Preparation method of rare earth compound nano-particle

A rare earth complex and nanoparticle technology is applied in the preparation of rare earth complex nanoparticles and in the field of nanomaterials to achieve the effects of uniform particles, mild preparation conditions and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

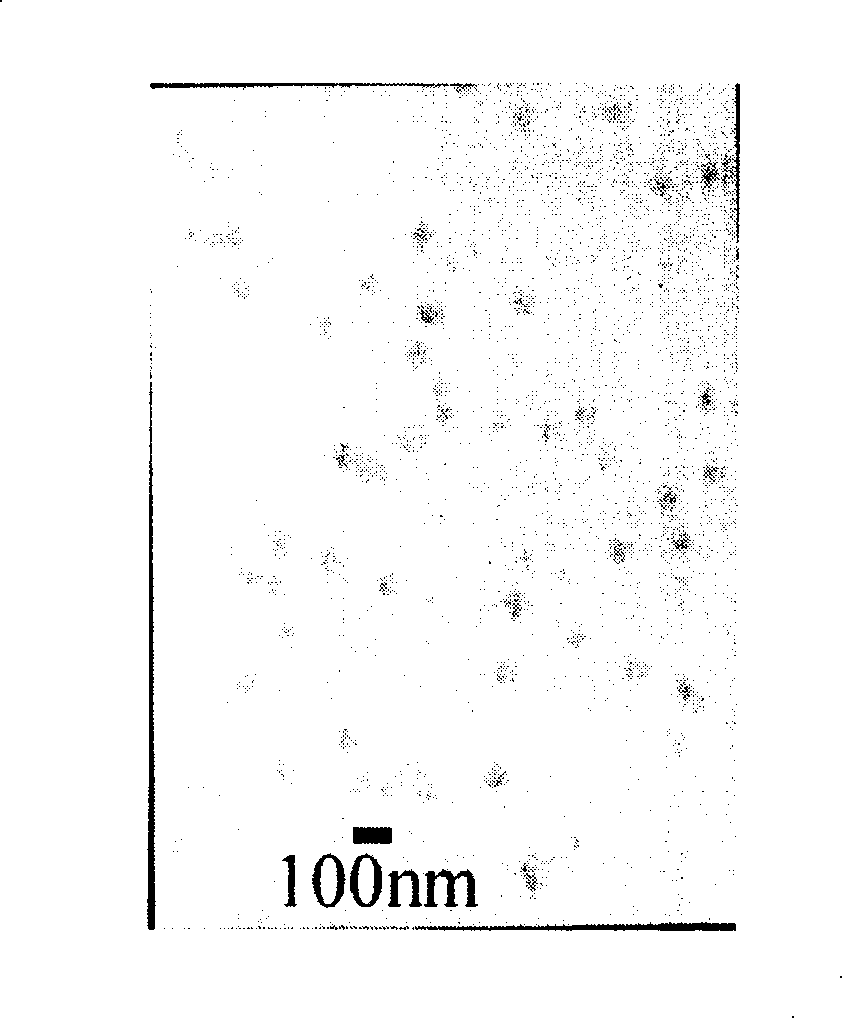

[0019] Weigh 0.03 grams of Eu(TTA)3Phen complex solid powder and dissolve it in 2.5 milliliters of acetone, add the above solution to 50 milliliters of n-propanol, stir and mix evenly at 2°C, and gradually precipitate the rare earth complex nanoparticles, The mixed solution turns into a gray complex nano sol, and the sol is vacuum-dried at 30°C to obtain Eu(TTA)3Phen complex nanoparticles with a particle diameter of about 70 nm. (TEM photo see figure 1 )

Embodiment 2

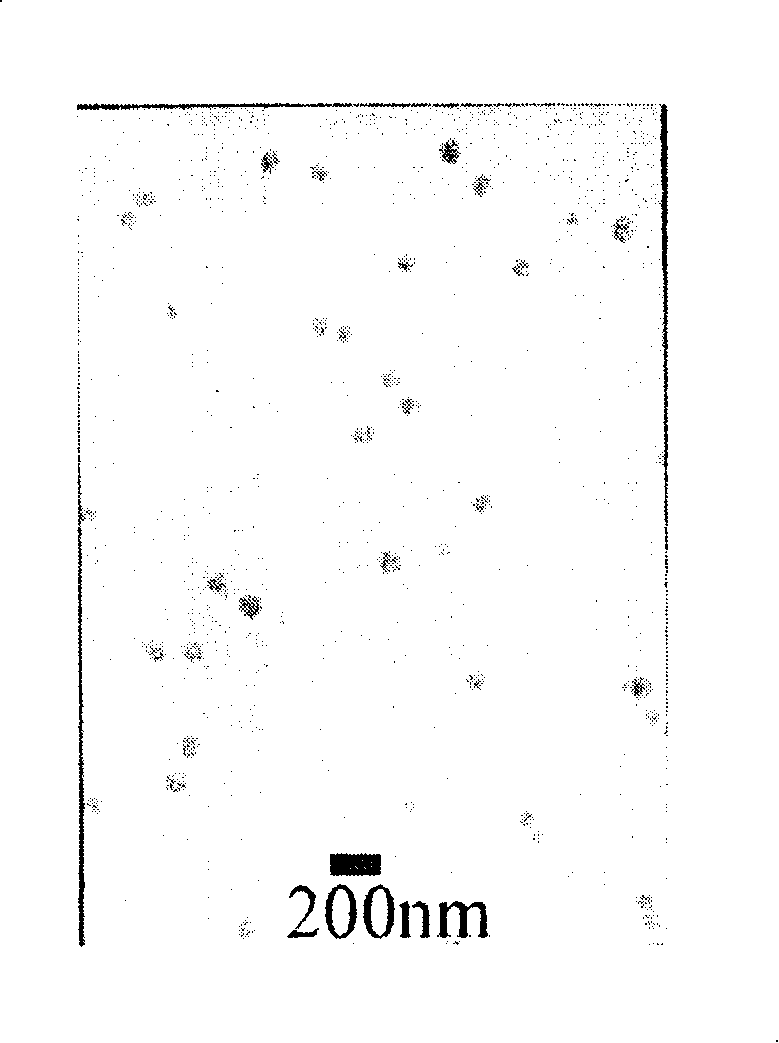

[0021] Weigh 0.03 grams of Eu(TTA)3Phen complex solid powder and dissolve it in 2.5 milliliters of acetone, add the above solution to 100 milliliters of n-propanol, stir and mix at 25°C, and gradually precipitate out the rare earth complex nanoparticles, The mixed solution turns into a gray rare earth complex nano sol, and the sol is vacuum-dried at 60° C. to obtain Eu(TTA)3Phen complex nanoparticles with a particle diameter of about 100 nm. (TEM photo see figure 2 and Figure 4 )

Embodiment 3

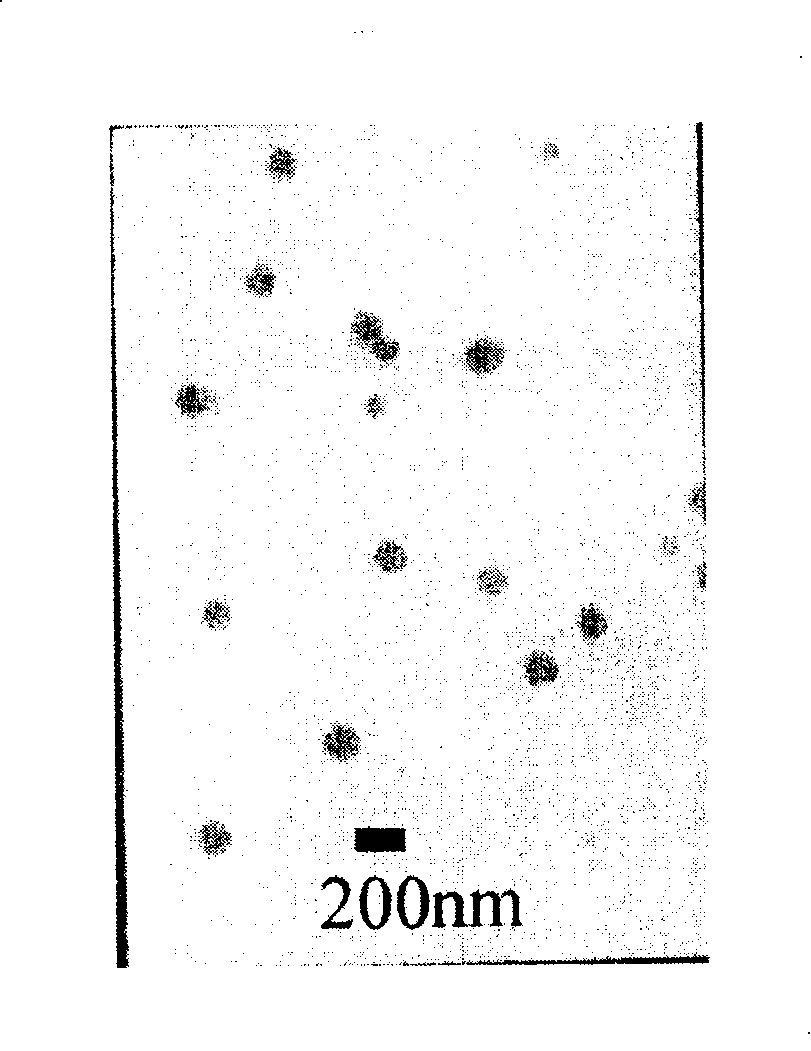

[0023] Weigh 0.06 g of Eu(TTA)3Phen complex solid powder and dissolve it in 5.0 ml of acetone, add the above solution into 50 ml of n-propanol, stir and mix well at 58°C, with the gradual precipitation of rare earth rare earth complex nanoparticles , the mixed solution becomes a gray rare earth complex nano sol, and the sol is vacuum-dried at 130° C. to obtain Eu(TTA)3Phen complex nanoparticles with a particle diameter of about 150 nm. (TEM photo see image 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com