Novel magnetic nano magnetic seed and the method and application thereof in treating industrial biochemical tail water

A magnetic nanometer and industrial wastewater technology, which is applied in the fields of magnetic field/electric field water/sewage treatment, inorganic material magnetism, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of TOC and EfOM protein exceeding the standard, and achieve the increase of specific surface area, The effect of increasing the removal effect and improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

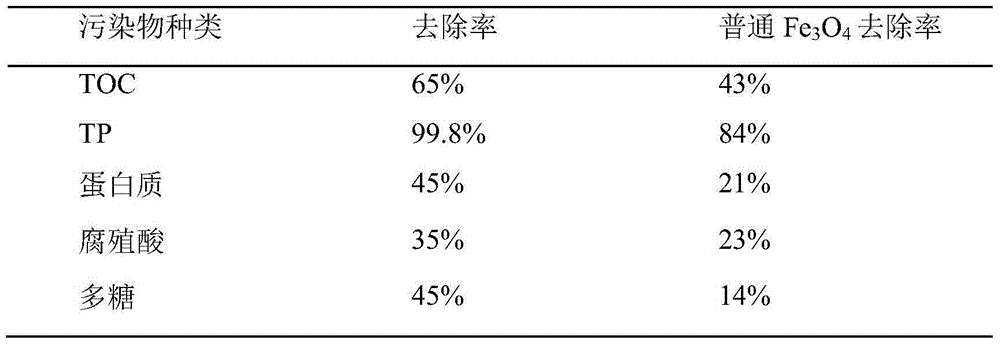

Embodiment 1

[0033] (1) 1.3gFeCl 3 ·6H 2 O was dissolved in 40mL of ethylene glycol, ultrasonically dissolved, 3.5g of anhydrous sodium acetate was added, stirred and mixed, 40mL of the dissolved sample was transferred to a 50mL polytetrafluoroethylene reactor, and reacted at 200°C for 12h to prepare Uniform spherical superparamagnetic Fe with a particle size of about 500 nm 3 o 4 nanoparticles;

[0034] (2) At room temperature (25°C), take 2.5g of cetyltrimethylammonium bromide and 200mL of deionized water, stir to dissolve, and add 1g of Fe prepared in step (1) 3 o 4 Nanoparticles, add 300mL deionized water and mechanically stir for 10min, under the protection of nitrogen, add dropwise 60mgNaOH solution, in which the concentration of NaOH is 1mol / L, the dropping rate is 1 drop / min, mechanically stir for 20min; add 3mL of anhydrous Ethanol and 3mL tetraethyl orthosilicate, heated in a water bath to 55°C for 2 hours at a constant temperature;

[0035] (3) Add 3mL of 3-aminopropyltrie...

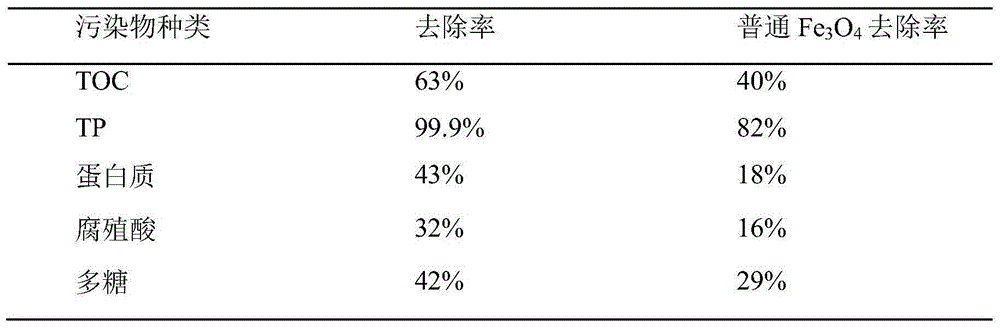

Embodiment 2

[0042] (1) Add 1.5gFe 2 (SO 4 ) 3 Dissolve in 40mL ethylene glycol, ultrasonically dissolve, add 3.8g sodium citrate, stir and mix, transfer 40mL dissolved sample to a 50mL polytetrafluoroethylene reactor, react at 200°C for 12h, and prepare the particle size Uniform spherical superparamagnetic Fe of about 500 nm 3 o 4 nanoparticles;

[0043] (2) At room temperature (25°C), take 2.5g of cetyltrimethylammonium bromide and 200mL of deionized water, stir to dissolve, and add 1g of Fe prepared in the above steps 3 o 4 Nanoparticles, add 300mL deionized water and mechanically stir for 10min, under the protection of nitrogen, add 60mgNH 3 ·H 2 O solution, where NH 3 ·H 2 The concentration of O is 1mol / L, the rate of addition is 1 drop / min, and mechanically stirred for 20 minutes; add 3mL of absolute ethanol and 3mL of tetraethyl orthosilicate at room temperature, and heat it in a water bath to 55°C for 2 hours at a constant temperature;

[0044] (3) Add 3mL of 3-aminopropy...

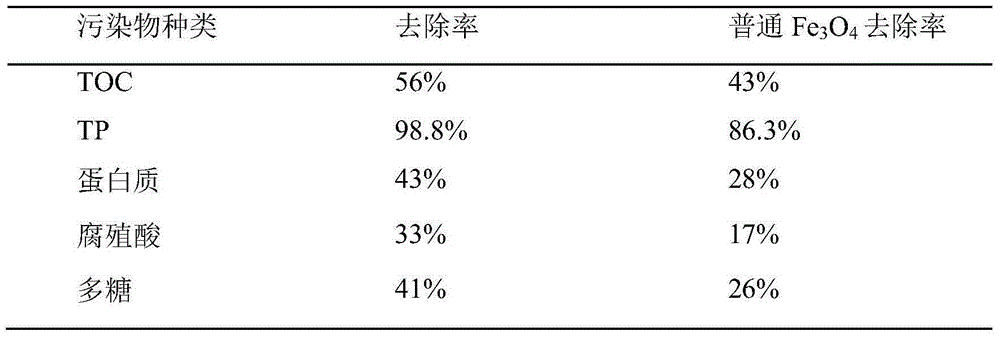

Embodiment 3

[0051] (1) 1.3gFeCl 3 ·6H 2O was dissolved in 40mL of ethylene glycol, ultrasonically dissolved, 3.5g of anhydrous sodium acetate was added, stirred and mixed, 40mL of the dissolved sample was transferred to a 50mL polytetrafluoroethylene reactor, and reacted at 200°C for 12h to prepare Uniform spherical superparamagnetic Fe with a particle size of about 500 nm 3 o 4 nanoparticles;

[0052] (2) At room temperature (25°C), take 2.5g of cetyltrimethylammonium bromide and 200mL of deionized water, stir to dissolve, and add 1g of Fe prepared in the above steps 3 o 4 Nanoparticles, add 300mL deionized water and mechanically stir for 10min, under the protection of nitrogen, add dropwise 60mgNaOH solution, wherein the concentration of NaOH is 1mol / L, the dropping rate is 1 drop / min, mechanically stir for 20min; add 3mL of anhydrous Ethanol and 3mL tetraethyl orthosilicate, then heated in a water bath to 55°C for 2 hours at a constant temperature;

[0053] (3) Add 3mL of 3-amino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com