Pressure-sensitive adhesive sheet

a technology of adhesive sheets and adhesive sheets, applied in the direction of film/foil adhesives, synthetic resin layered products, protective garments, etc., can solve the problems of increasing the adhesive strength of aged sheets, increasing the age of adhesive sheets, so as to prevent corrosion of metal sheets and good removability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

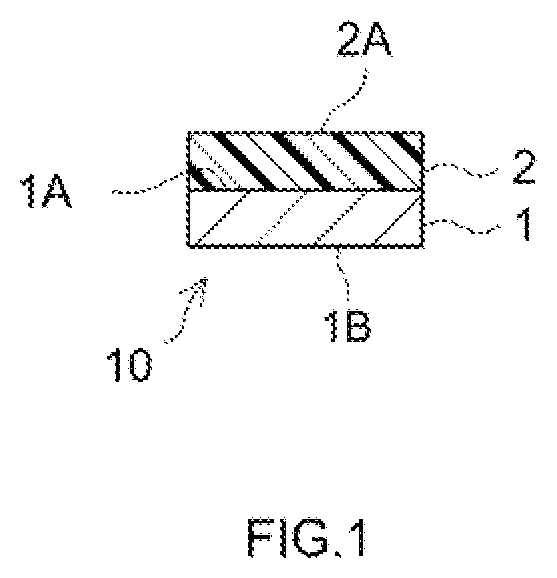

Image

Examples

example 1

[0229]Were mixed a starting monomer mixture comprising 58 parts of 2-ethylhexyl acrylate, 40 parts of n-butyl methacrylate and 2 parts of acrylic acid with 3 parts of surfactant (trade name AQUALON KH-1025 available from Dai-ichi Kogyo Seiyaku Co., Ltd.; ammonium polyoxyethylene-1-(allyloxymethyl) alkyl ether sulfate with up to 30 moles of added EO) and 150 parts of polymerization water. The resulting mixture was emulsified under nitrogen flow with an emulsifying machine (homo mixer) to prepare an emulsion of the starting monomers.

[0230]Into a reaction vessel equipped with a thermometer, nitrogen inlet, condenser and stirrer, was placed the emulsion and heated under nitrogen flow to a liquid temperature of 50° C. while stirring. To this, was added 0.03 part of 2,2′-azobis(2-methylpropionamidine)dihydrochloride (product name V-50 available from Wako Pure Chemical industries, Ltd.) as polymerization initiator and the polymerization reaction was carried out for 5 hours while maintainin...

examples 2 to 5

[0233]Rust inhibitor A was used in the amounts show in Table 1. Otherwise in the same manner as Example 1, were obtained PSA sheets according to the respective Examples.

examples 6 to 7

[0234]Rust inhibitor A was changed to rust inhibitor B (product name CHELESLITE W-16B available from Chelest Corporation, containing organic acid salt and rust inhibitor for iron) or to rust inhibitor C (product name THIOLITE C-560R13 available from Chiyoda Chemical Co., Ltd., 50-60% triethanolamine). Otherwise in the same manner as Example 3, were obtained PSA sheets according to the respective Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| adhesive strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com