A sprayed concrete device for tunnel construction with reduced rebound rate

A technology for tunnel construction and rebound rate, which is used in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of waste, scattered in the tunnel, and increased construction costs of injection concrete, so as to reduce the rebound rate, simplify the structure, and avoid the The effect of sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

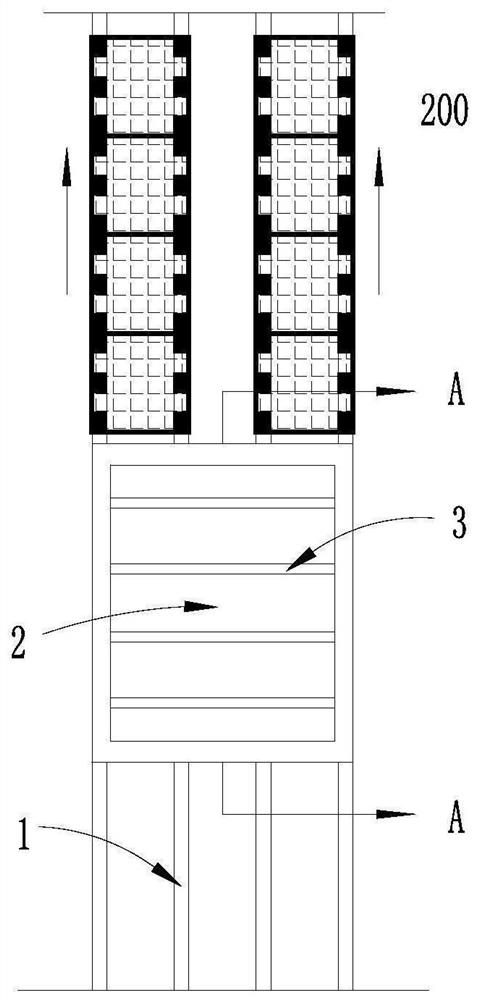

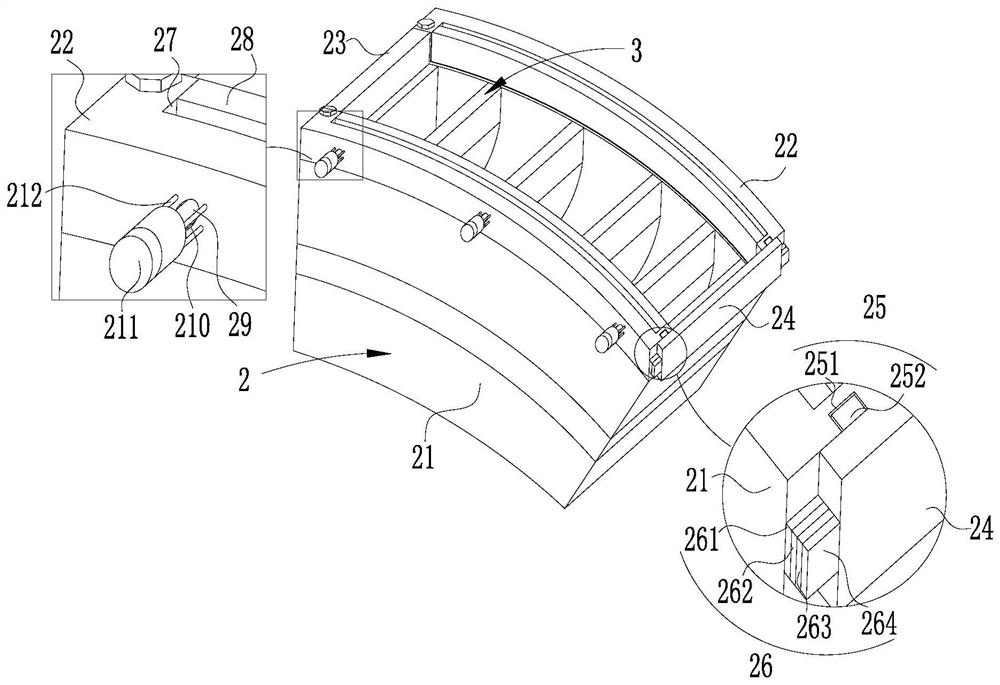

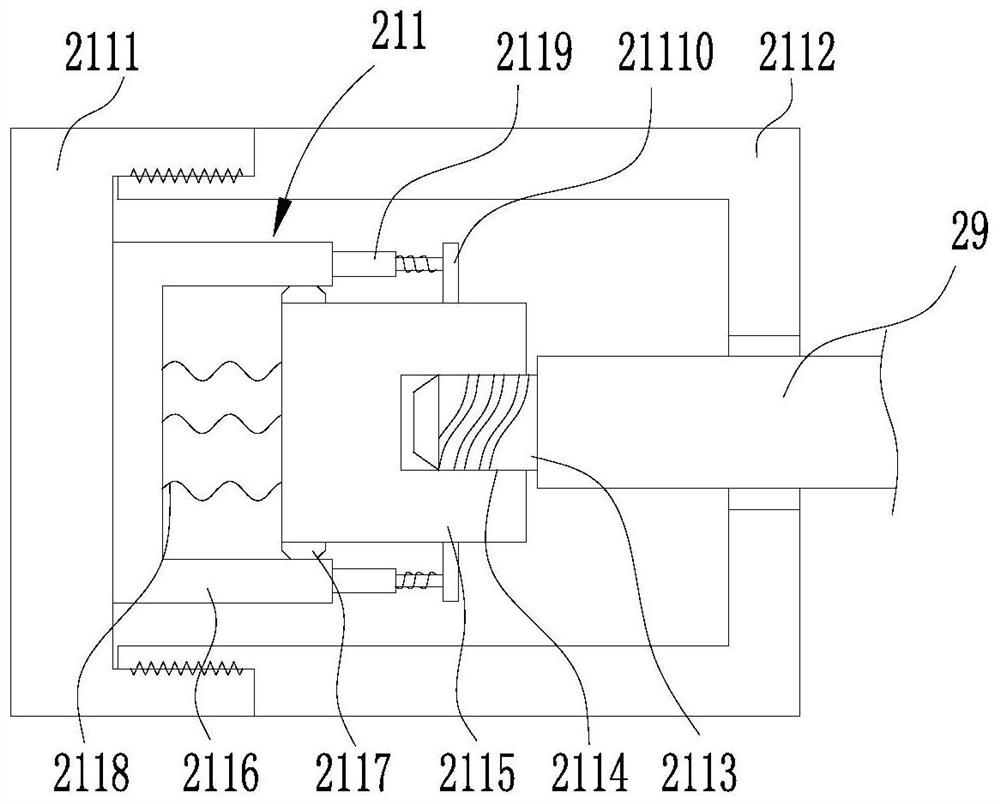

[0040] Attached below Figure 1-5 The present invention is further described with embodiment:

[0041]A spraying concrete device for tunnel construction with reduced rebound rate, the main body is supported by a steel arch 1, including an anti-splash mechanism 2 arranged on the steel arch 1, and the movement direction of the anti-splash mechanism 2 is along the The moving direction of the slurry anti-sputtering mechanism is 200°, the filling direction of the mixture is along the moving direction of the slurry 100°, and four powerful electromagnets 3 are arranged in the anti-sputtering mechanism 2, and the anti-sputtering mechanism 2 includes: arc tube 21. The activity is set on the steel arch 1. Specifically, when working, the sealed cavity formed by the arc tube 21 and the powerful electromagnet 3 can prevent the rebound of the mixture in the early stage; the No. 1 anti-sputter plate 22, Set on the upper end face of the arc tube 21, the No. 1 anti-sputter plate 22 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com