Vacuum smelting method and apparatus for copper-indium-gallium-selenium photovoltaic material

A technology of copper indium gallium selenide and photovoltaic materials, applied in the field of production of solar cell materials, can solve the problems of easy safety accidents, highly toxic steam, low production efficiency, etc., achieve low cost and solve the effect of energy crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

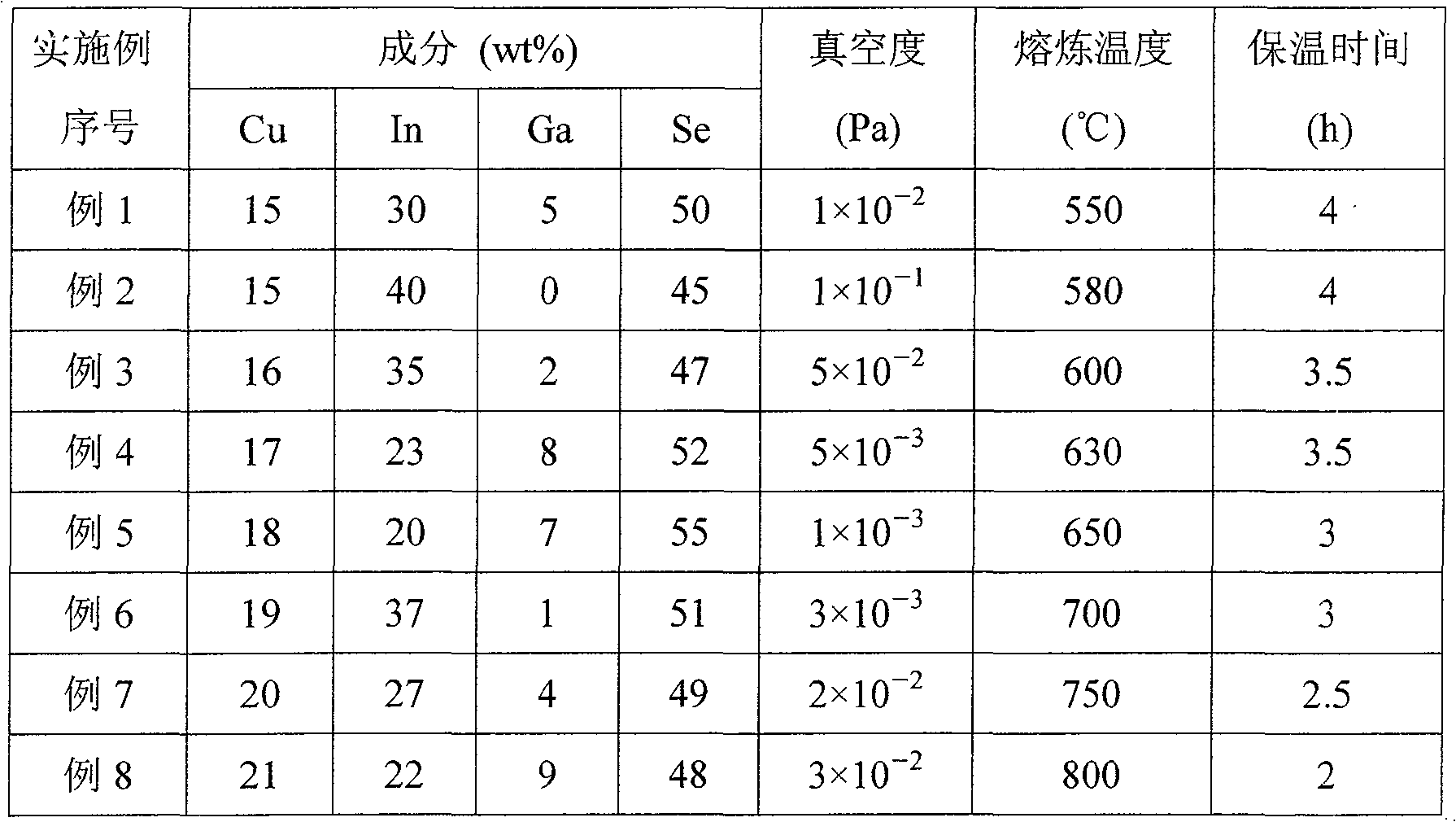

Examples

Embodiment 1

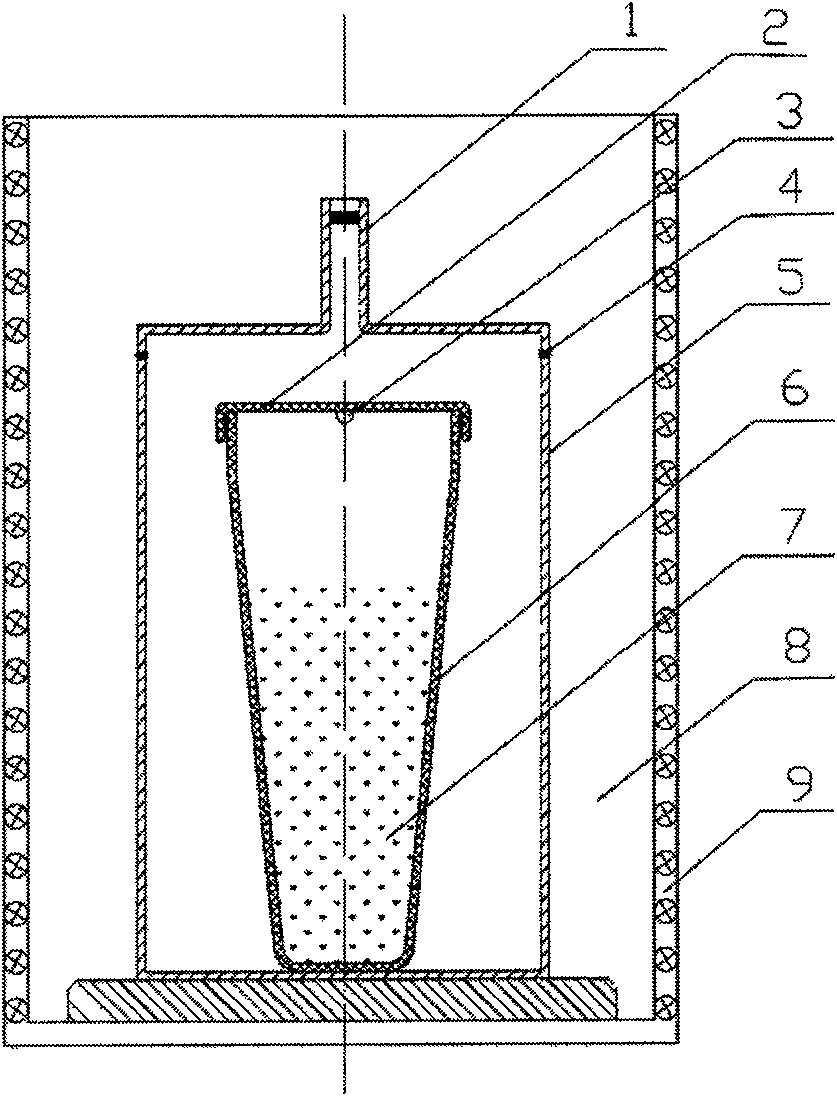

[0057] figure 1 In the schematic diagram of the structure containing the vacuum container melting device shown, the heating equipment is composed of a crucible 6, a vacuum container 5 and a well-type electric resistance furnace 9. The crucible 6 is placed on the base of the vacuum container 5, and the vacuum container 5 is placed on the well-type electric furnace 9. On the base, the crucible has a cover 2, the crucible and the crucible cover are sealed and connected, the crucible cover has a vent hole 3, the top of the vacuum vessel is a cover welded along the weld 4, and the cover has an exhaust pipe 1, which is welded to the vacuum after vacuuming. Sealed, the crucible and crucible cover are made of quartz material with a purity of ≥99.99%, the vacuum container is made of 2-5mm thick steel plate, and there are evenly arranged heating wires on the well-type resistance furnace wall, and 7 is the charge placed in the crucible.

Embodiment 2

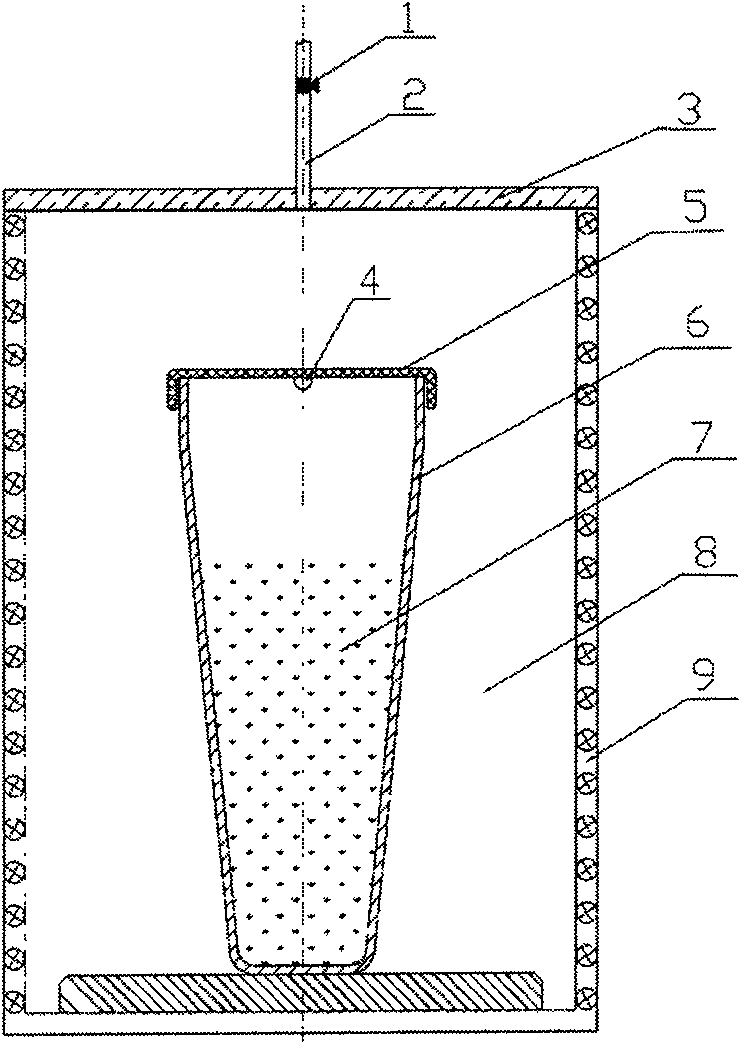

[0059] figure 2 The schematic diagram of the smelting device without a vacuum vessel is shown. The heating equipment consists of a crucible and a vertical vacuum resistance furnace. The crucible 6 is placed in a well-type vacuum resistance furnace 9. There are vent holes 4 on the top of the crucible and a cover 5 on the crucible. The well-type vacuum resistance furnace has a vacuum valve 1 and a crucible 6. It is sealed and connected with the crucible cover 5, and is made of high-purity graphite material with a purity ≥ 99.99%. There are evenly arranged heating wires on the well-type vacuum electric furnace body, and 7 is the charge placed in the crucible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com