Method for removing phosphor-containing wastewater by using fly ash aerated concrete slag

A technology for aerated concrete and fly ash, which is applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of long processing time, uneconomical, low efficiency, etc., and achieves a simple process device. , the effect of low operating cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

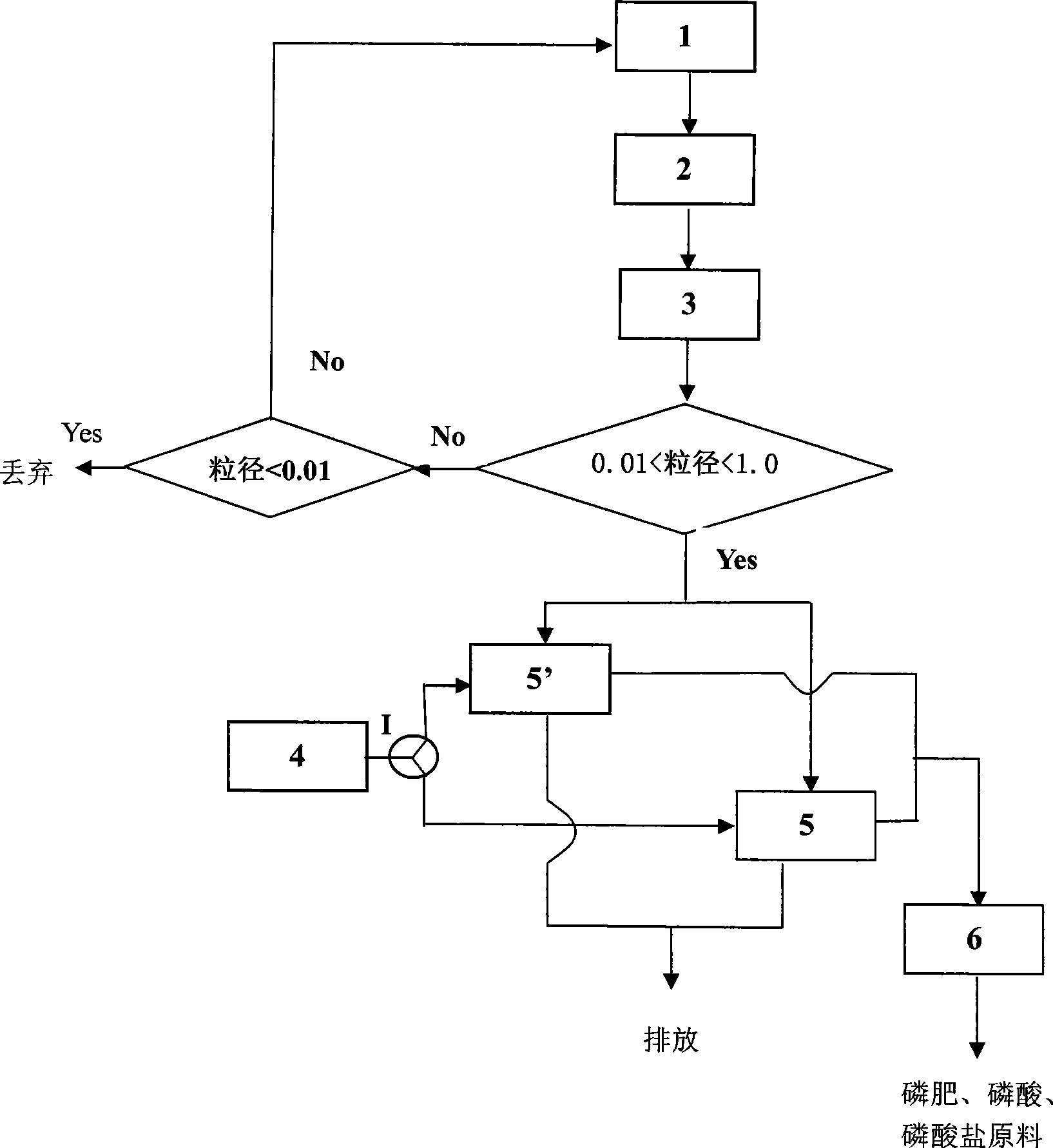

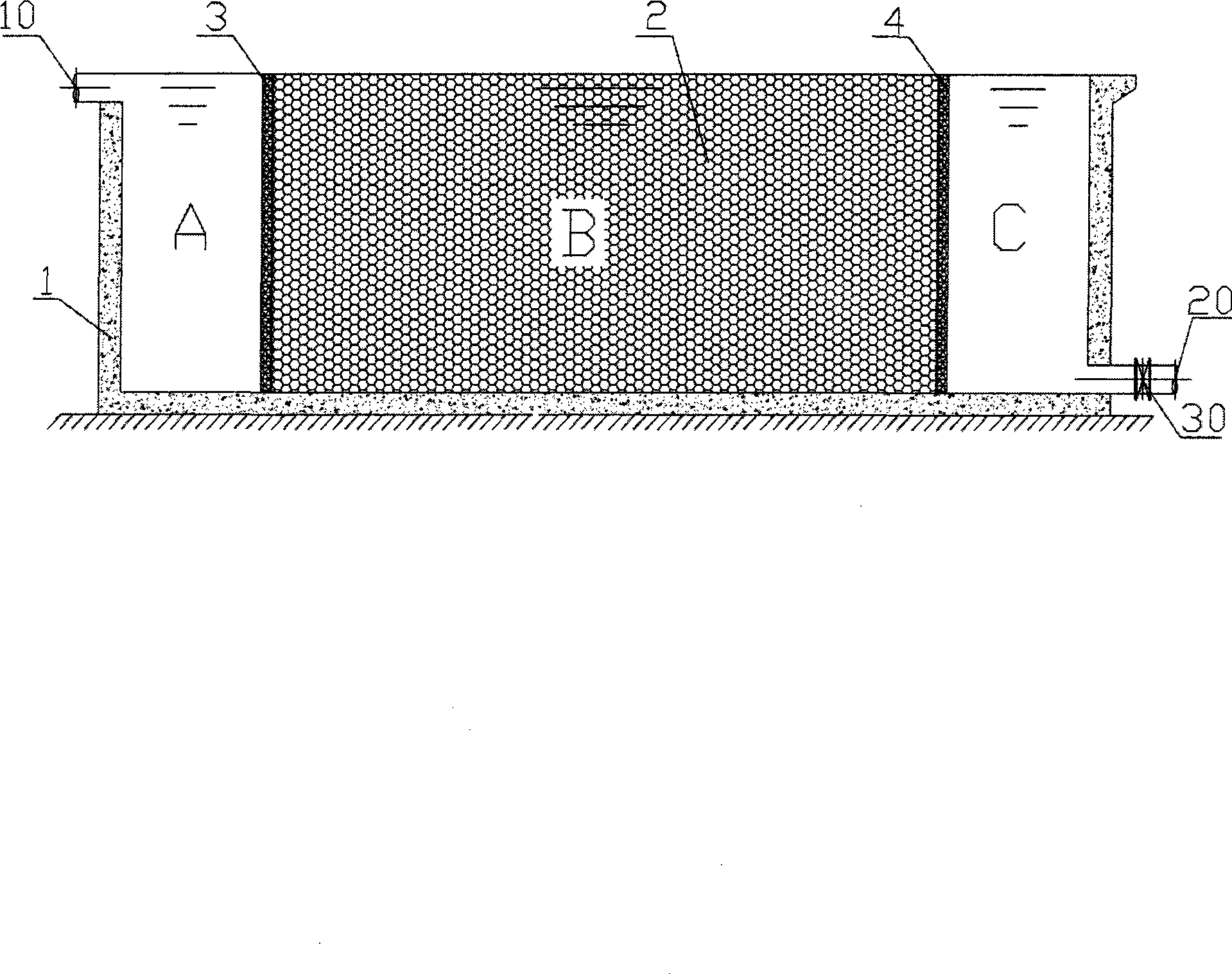

[0023] Determination of the isotherm curve of fly ash air-entrained concrete slag adsorbing phosphate in phosphorus-containing sewage.

[0024] 1. Crush and sieve the collected waste fly ash aerated concrete blocks to obtain slag with a particle size of 0.01-1.0mm;

[0025] 2. Use potassium dihydrogen phosphate and distilled water to prepare 100ml of artificial phosphorus-containing sewage with a phosphorus content of 10mg / l, 20mg / l, 50mg / l, 80mg / l, 100mg / l, 500mg / l, and 1000mg / l, respectively, and respectively placed in 250ml Erlenmeyer flasks;

[0026] 3. Add 10g of fly ash aerated concrete slag baked at 100 degrees Celsius to constant weight to the above-mentioned various artificial phosphorus-containing sewage. Shake and soak for 45 minutes on a rotary shaker with a rotation speed of 100rpm and a temperature set at room temperature, so that the fly ash aerated concrete slag reaches the adsorption phosphorus equilibrium;

Embodiment 2

[0037] 1. Crush and sieve the collected fly ash aerated concrete blocks to obtain slag with a particle size of 0.01-1.0 mm, and dry it;

[0038] 2. Take 10g of baked fly ash aerated concrete slag, add 100ml of distilled water, and then add 6.59g of solid potassium dihydrogen phosphate every 60min. And use the ammonium molybdate method to measure the change of the phosphorus content in the solution, until the phosphorus content in the aqueous solution no longer drops, stop adding potassium dihydrogen phosphate. At this time, the fly ash aerated concrete slag reaches the adsorption saturation state;

[0039] 3. According to the supernatant volume and phosphorus content when the fly ash aerated concrete slag reaches the adsorption saturation state, the maximum phosphorus adsorption capacity of the fly ash aerated concrete slag per unit weight can be calculated. Its value is 0.535g / g, that is, every gram of fly ash aerated concrete slag can absorb 0.535g of phosphorus.

Embodiment 3

[0041] 1. Crush and sieve the collected fly ash aerated concrete blocks to obtain slag with a particle size of 0.01-1.0 mm, and bake to constant weight;

[0042] 2. Add 20g of baked fly ash aerated concrete slag to 100ml of standard dipotassium hydrogen phosphate solution with a concentration of 50mg / l, 80mg / l, 100mg / l, 120mg / l, and 150mg / l, soak 30min;

[0043] 3. Take the soaking solution to detect the phosphorus content therein. The measured phosphorus removal rates were 100%, 100%, 99.5%, 97.8%, and 86.4%, respectively. Except that the phosphorus removal rate of the sewage with a concentration of 150mg / l is less than 90%, the phosphorus removal rates of the other four kinds of phosphorus-containing sewage are all above 97.5%. It shows that the fly ash aerated concrete slag can be used to treat medium and low phosphorus sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com