Electrochemical preparation method of LiFeAs superconductor

A superconducting and electrochemical technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of high requirements on experimental conditions and long period of LiFeAs superconductor, and achieve simple process equipment, The effect of rapid preparation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

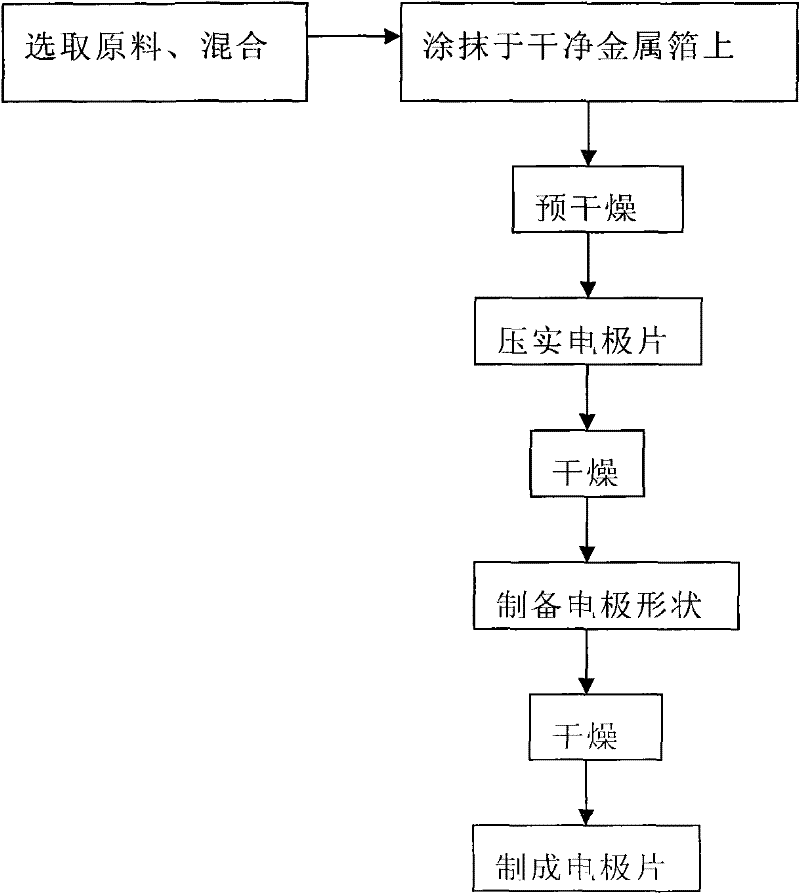

[0029] figure 1 It is a flow chart of the electrochemical preparation method of a LiFeAs superconductor of the present invention to prepare the positive electrode, as figure 1 Shown: The ingredients and mass percentages of selected electrodes are: FeAs powder 66%-74%, acetylene black 14%-18%, binder 12%-16%; mix 0.1-1mL N-methylpyrrolidone with the Put the ingredients and ingredients of the above electrodes together into a mortar, mix and grind them into gel, and apply them on a clean metal foil to make an electrode sheet; place the electrode sheet in a drying oven, pre-dry it at 50-75°C, and wait for N- After the methylpyrrolidone is completely volatilized, lightly press the electrode sheet on the press, and then vacuum-dry it in a drying oven at 110-150°C for 2-3 hours until the electrode sheet is completely dry. After the temperature gradually drops to room temperature, take out the electrode sheet and print it After preparing the shape of the electrode, put it in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com