Sodium hypochlorite conveying device for viscose fiber production refining process and use method thereof

A sodium hypochlorite and viscose fiber technology, applied in the field of viscose fiber production, can solve the problems of unmonitored sodium hypochlorite addition, complicated process equipment, affecting product quality, etc., and achieves the effects of constant flow, simple process equipment, and reduced process fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

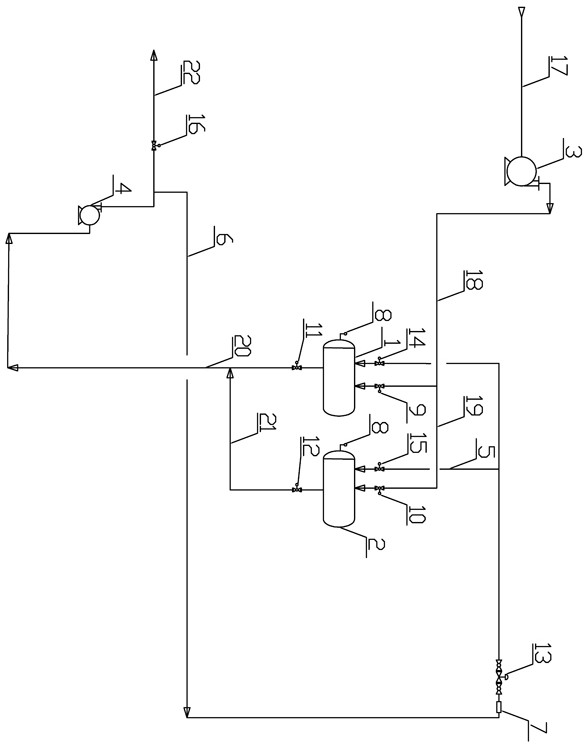

[0020] Embodiment 1: as attached figure 1 As shown, the sodium hypochlorite conveying device in the refining process of viscose fiber production includes the first sodium hypochlorite storage tank 1 and at least one second sodium hypochlorite storage tank 2, hyposodium discharge pump 3, hyposodium metering pump 4 and control unit, hyposodium The liquid inlet of the unloading pump 3 is fixedly connected with the first discharge pipeline 17, and the first liquid inlet at the top of the first sodium chlorate storage tank 1 and the liquid outlet of the secondary sodium unloading pump 3 are fixedly connected with the second discharge pipeline 18 , a third discharge pipeline 19 is fixedly connected between the first liquid inlet at the top of the second sodium hypochlorite storage tank 2 and the second discharge pipeline 18, and the liquid outlet at the bottom of the first sodium hypochlorite storage tank 1 and the liquid inlet of the sodium hypochlorite metering pump 4 The first li...

Embodiment 2

[0023] Embodiment 2: as attached figure 1 As shown, as an optimization of the above embodiment, the first return line 6 is communicated with the third liquid delivery line 22 between the first liquid delivery line 20 and the secondary sodium metering pump 4 .

Embodiment 3

[0024] Embodiment 3: as attached figure 1 As shown, a second return line 5 is fixedly connected between the first return line 6 and the second liquid inlet at the top of the second sodium hypochlorite storage tank 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com