Pressure roller device of fertilizer extrusion molding machine

The technology of a pressure roller device and a forming machine, which is applied in the field of pressure roller devices, can solve problems such as unreasonable design of pressure roller devices, unsuitability for forming processing, and aggravated wear of abrasive tools, so as to avoid local blockage and mold loss, avoid Partial jamming phenomenon, the effect of reducing the loss of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

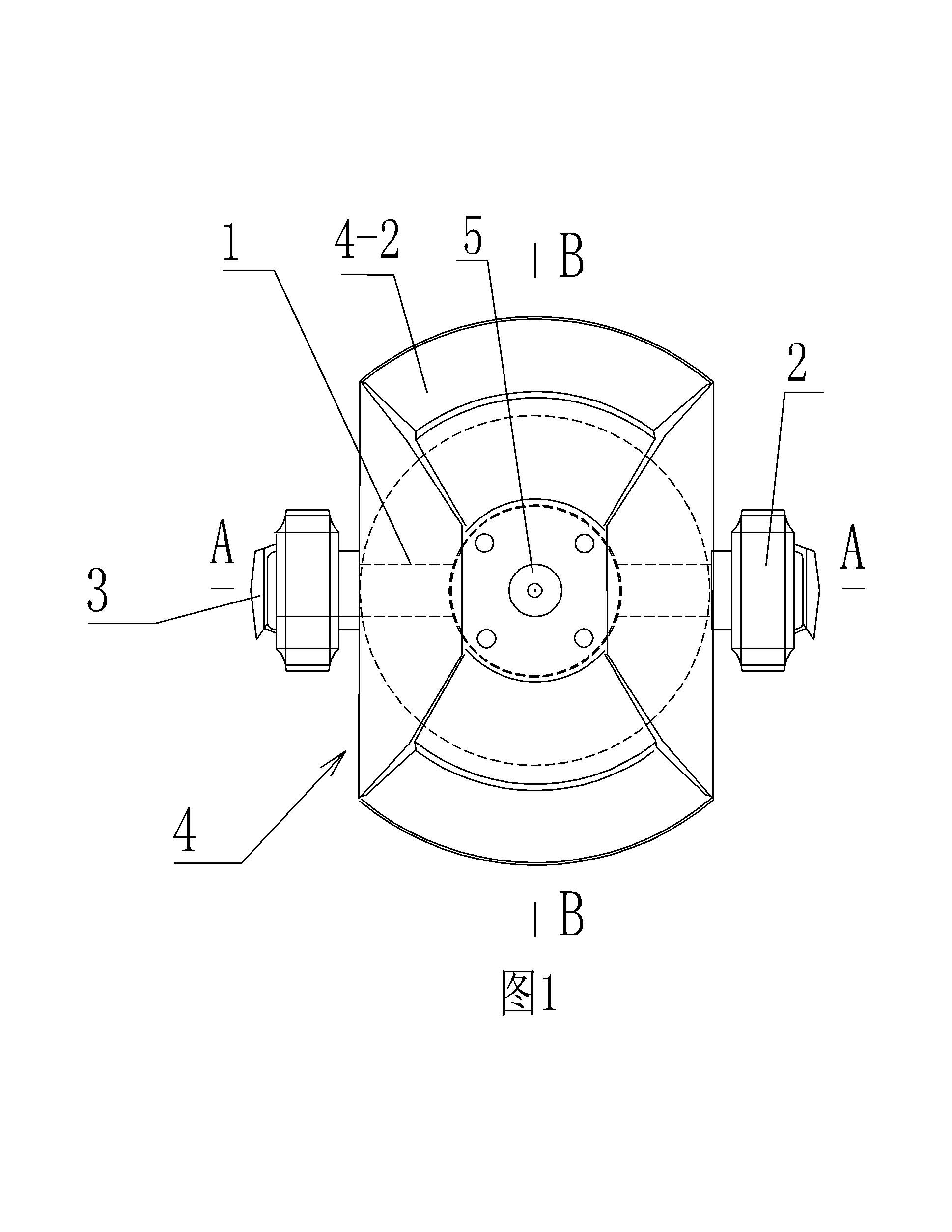

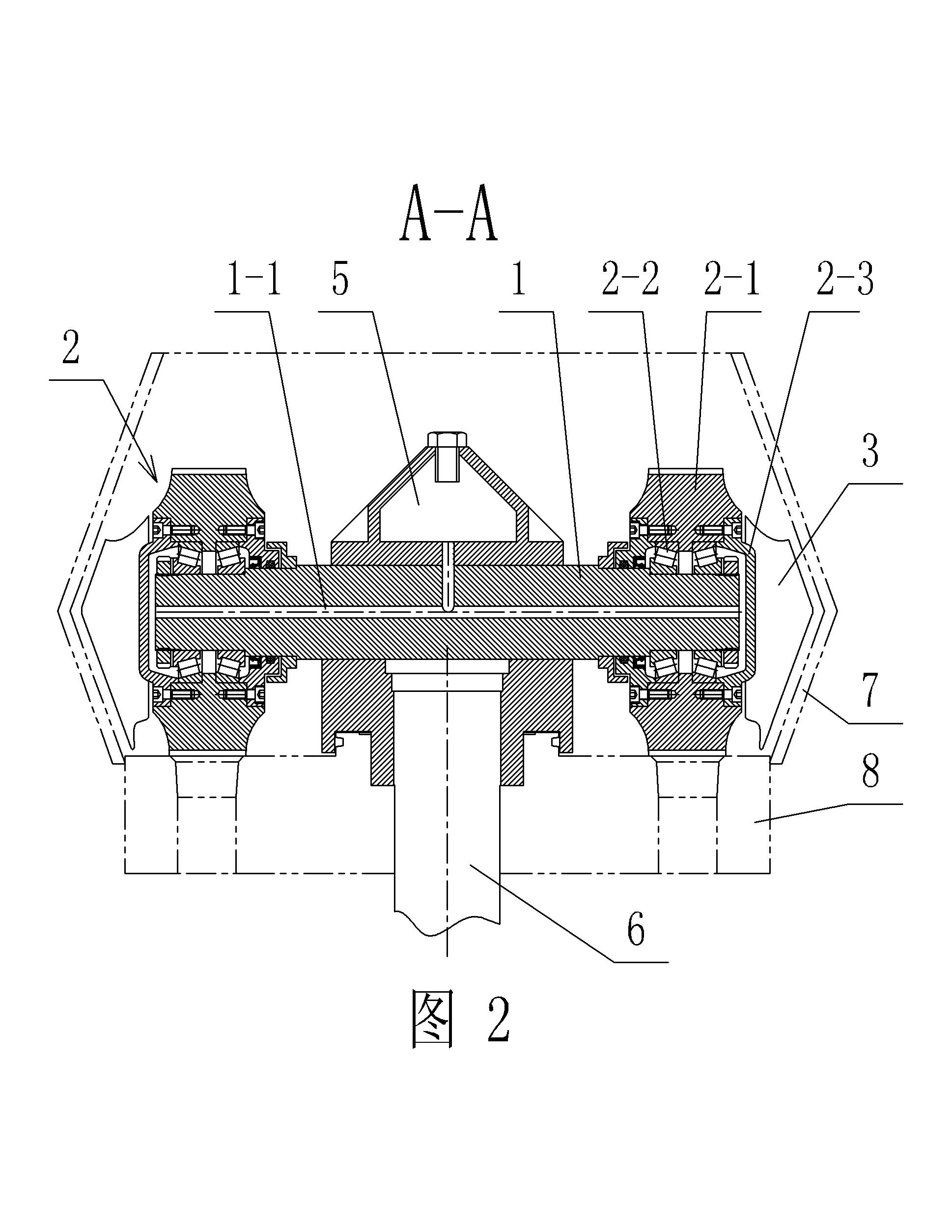

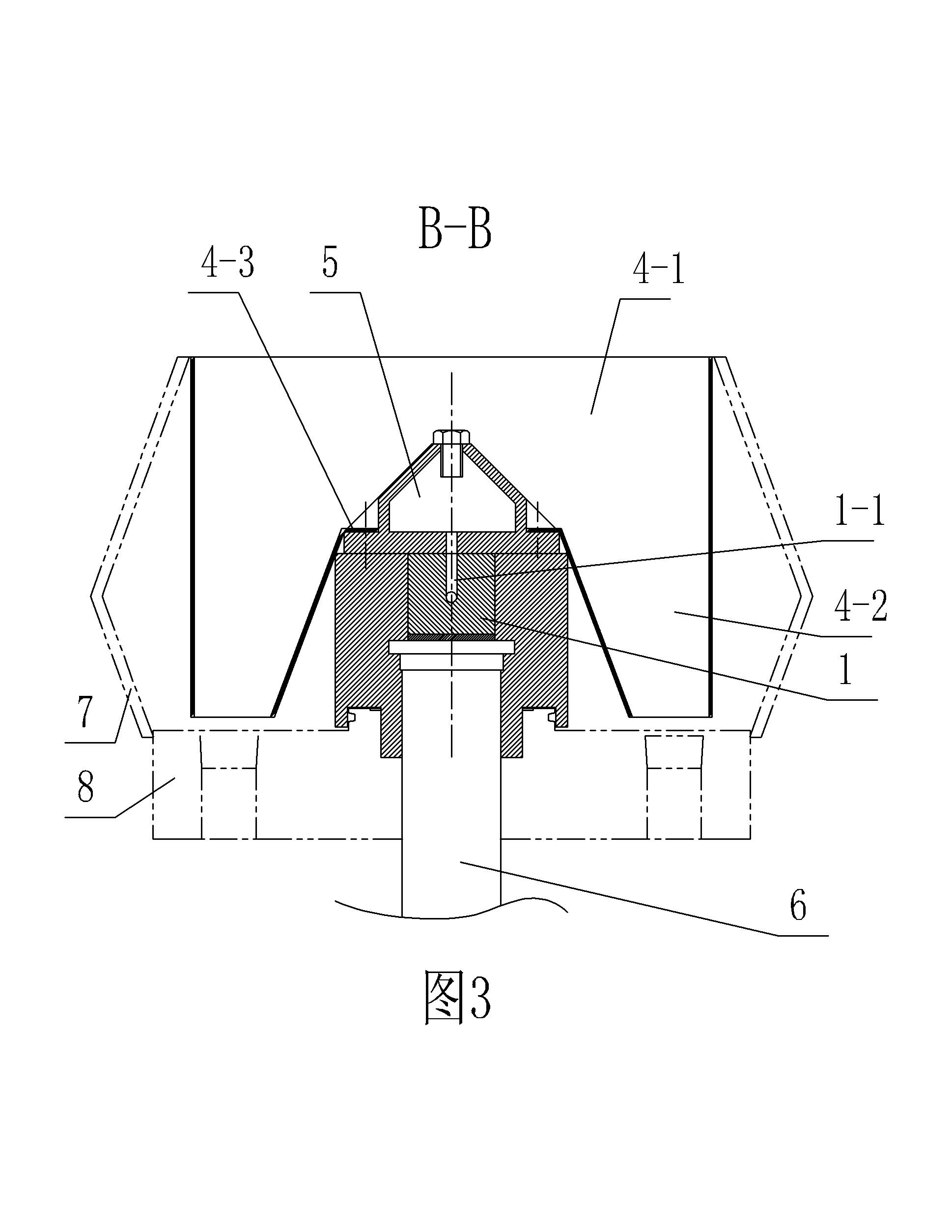

[0025] like Figure 1-Figure 6 Shown is a pressure roller device for a fertilizer extrusion molding machine provided by the present invention, which includes a pressure roller shaft 1 for vertical connection and transmission with the power shaft 6 and a pair of The pressure roller wheel 2 is characterized in that it also includes a material distribution guide device 4, and the material distribution guide device 4 includes a feed groove 4-1 arranged above the pressure roller shaft 1 and connected to the left and right sides of the feed groove 4-1. A pair of distributing troughs 4-2 are arranged on the bottom of both sides and interlaced with the two pressure rollers 2. The top of the feed trough 4-1 is provided with a feed port, and the bottom of the feed trough 4-1 is provided with a The pressure roller shaft 1 is relatively fixedly connected to the connecting trough plate 4-3, and the left and right sides below the feeding chute 4-1 are provided with a feeding port connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com