A kind of preparation method of non-quenched and tempered steel for automobile chassis

A non-quenched and tempered steel, automobile chassis technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high cost, unstable internal structure and grain size control, long production process, etc., to reduce The effect of composition segregation, avoiding grain growth and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

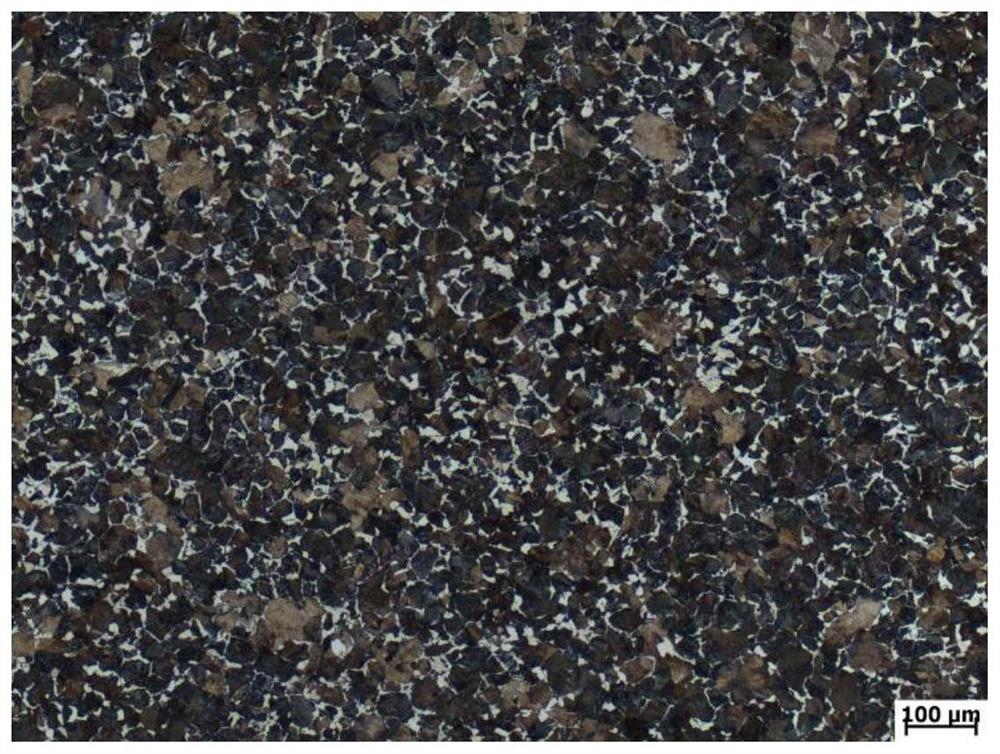

Embodiment 1

[0033] Embodiment 1 relates to the preparation or production method of non-quenched and tempered steel for automobile chassis parts, wherein in the non-quenched and tempered steel billet heating step, the billet is heated by a heating furnace, and the control range of the heating temperature is: the temperature of the preheating section is 660 ℃, heating time 40min; first-stage heating 900℃, heating time 60min; second-stage heating 1120℃, heating time 60min; third-stage heating 1000℃, heating time 80min.

[0034] Through the above-mentioned reasonable heating temperature and holding time of the preheating section and the three-stage method, the non-quenched and tempered steel material can be solid solution treated, the alloy elements are solid-dissolved into the matrix, the material components are uniformly dispersed, and the composition segregation is reduced, avoiding The original austenite grain grows and has sufficient plasticity during rolling, which lays the foundation fo...

Embodiment 2

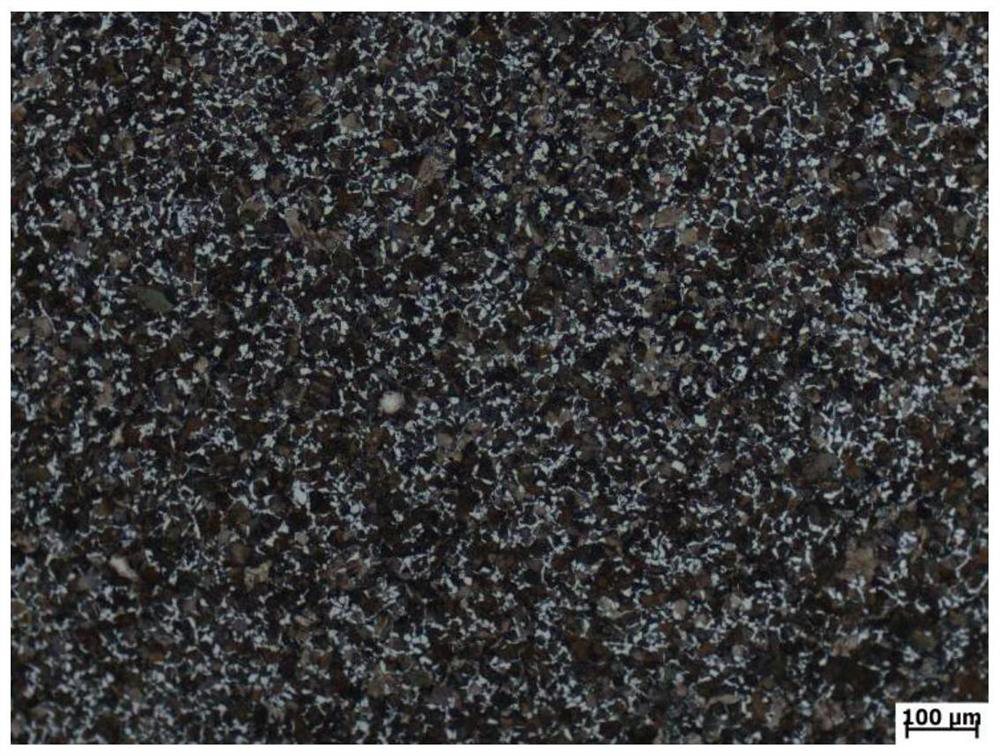

[0045] Like the preparation steps of Example 1, in the billet steel ingot heating step of Example 2, the steel ingot is heated by a heating furnace, and the control range of the heating temperature is: the temperature of the preheating section is 800°C, and the heating time is 60min; The time is 100min; the second stage is heated at 1200°C, and the heating time is 100min; the third stage is heated at 1080°C, and the heating time is 100min.

[0046] In the controlled rolling and controlled cooling step, the initial rolling temperature is 1010°C; the intermediate rolling temperature is 880°C; #The temperature of the water-cooled box is 850°C, and the temperature of the bar after passing through all the last group of cooling water tanks is controlled at 720°C; the temperature of the upper cooling bed is 680°C.

[0047] Among them, when entering the 1# water cooling box, the control pump frequency is 45Hz; the water nozzle pressure is 3.0MPa; the valve opening is 25%; the water fl...

Embodiment 3

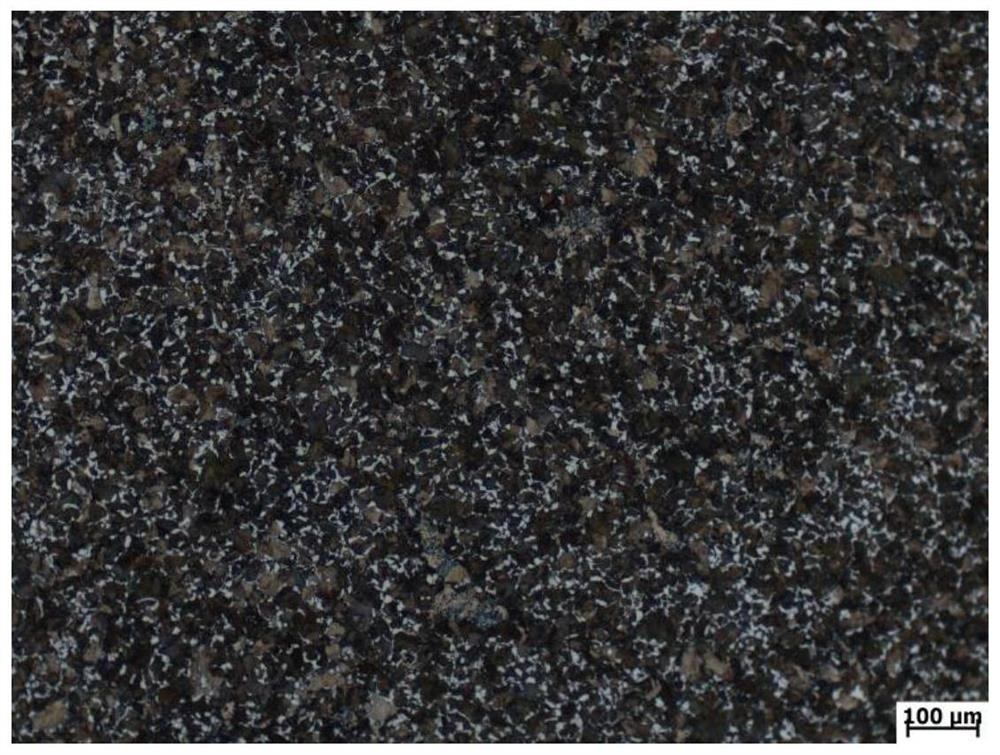

[0051] As in the preparation steps of Example 1, the control range of the heating temperature of the billet ingot in Example 3 is: the temperature of the preheating section is 860°C, and the heating time is 70min; the heating period of the first stage is 1080°C, and the heating time is 130min; 130min; three-stage soaking at 1150°C, heating time 135min.

[0052] The initial rolling temperature is 1035°C; the intermediate rolling temperature is 890°C; the temperature of the 1# water cooling box is 920°C; the finishing rolling temperature is 925°C; the temperature of the 2# water cooling box is 935°C, and the bar passes through all the last group of cooling water tanks The final redness temperature is controlled at 750°C; after sizing by the sizing machine, the temperature of the upper cooling bed is 701°C.

[0053] Among them, the control pump frequency is 45Hz when passing through the water for cooling into the 1# water cooling box; the water spray pressure of the water nozzle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com