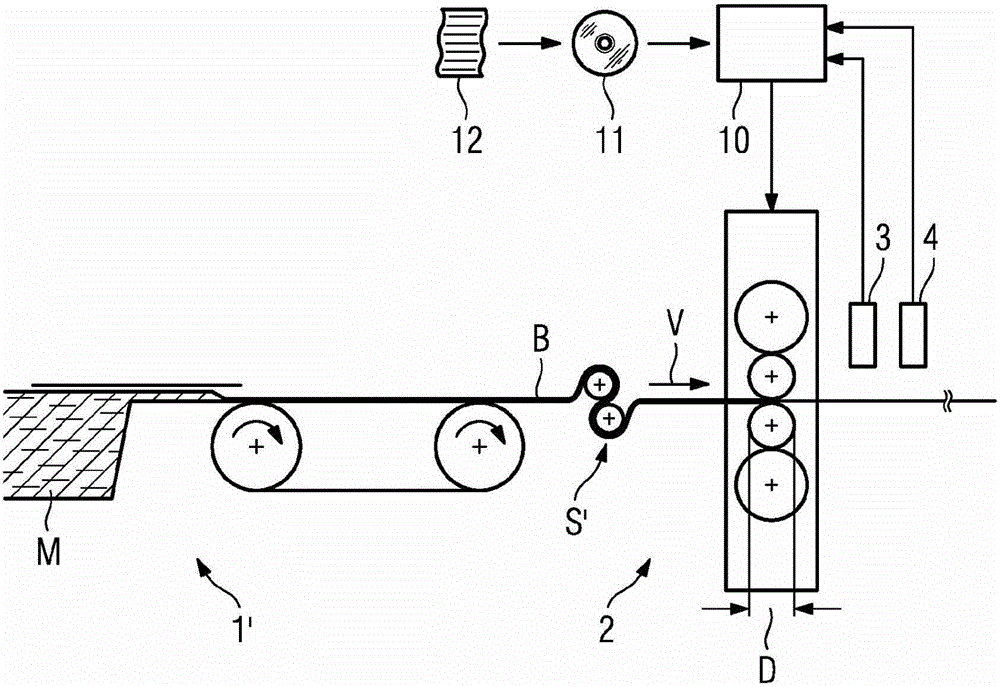

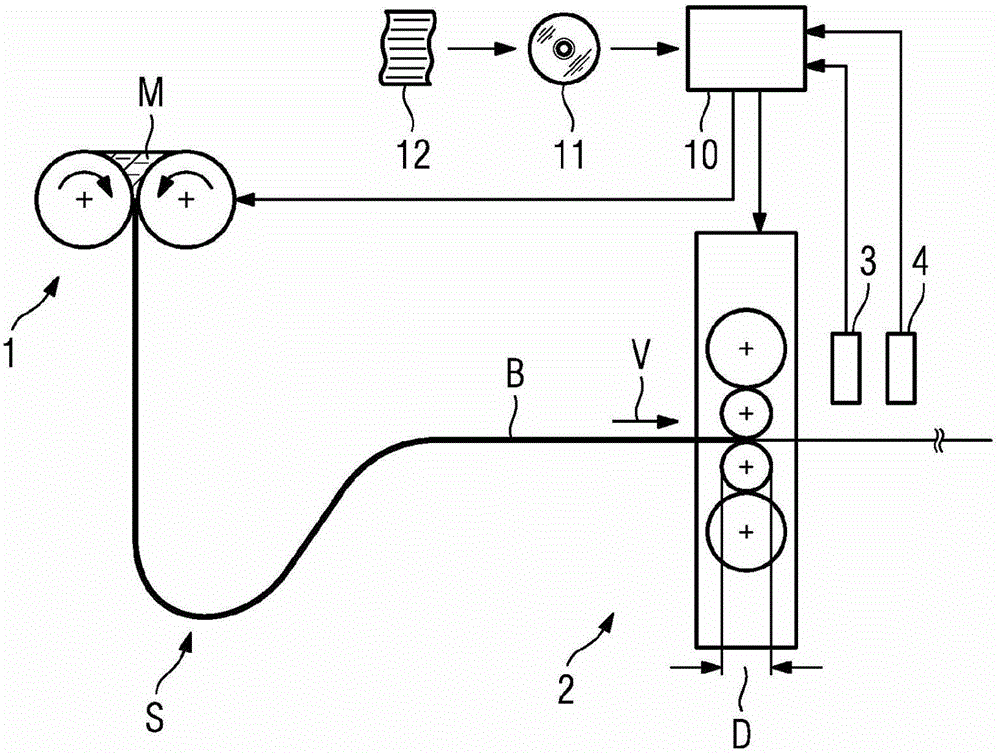

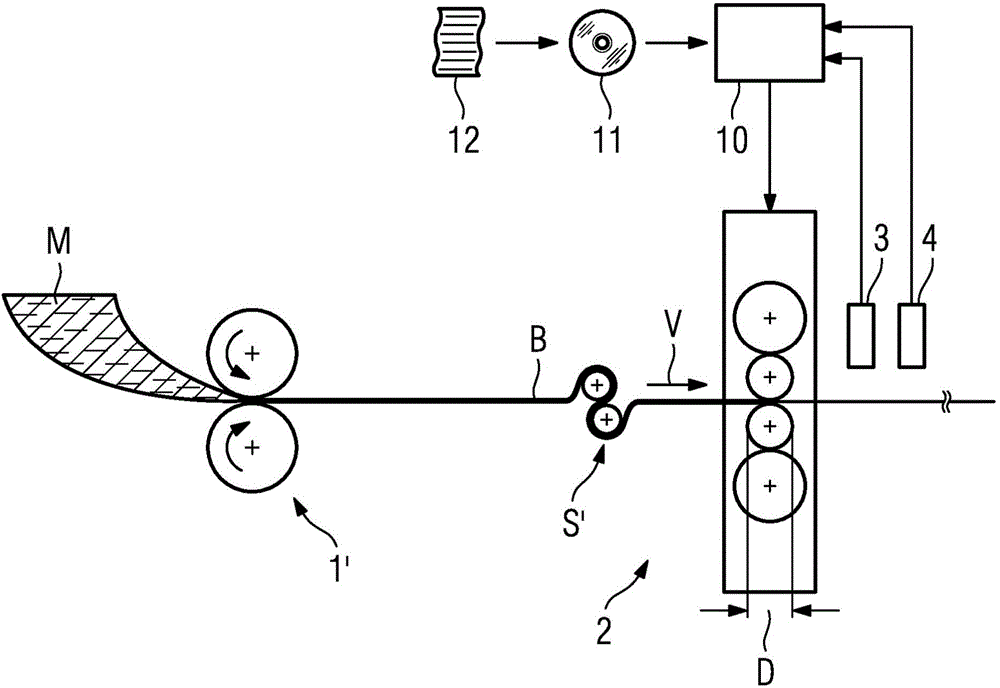

[0036] figure 1 Shown is a strand-direct-rolling combination comprising an endless belt casting installation 1' or a "strip casting" installation, with which liquid metal M can be cast onto an endless casting belt. Here the metal solidifies and forms a thin metal strip B as a rolling stock, which can be further processed in a strand-to-rolling complex.

[0037] In addition, the slab direct rolling unit includes a rolling mill 2 . The rolling mill 2 can have one rolling stand or also a plurality of rolling stands. The rolling mill 2 is used for hot forming the metal strip B. In particular, the metal strip B is rolled to its final thickness by means of such a rolling mill.

[0038] The metal strip B extends continuously from the endless belt casting device 1 ′ to the rolling mill 2 . As a rule, that is to say during smooth operation of the strand direct rolling complex, all the trains of the strand direct rolling complex are connected to one another via the metal strip B.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com