Presser foot lifting and trimming driving structure of sewing machine and control method thereof

A driving structure and presser foot lifting technology, which is applied in the field of sewing machines, can solve the problems that the control of the cam structure is not flexible and fast, the thread trimming mechanism is not suitable for long-distance transmission, and the structure has poor adaptability, so as to reduce the driving source and the number of parts, Simple assembly and low overall noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

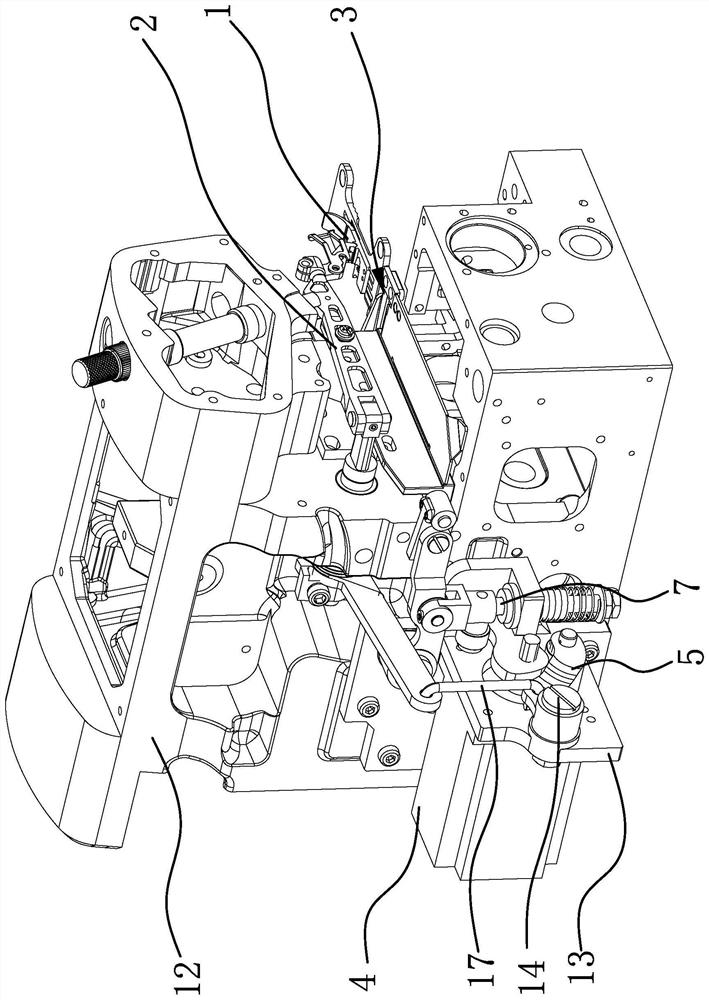

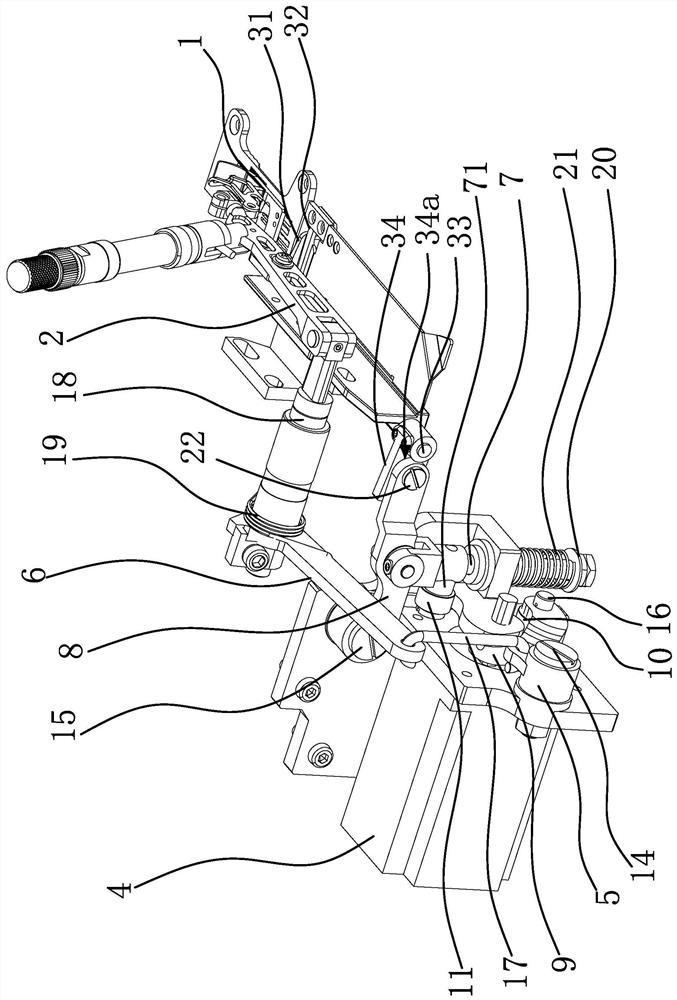

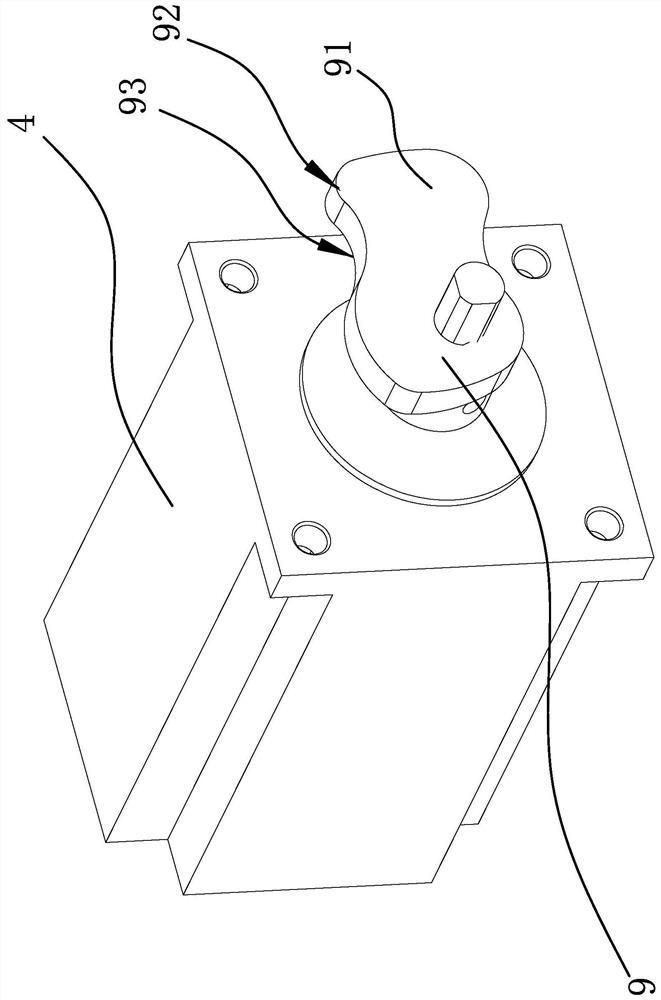

[0036] Such as figure 1 , figure 2 with image 3 As shown, the sewing machine includes a casing 12, a thread trimmer assembly 3, a presser foot arm 2, and a presser foot 1 arranged at the end of the presser foot arm 2. The thread trimmer assembly 3 includes a moving knife 31, a fixed knife 32, and drives the moving knife 31 toward The thread trimming pin 33 that fixed knife 32 swings, this drive structure comprises stepper motor 4, can swing presser foot lifter crank 5, presser foot lifter lever 6, vertically arranges and can move up and down push rod 7 and thread trimmer connection. Rod 8; The casing 12 is fixedly provided with a mounting plate 13, the stepper motor 4 is fixedly mounted on the mounting plate 13, the output shaft of the stepping motor 4 is fixedly provided with a drive cam 9, and the crank 5 for lifting the presser foot is provided with a The roller 10 that the outer contour of the drive cam 9 contacts, the presser foot lifter lever 6 is connected with the ...

Embodiment 2

[0044] combine Figure 4 with Figure 5 As shown, this embodiment provides a control method for the sewing machine presser foot lifter and thread trimmer driving. The sewing machine includes the presser foot lifter and thread trimmer drive structure in Embodiment 1, and also includes a controller and a control panel. It is characterized in that, The control method includes the following steps:

[0045] a. Setting parameters: pre-set the rotation angle parameters of the stepping motor 4 through the controller or the control panel;

[0046] b. Presser foot lift action: when the presser foot needs to be lifted, send the presser foot lift signal to the controller, the stepper motor 4 rotates clockwise at a preset angle, and the drive cam 9 on the output shaft of the stepper motor 4 drives the lifter The foot crank 5 moves, thereby driving the presser foot lever 6 and the presser arm 2 to move, and finally drives the presser foot 1 on the presser arm 2 to lift. 18 and presser fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com