Liquid flow type sea water desalting plant in capacitance model and manufacturing method

A manufacturing method and capacitive technology, which is applied in seawater treatment, separation methods, and separation of dispersed particles, can solve the problems of low effective surface area, high resistivity of activated carbon, and no research on electrodes of seawater desalination devices, so as to achieve easy implementation and low energy consumption. Small =, the effect of overcoming metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

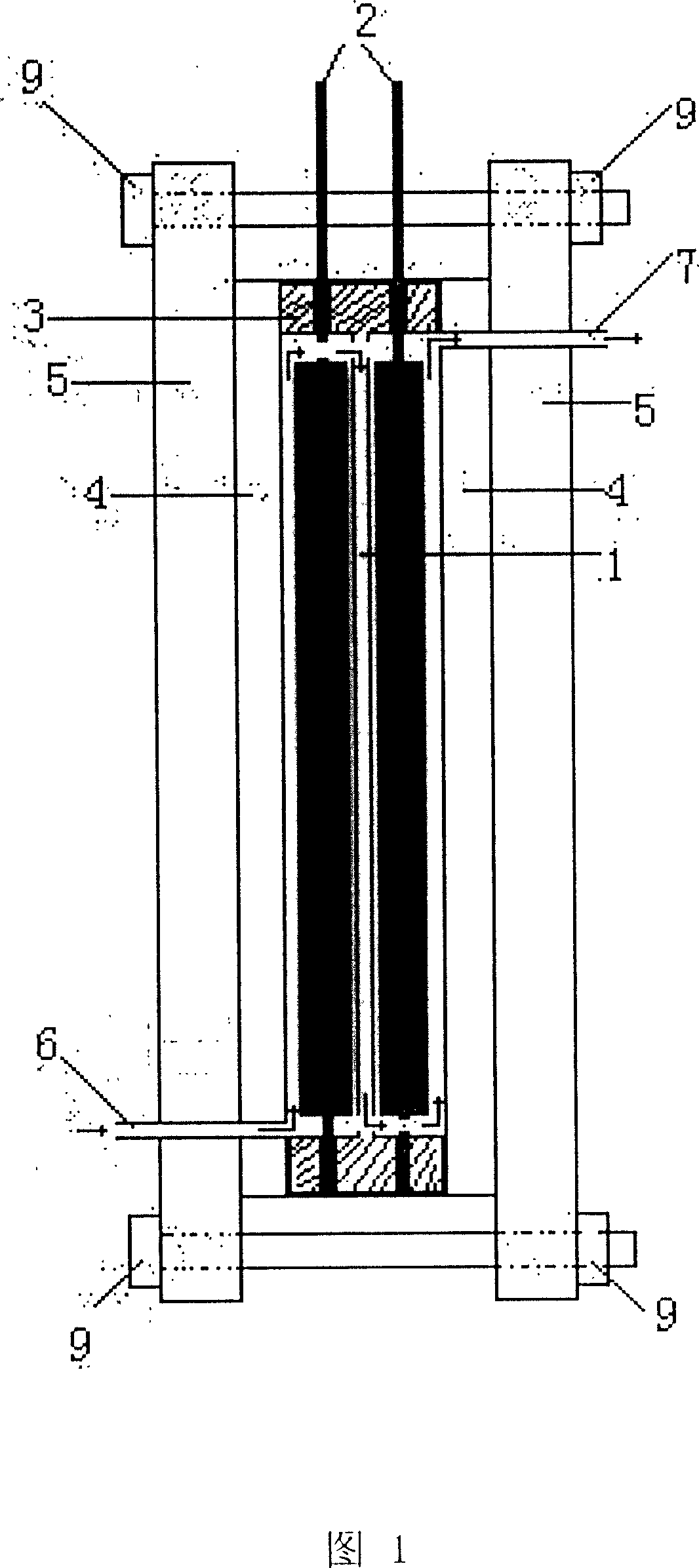

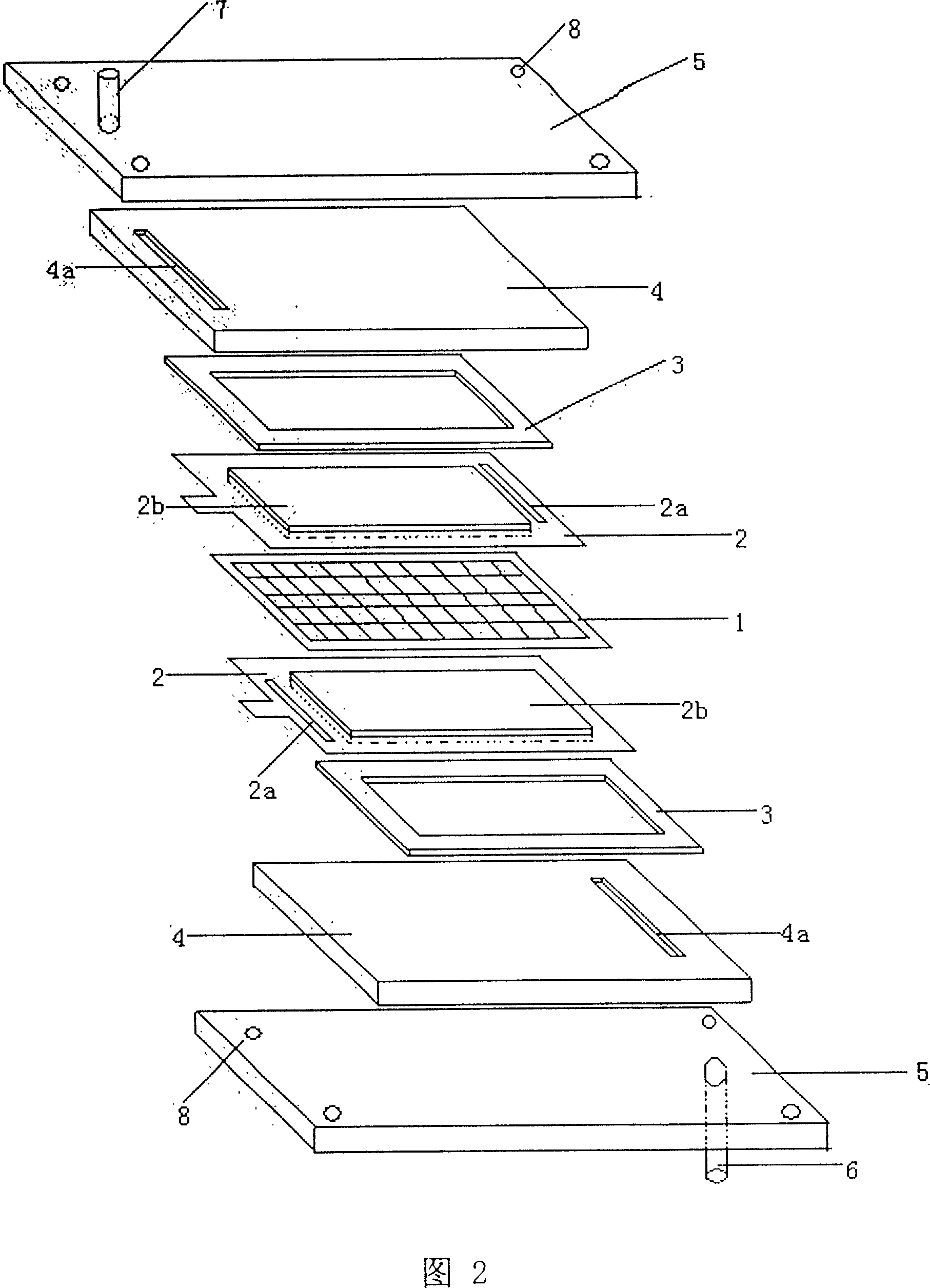

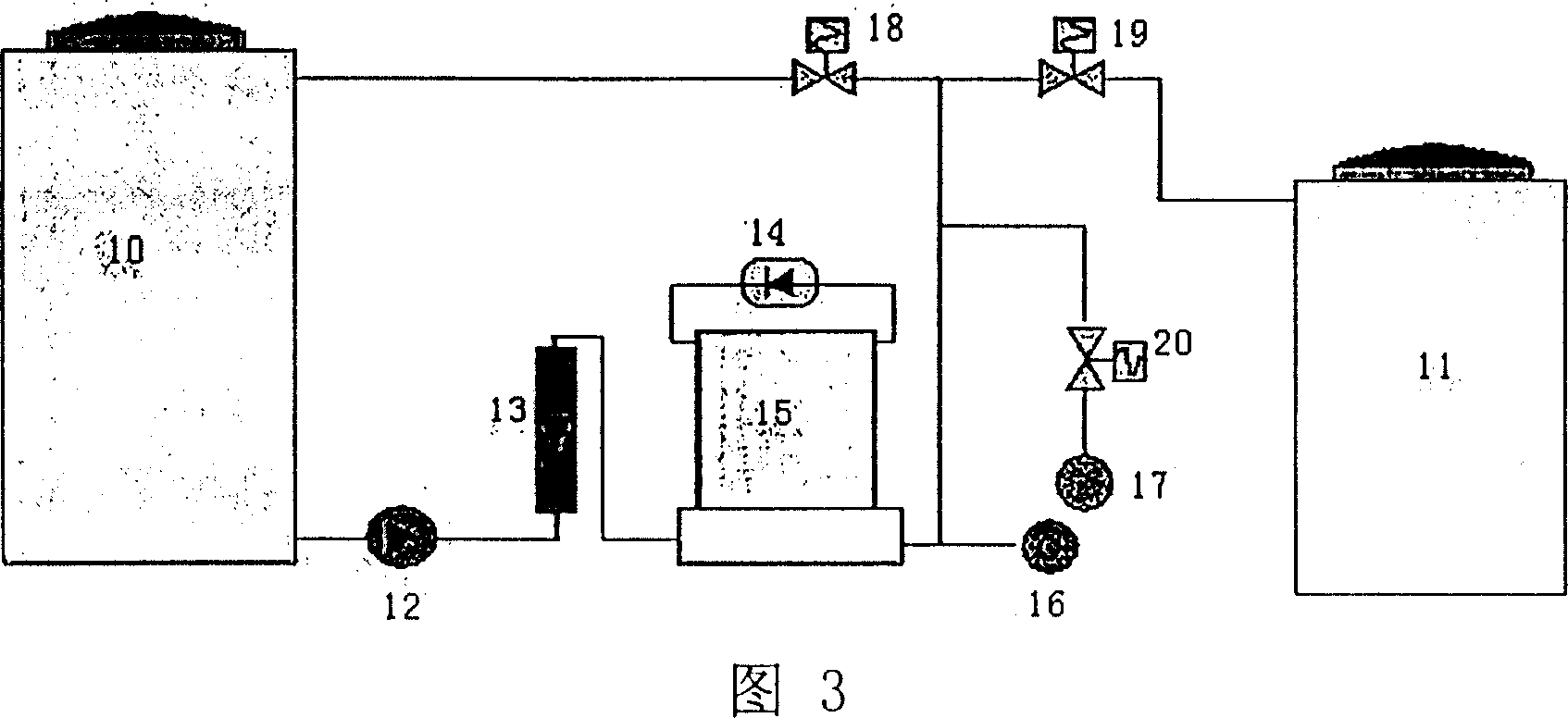

[0026] Embodiment 1: Referring to Fig. 1 and Fig. 2, this liquid flow capacitive seawater desalination device mainly uses carbon nanotubes as electrode materials, and the core components of the device are a pair of carbon nanotubes with a common collector 2 interposed therebetween The combined electrode formed by the electrode sheet 2b; a pair of combined electrodes is provided with a layer of insulating fabric isolation film 1 between the two, such as glass fiber mesh; a pair of combined electrodes is respectively provided with a water guide plate 4 on the outer side of the water guide plate 4. There is a notch 4a; the seawater to be treated can enter the water container from the lower water inlet 6 through the notch 4a on the water guide plate 4 to the upper water guide plate and communicate with the notch to get the water outlet 7 to flow out; There is a counter electrode 2 protruding from the upper end of the electrode; the bottom and the top of the water container are resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com