Treatment device and method for completely recycling electroplating rinse water

A treatment device and technology for rinsing water, applied in the electrolysis process, electrolysis components, cells, etc., to achieve the effects of small one-time investment, saving rinsing water, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

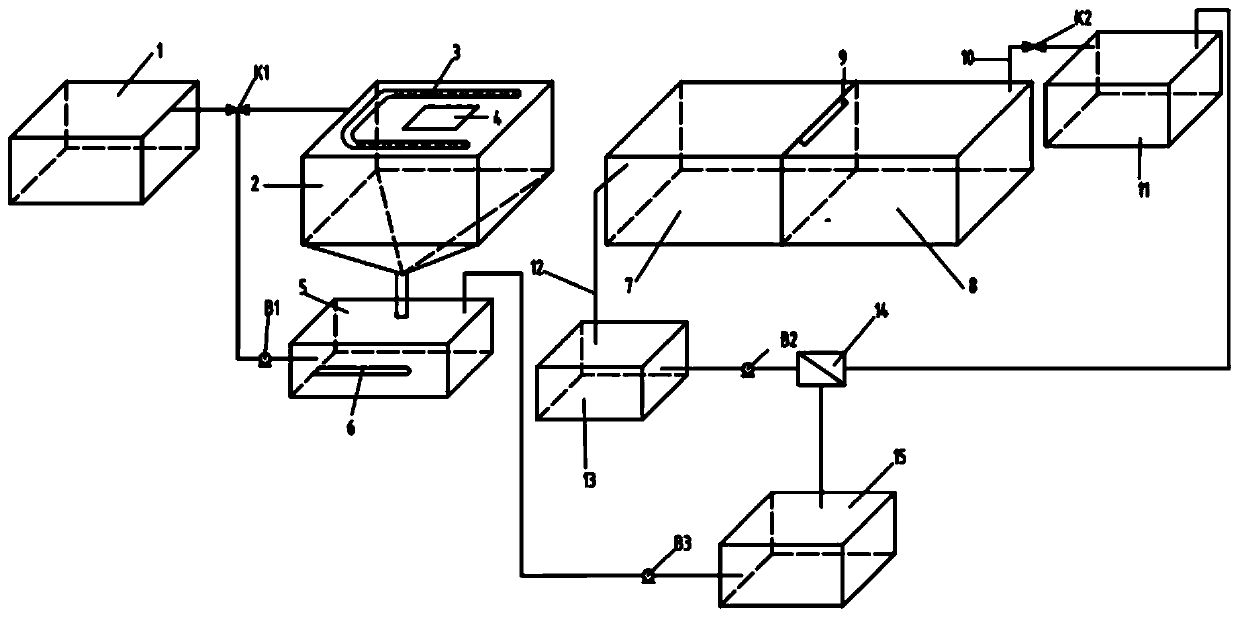

[0021] Such as figure 1 A treatment device for full recovery and utilization of electroplating rinsing water includes a spray concentration system device, a countercurrent rinse concentration system and a plating tank 1. The spray concentration system device includes a first water pump B1, a spray tank 2, The nozzle 3 and the spray recovery tank 5, the spray tank communicates with the plating tank through the first pipeline, the first pipeline is equipped with a three-way valve K1, the nozzle is arranged in the spray tank, The spray recovery tank is arranged under the spray tank and communicates with the bottom of the spray tank through the second pipeline, and the spray recovery tank is also connected with the three-way valve K1 through the third pipeline. The third pipeline is provided with a first water pump, and the countercurrent rinsing concentration system is composed of a countercurrent rinsing tank, an overflow recovery tank 13, a membrane concentration device 14, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com