A method for preparing flaky ibuprofen crystals from aqueous solution by adding crystal form control agent

A technology of crystal form control agent and aqueous solution, applied in the new field of pharmaceutical preparations, can solve the problems of few ibuprofen crystals, etc., and achieve the effects of low price, reduced impact, and simple process device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

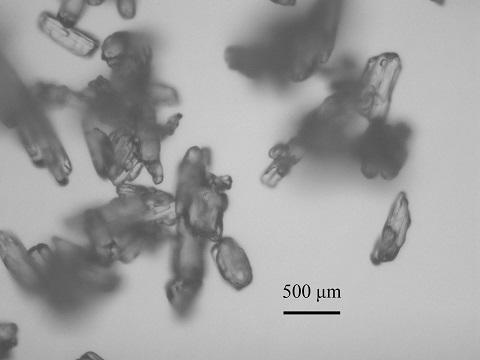

[0018] (1) Prepare an aqueous solution containing 8.88 mg / ml of ibuprofen, 3.33 mg / ml of urea and 3.33 mg / ml of polyvinyl alcohol (polyvinyl alcohol 124 with a molecular weight of 105,000 grams per mole), and raise the temperature to 100°C , cooling to room temperature after heat preservation for 24 hours, and preparing ibuprofen aqueous solution;

[0019] (2) Use hydrochloric acid and potassium chloride to prepare 180 ml of buffered aqueous solution with pH=1, and then add polyethylene glycol with a molecular weight of 2000 grams per mole to make the concentration of polyethylene glycol with a molecular weight of 2000 grams per mole be 0.83 mg per milliliter, then 15 milliliters of the ibuprofen aqueous solution prepared in step (1) was added dropwise to the buffered aqueous solution of pH=1 containing polyethylene glycol with a molecular weight of 2000 grams per mole, stirred and reacted for 4 hours and then filtered, Wash twice with deionized water, and finally dry at 40°C ...

Embodiment 2

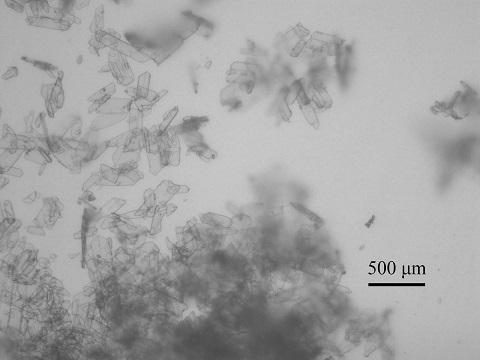

[0021] (1) Prepare an aqueous solution containing 8.88 mg / ml of ibuprofen, 3.33 mg / ml of urea and 3.33 mg / ml of polyvinyl alcohol (polyvinyl alcohol 124 with a molecular weight of 105,000 grams per mole), and raise the temperature to 100°C , cooling to room temperature after heat preservation for 24 hours, and preparing ibuprofen aqueous solution;

[0022] (2) Use hydrochloric acid and potassium chloride to prepare 180 ml of buffered aqueous solution with pH=1, and then add polyethylene glycol with a molecular weight of 10,000 grams per mole so that the concentration of polyethylene glycol with a molecular weight of 10,000 grams per mole is 2.50 mg per milliliter, then 15 milliliters of the ibuprofen aqueous solution prepared in step (1) was added dropwise to a buffered aqueous solution of pH=1 containing polyethylene glycol with a molecular weight of 10,000 grams per mole, stirred and reacted for 4 hours and then filtered, Wash twice with deionized water, and finally dry at 4...

Embodiment 3

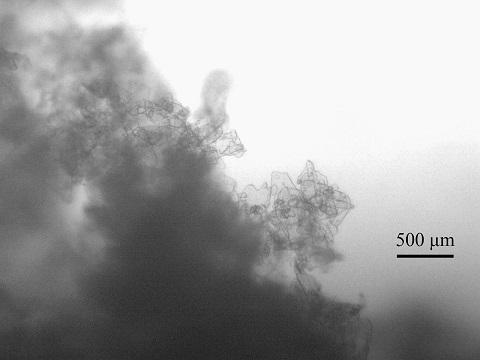

[0024] (1) Prepare an aqueous solution containing 8.88 mg / ml of ibuprofen, 3.33 mg / ml of urea and 3.33 mg / ml of polyvinyl alcohol (polyvinyl alcohol 124 with a molecular weight of 105,000 grams per mole), and raise the temperature to 100°C , cooling to room temperature after heat preservation for 24 hours, and preparing ibuprofen aqueous solution;

[0025] (2) Prepare 180 milliliters of buffered aqueous solution with pH=1 with hydrochloric acid and potassium chloride, then add polyacrylic acid to make the concentration of polyacrylic acid 1.25 mg per milliliter, then add 15 milliliters of the ibuprofen prepared in step (1) The aqueous solution was added dropwise to the buffered aqueous solution containing polyacrylic acid at pH=1, stirred and reacted for 4 hours, then filtered, washed twice with deionized water, and finally dried at 40°C for 12 hours to obtain the flaky ibuprofen crystals ( See Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com