Extraction device used for paper-making reconstituted tobacco and technology for preparing reconstituted tobacco

A technology of reconstituted tobacco leaf and extraction device, which is applied in the direction of tobacco preparation, tobacco application, etc., and can solve problems such as uneven discharge, difficult equipment cleaning, and poor sensory quality of tobacco sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Extraction device for reconstituted tobacco leaves by papermaking method, including primary extraction tank, screw conveyor, primary screw pump, primary screw discharge centrifuge, secondary extraction tank, secondary screw pump, secondary screw discharge centrifuge , Three-stage extraction tank, three-stage screw pump, three-stage screw discharge centrifuge and thickening tank.

[0110] in:

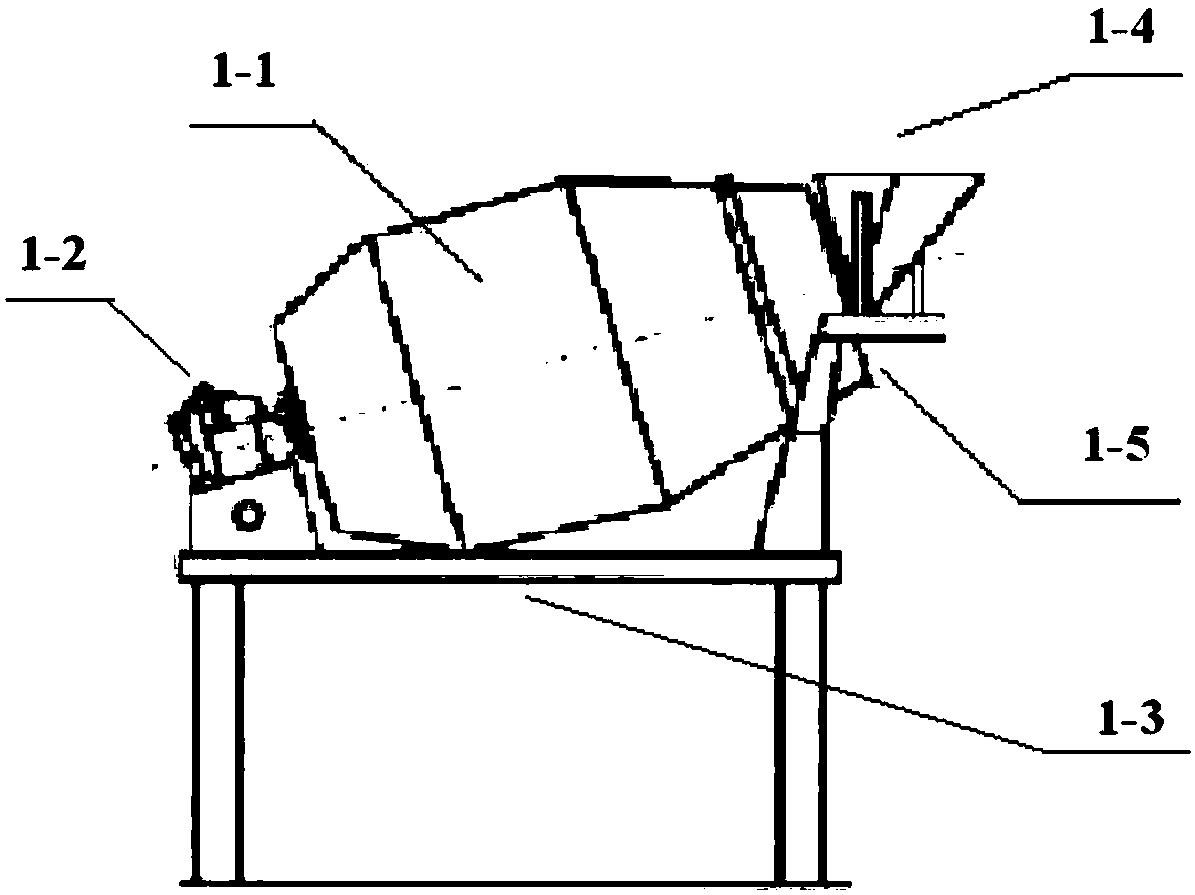

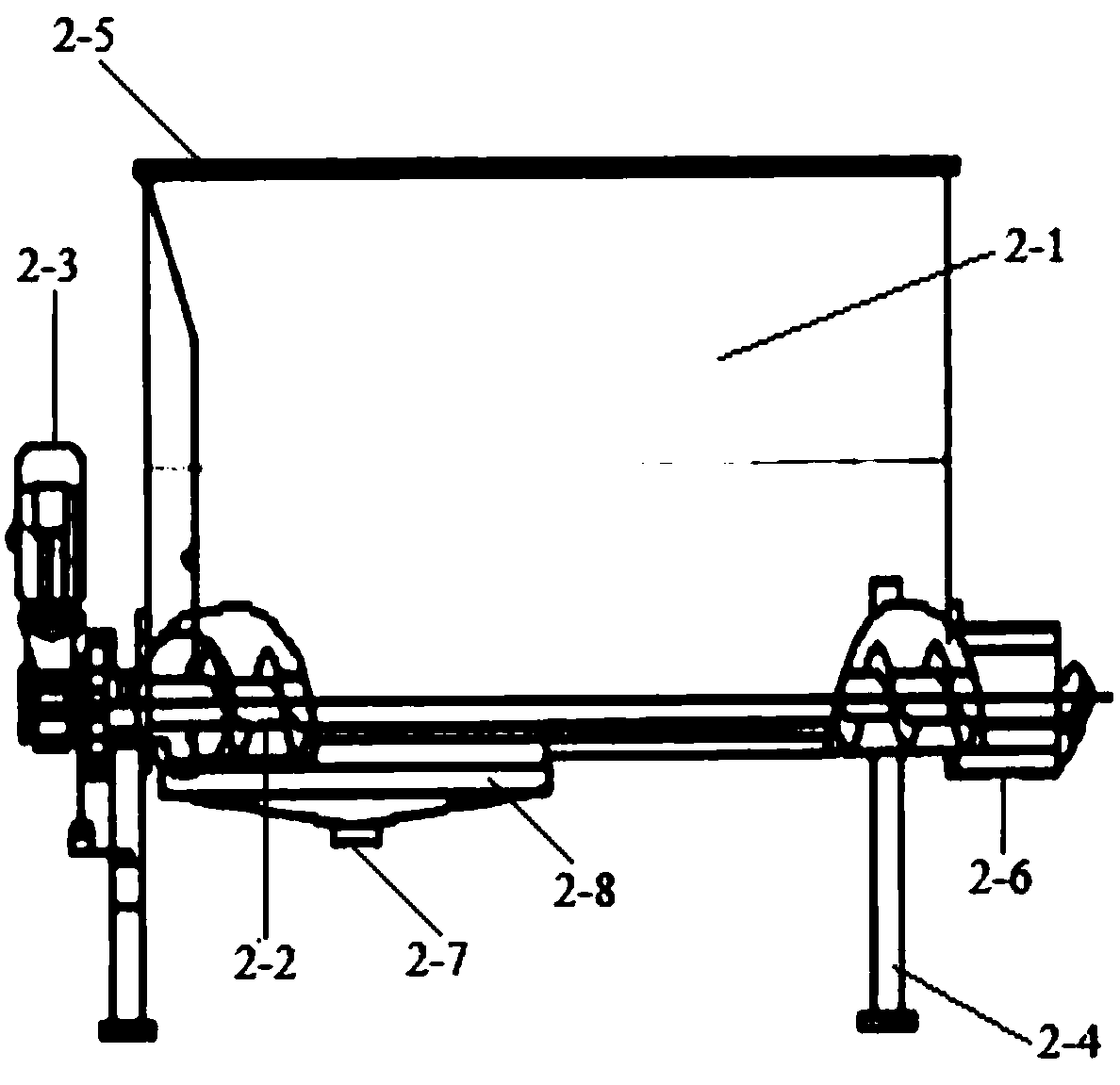

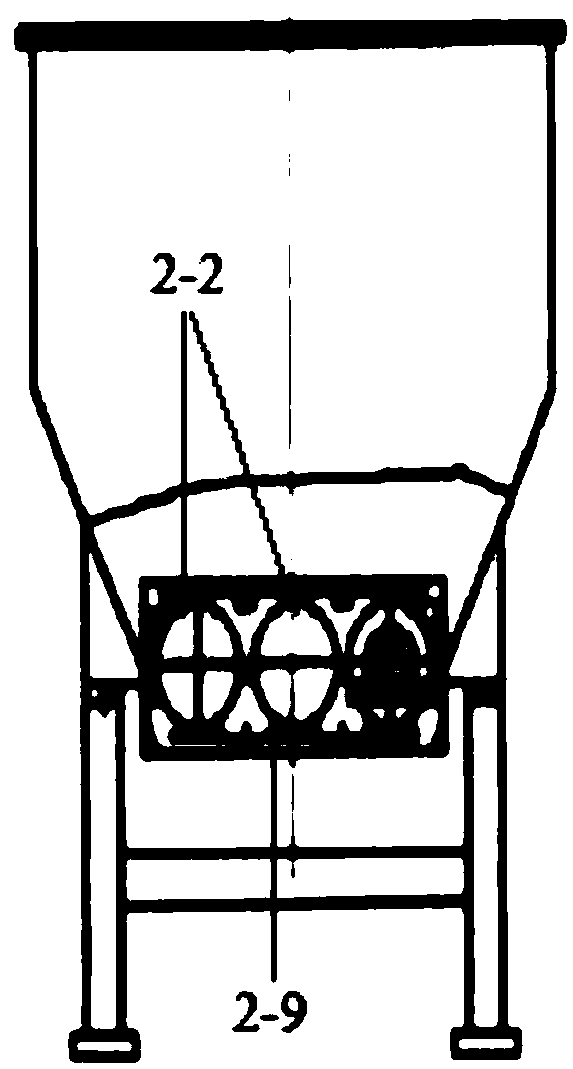

[0111] Such as figure 1 As shown, the first-stage extraction tank is an inclined horizontal drum extraction tank, which includes a tank body 1-1, a driving mechanism 1-2 and a bracket 1-3; the driving mechanism 1-2 is connected with the bracket 1-3, and the tank body 1- 1 Inclined on the support 1-3 and connected with the support 1-3 through the drive mechanism 1-2; the drive mechanism 1-2 drives the tank body 1-1 to rotate around its own central axis; the inner wall of the tank body 1-1 is connected There is a deflector, and the deflector is arranged in a spiral shape around th...

Embodiment 2

[0123] The technological process that adopts embodiment 1 extraction device to extract is as Figure 8 shown, including:

[0124] (1) Put the broken tobacco pieces (the broken tobacco pieces of flue-cured tobacco produced in Fujian) and 60°C hot water in a weight ratio of 1:6 into the primary extraction tank, and roll at a constant temperature of 60°C for 20 minutes to obtain a mixture;

[0125] (2) The mixture obtained in step (1) is quickly unloaded into the screw conveyor, and the screw conveyor is 15m 3 The flow rate of / h sends the material into the first-stage screw pump;

[0126] (3) The first stage screw pump is 15m 3 The flow rate of / h sends the material into the first-stage screw discharge centrifuge for solid-liquid separation, and the centrifugal speed is 2700r / min to obtain liquid phase and solid phase. Wherein, the solid content in the feed of the first-stage screw discharge centrifuge is 14% to 15% (w / w), and the water content of the obtained solid phase is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com