Patents

Literature

35results about How to "The process device is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

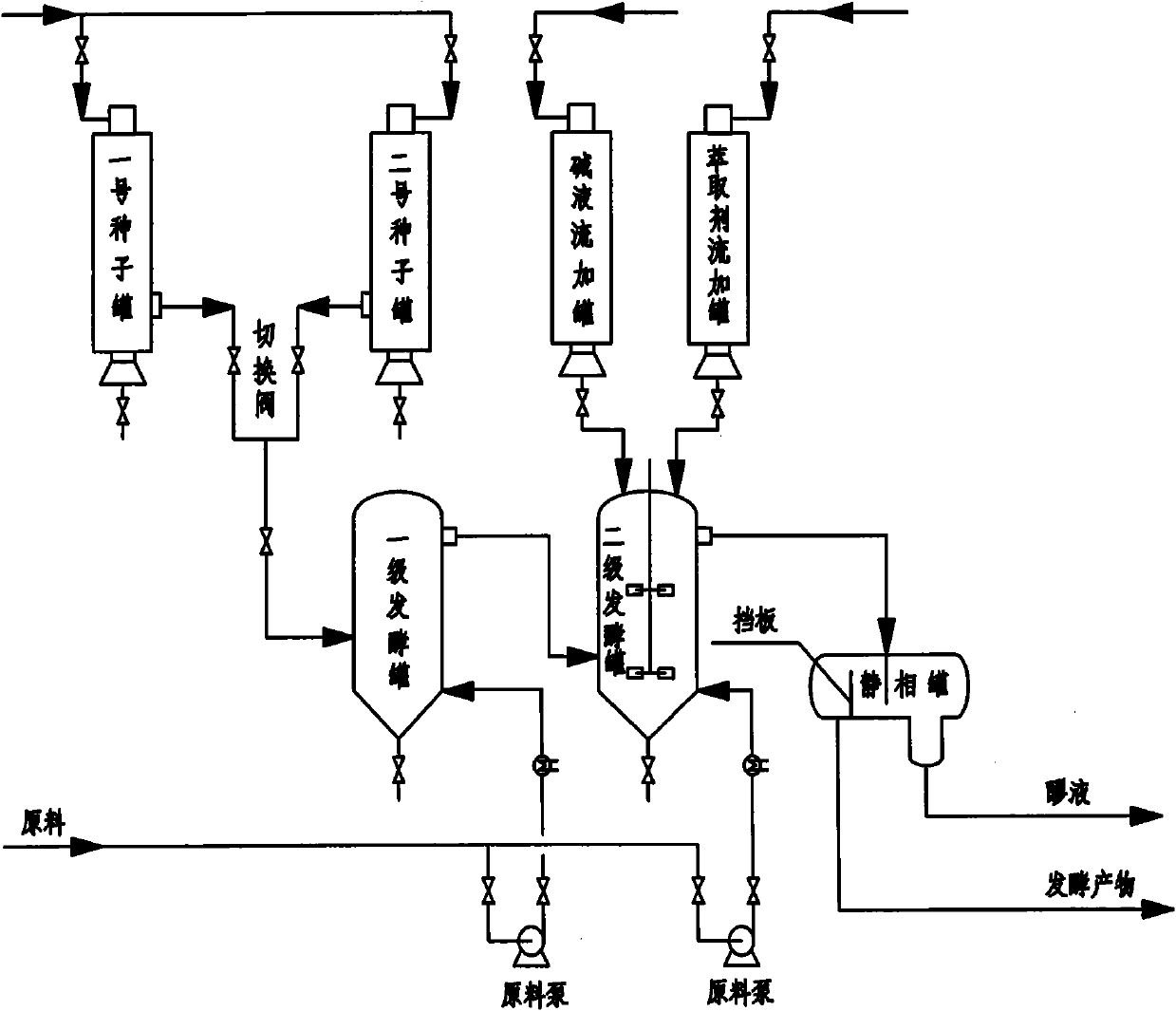

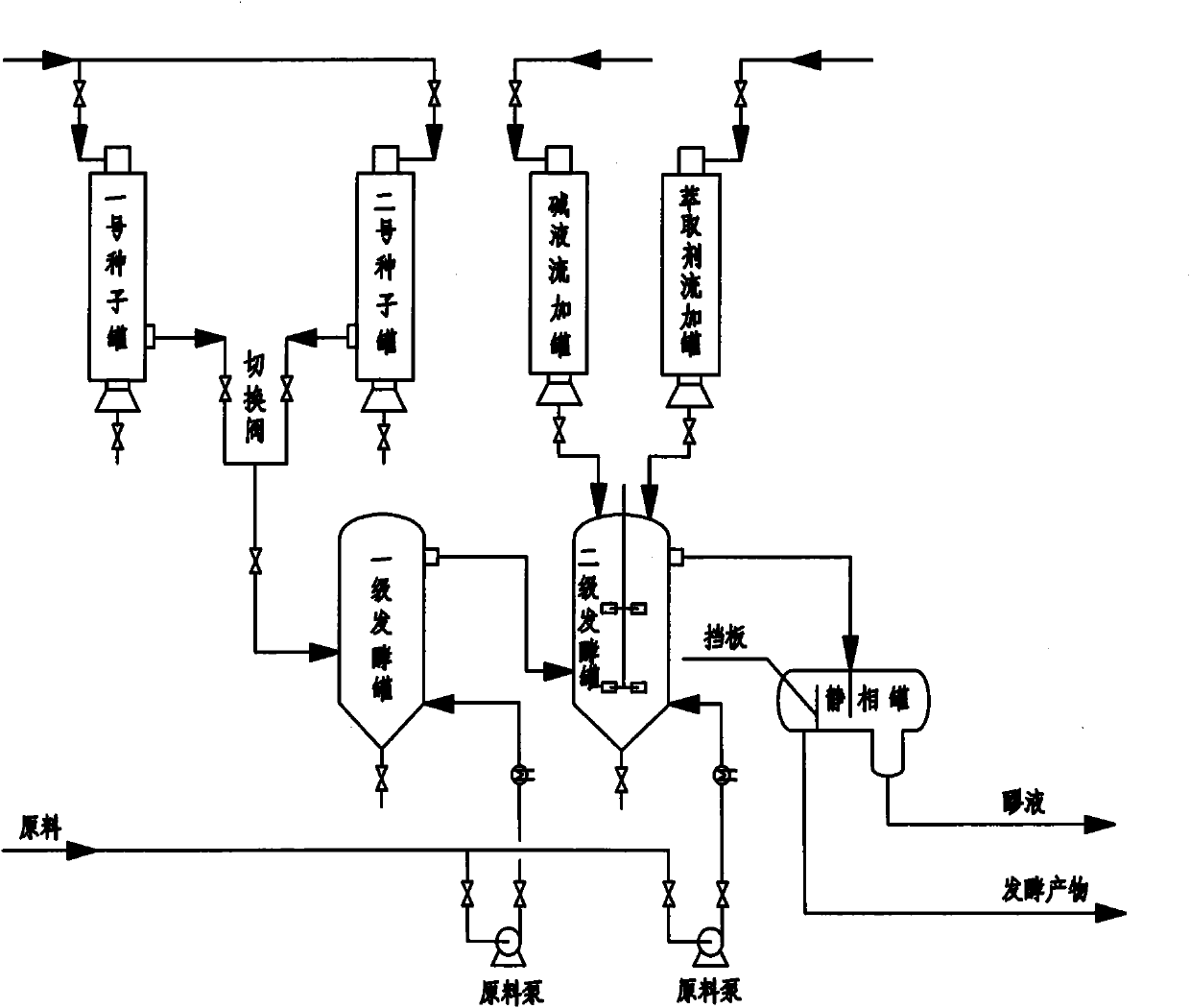

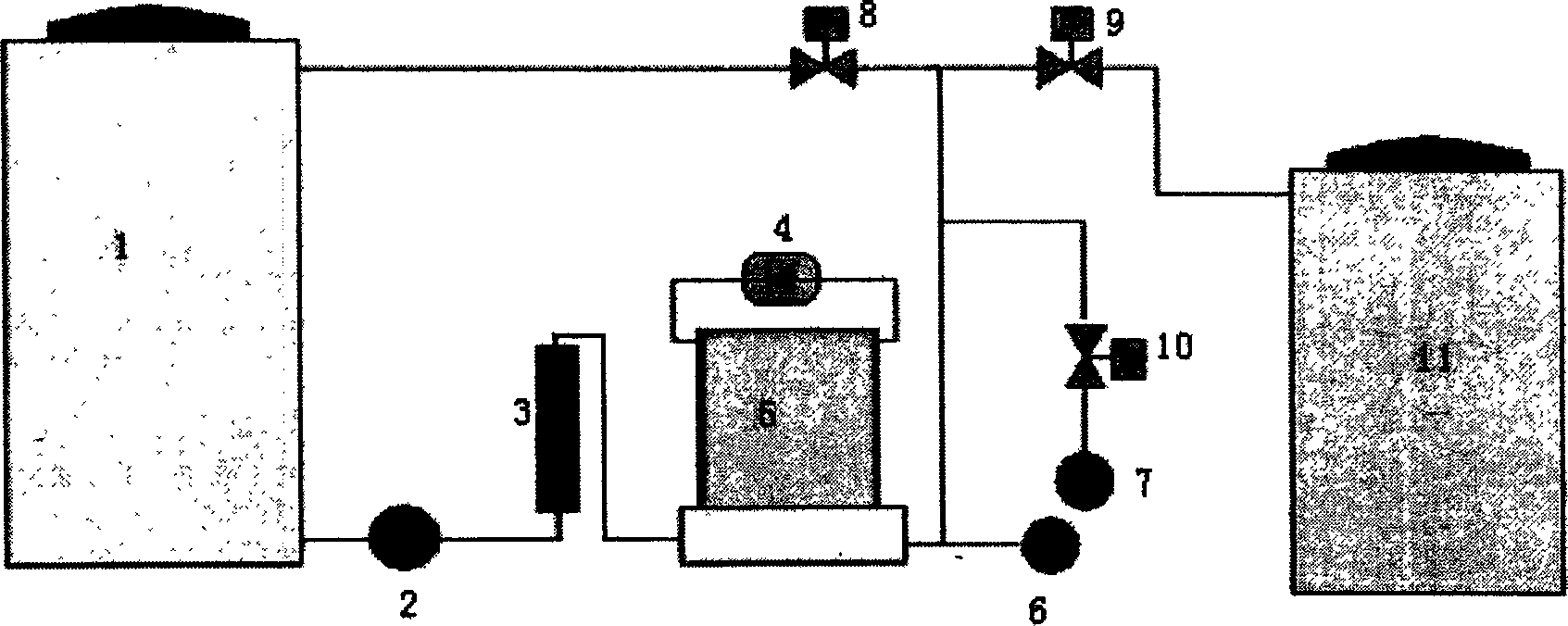

Acetone-butanol in-situ extraction continuous fermentation device and technology

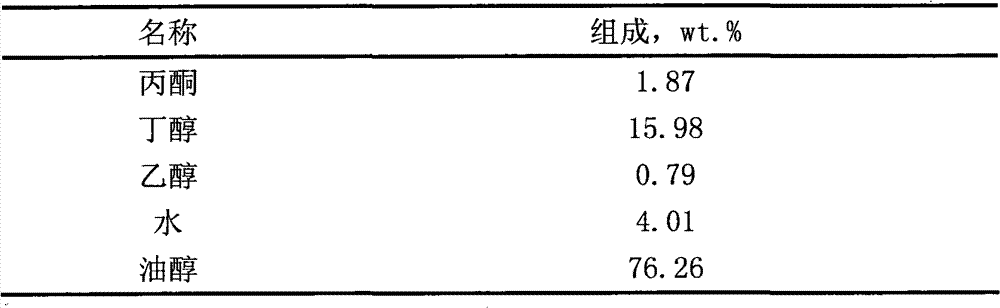

InactiveCN101948737AEasy to implementBroad application prospectsBioreactor/fermenter combinationsBiological substance pretreatmentsButanolChemistry

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

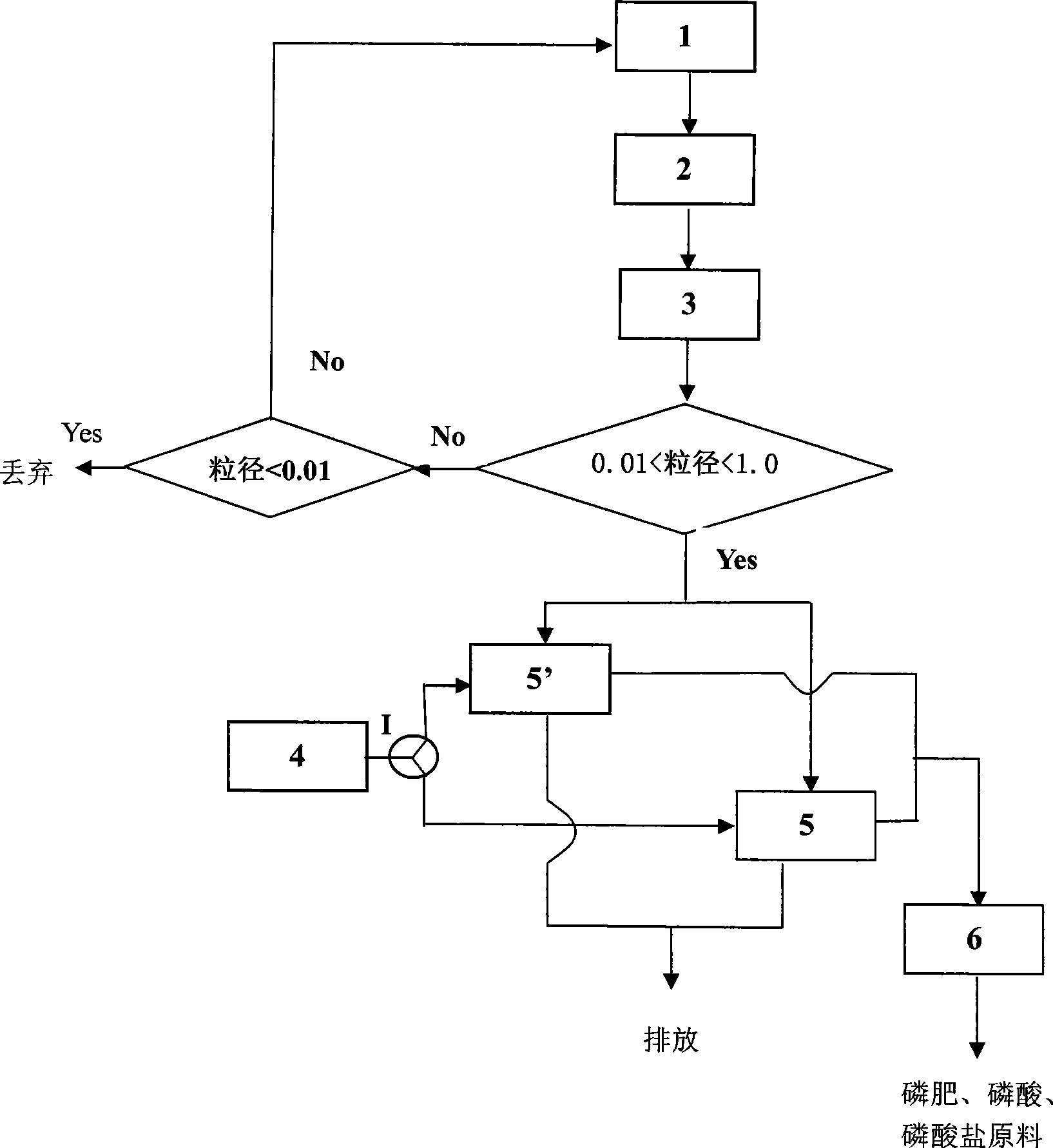

Method for removing phosphor-containing wastewater by using fly ash aerated concrete slag

InactiveCN101475253AAchieve the purpose of recyclingThe process device is simpleWater/sewage treatment by sorptionSlagResource utilization

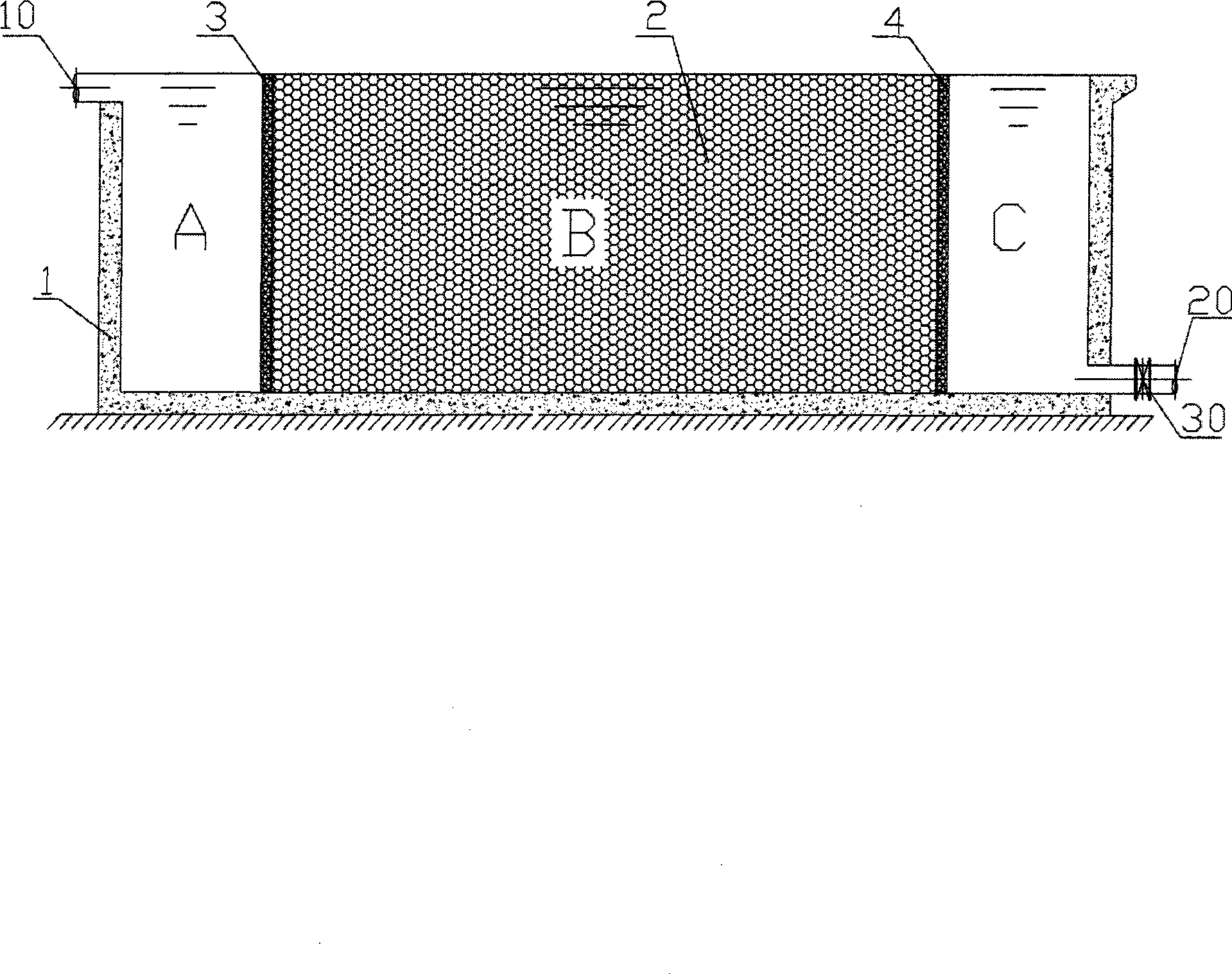

The invention discloses a method for removing phosphorus in phosphorous wastewater through broken slag of building waste such as waste fly ash aerated concrete blocks. After treatment, the removing rate of the phosphorus can reach over 99 percent. The fly ash aerated concrete blocks are crushed to form the broken slag having the particle diameter of between 0.01 and 1.0 mm; and the broken slag is filled in equipment with a similar sand filter structure to form a phosphorus filter. As fly ash aerated concrete has the property of high-efficiency adsorption to the phosphorous, the phosphorous in the wastewater is continuously adsorbed and removed when the phosphorous wastewater passes through the phosphorus filter; the content of the phosphorus in the adsorbed saturated broken slag reaches as high as 34.85 percent (be equivalent to 79 percent of P2O5); and the broken slag can be used as a slow-release phosphate fertilizer for application or a high-quality raw material for preparing phosphoric acid and phosphate. The method has a simple process and easy implementation, can remove pollution of the phosphorus of the wastewater to environment, can perform resource utilization of the phosphorus in the waste fly ash aerated concrete blocks and the wastewater, uses waste to treat waste, and is environment-friendly.

Owner:深圳龙澄高科技环保股份有限公司

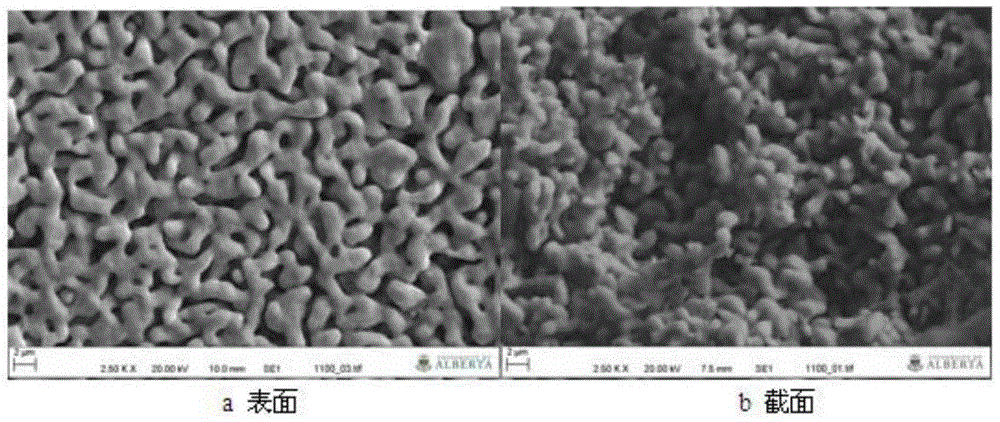

Film lithium niobate optical waveguide chip polishing device and polishing method thereof

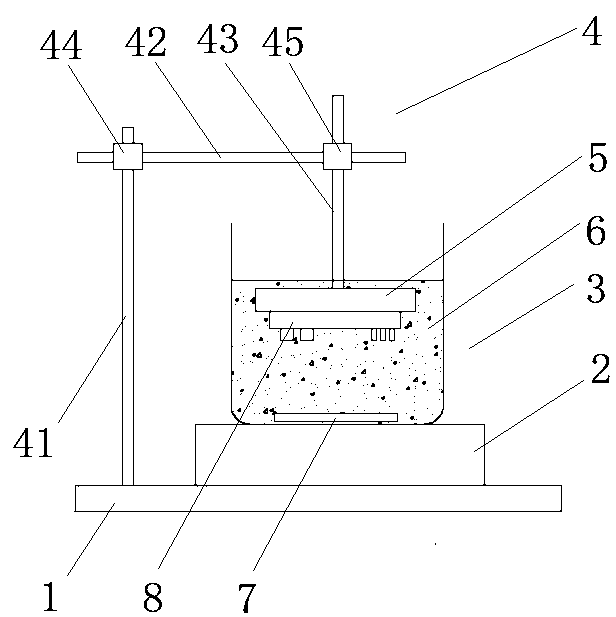

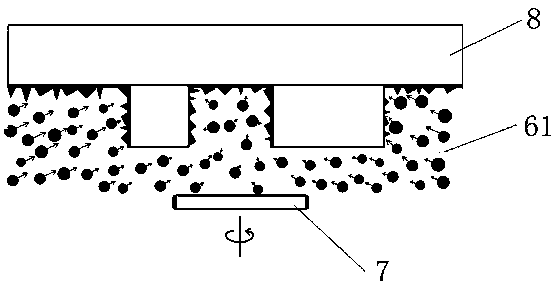

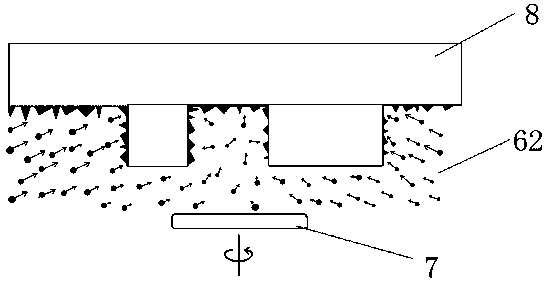

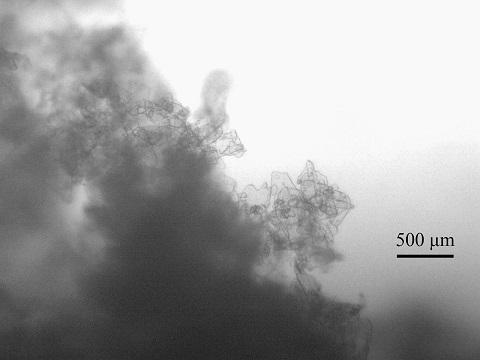

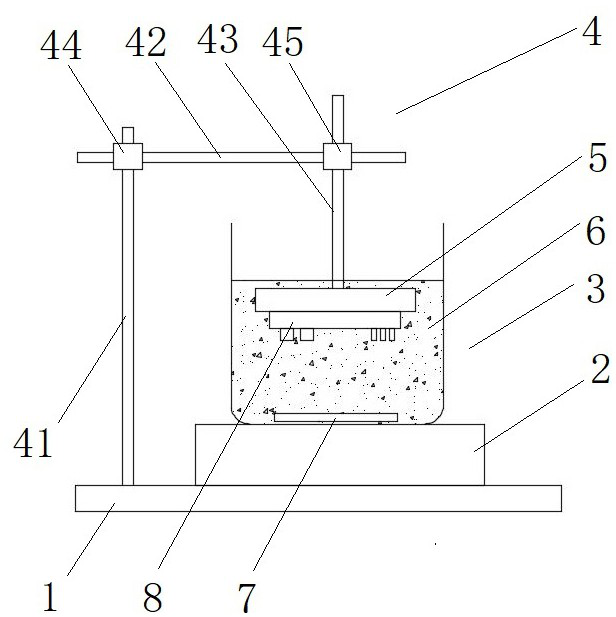

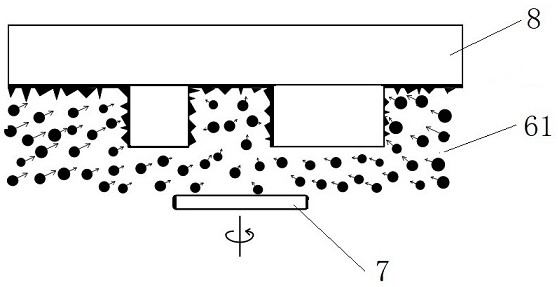

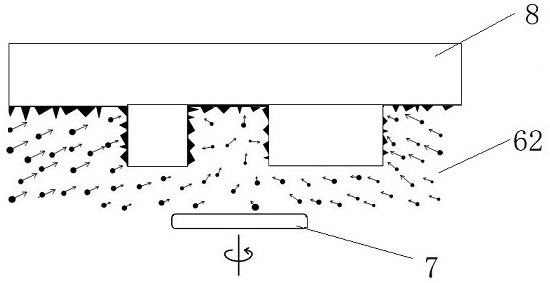

The invention provides a film lithium niobate optical waveguide chip polishing device and a polishing method thereof. A magnetic stirring table is used for driving a magnetic rotor to rotate in a polishing solution, then the polishing solution is stirred to generate flowing contact with the surface of a chip, polishing particles in the polishing solution generate half contact or sliding contact with the surface of the chip subjected to dry etching, slight particle bombardment is associated, meanwhile, alkali ions in a polishing solvent and the etched surface generate a chemical etching reaction, chemical etching and particle bombardment in the direction parallel to the etched surface are achieved through instant stirring of the polishing solution, then etching products deposited on the dryetched surface and spikes and protrusions generated by dry etching are removed, and the effect that the etched surface and the waveguide side wall are smooth is achieved. Compared with traditional contact type mechanical grinding and polishing and chemical-mechanical grinding methods, the device and the method have the advantages that the structure is simple, operation is simple and convenient, cost is low, and surface damage is small.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

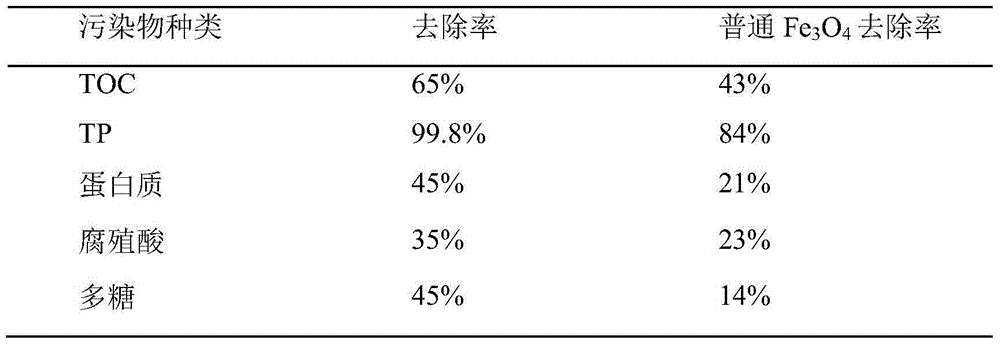

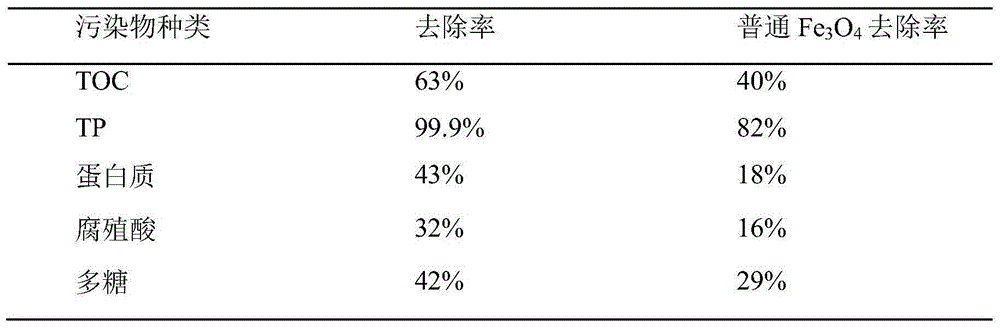

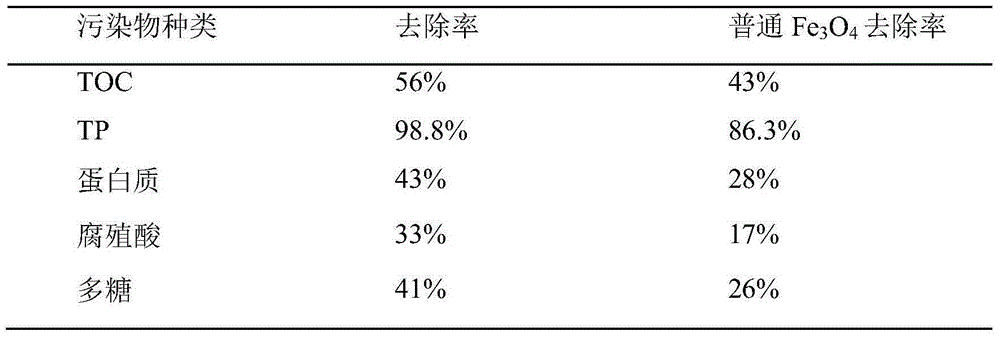

Novel magnetic nano magnetic seed and the method and application thereof in treating industrial biochemical tail water

ActiveCN105217695AEasy to prepareLarge specific surface areaWater/sewage treatment by magnetic/electric fieldsInorganic material magnetismSuperparamagnetismOrganic matter

The invention discloses a novel magnetic nano magnetic seed and the method and application thereof in treating industrial biochemical tail water, and belongs to the field of industrial wastewater advanced treatment. The invention utilizes a hydrothermal method to prepare Fe3O4 nano particles with superparamagnetism; and the Fe3O4 nano particles are covered by SiO2 and grafted with -NH2 groups to prepare Fe3O4@SiO2-NH2 as a magnetic seed. The magnetic seed, a coagulant and a coagulant aid are added to the secondary industrial wastewater, stirred and mixed; the coagulated wastewater is placed in a magnetic field; and under the action of magnetic field force, the flocculation with magnetic seeds is quickly separated from the wastewater being treated. The method has the advantages of convenient operation and simple device, can effectively reduce the organic substances in secondary industrial wastewater; compared to a traditional chemical coagulation method, the method has greatly reduced settlement time; compared with the existing coagulation and magnetic separation method, the method has higher removal efficiency, and greatly reduced amount of sediment; therefore, the invention has relatively broad application prospects in depth processing of industrial wastewater.

Owner:NANJING UNIV

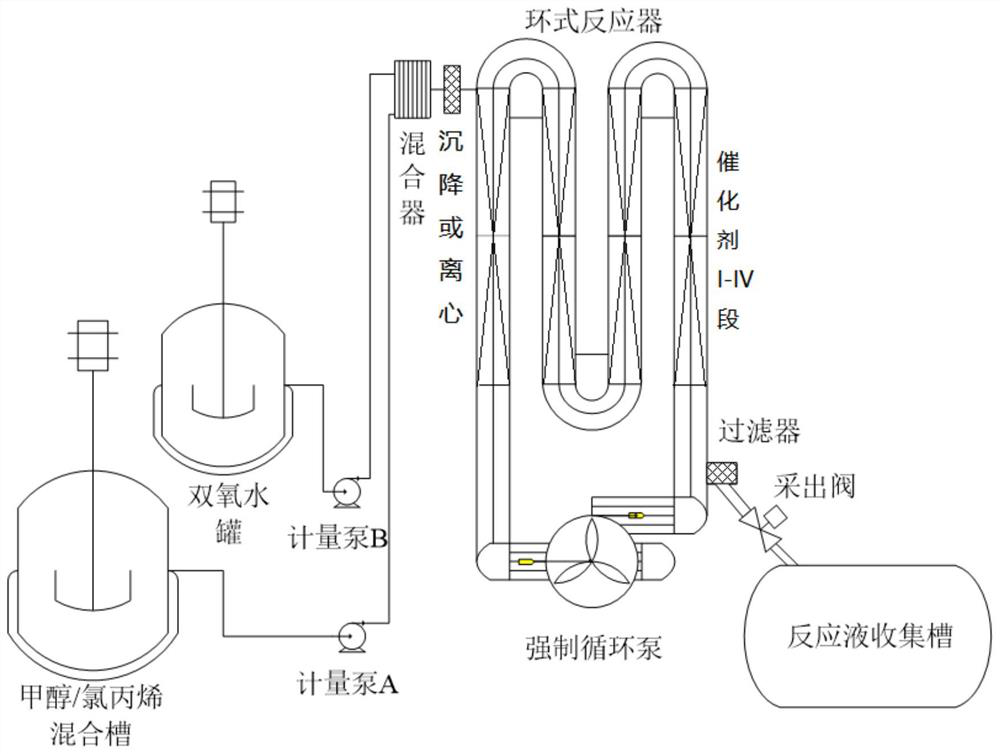

Continuous synthesis process of epoxy chloropropane by hydrogen peroxide method

PendingCN111978273AAchieve separationHigh selectivityOrganic chemistryPtru catalystProcess engineering

The invention provides a continuous synthesis process of epoxy chloropropane by hydrogen peroxide method. The continuous synthesis process comprises the following steps of adding hydrogen peroxide, methanol, chloropropene and a catalyst into a reactor for epoxidation reaction, wherein the reactor is a ring reactor, and the catalyst is pre-loaded into the ring reactor; enabling the chloropropene and the methanol to form a chloropropene and methanol mixed solution in a mixing tank, pumping chloropropene and methanol mixed solution into the ring reactor by a metering pump A, and pumping hydrogenperoxide into the ring reactor by a metering pump B. The synthesis process provided by the invention has the advantages of low methanol consumption, long service life of the catalyst, simple process device, realization of continuous operation, and realization of stable hydrogen peroxide conversion rate and high epichlorohydrin selectivity in a long-term continuous operation process.

Owner:JIANGSU YANGNONG CHEM GROUP +2

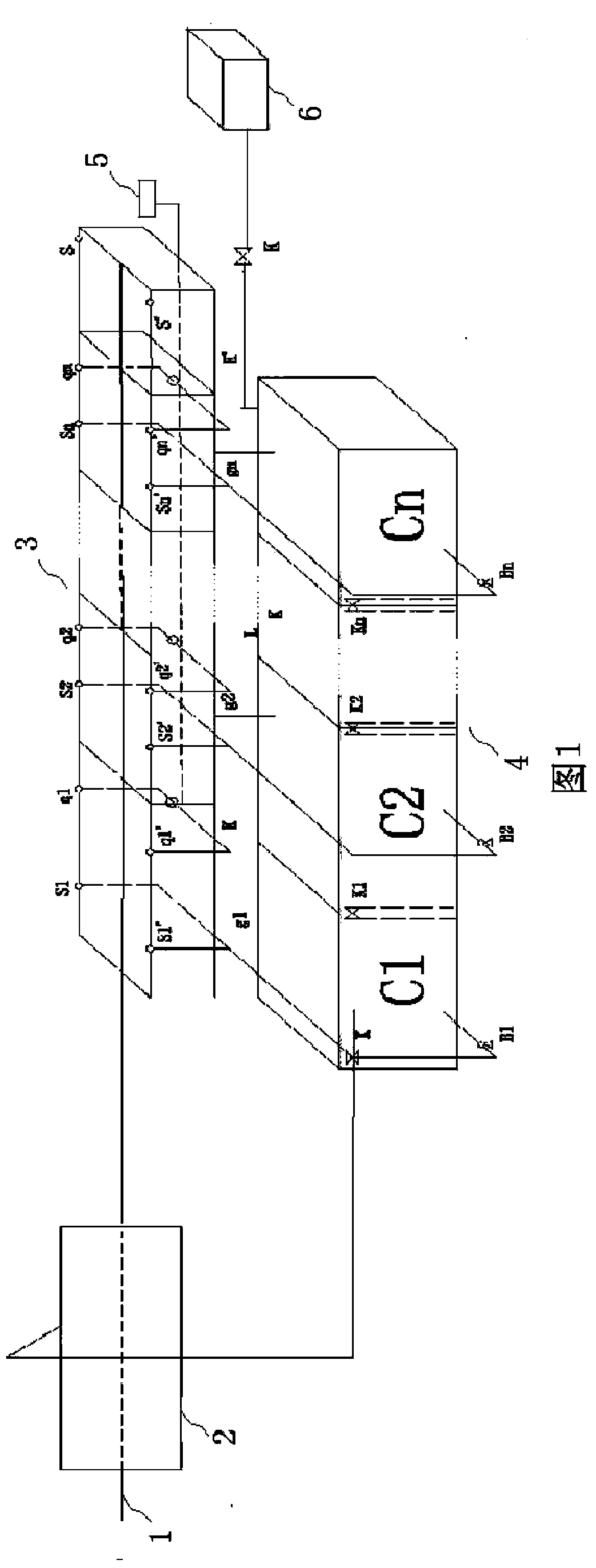

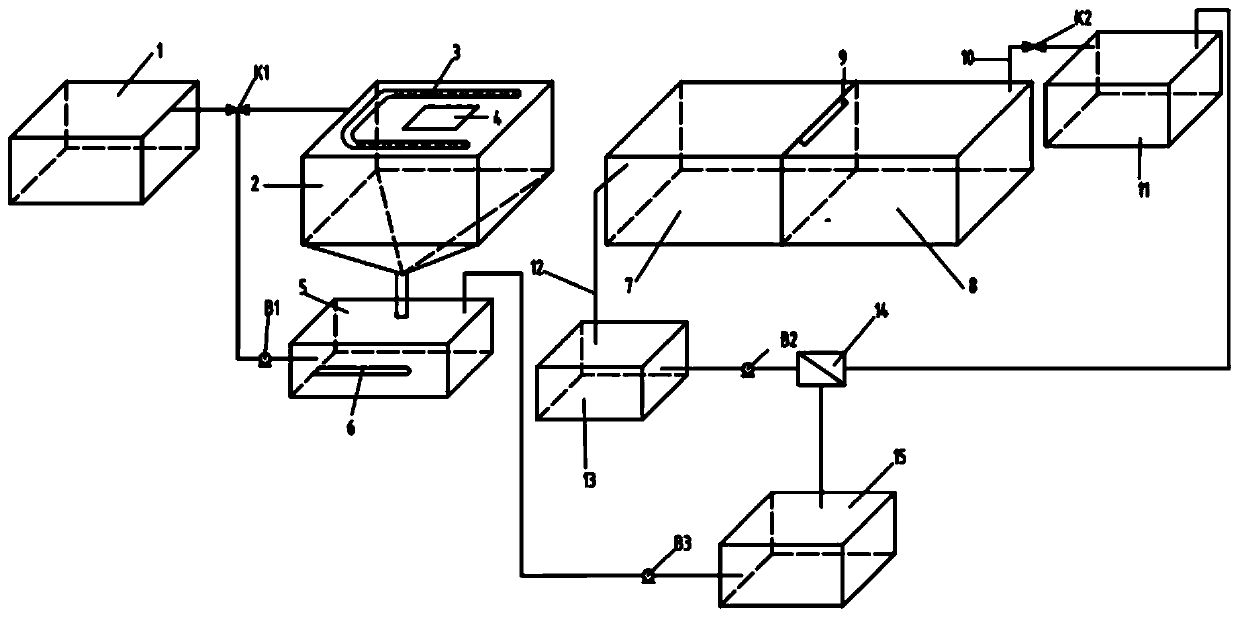

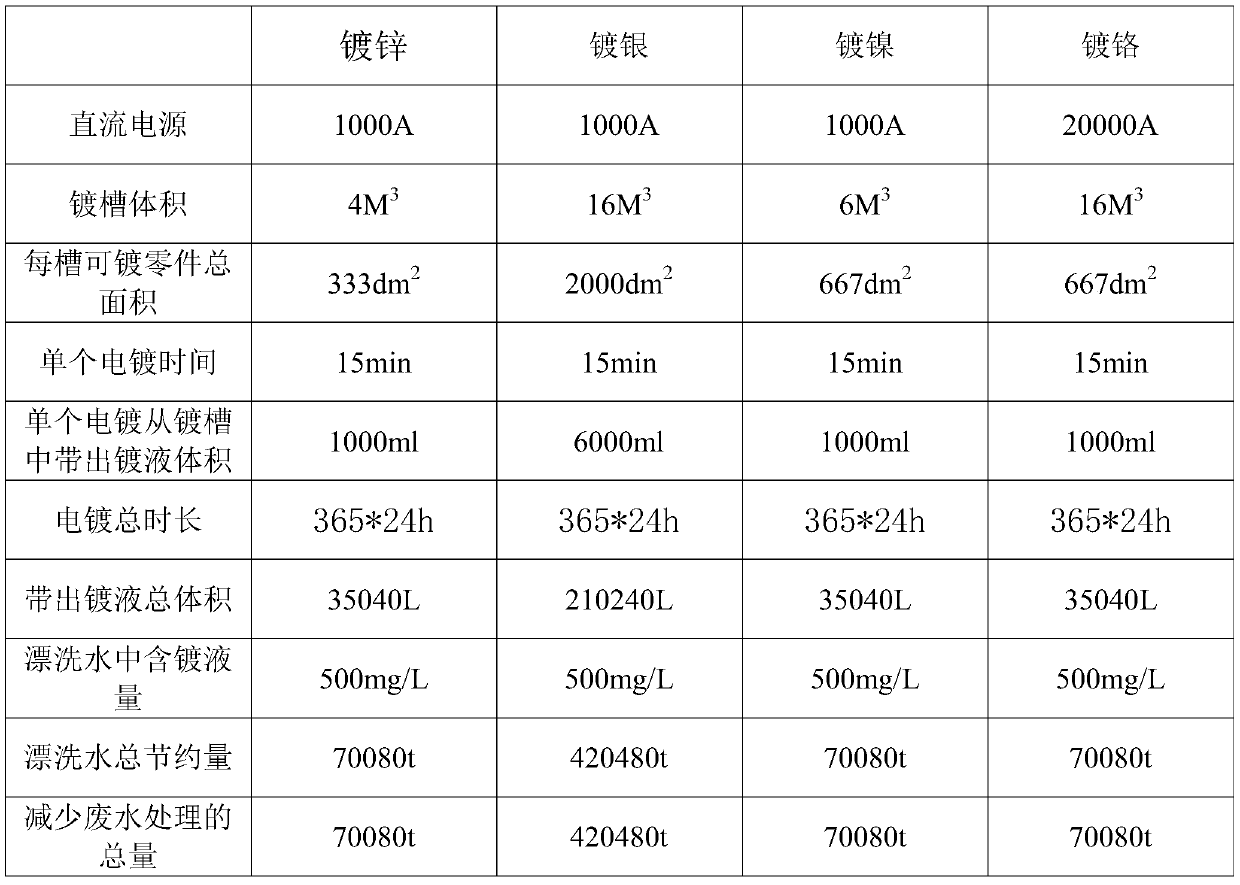

Device for recycling electro-plating spraying cleaning liquid

InactiveCN103952751AThe process device is simpleReduce energy consumptionCellsProduction lineSpray nozzle

The invention relates to an electro-plating wastewater treatment method, and in particular relates to a device for recycling electro-plating spraying cleaning liquid. The device comprises a plurality of circulating cleaning systems arranged along a production line, wherein the circulating cleaning systems are sequentially cascaded in series along the production line; each circulating cleaning system comprises a spraying cleaning tank, a spray nozzle and a pump; the spray nozzle is fixed on the spraying cleaning tank, and is connected with the pump by virtue of a pipeline; each stage of circulating cleaning systems is connected with a corresponding cleaning and rinsing liquid recycling system; the pump is connected with the cleaning and rinsing liquid recycling system. The electro-plating spraying cleaning liquid can be recycled by adopting the structure. The process is simple in device, has power equipment only including a circulating pump, is low in energy consumption, easy in equipment maintenance and management, low in running cost and less in one-time investment, can be used for recycling a plating solution brought out from a plating slot and saving a great number of rinsing water, and can be applied to enterprises having continuous electro-plating production lines.

Owner:NANJING UNIV OF TECH

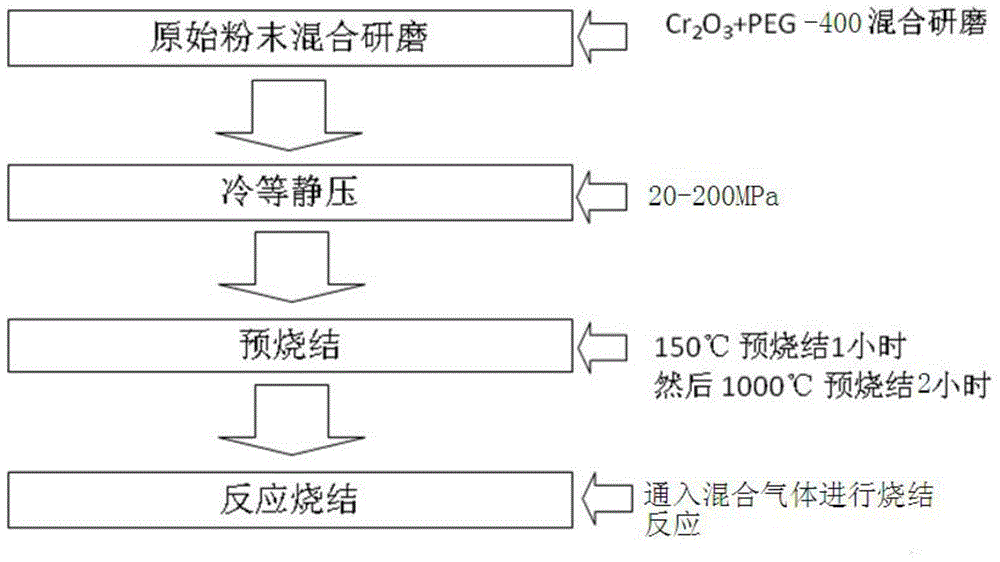

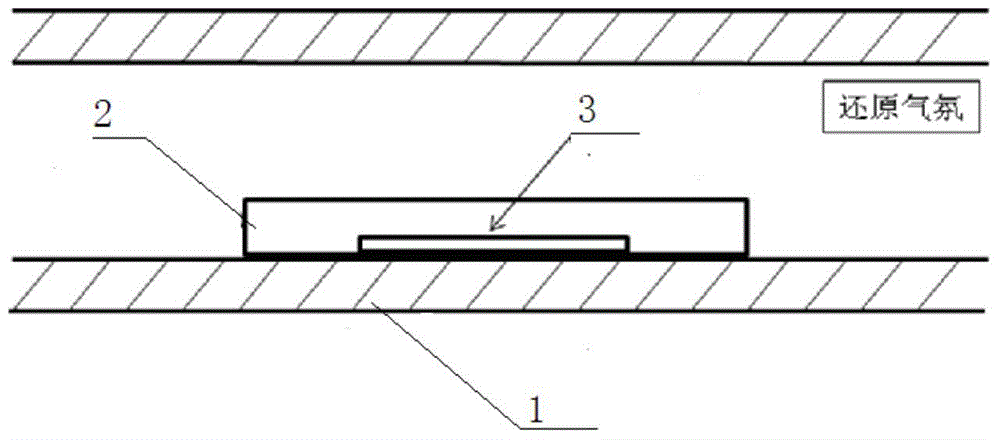

Method for preparing porous chromium carbide by using reaction sintering process

The invention relates to a method for preparing porous chromium carbide by using a reaction sintering process. The method comprises the following steps: adding chromic oxide powder into alumina balls; grinding for 10 hours through a ball mill till the powder is uniform; adding a binder PEG-400 (Polyethylene Glycol) and uniformly mixing; pressing the uniformly mixed powder in a die to form a blank by an isostatic cool pressing method; placing the blank in a vacuum tubular furnace; sintering for 1 hour at 150 DEG C and then heating to 1000 DEG C and sintering for 2 hours; introducing a mixed gas; and sintering for 10-20 hours at 1000-1300 DEG C to obtain a chromium carbide ceramic block material in a macroporous form. In order to prevent oxidization of porous chromium carbide at a high temperature, argon is intruded in the cooling process to chieve a protection function. According to the method provided by the invention, macroporous chromium carbide block materials in various shapes can be obtained. The method has strong operability and controllability to a microstructure of the porous material. Compared with conventional method, the method is simple, easy in forming and applicable to industrial preparation of porous ceramics.

Owner:UNIV OF SCI & TECH BEIJING

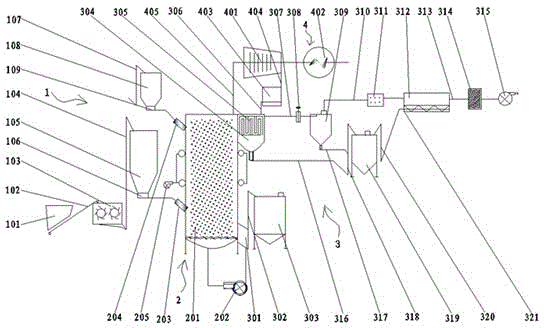

Waste electric appliance circuit board energy regeneration innocent treatment system

ActiveCN104633675AThe process device is simpleAccurate processingIncinerator apparatusCombined combustion mitigationAutomatic controlPre treatment

A waste electric appliance circuit board energy regeneration innocent treatment system comprises a pretreatment device, an alkalization incinerator, a multi-metal and oxide recycling and smoke purifying device, a recycled heat energy generating set and an electrical automatic control device. The pretreatment device is connected with the alkalization incinerator, the alkalization incinerator is connected with the multi-metal and oxide recycling and smoke purifying device and the recycled heat energy generating set, and the electrical automatic control device is connected with the pretreatment device, the alkalization incinerator, the multi-metal and oxide recycling and smoke purifying device and the recycled heat energy generating set. The technological devices are relatively simple, accurate in treatment, low in investment, low in operation power consumption and low in operation cost due to water utilization treatment; by means of the devices, resources can be fully utilized, and secondary pollution is avoided.

Owner:长沙紫宸科技开发有限公司 +1

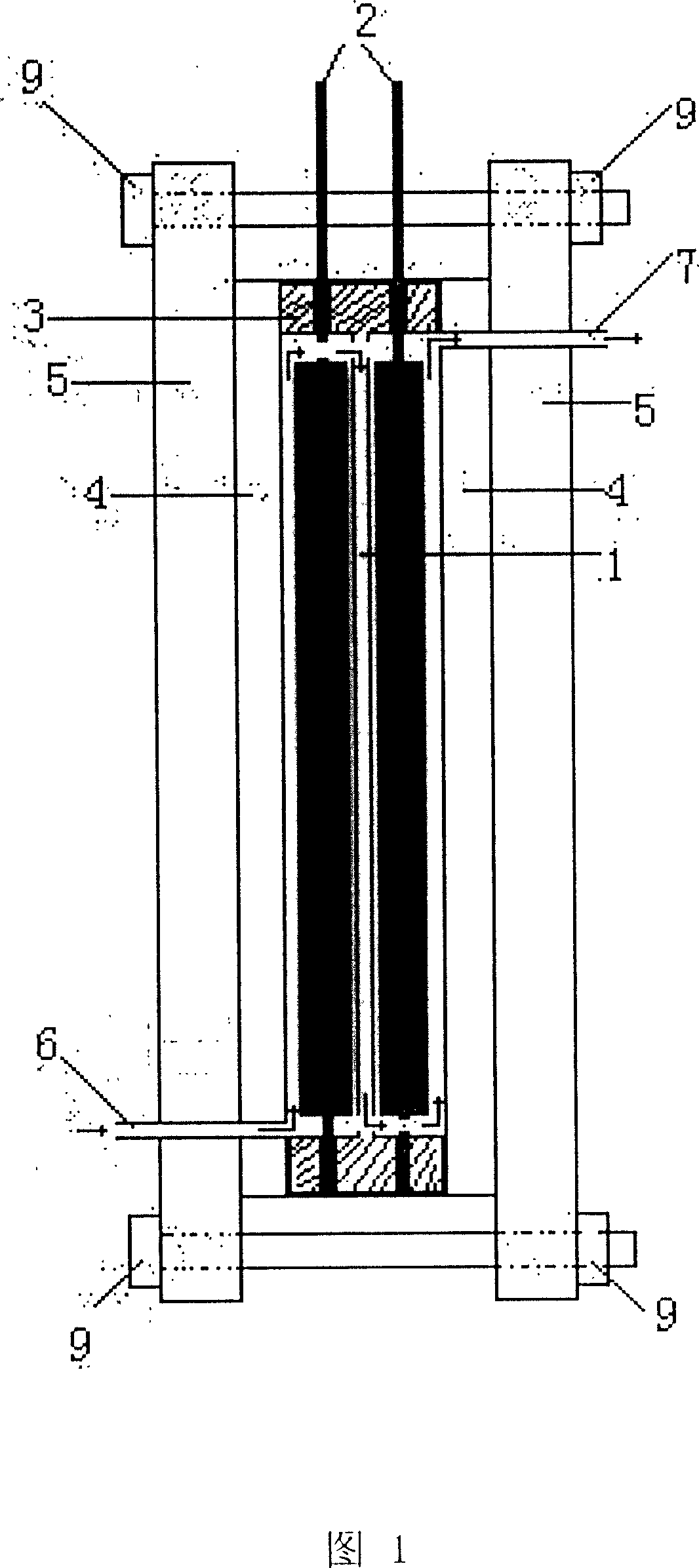

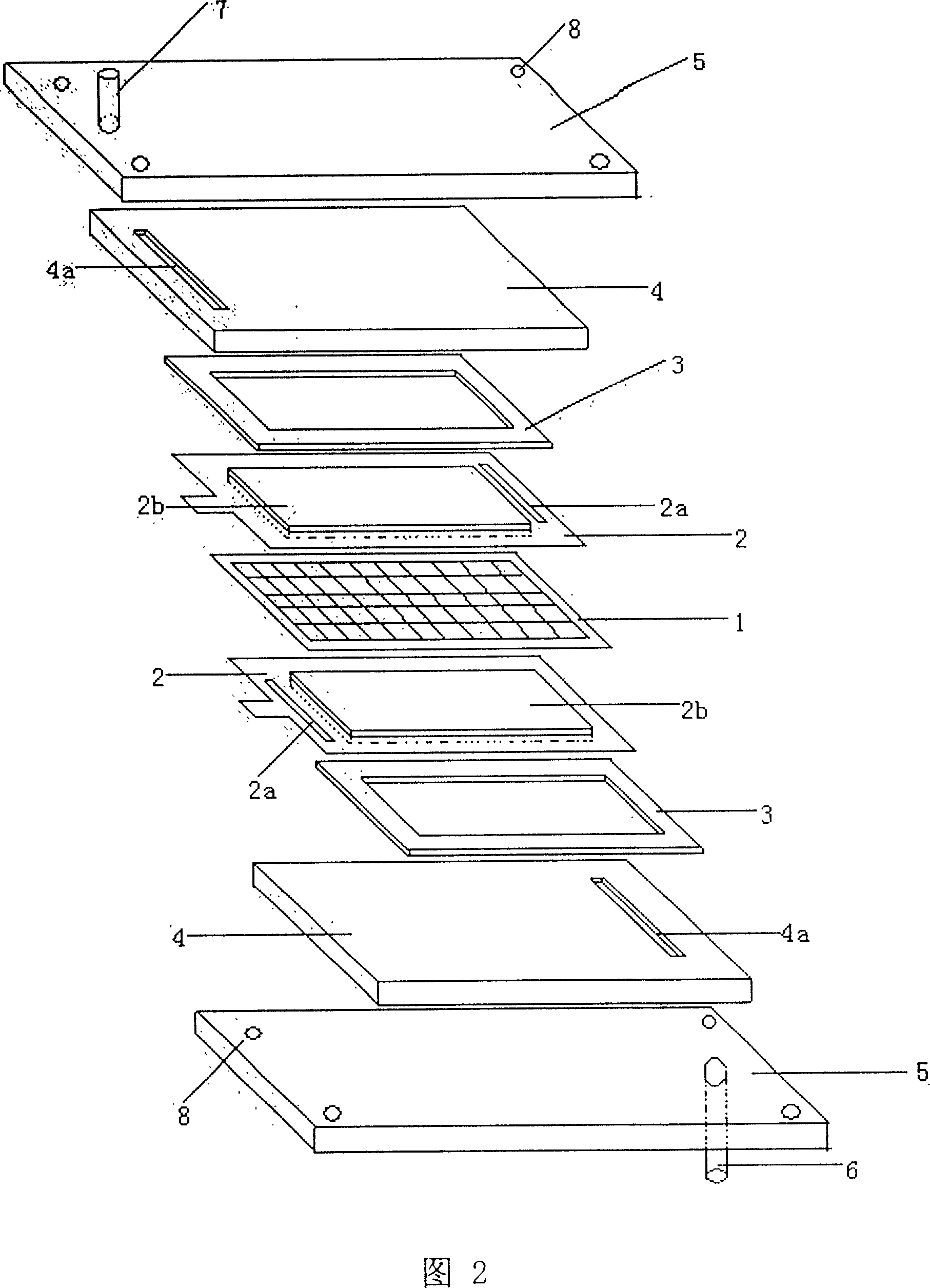

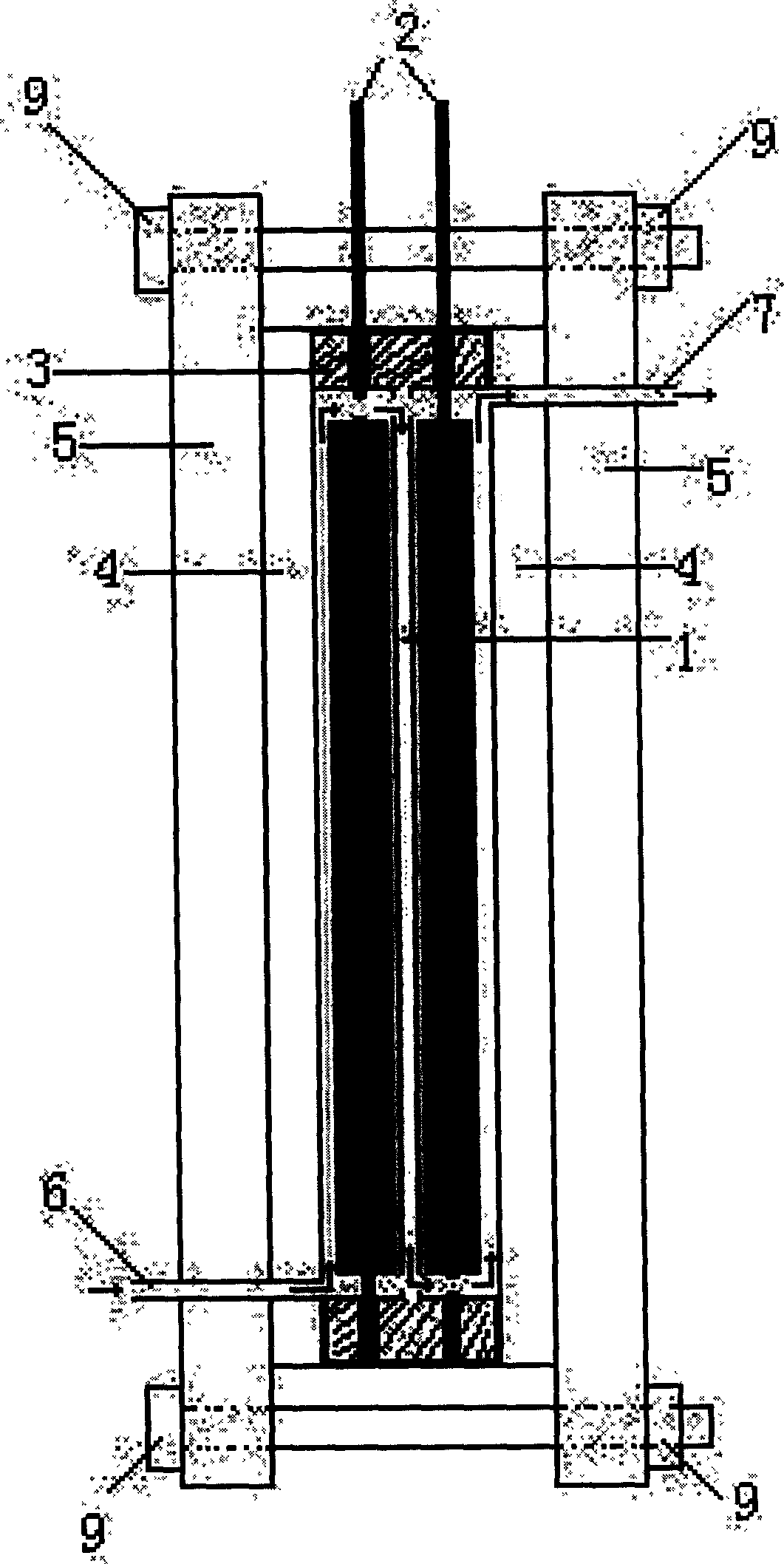

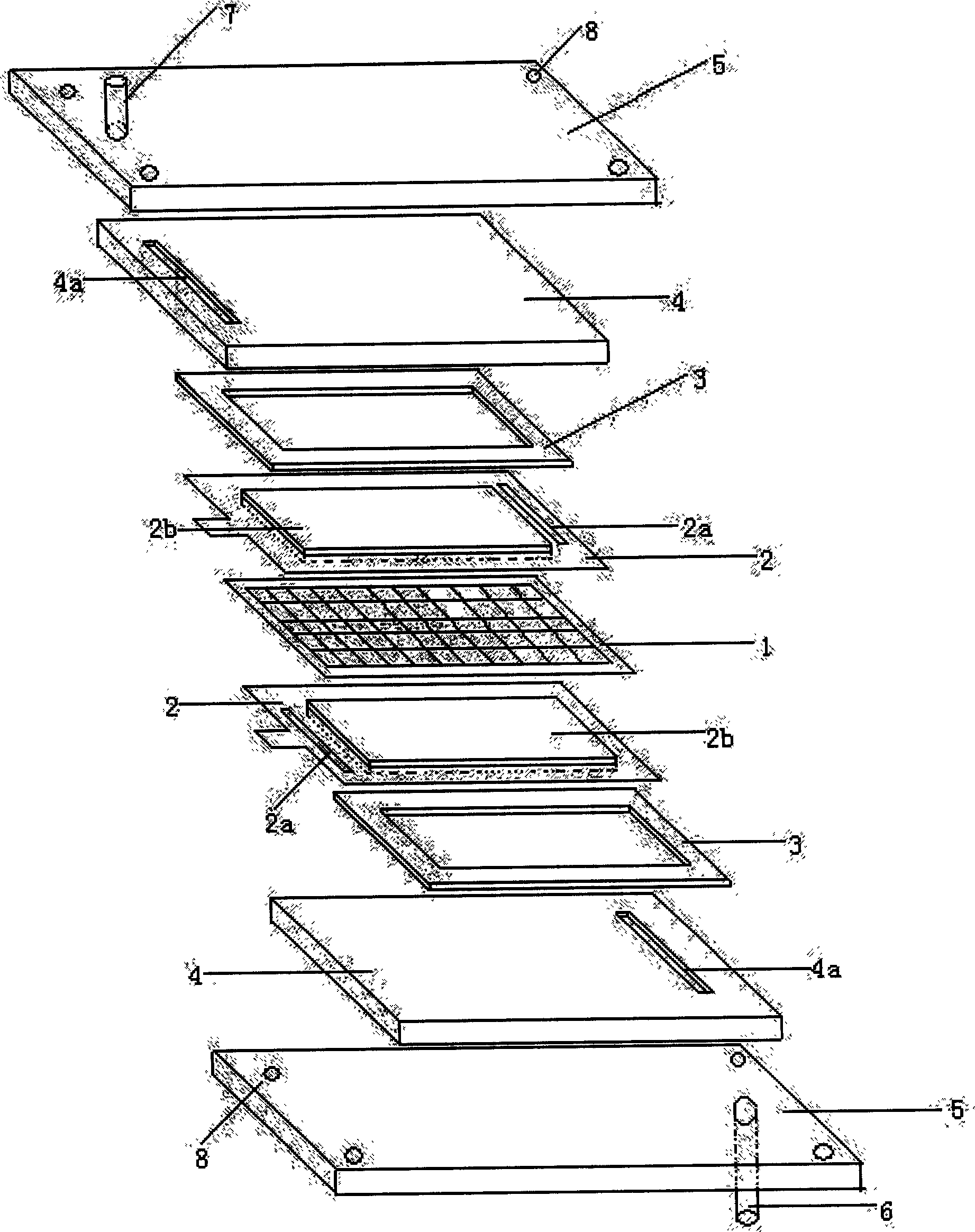

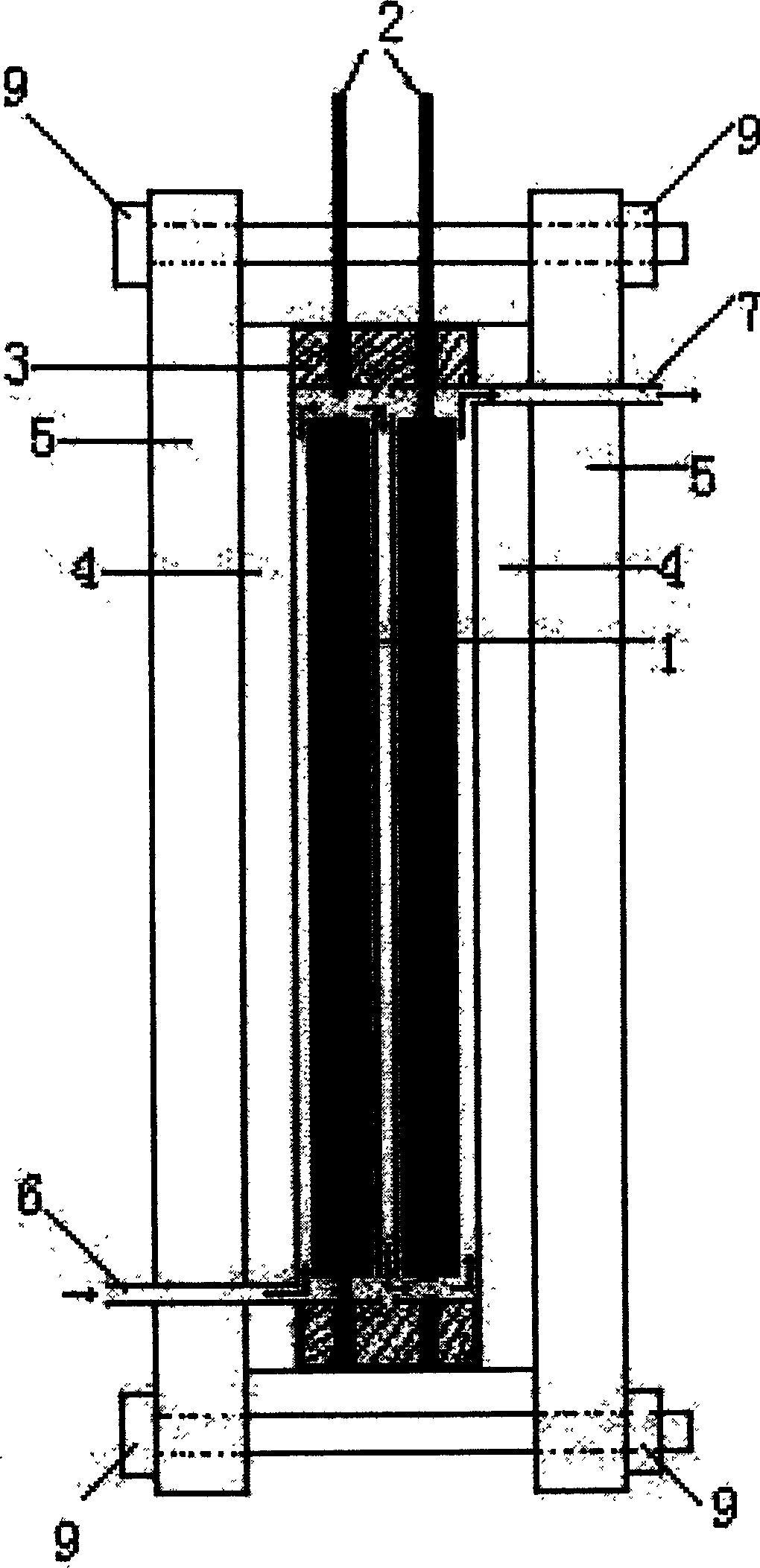

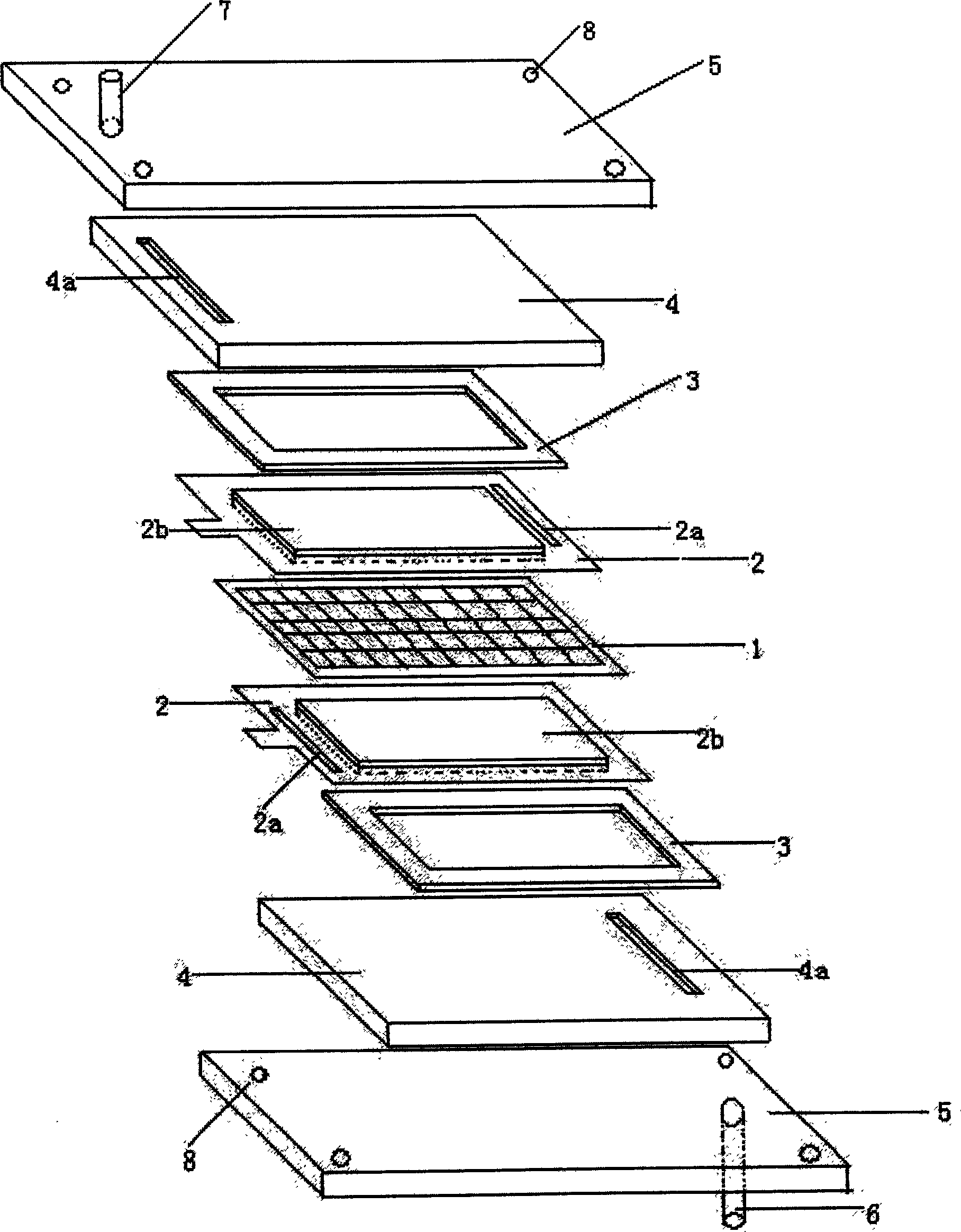

Liquid flow type sea water desalting plant in capacitance model and manufacturing method

ActiveCN1328182CPrevent metal corrosionThe process device is simpleSeawater treatmentDispersed particle separationCapacitanceDesalination

In the device, nanometre carbon tube is used as electrode material. The characteristics are: a couple of combination electrodes composed by nanometre tube which shared collecting electrode is in middle of its core parts of the device, there is a layer of insulate textile film is fixed between said combination electrodes, two weather board with notch are fixed at out side of said combination electrodes separately, sea water to be processed is send into water container through the notch on weather board from bottom water entrance and into upper weather board in way of circuitous liquid flow. There is an isoelectrode on and stick out the electrides, seal water-proof rubber grommers are fid on bottom and top of the water container, central core parts is fixed by steel plate frame arounding it and screwing up bolt and nut.

Owner:SHANGHAI UNIV +1

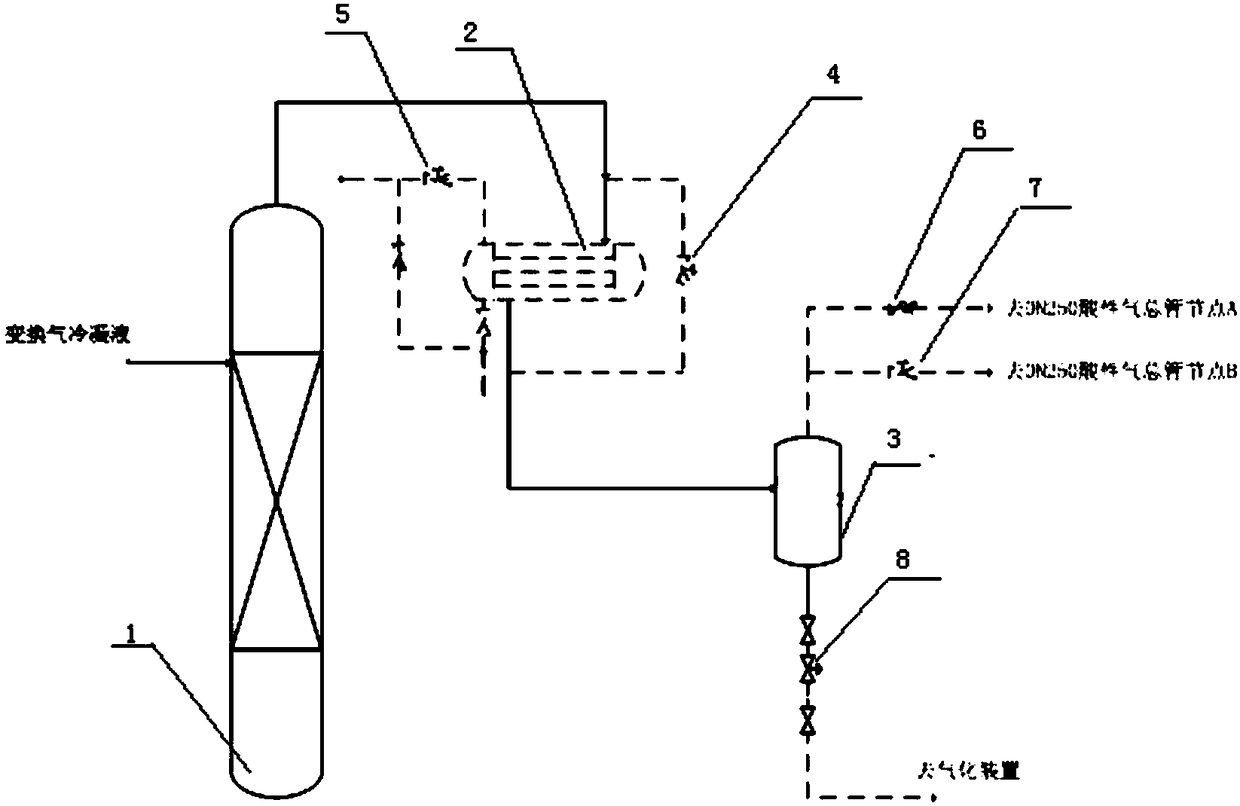

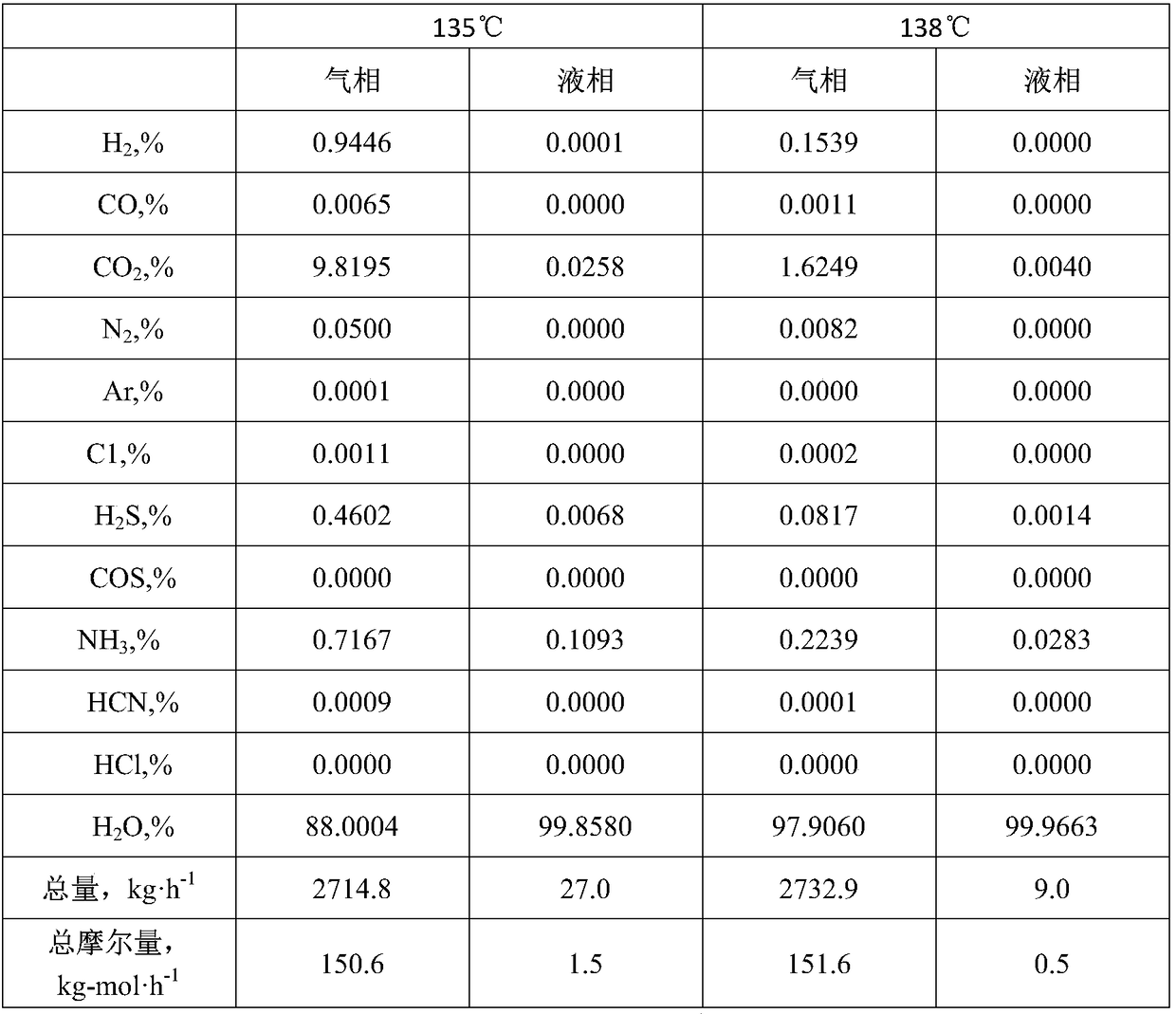

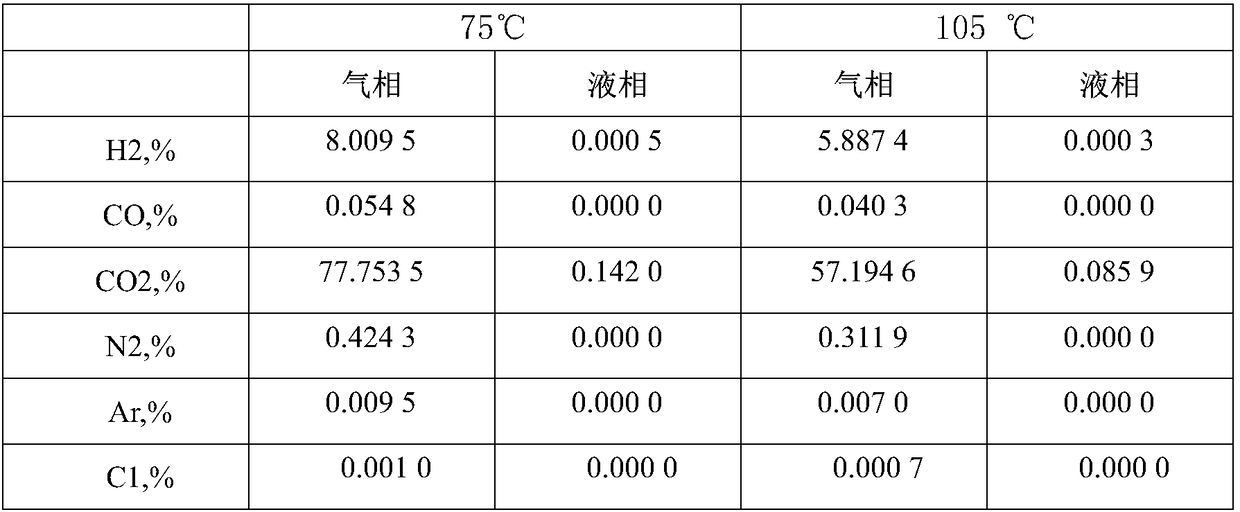

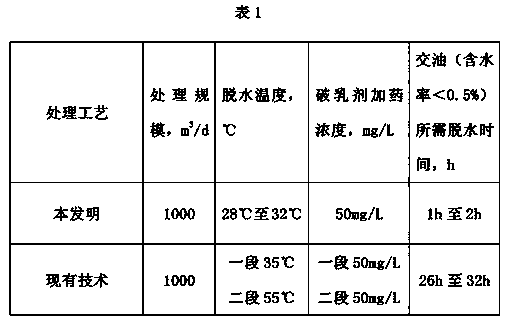

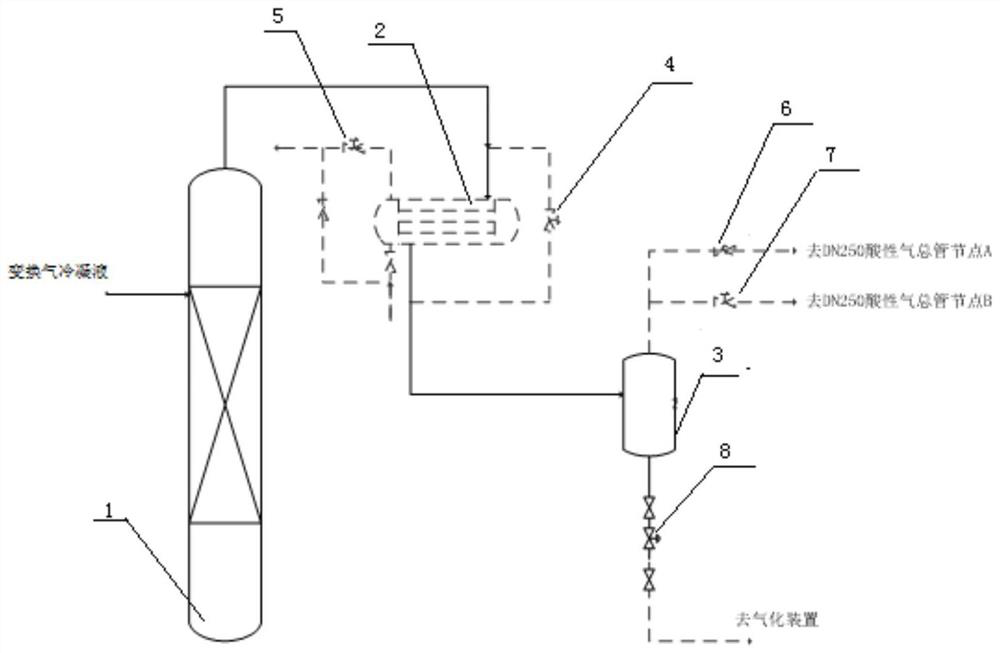

Conversion unit high ammonia nitrogen acid condensate pretreatment system and conversion unit high ammonia nitrogen acid condensate pretreatment method

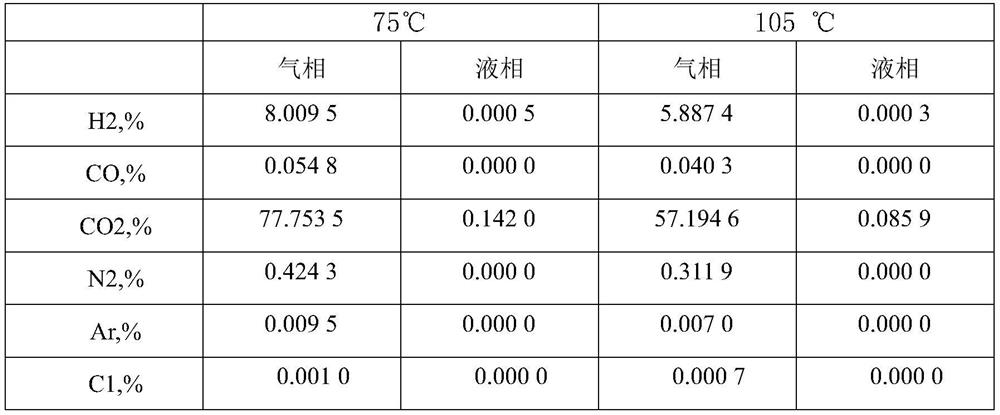

ActiveCN109381887AGood separation effectAvoid corrosionLiquid degasificationSteam distillationAmount of substanceChemistry

The invention belongs to the field of treatment of coal chemical wastewater and waste gas, and particularly relates to a conversion unit high ammonia nitrogen acid condensate pretreatment system and aconversion unit high ammonia nitrogen acid condensate pretreatment method. According to the present invention, a coal gasification conversion unit circulating water heat exchanger is replaced with adeineralized water heat exchanger, the deineralized water is used as a heat medium to recover heat and reduce the circulating water field load, the temperature of a steam stripping liquid at a separation tower inlet is raised to 100-138 DEG C, and acid condensate (containing high ammonia nitrogen) sewage wastewater is pretreated in the separation tower by using a steam-like steam stripping method,such that the dissolved gases (high ammonia nitrogen materials and the like) in the liquid phase are gasified and separated as much as possible; and the results show that the total amounts of the high ammonia nitrogen materials, the organic matters and the sulfur-containing compounds in the gas phase is greatly increased, and the liquid phase finally enters the a biochemical unit at a low total amount of less than 50 kg / h, such that the treatment load of the biochemical unit is achieved so as to ensure the standard discharge after the biochemical treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

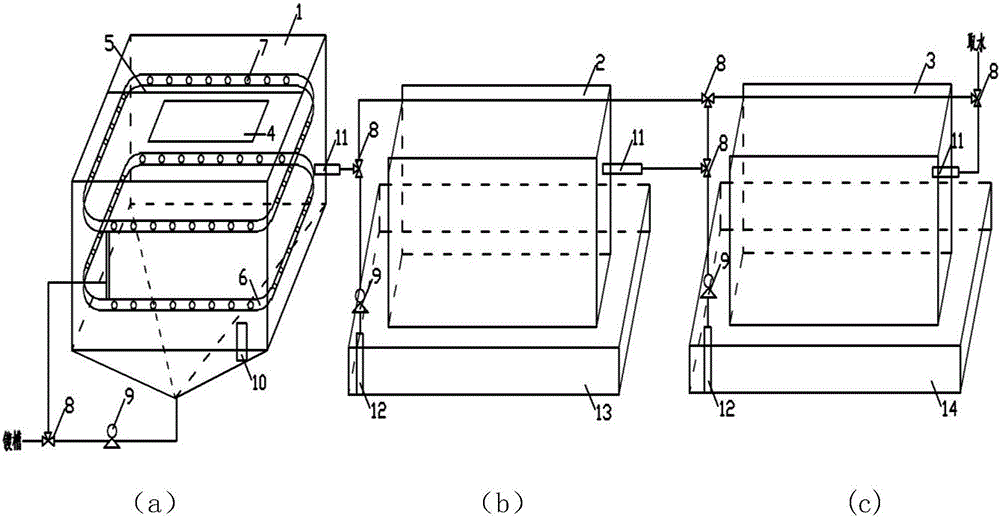

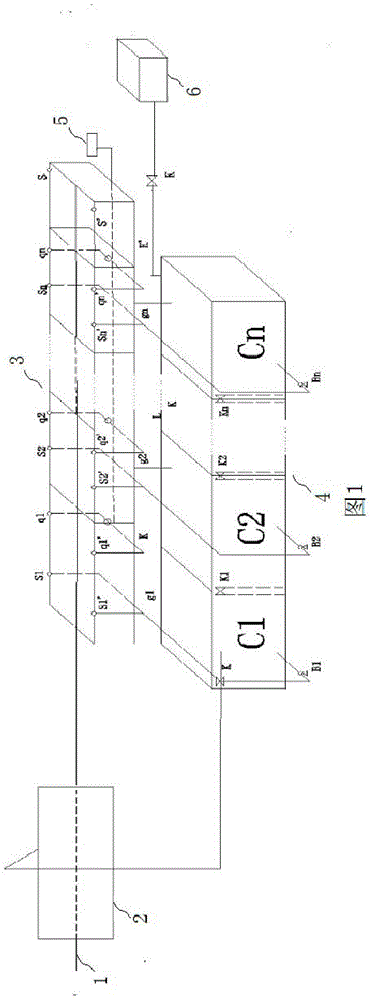

Treatment device and method for implementing total recycling of electroplating rinse water

The invention discloses a treatment device and method for implementing total recycling of electroplating rinse water. By the device, a plating solution which is brought out from a plating tank can be basically recycled completely, any waste water is not generated, and all rinse water (except rinse water evaporated in air) is reused completely. The device comprises a spraying system device (a) and two reverse-flow rinse systems (b) and (c), wherein the spraying system device (a) comprises a water pump, a spraying tank, a nozzle and a connecting pipeline; a pipeline of the nozzle is fixed at a corresponding position of the spraying tank; the spraying tank is provided with a corresponding water tank and a three-way valve; a water outlet is formed in the left side of the three-way valve and can lead to the plating tank; each of the two reverse-flow rinse systems (b) and (c) comprises two rinse tanks, two water collecting ponds, a water pump, a three-way valve, a water outlet, a water inlet and a pipe network; the two rinse tanks of each of the two reverse-flow rinse systems (b) and (c) are serially connected, meanwhile, the water inlet is formed in the upper end of the three-way valve of the water inlet of the corresponding secondary rinse tank, and then water is taken and supplemented.

Owner:NANJING UNIV OF TECH

Energy-saving environmentally-friendly treatment method for sewage in power generation system

InactiveCN109704523AReduce in quantityThe process device is simpleWater contaminantsMultistage water/sewage treatmentWater qualityHigh heat

The invention belongs to the technical field of wastewater treatment, and particularly relates to an energy-saving environmentally-friendly treatment method for sewage in a power generation system. Aiming at the prior art that in the treatment process of landfill leachate, more incineration equipment is required, and combustion heat cannot be effectively utilized, the invention provides the following technical solution: [1] performing primary sedimentation to remove suspended matter; [2] allowing an influent water quantity and influent water quality to be uniform respectively by utilizing a quantity homogenizing tank and a quality homogenizing tank; [3] performing an anaerobic reaction in an anaerobic reaction tank, collecting biogas generated by the anaerobic reaction, introducing the biogas into an incinerator, and performing incineration to generate a high-temperature flue gas; [4] performing nitrification: performing denitrification treatment; [5] performing a membrane biological reaction: performing solid-liquid separation, and performing a biochemical reaction on the sewage; [6] performing nanofiltration: performing nanofiltration to further remove macromolecular organic matter and high-valent charged ions in water to obtain a treated clear liquid; and [7] performing incineration on sludge: collecting the sludge produced in each step, performing uniform preheating and drying, sending the dried sludge to an incinerator, and performing incineration. The method provided by the invention is applicable to treatment of the landfill leachate.

Owner:中机眉山再生能源有限公司

Liquid flow type sea water desalting plant in capacitance model and manufacturing method

ActiveCN1562782AThe process device is simpleEasy to operateDispersed particle separationSteel platesSeawater

In the device, nanometre carbon tube is used as electrode material. The characteristics are: a couple of combination electrodes composed by nanometre tube which shared collecting electrode is in middle of its core parts of the device, there is a layer of insulate textile film is fixed between said combination electrodes, two weather board with notch are fixed at out side of said combination electrodes separately, sea water to be processed is send into water container through the notch on weather board from bottom water entrance and into upper weather board in way of circuitous liquid flow. There is an isoelectrode on and stick out the electrides, seal water-proof rubber grommers are fid on bottom and top of the water container, central core parts is fixed by steel plate frame arounding it and screwing up bolt and nut.

Owner:SHANGHAI UNIV +1

Liquid-flowing capacitor seawater desalination apparatus and manufacture thereof

InactiveCN1778698APrevent metal corrosionThe process device is simpleSeawater treatmentWater/sewage treatment by electrochemical methodsCapacitanceSeawater

A fluid-flow capacitance-type seawater desalination apparatus and its manufacture are disclosed. The apparatus is taken carbon nanometer tube as electrode materials, it is characterized by assembled electrode is made up of a pair of carbon nanometer tube electrode pieces with shared electrode as core element, a layer insulating fabric separating membrane is set between a pair of assembled electrodes, water-guiding panel are set at the external side of a pair of assemble electrodes separately, notch is opened on water-guiding panel, the treated seawater can enter into water container from bottom water inlet by notch of water-guiding panel with snaking liquid-flow way to top of water-guiding panel and be communicated with notch to flow water out, isoelectrode is extended from top of electrode, sealed water-proof rubber carrier rings are arranged at the top and bottom of container separately, and core element in the middle is fixed by periphery steel panel stand and pressed bolt and nut. It has simple structure, less consumption, high desalination efficiency and long life.

Owner:上海维安新材料研究中心有限公司

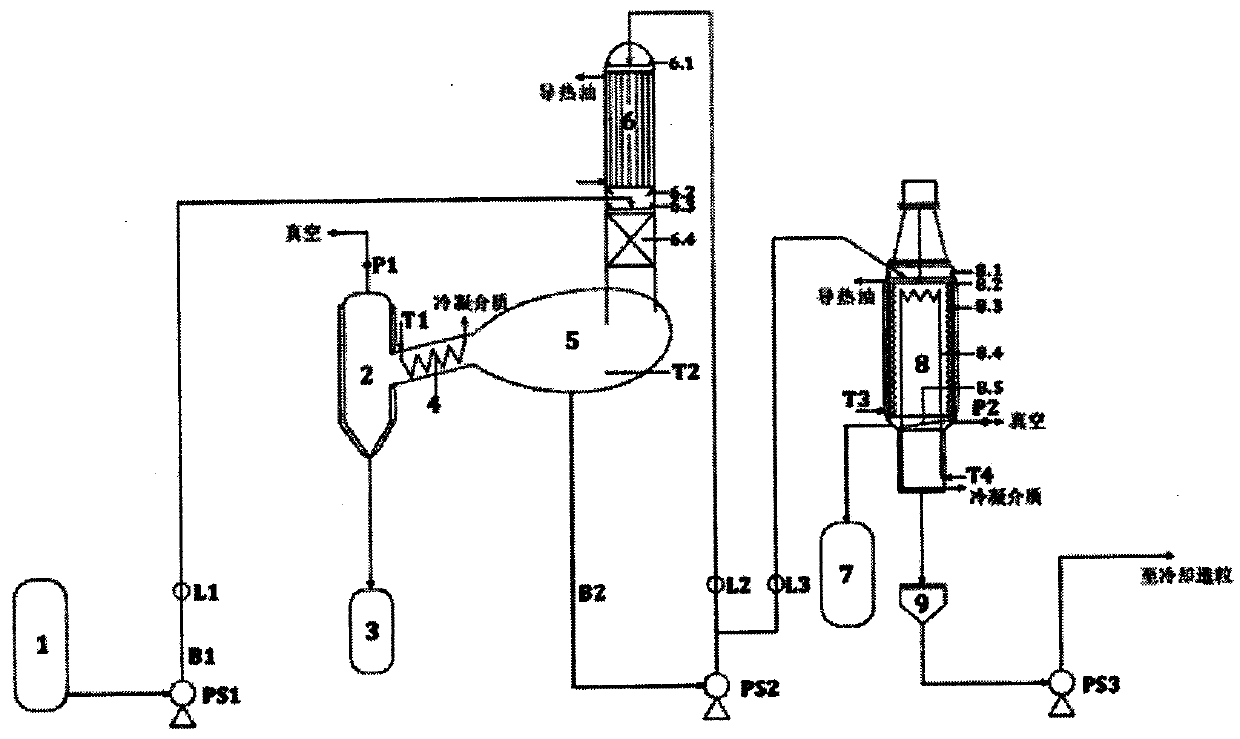

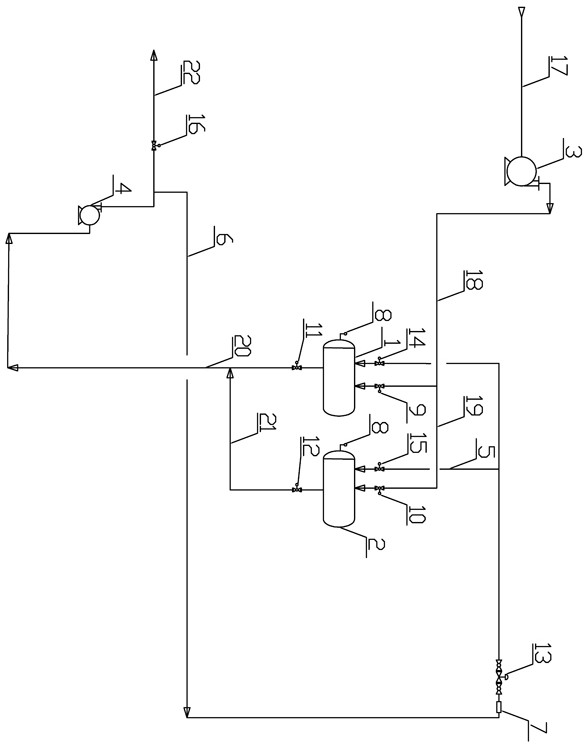

A continuous separation and purification device and method for behenic acid amide

ActiveCN107050903BReduce processing costsHigh yieldDistillation in boilers/stillsCarboxylic acid amide separation/purificationBoiling pointEvaporation

The invention provides a continuous separation and purification device and method for behenamide. The continuous separation and purification device for behenamide is characterized by comprising a coarse product storage tank, a first-stage falling film evaporation device and a second-stage rotary wiped film short-path distillation device which are sequentially connected, wherein the first-stage falling film evaporation device is used for distilling and separating a light component; and the second-stage rotary wiped film short-path distillation device is used for distilling behenamide and separating behenamide from a heavy component. Through first-stage falling film distillation, low-boiling substances affecting the color and luster, the odor and the melting point of a product are separated by using falling film heating evaporation and short-path distillation; through second-stage rotary wiped film short-path distillation, behenamide is distilled by adopting the rotary wiped film short-path distillation device, and is separated from high-boiling substances which are large in viscosity and high in color and luster, so that continuous and automatic stable production capable of separating and purifying high-melting-point and high-boiling-point substances is achieved. The continuous separation and purification device has the advantages of high pertinence, good separation effect, simple and practical process device, high product yield, stable quality and low processing cost.

Owner:SHANGHAI HAIYI ENVIRONMENTAL PROTECTION TECH

Treatment device and method for completely recycling electroplating rinse water

The invention relates to a treatment device for completely recycling electroplating rinse water. The treatment device comprises a spraying concentrating system device, a counter-current washing concentrating system and a plating slot, wherein the spraying concentrating system device comprises a first water pump, a spraying slot, a spray nozzle and a spraying recycling slot; the spraying slot communicates with the plating slot through a first pipeline; a three-way valve is mounted on the first pipeline; the spray nozzle is arranged in the spraying slot; the spraying recycling slot is formed below the spraying slot, and communicates with the bottom of the spraying slot through a second pipeline; the spraying recycling slot is further connected to the three-way valve through a third pipeline;and the first water pump is arranged on the third pipeline.

Owner:NANJING UNIV OF TECH

A device for recovering and recycling electroplating spray cleaning liquid

InactiveCN103952751BThe process device is simpleReduce energy consumptionCellsProduction lineSpray nozzle

The invention relates to an electro-plating wastewater treatment method, and in particular relates to a device for recycling electro-plating spraying cleaning liquid. The device comprises a plurality of circulating cleaning systems arranged along a production line, wherein the circulating cleaning systems are sequentially cascaded in series along the production line; each circulating cleaning system comprises a spraying cleaning tank, a spray nozzle and a pump; the spray nozzle is fixed on the spraying cleaning tank, and is connected with the pump by virtue of a pipeline; each stage of circulating cleaning systems is connected with a corresponding cleaning and rinsing liquid recycling system; the pump is connected with the cleaning and rinsing liquid recycling system. The electro-plating spraying cleaning liquid can be recycled by adopting the structure. The process is simple in device, has power equipment only including a circulating pump, is low in energy consumption, easy in equipment maintenance and management, low in running cost and less in one-time investment, can be used for recycling a plating solution brought out from a plating slot and saving a great number of rinsing water, and can be applied to enterprises having continuous electro-plating production lines.

Owner:NANJING TECH UNIV

Sodium hypochlorite conveying device for viscose fiber production refining process and use method thereof

InactiveCN111649239AConstant flowStable Process ConcentrationArtificial filaments from viscosePipeline systemsControl cellProcess engineering

The invention relates to the technical field of viscose fiber production, in particular to a sodium hypochlorite conveying device for a viscose fiber production refining process and a using method thereof. The sodium hypochlorite conveying device comprises at least two sodium hypochlorite storage tanks including a first sodium hypochlorite storage tank and a second sodium hypochlorite storage tank, a sodium hypochlorite discharging pump, a sodium hypochlorite metering pump and a control unit; and the the using method is characterized in that the control unit automatically controls the startingand stopping of a pump and the switching of a valve to finish automatic production operation. According to the device and the using method, the process device is simple, manual contact is not neededin the whole using process of sodium hypochlorite, personnel safety is guaranteed, meanwhile, a flow meter is interlocked with an automatic adjusting valve, metering monitoring and flow control are achieved, constant flow of sodium hypochlorite, stable process concentration and stable product quality are guaranteed, the sodium hypochlorite storage tanks are automatically switched, and the storagetank emptying cutoff caused by inattention of personnel is reduced, and the field process fluctuation is reduced.

Owner:XINJIANG FULIDA FIBER CO LTD +1

Method for removing fluorine ions from F22 by-product hydrochloric acid

InactiveCN108017038AAchieve reuseThe process device is simpleSilicon organic compoundsChlorine/hydrogen-chloride purificationDisiloxaneOrganic synthesis

The invention relates to a method for removing fluorine ions from F22 by-product hydrochloric acid. According to the method, hexamethyl disiloxane is added into the F22 by-product hydrochloric acid for reaction to produce trimethylfluorosilane, thus realizing removal of fluorine ions. The method converts the F22 by-product hydrochloric acid from waste acid into finished product acid, and belongs to the organic synthesis field. The process unit is simple, can achieve continuous operation under normal pressure, and the trimethylfluorosilane produced by cracking is condensed by an alkali metal salt to further produce hexamethyl disiloxane. The method realizes reutilization of the raw materials, is environmentally friendly, and is easy for industrial production.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Tool body and blade separating method of embedded and brazed tool

InactiveCN105441948AGuaranteed sizeEmbedded firmlyMetallic material coating processesSand blastingPhosphoric acid

The invention discloses a tool body and blade separating method of an embedded and brazed tool. The method includes the steps that the tool with a tool body capable of being recycled is subjected to chemical oil contamination removing, rinsed and blown to be dry, then the tool enters a soaking solution in a chemical dissolution soaking tank to be soaked at the normal temperature to enable brass soldering flux on the tool to be completely dissolved, a hard alloy blade and the high-quality carbon steel tool body are effectively separated, the tool body obtained after separation is rinsed through cold water twice, subjected to JML normal-temperature phosphorization, then rinsed, blown to be dry and subjected to sand blasting, and residues on the tool body are thoroughly removed. The soaking solution is a mixed solution of nitric acid with the concentration of 70% and phosphoric acid with the concentration of 85%, the volume ratio of the nitric acid to the phosphoric acid is 7:5, the soaking solution can not corrode the tool body, and therefore the size of the tool body is guaranteed. The tool body obtained through separation with the method is free of deformation and corrosion, and the original size of the tool body can be guaranteed; meanwhile, the tool body is subjected to phosphorization and sand blasting, and the tool body obtained after separation is prevented from being corroded; and meanwhile the method is easy to operate and low in cost, and waste liquid is nontoxic and environment-friendly.

Owner:CHONGQING JIANSHE IND GRP

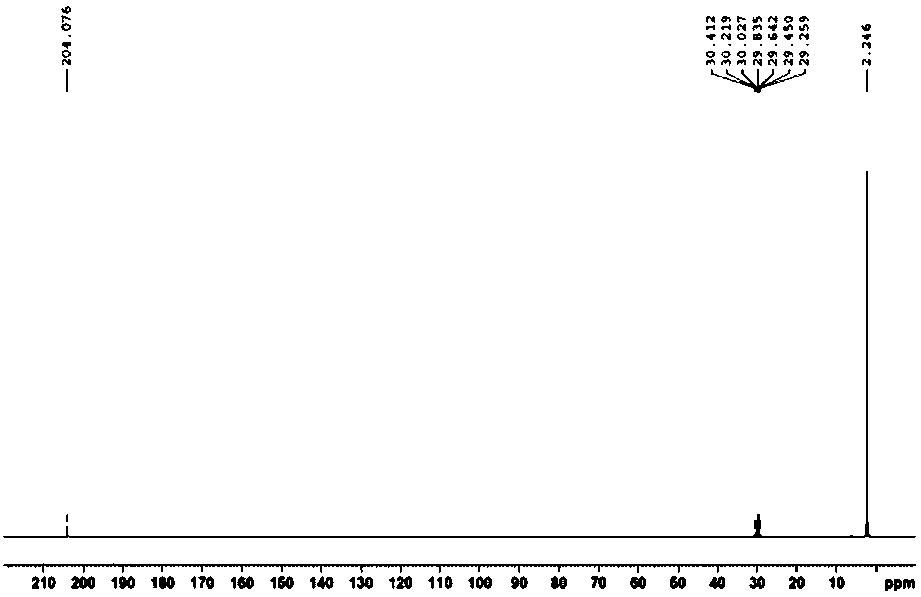

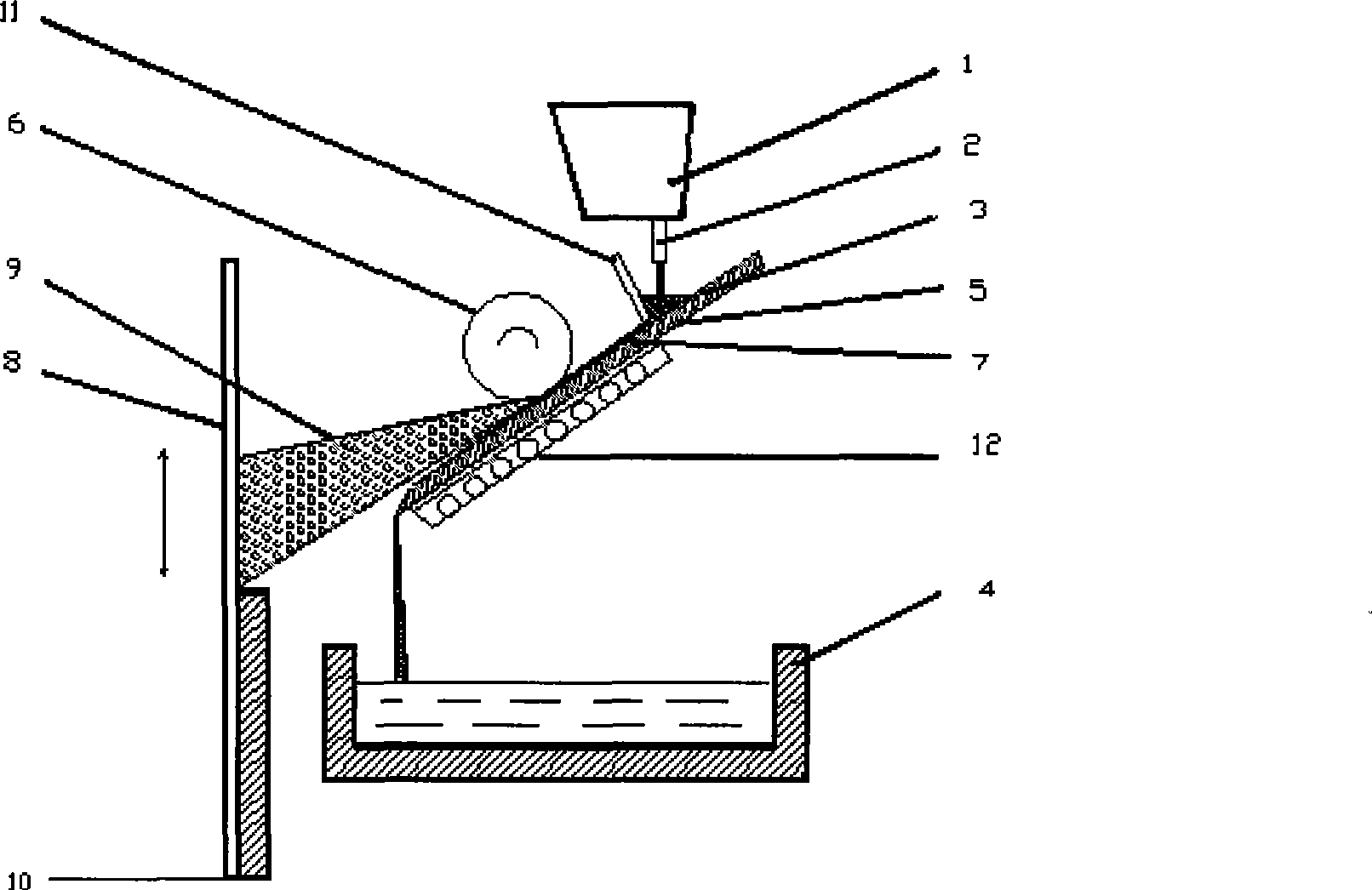

Sputtering and forming device by tumbling cylinder method

InactiveCN101439397AThe process device is simpleFacilitate continuous productionThin crystalCrystallite

The invention relates to a sputtering forming technology by a rotating-drum method and a device thereof, belonging to the fast solidifying and near net-shape forming field in metallurgy of iron and steel. The invention is characterized in that the bottom of a pouring box is provided with a molten metal drainage passage; a port of the molten metal drainage passage is provided with a high temperature roller; a gap is reserved between the high temperature roller and a soleplate of the molten metal drainage passage; the front end of the soleplate of the molten metal drainage passage is provided with a baffle; the lower surface of the soleplate of the molten metal drainage passage is provided with a heater; and a sediment baseplate is arranged at the lateral side of the pouring box in front of the high temperature roller. The invention can prepare deposited blanks including plate, tube blank, composite processing piece and the like; the surface of a deposited layer is uniform; the tissue of a prepared ingot blank is more uniform; the device can prepare metal material with very thin crystal grain; and the technology has simple equipment and is convenient for continuous production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

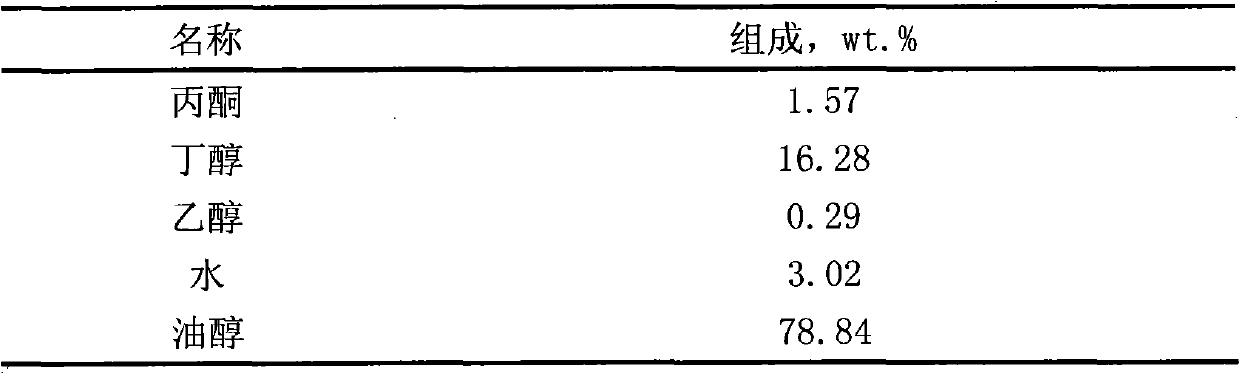

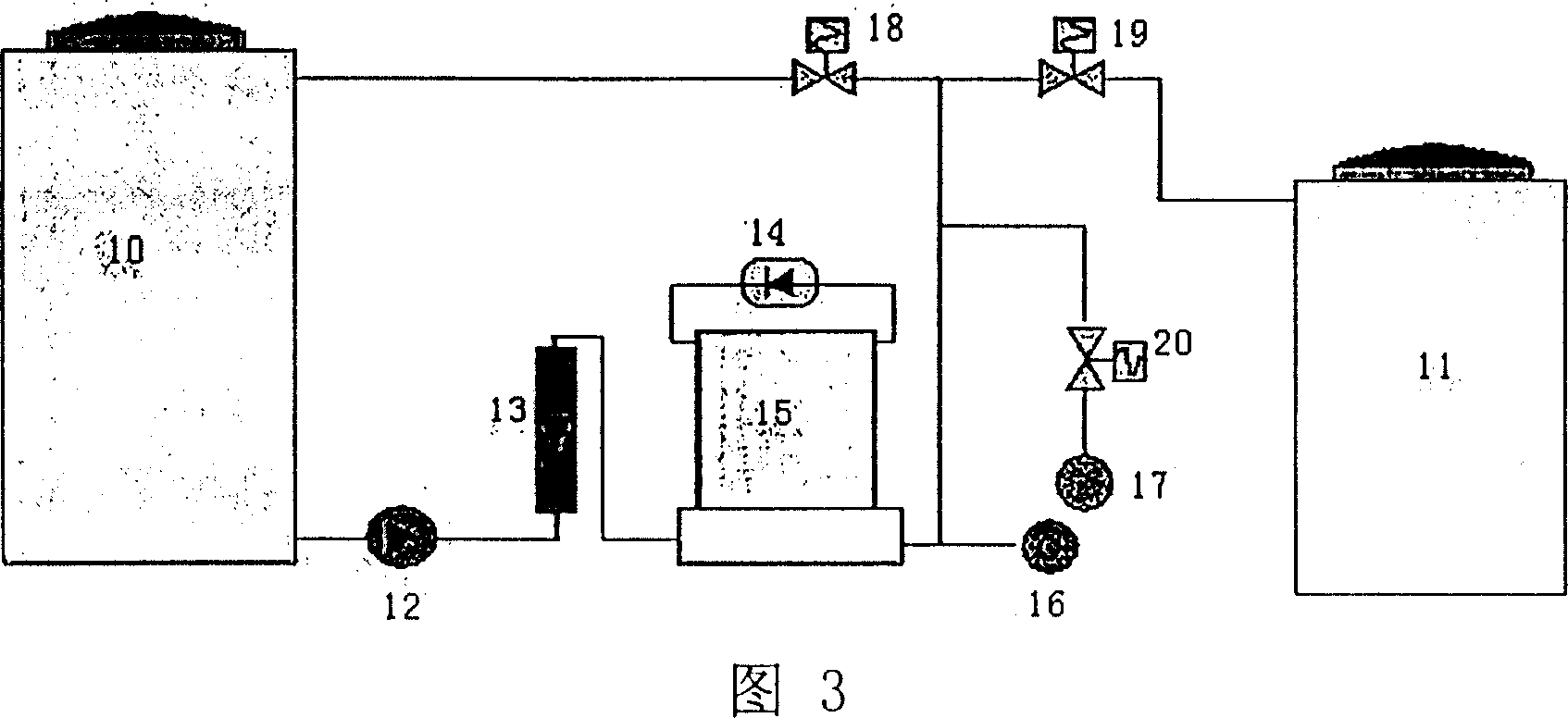

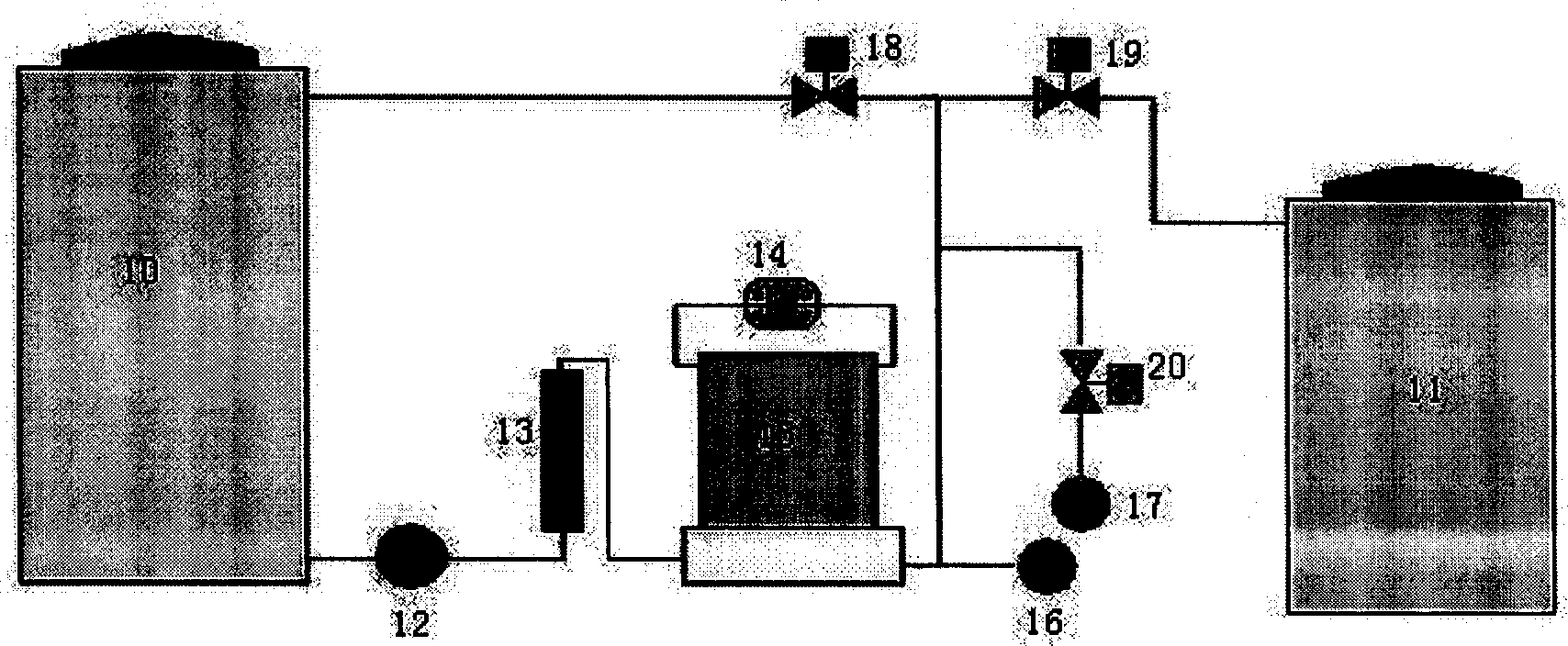

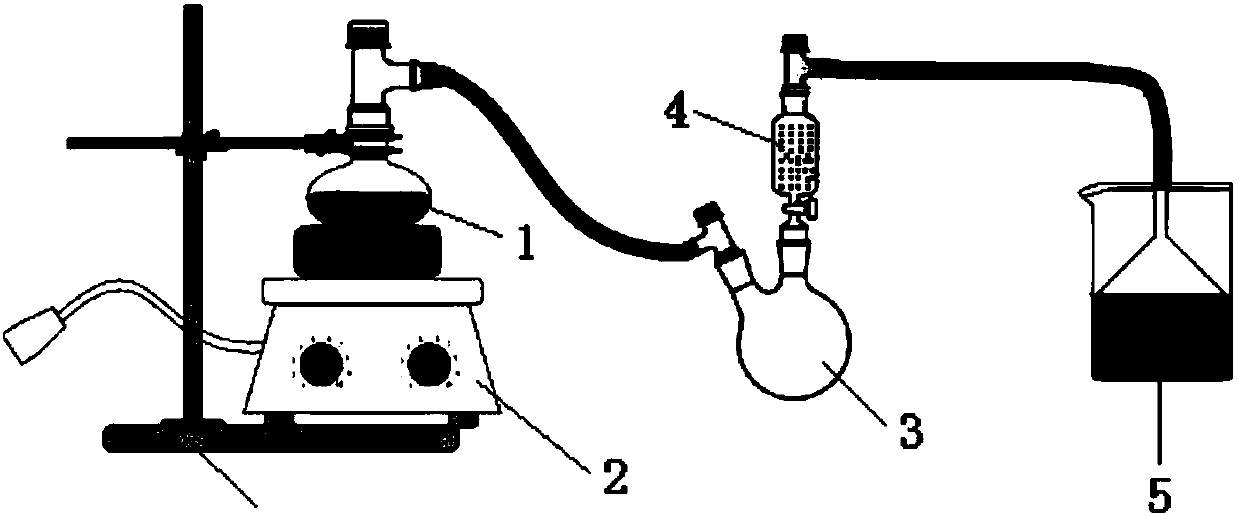

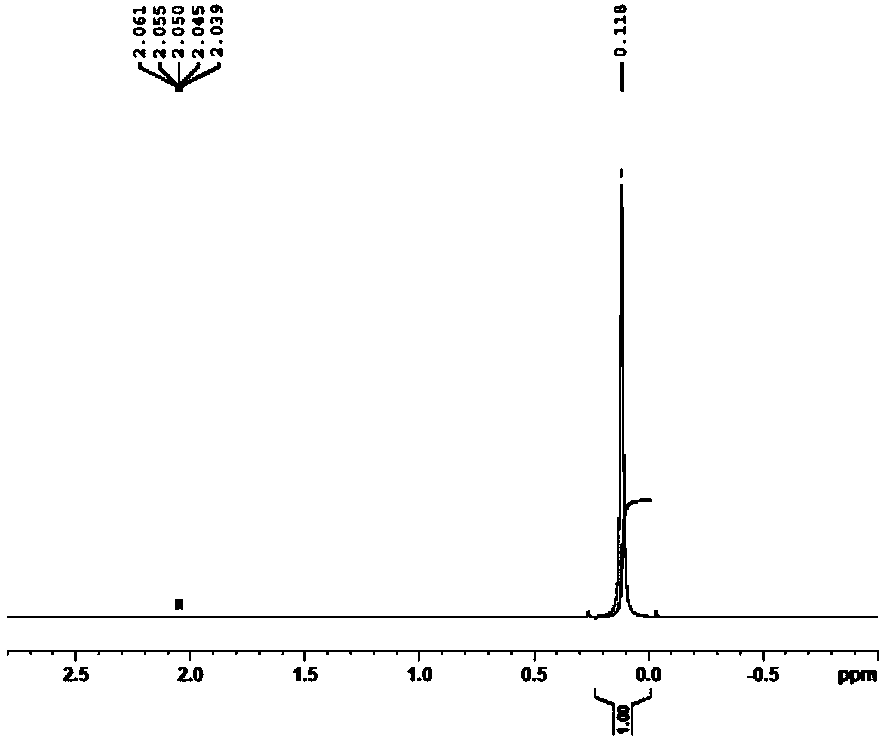

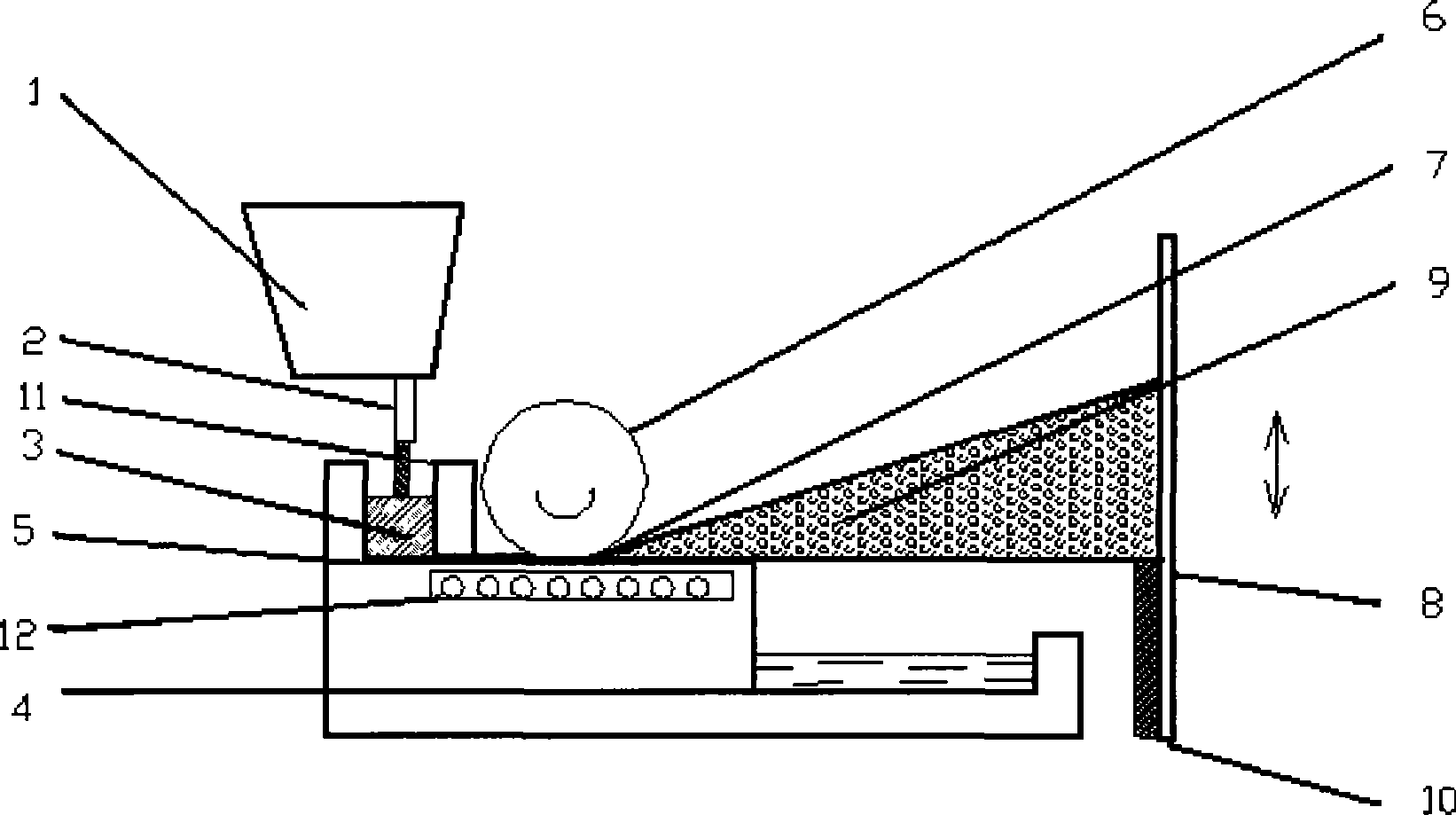

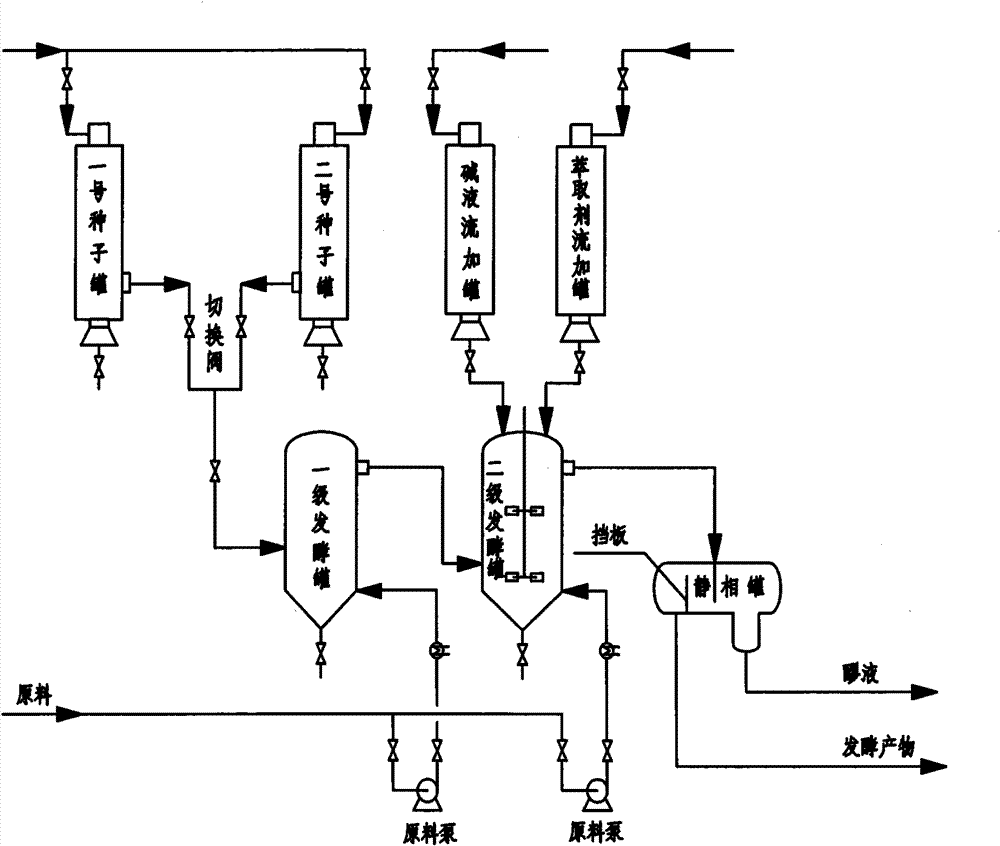

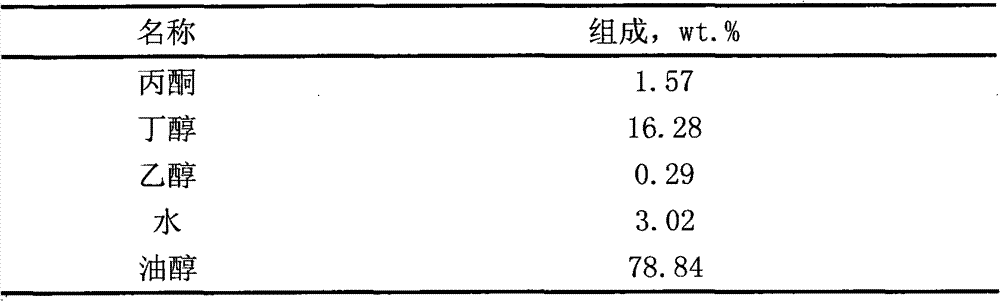

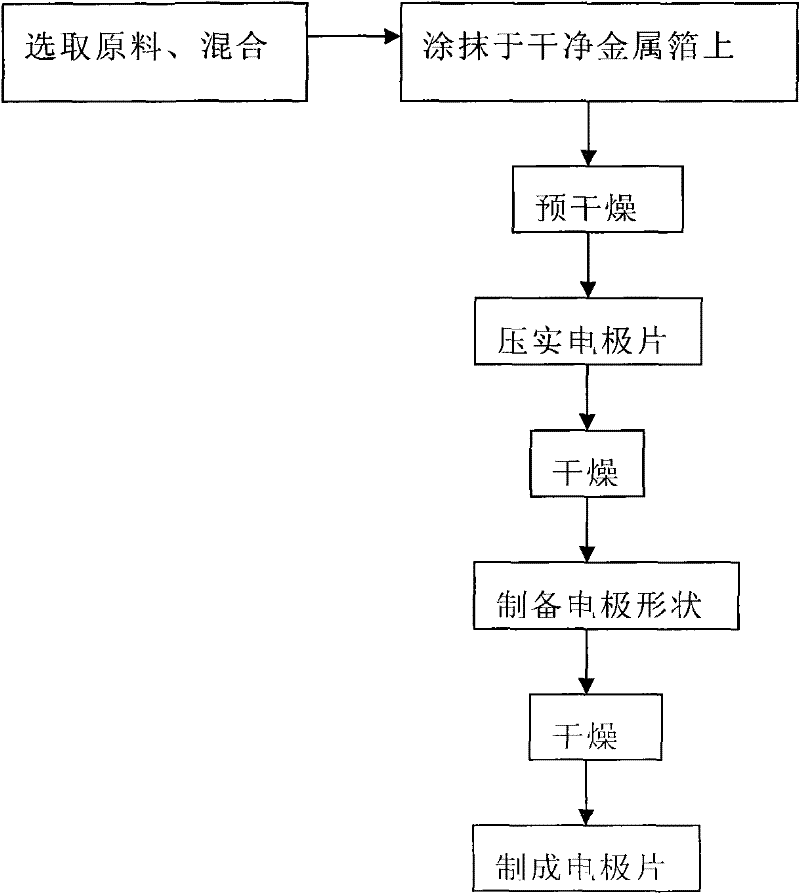

Acetone-butanol in-situ extraction continuous fermentation device and technology

InactiveCN101948737BReduce dosageSpeed up entryBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationEconomic benefits

The invention provides an acetone-butanol in-situ extraction continuous fermentation device and technology. The device comprises an No.1 seeding tank and an No.2 seeding tank which are alternately inoculated. Acetone-butanol fermentation is divided into two stages to continuously operate, wherein the first stage is conventional acid production period fermentation, and the second stage is in-situ extraction product synthesis period fermentation; the second period adopts a method of coupling extraction and fermentation and is matched with low-speed stirring to furthest lower product inhibiting effect and greatly improve butanol fermentation efficiency; and finally, static phase processing realizes the initial separation of mash and fermentation products. The invention has the advantages that the device and the technology have good extraction effect in production, can obviously improve butanol ratio in the fermentation product, can greatly lower production cost, and have obvious economic benefit. The technology is scientific and reasonable. The flow device is simple and easy to realize, can realize the new fermentation technology provided by the invention by slightly reforming the traditional butanol fermentation flow, and has wide application prospect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

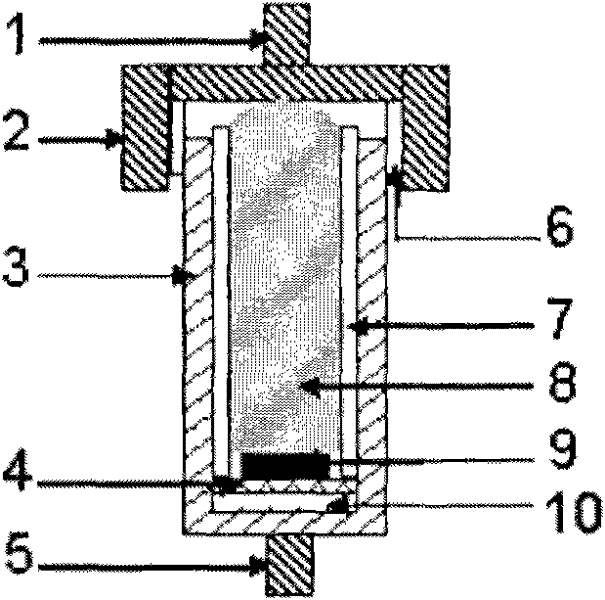

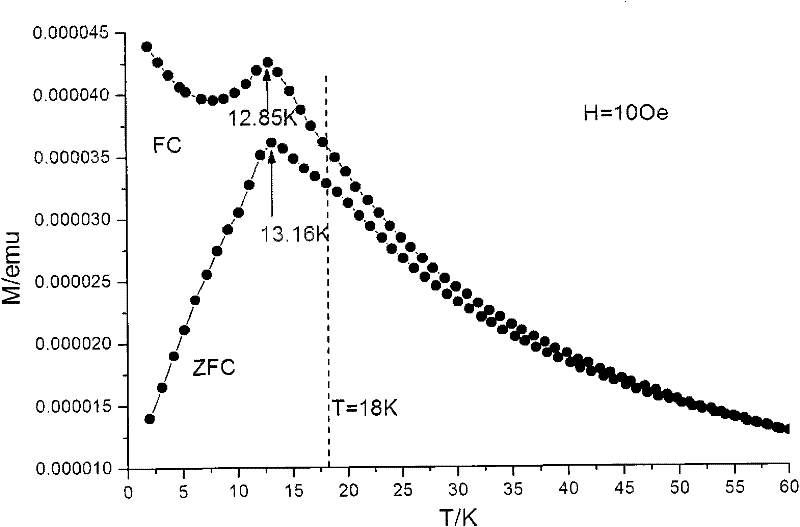

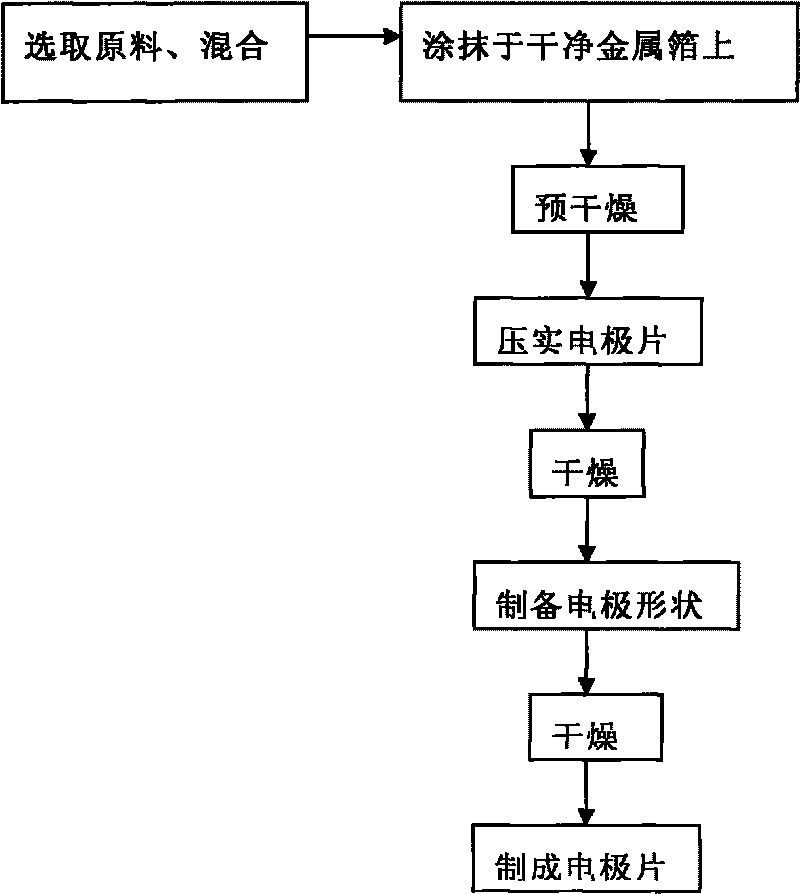

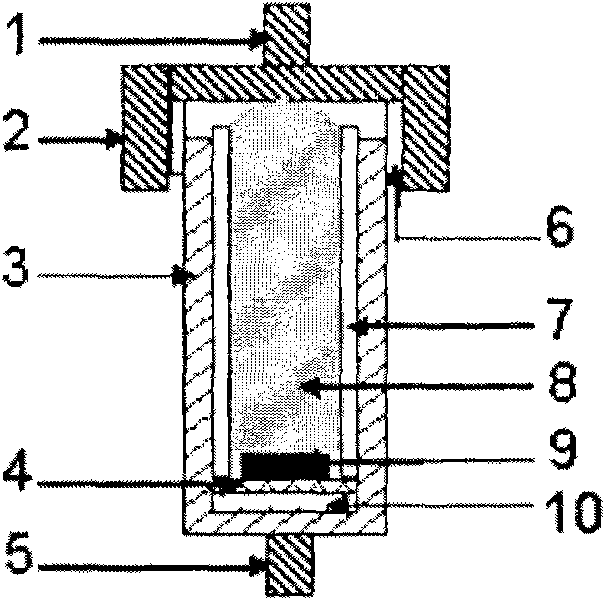

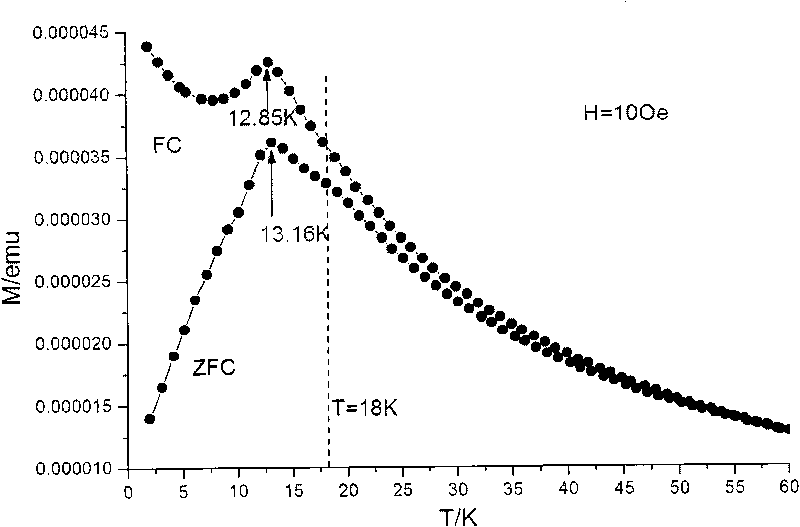

Electrochemical preparation method of LiFeAs superconductor

InactiveCN101740173BLowering experimentShort manufacturing cycleSuperconductors/hyperconductorsSuperconductor devicesShielding gasColloid

The invention relates to an electrochemical preparation method of an LiFeAs superconductor, comprising the following steps of: firstly, preparing the positive pole for structuring a battery, i.e. mixing FeAs powder with acetylene black, a bonder and methyl pyrrolidone according to a proportion in a mortar, and grinding into colloids; spreading the colloid on a clean base plate; preparing a positive pole piece through drying, compacting and drying; then assembling the battery, wherein the battery must be assembled in a glove box filled with protective gases, that moisture of the glove box is ensured to be less than 1 ppm, two poles of the battery must comprise an Li pole and the prepared positive pole and are separated by an electrolyte membrane, and a proper amount of electrolyte is addedto the battery; and finally charging the assembled battery to produce the LiFeAs superconductor on the positive pole. The invention has simpler process device, short preparation period and low production cost and is more suitable for preparing the LiFeAs superconductor in a laboratory.

Owner:UNIV OF SCI & TECH BEIJING

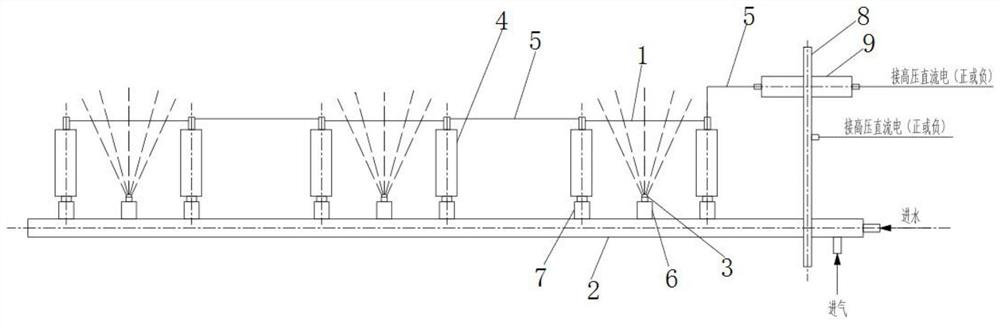

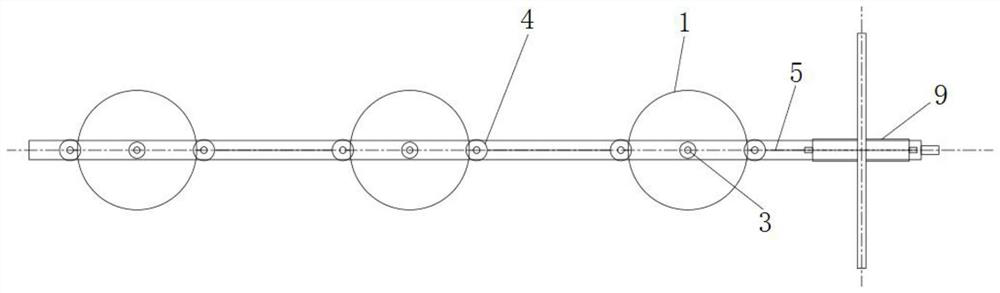

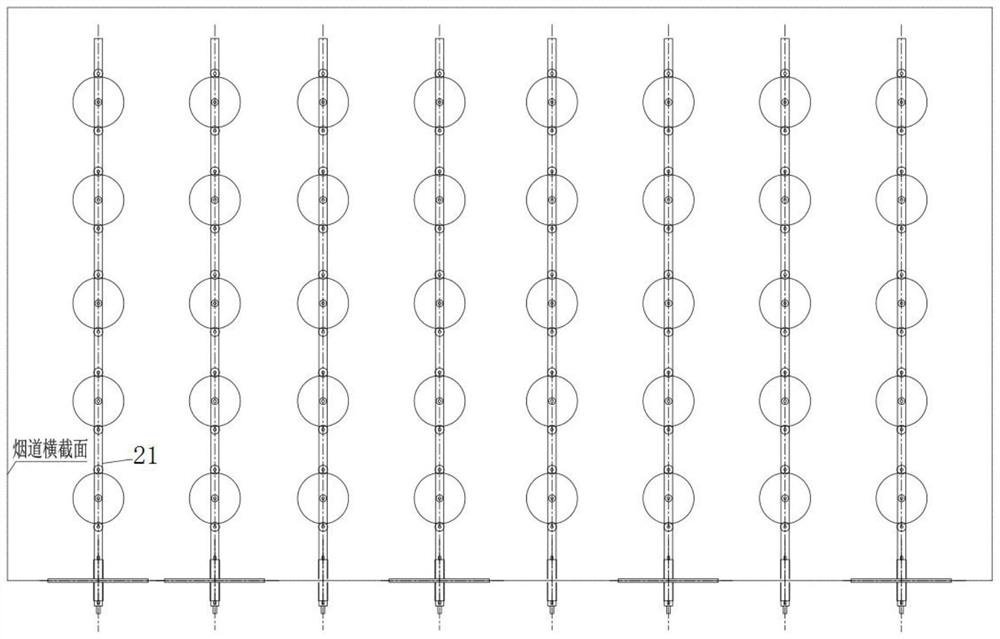

Spray gun and dust removal system

PendingCN114367380AReduce usageReduce maintenance workloadElectrostatic separation detailsSpray discharge apparatusFlue gasDust control

The invention relates to the technical field of dust removal, and provides a spray gun which comprises a discharge ring, a liquid spraying pipe, a nozzle communicated with the liquid spraying pipe and insulators arranged on the liquid spraying pipe, at least two insulators are arranged on the two sides of the nozzle, and the nozzle sprays atomized liquid drops towards the direction of a space formed by the two insulators. The two insulators are both electrically connected to the discharge ring, and the discharge ring and the nozzle are both powered on. The invention further provides a dust removal system which comprises the spray gun. The atomized liquid drops are charged, so that the dust removal efficiency can be greatly improved, the use amount of water can be reduced, water mist can be completely evaporated in a flue, caking of a spray gun and a nozzle and dust deposition and caking of the flue can be relieved and even eliminated, the maintenance workload of dust removal of the spray gun, the nozzle and the flue is greatly reduced, and the maintenance cost is reduced. And adverse effects on a flue gas and air system of a factory are reduced to the minimum or eliminated.

Owner:武汉天空蓝环保科技有限公司

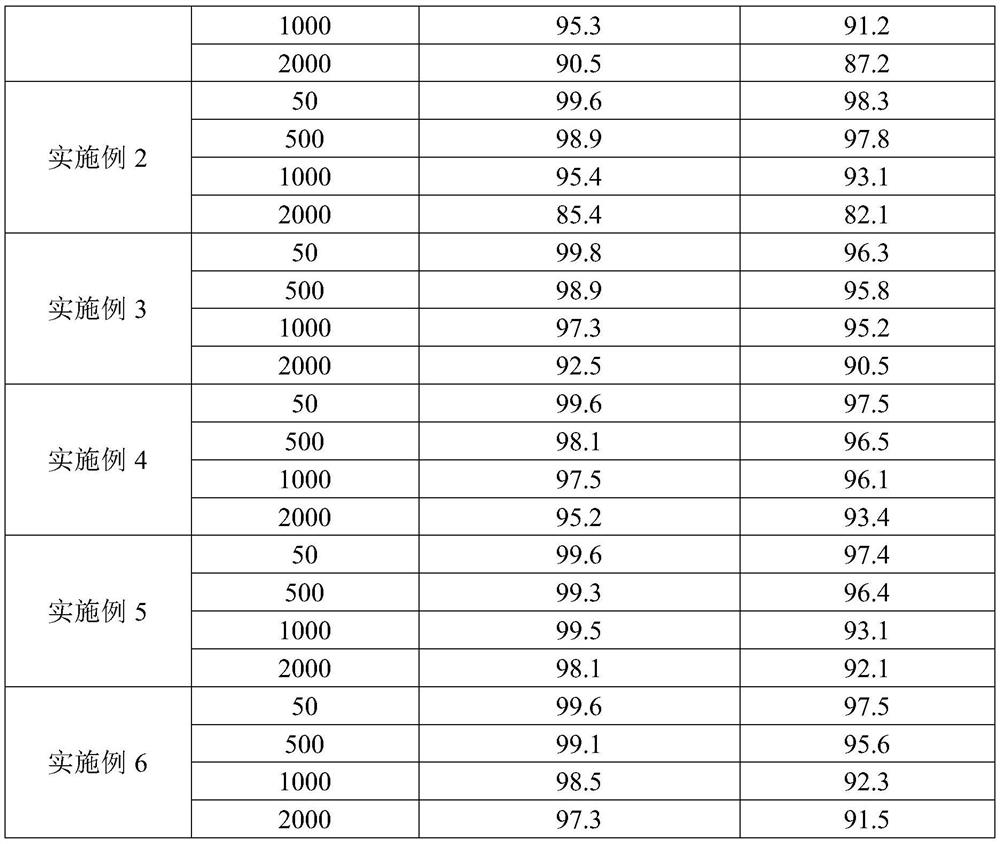

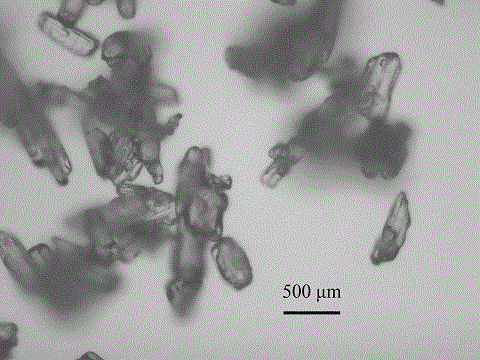

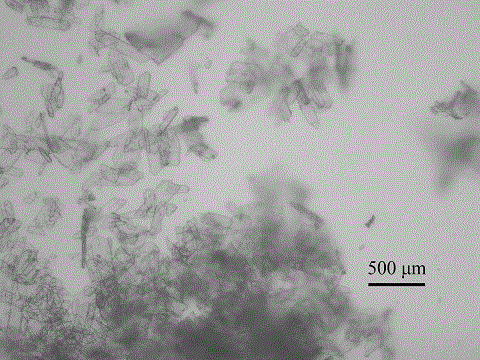

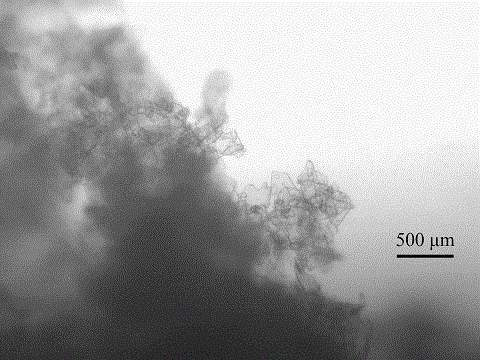

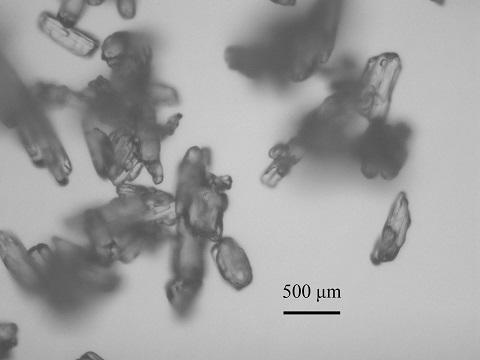

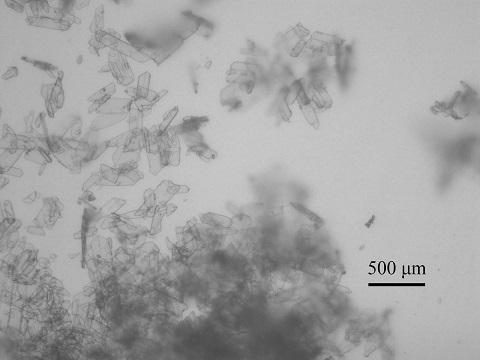

Method for preparing flaky ibuprofen crystal by adding crystal-growing controlling agent into aqueous solution

InactiveCN106518655ALow priceThe process device is simpleCarboxylic compound separation/purificationThermal insulationPotassium

A method for preparing flaky ibuprofen crystal by adding a crystal-growing controlling agent into an aqueous solution belongs to the field of a novel technology of a medicinal preparation and comprises the following steps: firstly preparing an aqueous solution containing ibuprofen, urea and polyvinyl alcohol, heating to 100 DEG C, carrying out thermal insulation for 12-24 h, and cooling to room temperature so as to prepare an ibuprofen aqueous solution; preparing a buffer aqueous solution with pH being 1 by using hydrochloric acid and potassium chloride and adding one of polyethylene glycol with molecular weight being 400 g per mole, polyethylene glycol with molecular weight being 1,000 g per mole, polyethylene glycol with molecular weight being 2,000 g per mole, polyethylene glycol with molecular weight being 10,000 g per mole, L-glutamic acid or polyacrylic acid as a crystal-growing controlling agent, dropwise adding the ibuprofen aqueous solution into the pH=1 buffer aqueous solution containing the crystal-growing controlling agent, stirring and reacting for 4 h, filtering, washing with deionized water twice, and finally drying at 40 DEG C for 12 h so as to prepare the flaky ibuprofen crystal. The size of the prepared flaky ibuprofen crystal is adjustable and controllable and uniform, thus being beneficial to follow-up tabletting and coating processes. As the crystal has small specific surface area, the ibuprofen slowly-releasing effect can be achieved.

Owner:SHANDONG UNIV OF TECH

A method for preparing flaky ibuprofen crystals from aqueous solution by adding crystal form control agent

InactiveCN106518655BLow priceThe process device is simpleCarboxylic compound separation/purificationPolyvinyl alcoholThermal insulation

A method for preparing flaky ibuprofen crystals from an aqueous solution by adding a crystal form control agent, belonging to the new technical field of pharmaceutical preparations, comprising the following steps: first preparing an aqueous solution containing ibuprofen, urea and polyvinyl alcohol, and raising the temperature to 100° C, keep warm for 12 to 24 hours and then cool to room temperature to prepare ibuprofen aqueous solution; then use hydrochloric acid and potassium chloride to prepare a buffered aqueous solution of pH=1 and add polyethylene glycol with a molecular weight of 400 grams per mole and a molecular weight of 1000 Polyethylene glycol in grams per mole, polyethylene glycol with a molecular weight of 2000 grams per mole, polyethylene glycol with a molecular weight of 10000 grams per mole, L-glutamic acid or polyacrylic acid as a crystal form control agent, Subsequently, the ibuprofen aqueous solution was added dropwise to the pH=1 buffer aqueous solution containing the crystal form control agent, stirred and reacted for 4 hours, filtered, washed twice with deionized water, and finally dried at 40°C for 12 hours to prepare the tablet ibuprofen crystals. The flaky ibuprofen crystals prepared by the method are adjustable in size and uniform in size, which is beneficial to the realization of subsequent tableting and wrapping processes, and the specific surface area of the crystals is small, so that the effect of slowly releasing the ibuprofen can be realized.

Owner:SHANDONG UNIV OF TECH

A polishing method for a thin-film lithium niobate optical waveguide chip polishing device

A thin-film lithium niobate optical waveguide chip polishing device and polishing method proposed by the present invention use a magnetic stirring table to drive a magnetic rotor to rotate in a polishing solution, and then stir the polishing solution to flow into contact with the surface of the chip, and the polishing particles therein are in contact with the dry Semi-contact or sliding contact occurs on the surface of the chip etched by the method, accompanied by a small amount of particle bombardment. At the same time, the alkaline ions in the polishing solvent react chemically with the etched surface. Chemical etching and particle bombardment in the parallel direction of the surface, and then remove the etching products deposited on the dry etching surface and the peaks and protrusions produced by dry etching, so as to achieve the smoothing effect of the etching surface and the side wall of the waveguide. Compared with traditional contact mechanical grinding and polishing and chemical mechanical polishing methods, it has the advantages of simple structure, easy operation, low cost and less surface damage.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

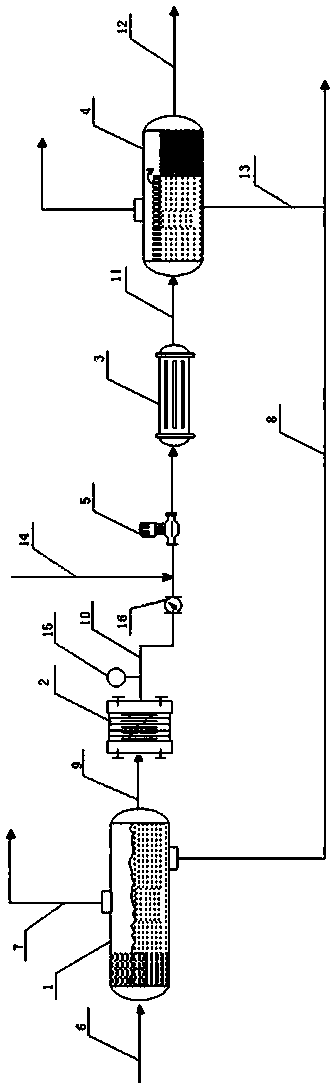

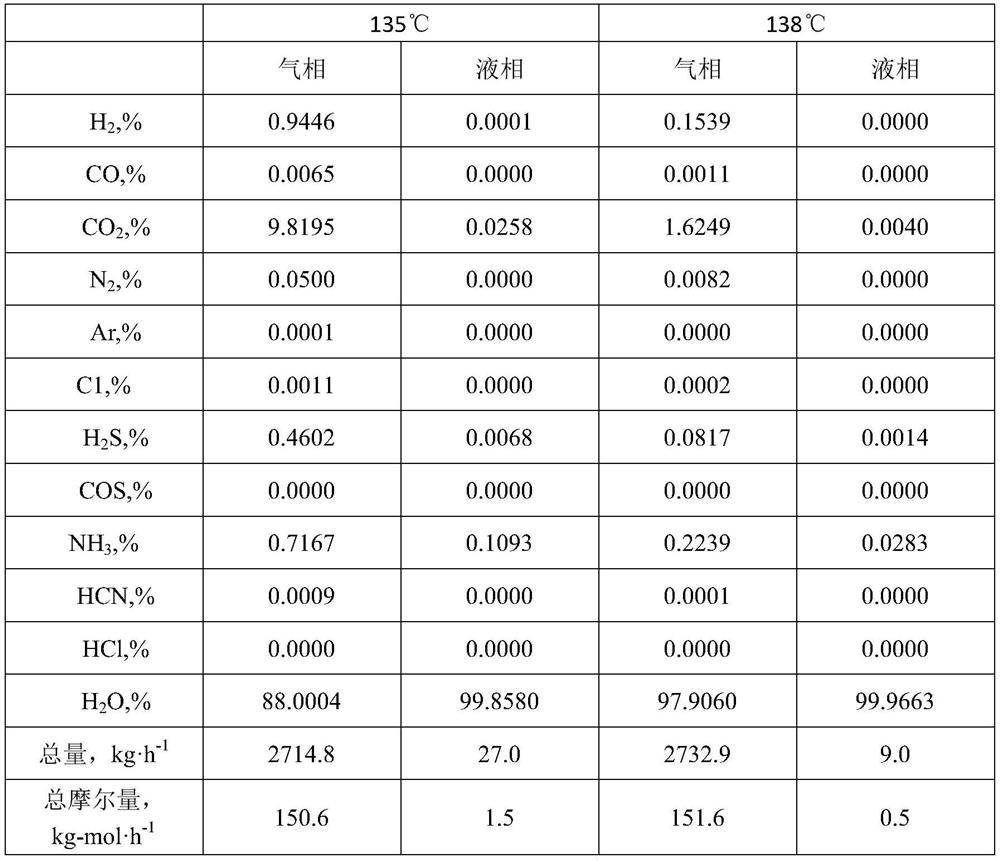

Rapid dehydration method for low-temperature sealed interface of produced liquid in oil field central treatment station and device for implementing method

InactiveCN109852416AQuick breakDosing concentration is lowDewatering/demulsification with chemical meansTreatment with plural serial refining stagesGas phaseOil phase

The invention relates to the technical field of produced liquid treatment in oil field central treatment stations, and relates to a rapid dehydration method for a low-temperature sealed interface of aproduced liquid in an oil field central treatment station and a device for implementing the method. The method is characterized in that after an oil phase, a gas phase and a water phase in the produced liquid are separated by adopting a three-phase separator, after water-containing crude oil is heated to a dehydration temperature by a steam phase change heating furnace, rapid dehydration is performed in a fast closed dehydrator, and therefore settling separation of the crude oil is realized; and the device is characterized by comprising the three-phase separator, the steam phase change heating furnace, the interface fast closed dehydrator and an oil-water sedimentation separator. According to the process provided by the invention, the device is simple and convenient, an oil-water interface film is rapidly broken by the interface fast closed dehydrator, oil beads are aggregated, water beads are coalesced, oil transaction indexes of rapid oil-water separation and a water content of lessthan 0.5% are achieved, so that the purposes of a reduced dehydration temperature, a reduced concentration of an added demulsifying agent, and shortened dehydration time are realized; and associatedgases are not discharged to the outside, so that the method and the device have significant environmentally-friendly, social and economic benefits.

Owner:XINJIANG KELI NEW TECH DEV

System and method for pretreatment of high ammonia nitrogen acid condensate in conversion unit

ActiveCN109381887BReduce the concentration of ammonia nitrogenTo achieve the purpose of removing pollutantsLiquid degasificationSteam distillationGas phaseChemistry

The invention belongs to the field of coal chemical wastewater and waste gas treatment, and in particular relates to a pretreatment system and method for high ammonia nitrogen acidic condensate of a conversion unit. The present invention replaces the circulating water heat exchanger of the coal gasification conversion unit with a desalinated water heat exchanger, uses the desalted water as the heat medium to recover heat, reduces the load of the circulating water field, and raises the temperature of the stripping liquid at the entrance of the separation tower to 100°C to 138°C. ℃, the acidic condensate (containing high ammonia nitrogen) sewage waste water is pretreated in the separation tower using a similar steam stripping method, so that the dissolved gases (high ammonia nitrogen substances, etc.) in the liquid phase are vaporized and separated as much as possible. The results show that: the total amount of high-ammonia-nitrogen substances, organic matter and sulfur-containing compounds in the gas phase increases significantly, while the liquid phase finally enters the biochemical unit with a low total amount of less than 50kg / h, which reaches the processing load of the biochemical unit, thus ensuring economical efficiency. Up-to-standard discharge after biochemical treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrochemical preparation method of LiFeAs superconductor

InactiveCN101740173ALowering experimentShort manufacturing cycleSuperconductors/hyperconductorsSuperconductor devicesShielding gasEngineering

The invention relates to an electrochemical preparation method of an LiFeAs superconductor, comprising the following steps of: firstly, preparing the positive pole for structuring a battery, i.e. mixing FeAs powder with acetylene black, a bonder and methyl pyrrolidone according to a proportion in a mortar, and grinding into colloids; spreading the colloid on a clean base plate; preparing a positive pole piece through drying, compacting and drying; then assembling the battery, wherein the battery must be assembled in a glove box filled with protective gases, that moisture of the glove box is ensured to be less than 1 ppm, two poles of the battery must comprise an Li pole and the prepared positive pole and are separated by an electrolyte membrane, and a proper amount of electrolyte is added to the battery; and finally charging the assembled battery to produce the LiFeAs superconductor on the positive pole. The invention has simpler process device, short preparation period and low production cost and is more suitable for preparing the LiFeAs superconductor in a laboratory.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com