Cobalt-modified bismuth tungstate composite photocatalyst, its preparation method and application thereof

A technology of bismuth tungstate and composite light, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve undisclosed morphological characteristics, the final product is difficult to have photocatalytic degradation effect, and the addition of raw materials Incorrect order and other problems, to achieve the effect of scientific preparation method, good visible light catalytic degradation effect, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

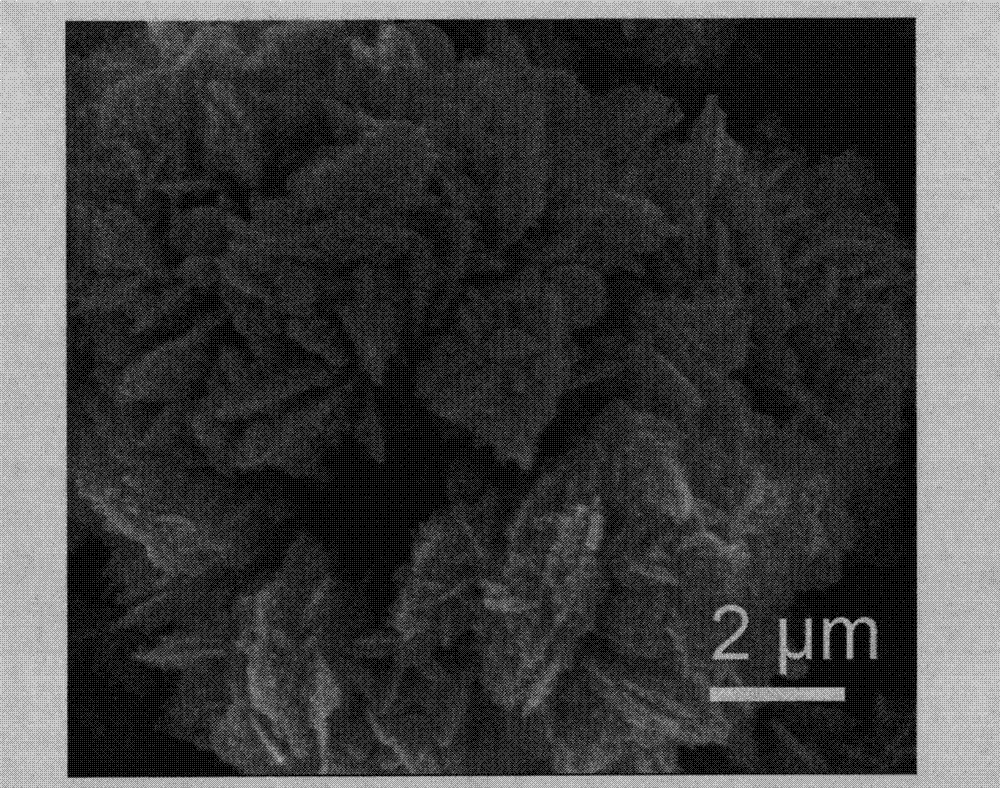

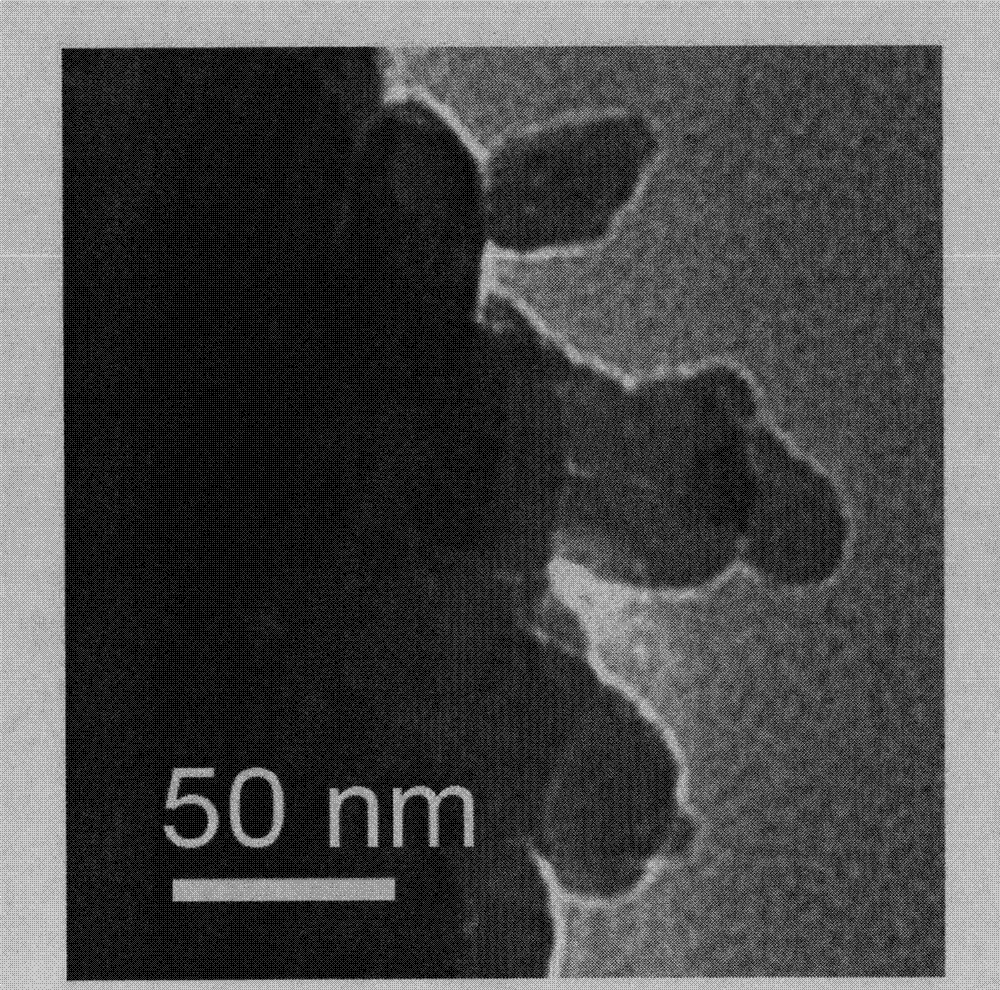

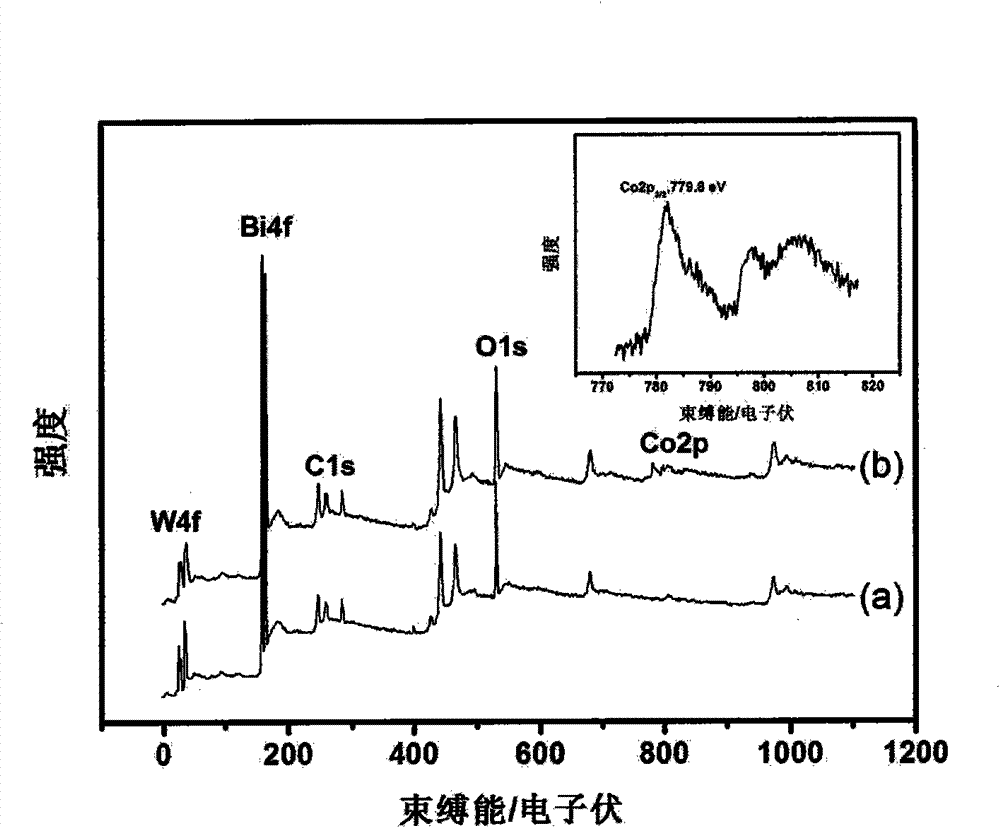

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, firstly add bismuth nitrate into the nitric acid solution with a concentration of 1 mol / L and stir for 30 minutes according to the mass ratio between bismuth nitrate and nitric acid of 3:1 to obtain a bismuth nitrate solution. Then add sodium tungstate into deionized water and stir evenly according to the mass ratio between sodium tungstate and deionized water of 30:1 to obtain a sodium tungstate solution. Next, first add cetyltrimethylammonium bromide to the sodium tungstate solution and stir evenly to obtain a mixed solution; wherein, the difference between sodium tungstate and cetyltrimethylammonium bromide in the mixed solution The mass ratio is 1.4:1. Then add bismuth nitrate solution into the mixed solution to obtain a precursor solution; wherein, the mass ratio between bismuth nitrate and sodium tungstate in the precursor solution is 2.8:1. Subsequently, the precursor solution was placed in an airtight sta...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] Step 1: firstly add bismuth nitrate into the nitric acid solution with a concentration of 2 mol / L and stir for 31 minutes according to the mass ratio between bismuth nitrate and nitric acid of 3.5:1 to obtain a bismuth nitrate solution. Then add sodium tungstate into deionized water and stir evenly according to the mass ratio between sodium tungstate and deionized water of 35:1 to obtain a sodium tungstate solution. Next, first add cetyltrimethylammonium bromide to the sodium tungstate solution and stir evenly to obtain a mixed solution; wherein, the difference between sodium tungstate and cetyltrimethylammonium bromide in the mixed solution The mass ratio is 1.5:1. Then add bismuth nitrate solution into the mixed solution to obtain a precursor solution; wherein, the mass ratio between bismuth nitrate and sodium tungstate in the precursor solution is 2.9:1. Subsequently, the precursor solution was first placed in a close...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1: firstly add bismuth nitrate into the nitric acid solution with a concentration of 3 mol / L and stir for 32 minutes according to the mass ratio between bismuth nitrate and nitric acid of 4:1 to obtain a bismuth nitrate solution. Then add sodium tungstate into deionized water and stir evenly according to the mass ratio between sodium tungstate and deionized water of 40:1 to obtain a sodium tungstate solution. Next, first add cetyltrimethylammonium bromide to the sodium tungstate solution and stir evenly to obtain a mixed solution; wherein, the difference between sodium tungstate and cetyltrimethylammonium bromide in the mixed solution The mass ratio is 1.6:1. Then add bismuth nitrate solution into the mixed solution to obtain a precursor solution; wherein, the mass ratio between bismuth nitrate and sodium tungstate in the precursor solution is 3:1. Subsequently, the precursor solution was first placed in a closed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com