3D printer

A 3D printer and printing table technology, applied in the field of 3D printing, can solve the problems such as the inability to achieve the smooth effect of the glass iron sheet, the rough surface printing texture, and the inability to remove it, and achieves easy promotion, low manufacturing costs, and reduced maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

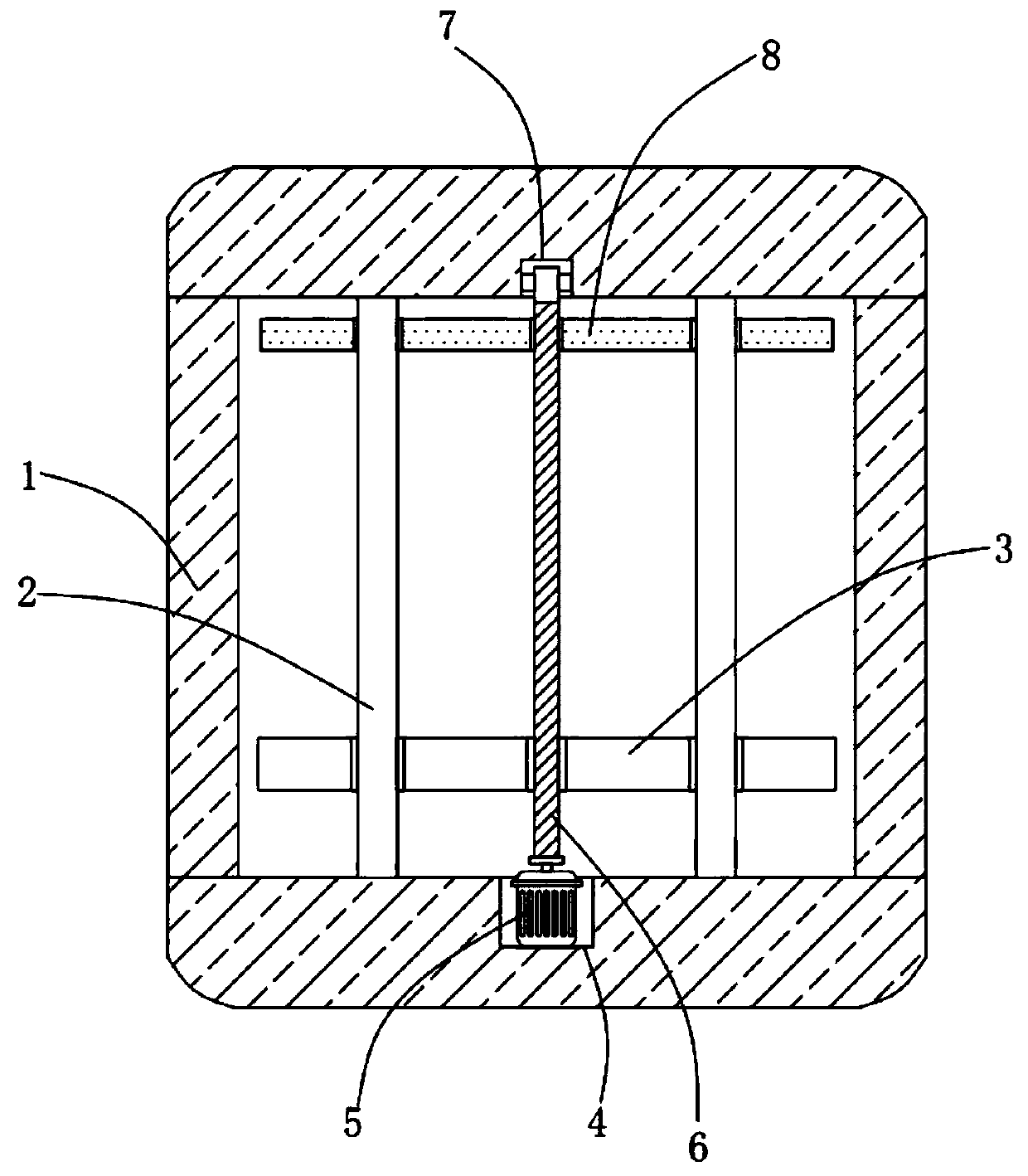

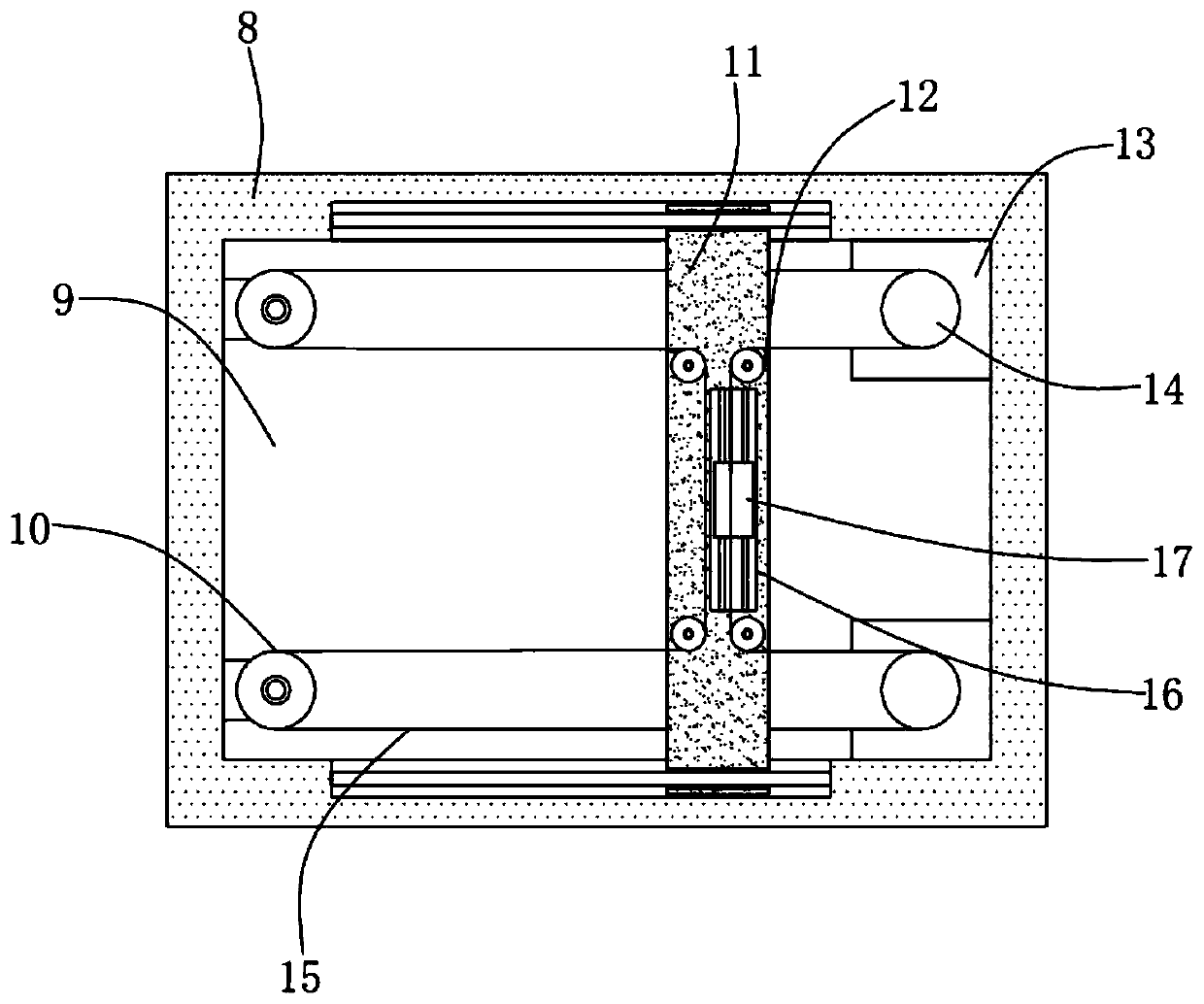

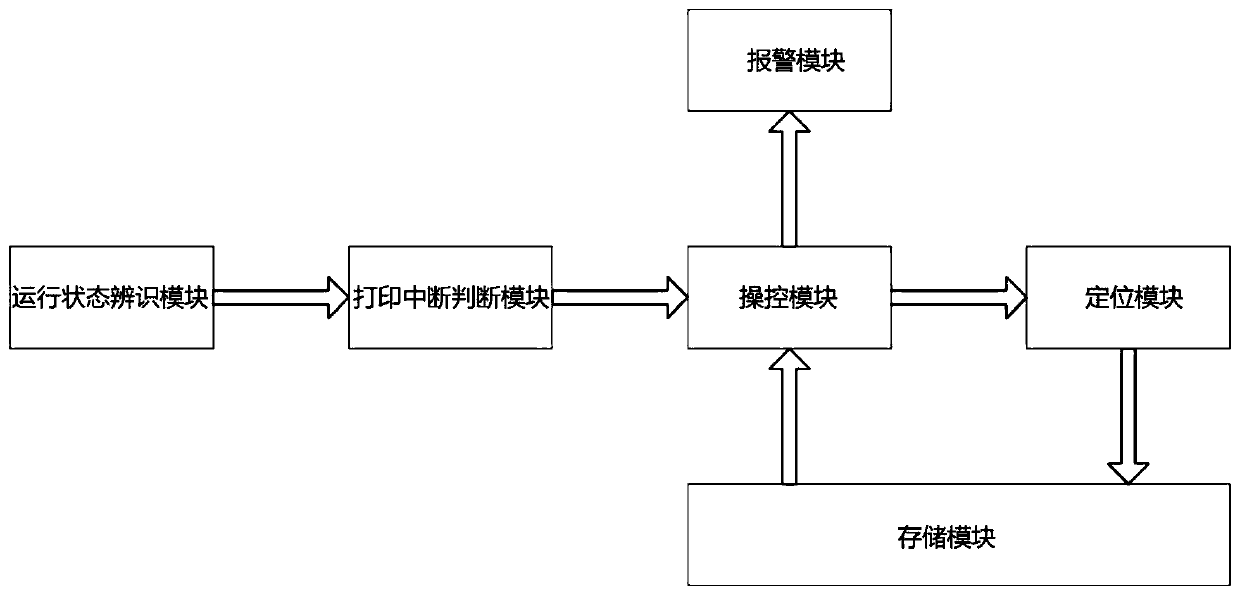

[0036] Such as Figure 1~5 A 3D printer is shown, which includes a housing; two optical axes are symmetrically and fixedly installed in the housing, and the same printing platform is slidably installed on the two optical axes; a heating bed for carrying products is provided on the printing platform; The side is provided with the print nozzle 17 facing the hot bed, and the hot bed includes a contact layer 18, a glued layer group and a magnetic magnetic paste layer 19 that are superimposed on top and bottom and are used to provide adsorption force; the contact layer 18 has a smooth surface One side of the model is the contact surface.

[0037] Among them, such as Figure 4~5 As shown, in this embodiment 1, the contact layer 18 is made of transparent PEI material, and its thickness is 0.45mm;

[0038] In the embodiment 1, a contact layer 18 , an upper glue layer 20 , a rubber layer 21 , a lower glue layer 22 , and a magnetism-providing magnetic layer 19 are arranged sequentiall...

Embodiment 2

[0047] Such as Figure 1~5 A 3D printer is shown, which includes a housing; two optical axes are symmetrically and fixedly installed in the housing, and the same printing platform is slidably installed on the two optical axes; a heating bed for carrying products is provided on the printing platform; The side is provided with the print nozzle 17 facing the hot bed, and the hot bed includes a contact layer 18, a glued layer group and a magnetic magnetic paste layer 19 that are superimposed on top and bottom and are used to provide adsorption force; the contact layer 18 has a smooth surface One side of the model is the contact surface.

[0048] Among them, such as Figure 4~5 As shown, in this embodiment 1, the contact layer 18 is made of transparent PEI material, and its thickness is 0.45mm;

[0049] In Example 2, a contact layer 18 , an upper glue layer 20 , a rubber layer 21 , a lower glue layer 22 , and a magnetism-providing magnetic paste layer 19 are arranged sequentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com