A nozzle support device and a character jet printing machine with the nozzle support device

A technology of bracket device and nozzle, applied in printing and other directions, can solve the problems of tilting, difficult and inconvenient operation of the mounting plate, and achieve the effect of improving adjustment accuracy, simplifying operation process and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

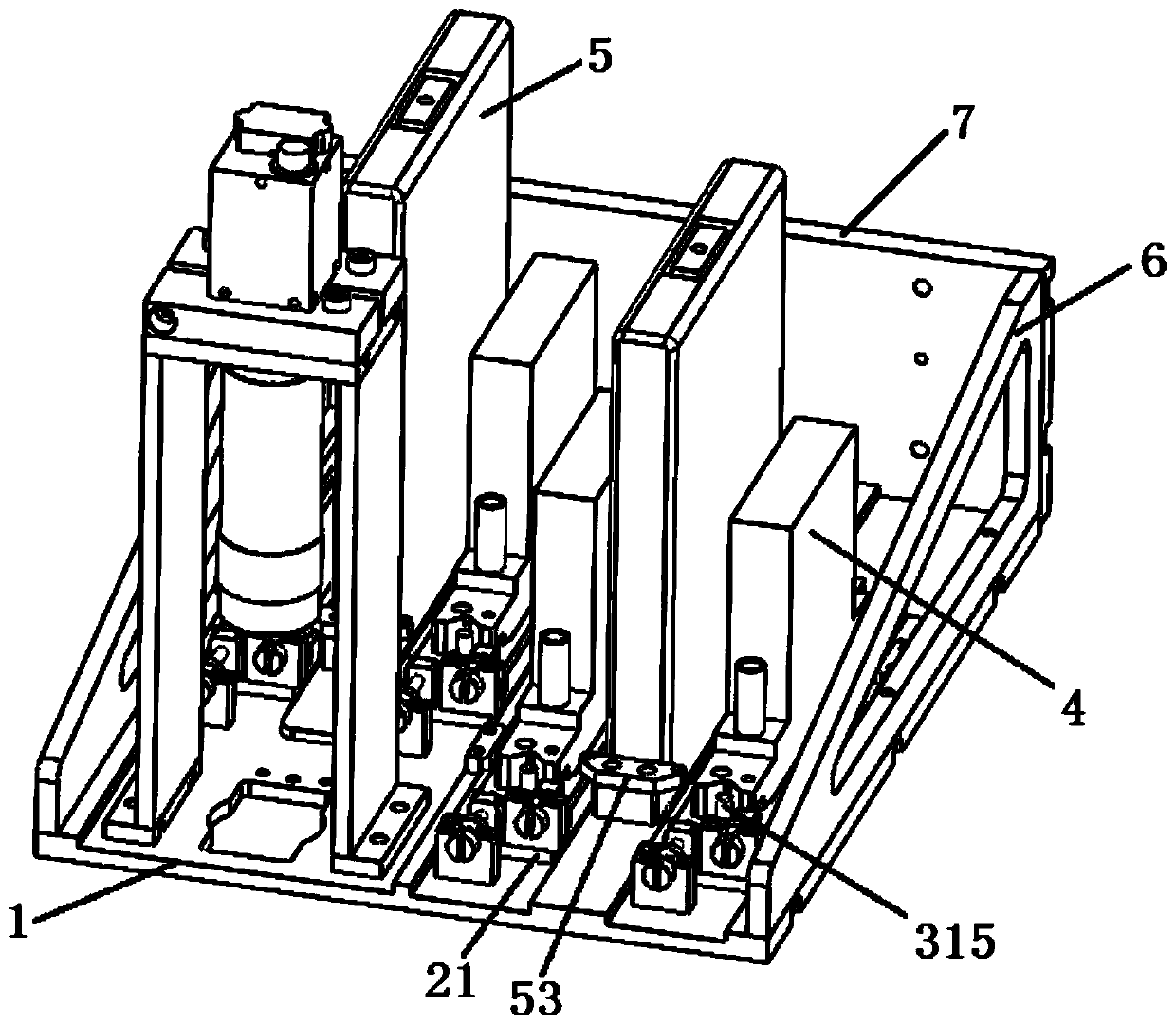

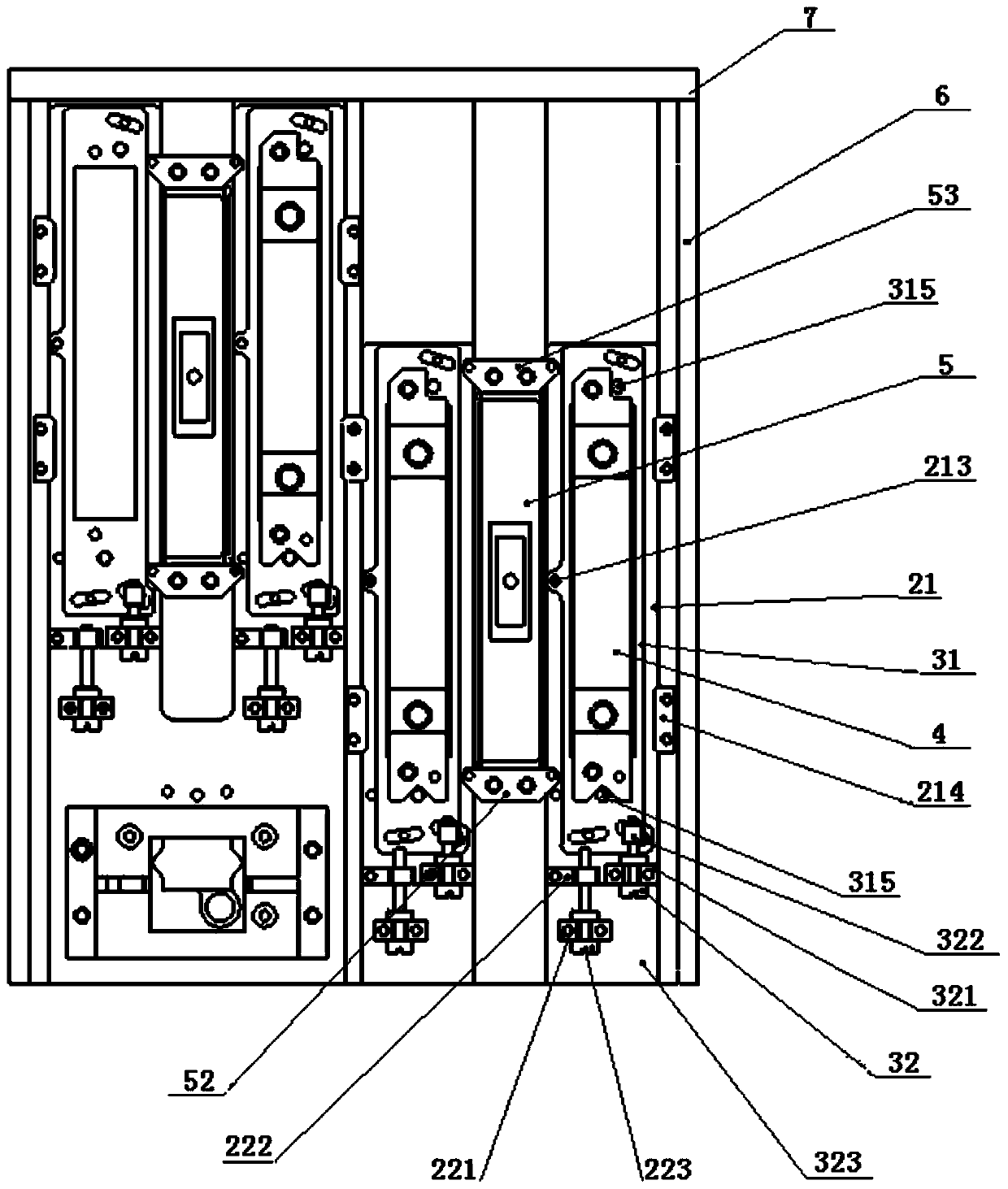

[0048] This embodiment provides a nozzle support device, such as Figure 1 to Figure 15 shown, including:

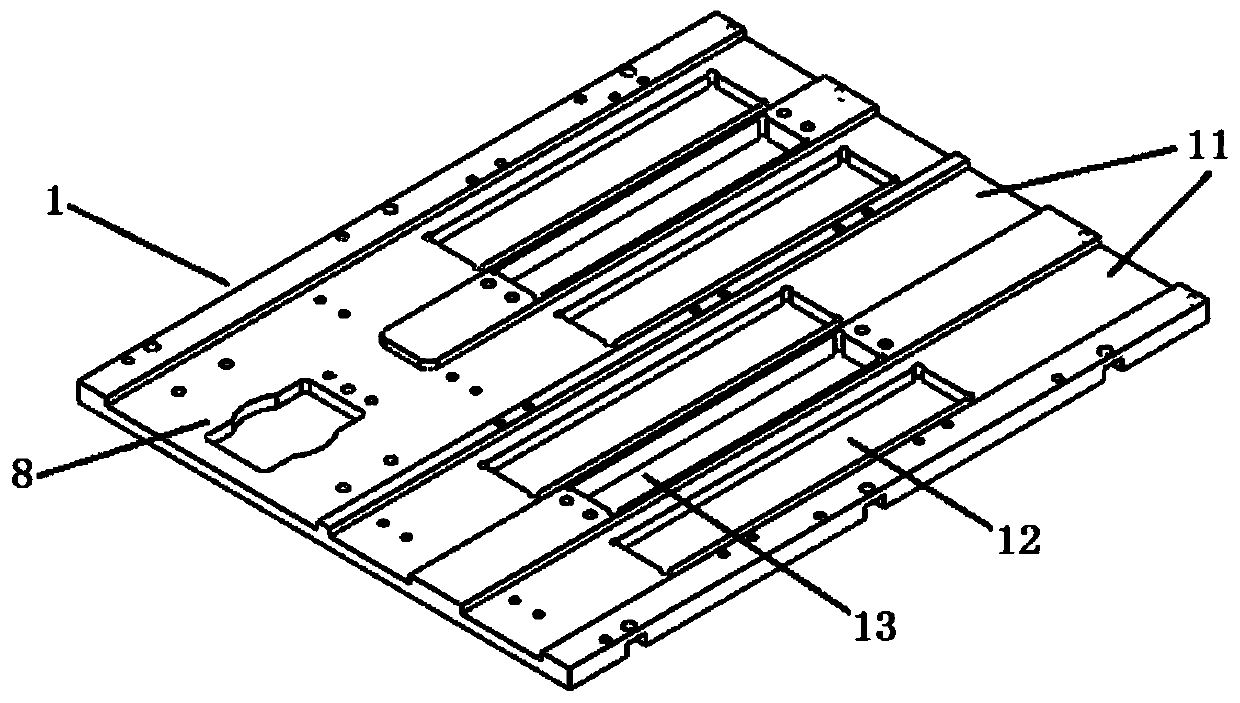

[0049] Bottom plate 1, two sets of chute 11 are set, and the elongated holes 12 are opened in the chute one by one, and a step surface is formed between the inner wall of the chute; a UVLED lamp is installed between each set of elongated holes. Groove 13, each group of elongated holes is arranged side by side, and the two groups of elongated holes are staggered and arranged in parallel;

[0050] The four first adjustment components correspond to the elongated holes one by one, and are installed in the chute of the bottom plate. Each first adjustment component includes a slide plate 21 and a first adjustment structure 22. A reserved gap is formed between the inner wall surfaces of the bottom plate, which can slide along the length direction of the bottom plate chute, and the first through hole 210 corresponding to the elongated hole is opened on the slide plate, and the ...

Embodiment 2

[0075] The present embodiment provides an inkjet printer, comprising:

[0076] frame;

[0077] Any one of the above-mentioned nozzle support devices arranged on the frame;

[0078] There are at least four spray heads, and the spray heads are slidably installed on the rotating fixed plate of the spray head support device.

[0079] The inkjet printer with the above structure, due to the use of the nozzle support device provided in Embodiment 1, makes the inkjet printer highly accurate and easy to operate when adjusting the position of the nozzle, and can be provided with a plurality of nozzles on the base plate to improve Inkjet printer productivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com