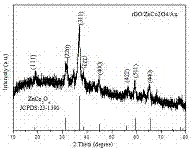

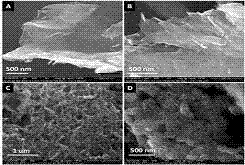

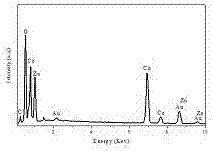

Preparation method of rGO/ZnCo2O4/Au ternary composite room temperature gas-sensitive material

A gas-sensitive material and ternary composite technology, which is applied in the fields of nanotechnology for materials and surface science, analysis of materials, analysis of gas mixtures, etc., can solve problems such as high-tech deep processing exploration is still in the initial stage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Weigh 10 mg of graphene oxide GO prepared by the improved Hummers method, and ultrasonically disperse it in 40 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.25 mg / mL;

[0017] (2) Weigh a certain amount of zinc nitrate hexahydrate, cobalt nitrate hexahydrate, sodium citrate and hexamethylenetetramine, dissolve into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, in which zinc nitrate hexahydrate The concentration of cobalt nitrate hexahydrate is 0.005mol / l, the concentration of cobalt nitrate hexahydrate is 0.01mol / l, the concentration of sodium citrate is 0.00375mol / l, the concentration of hexamethylenetetramine is 0.0125mol / l, and the concentration of nitric acid hexahydrate is controlled The molar ratio of zinc to cobalt nitrate hexahydrate is 1:2, the molar ratio of zinc nitrate hexahydrate to sodium citrate is 1:0.75, and the molar ratio of zinc nitrate hexahydrate to hexamethy...

Embodiment 2

[0021] (1) Weigh 20 mg of graphene oxide GO prepared by the improved Hummers method, and ultrasonically disperse it in 50 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.4 mg / mL;

[0022] (2) Weigh a certain amount of zinc nitrate hexahydrate, cobalt nitrate hexahydrate, sodium citrate and hexamethylenetetramine, dissolve into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, in which zinc nitrate hexahydrate The concentration of cobalt nitrate hexahydrate is 0.01mol / l, the concentration of cobalt nitrate hexahydrate is 0.02mol / l, the concentration of sodium citrate is 0.01mol / l, the concentration of hexamethylenetetramine is 0.02mol / l, and the concentration of nitric acid hexahydrate is controlled The molar ratio of zinc to cobalt nitrate hexahydrate is 1:2, the molar ratio of zinc nitrate hexahydrate to sodium citrate is 1:1, and the molar ratio of zinc nitrate hexahydrate to hexamethylenetetram...

Embodiment 3

[0026] (1) Weigh 15 mg of graphene oxide GO prepared by the improved Hummers method, and ultrasonically disperse it in 50 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 0.3 mg / mL;

[0027] (2) Weigh a certain amount of zinc nitrate hexahydrate, cobalt nitrate hexahydrate, sodium citrate and hexamethylenetetramine, dissolve into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, in which zinc nitrate hexahydrate The concentration of cobalt nitrate hexahydrate is 0.02mol / l, the concentration of cobalt nitrate hexahydrate is 0.06mol / l, the concentration of sodium citrate is 0.04mol / l, the concentration of hexamethylenetetramine is 0.06mol / l, and the concentration of nitric acid hexahydrate is controlled The molar ratio of zinc to cobalt nitrate hexahydrate is 1:3, the molar ratio of zinc nitrate hexahydrate to sodium citrate is 1:2, and the molar ratio of zinc nitrate hexahydrate to hexamethylenetetram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com