A kind of citrate starch and preparation method thereof

A technology of citric acid ester and citric acid, applied in the field of starch modification, can solve the problems of difficult continuous preparation, high cost of energy consumption, complicated preparation process and the like, and achieve the effects of continuous preparation, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

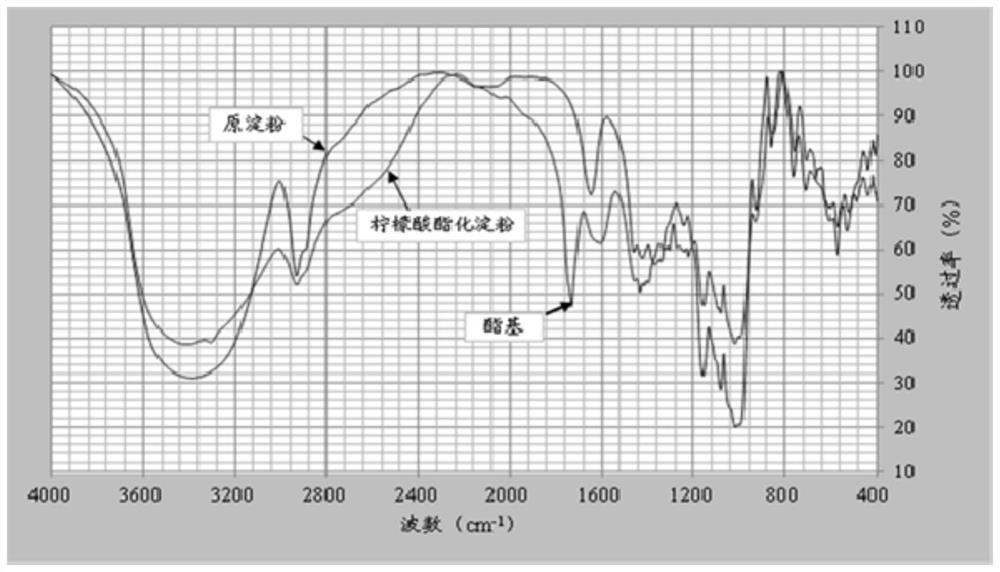

[0029] Mix the dried starch dry base with citric acid at a mass ratio of 4:1, add deionized water and NaOH, and blend evenly. Wherein, the sum of the added amount of deionized water and the water content of the starch is 20% by weight of the dry basis of the starch, and sodium hydroxide accounts for 3% by weight of the dry basis of the starch. The raw materials were mixed evenly, and the bag was sealed, kept for 6 hours, and then the bag was opened to obtain a premix. Add the premix from the feeding hopper of the subcritical extrusion equipment. The temperature of the equipment is set at 120°C, the screw speed is 20r / min, and the modified starch is prepared by continuous extrusion. After passing through a 100-mesh sieve, powder modified starch was obtained, and unreacted citric acid was eluted with ethanol to obtain citrate starch, and the degree of substitution was determined to be 0.23. The sample was scanned and analyzed by an infrared spectrometer, and the results are sho...

Embodiment 2

[0031] Mix the dried starch dry base with citric acid at a mass ratio of 8:1, add deionized water and sodium carbonate, and blend evenly. Wherein, the sum of deionized water addition and starch water content is 15wt% of starch dry basis, and sodium carbonate accounts for 9wt% of starch dry basis. After mixing all raw materials, seal the bag, keep it for 4 hours, and then open the bag to obtain the premixed things. Add the premix from the feeding hopper of the subcritical extrusion equipment. The temperature of the subcritical extrusion equipment is set at 110°C, the screw speed is 15r / min, and the modified starch is prepared by continuous extrusion. After the long strips are cut, they are dried at 80°C After crushing for 3 hours, pass through a 100-mesh sieve to obtain powder modified starch, elute unreacted citric acid with ethanol to obtain citrate starch, and measure its degree of substitution to be 0.07. The sample was scanned and analyzed by an infrared spectrometer, and...

Embodiment 3

[0033] Mix the dried starch dry base with citric acid at a mass ratio of 6:1, add deionized water and KOH, and blend evenly. Wherein, the sum of the amount of deionized water and the water content of the starch is 30wt% of the dry weight of the starch, and KOH accounts for 0.5wt% of the dry weight of the starch. After mixing the raw materials, the bag is sealed, kept for 4 hours, and the bag is opened to obtain the pre-packaged product. mixture. Add the premix from the feeding hopper of the subcritical extrusion equipment. The temperature of the subcritical extrusion equipment is set at 130°C and the screw speed is 25r / min. Continuous extrusion is used to prepare modified starch. After cutting the obtained long strips, dry at 50°C. After 12 hours of crushing, powder modified starch was obtained by passing through an 80-mesh sieve, and unreacted citric acid was eluted with ethanol to obtain citrate starch, and the degree of substitution was determined to be 0.21. The sample wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com