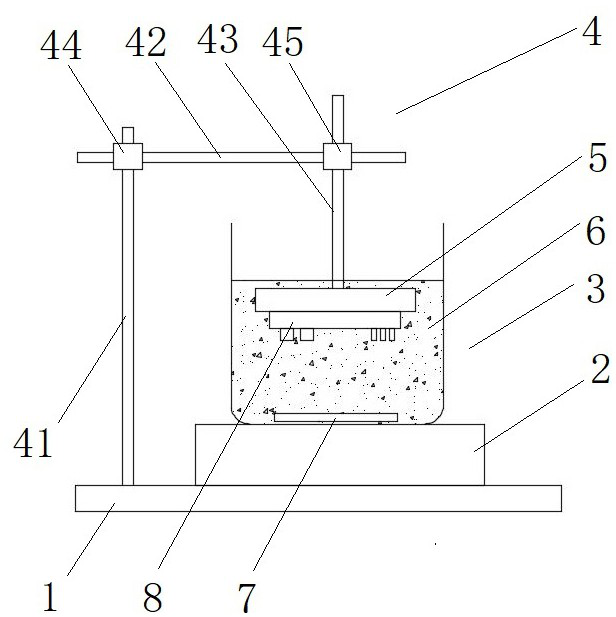

A polishing method for a thin-film lithium niobate optical waveguide chip polishing device

A polishing device and lithium niobate technology, which is applied in the field of integrated optical chip manufacturing and micro-nano processing, can solve the problems of large roughness, high price, and damage to the optical waveguide side wall and surface, and achieve the etching surface and waveguide. The side wall is smooth, the process equipment is simple, and the effect of surface damage is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

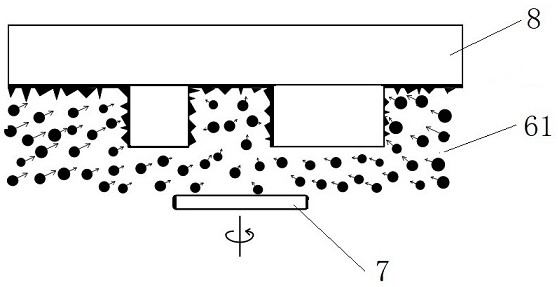

[0035]Add a rough polishing solution 61 with a diameter of 100 nm of silicon oxide polishing particles in the polishing container 3, then install the thin-film lithium niobate optical waveguide chip 8 to be polished on the chip holder 5, and immerse it in the rough polishing solution 61, and start magnetic stirring Stage 2, drives the magnetic rotor 7 to rotate at a high speed to stir the rough polishing solution 61, so that the rough polishing solution 61 flows into contact with the surface of the lithium niobate chip 8 to be polished, and the rough polishing particles in the rough polishing solution 61 and the niobate thin film to be polished The surface of the lithium optical waveguide chip 8 is in semi-contact and sliding contact, and the alkaline ions in the polishing solvent of the rough polishing solution 61 react chemically with the surface of the thin-film lithium niobate optical waveguide chip 8 to be polished. Chemical etching and flow erosion along the direction par...

Embodiment 2

[0038] Add a rough polishing solution 61 with a diameter of silicon oxide polishing particles of 650 nm in the polishing container 3, then install the thin-film lithium niobate optical waveguide chip 8 to be polished on the chip holder 5, and immerse it in the rough polishing solution 61, and start magnetic stirring Stage 2, drives the magnetic rotor 7 to rotate at a high speed to stir the rough polishing solution 61, so that the rough polishing solution 61 flows into contact with the surface of the lithium niobate chip 8 to be polished, and the rough polishing particles in the rough polishing solution 61 and the niobate thin film to be polished The surface of the lithium optical waveguide chip 8 is in semi-contact and sliding contact, and the alkaline ions in the polishing solvent of the rough polishing solution 61 react chemically with the surface of the thin-film lithium niobate optical waveguide chip 8 to be polished. Chemical etching and flow erosion along the direction pa...

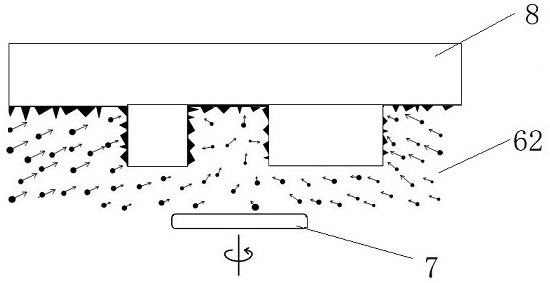

Embodiment 3

[0041] Add a rough polishing solution 61 with a diameter of silicon oxide polishing particles of 850 nm in the polishing container 3, then install the thin-film lithium niobate optical waveguide chip 8 to be polished on the chip holder 5, and immerse it in the rough polishing solution 61, and start magnetic stirring Stage 2, drives the magnetic rotor 7 to rotate at a high speed to stir the rough polishing solution 61, so that the rough polishing solution 61 flows into contact with the surface of the lithium niobate chip 8 to be polished, and the rough polishing particles in the rough polishing solution 61 and the niobate thin film to be polished The surface of the lithium optical waveguide chip 8 is in semi-contact and sliding contact, and the alkaline ions in the polishing solvent of the rough polishing solution 61 react chemically with the surface of the thin-film lithium niobate optical waveguide chip 8 to be polished. Chemical etching and flow erosion along the direction pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com