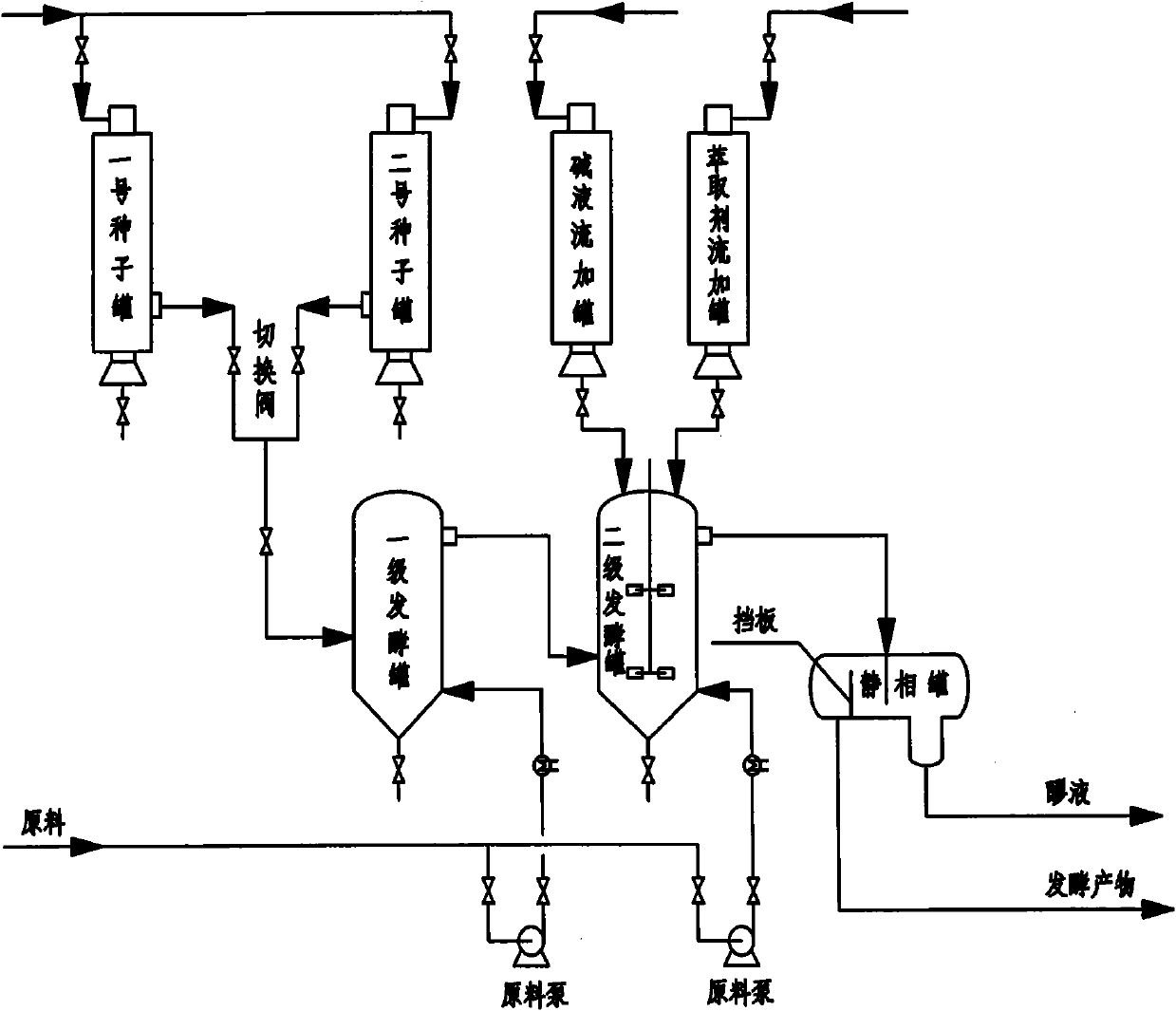

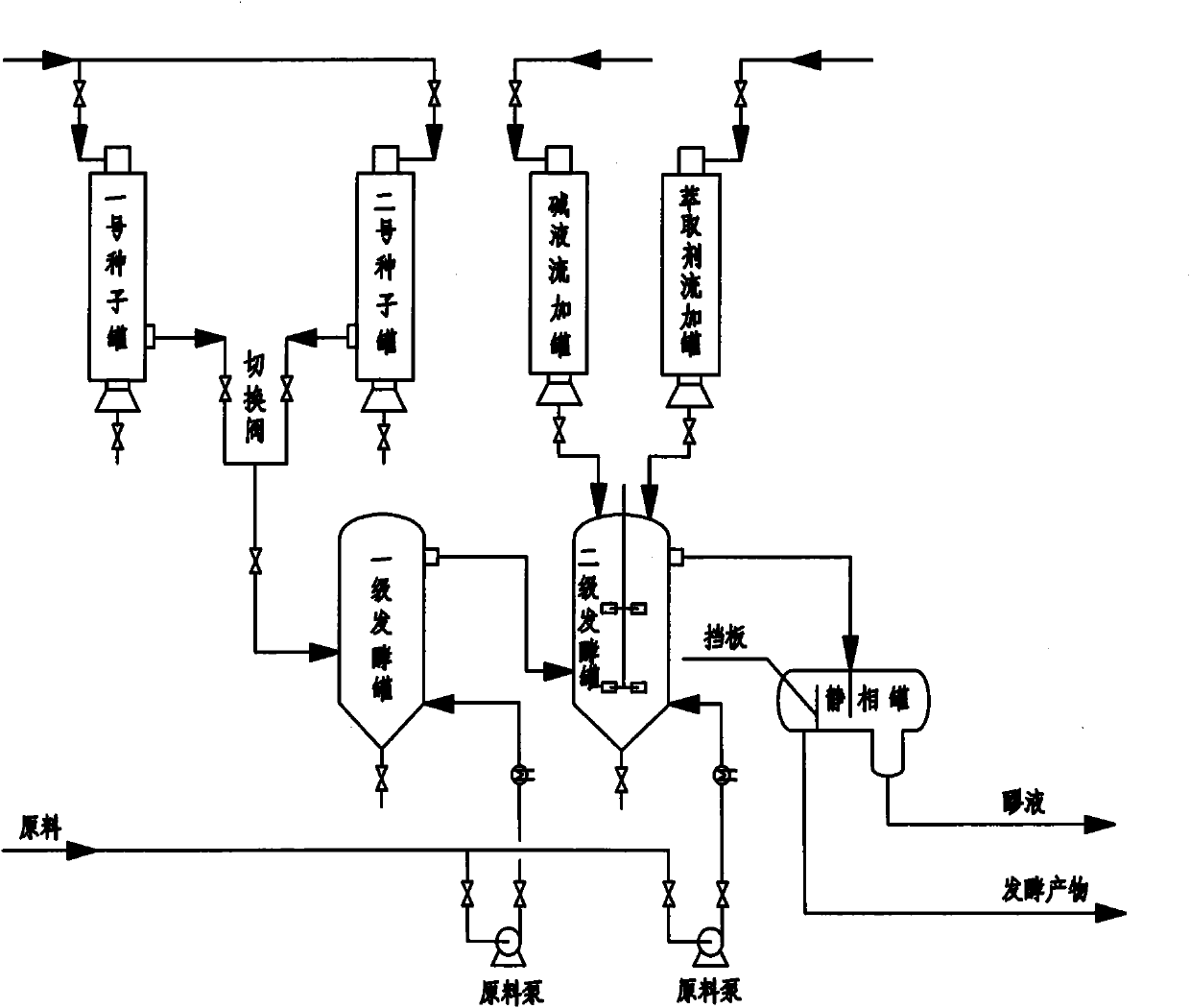

Acetone-butanol in-situ extraction continuous fermentation device and technology

A technology of acetone butanol and fermentation process, applied in fermentation, biochemical cleaning device, enzymology/microbiology device and other directions, can solve the problems of difficulty in large-scale production, high equipment price, poor stability, etc., and achieves easy implementation, The effect of increasing yield and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

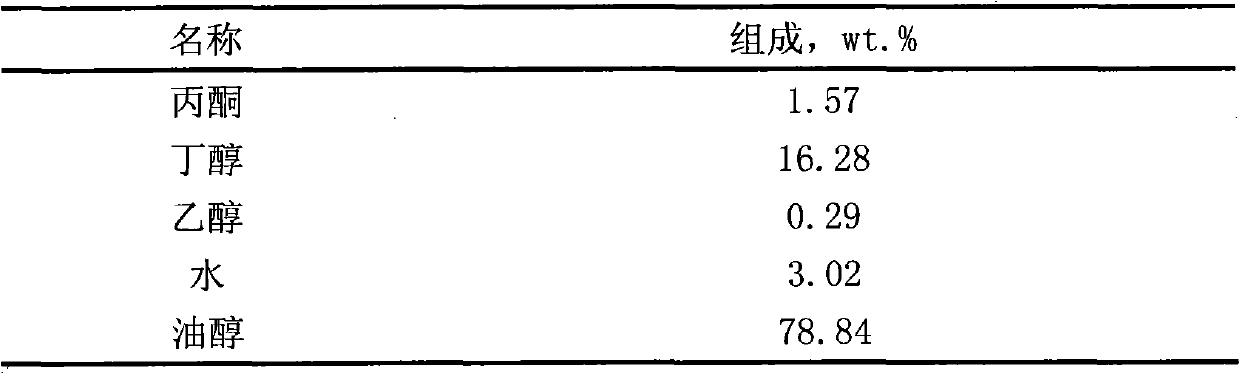

[0023] Example 1:

[0024] 1) Using corn steep liquor as raw material, its content in the culture medium is 20g / L, and additional nutrients are 0.3g / LCaCl 2 , 0.2g / L MgSO 4 ·7H 2 O, 0.5g / L KH 2 PO4, 0.5g / L urea; equipped with 0.5M NaOH injection lye tank; oleyl alcohol stock solution injected into the extractant storage tank for later use. The fermentation begins to steam sterilize the equipment in situ.

[0025] 2) Preparation of seed liquid: Clostridium acetobutylicun (CGMCCAS1.132) is used as the fermentation strain (purchased from the Common Microorganism Collection Center of the Chinese Microorganism Collection Management Committee), the composition of each liter of seed culture medium is: 40g glucose , 6g tryptone, 2g yeast extract, 2g beef extract, 3g (NH 4 ) 2 SO 4 , 0.2g MgSO 4 ·7H 2 O, 0.5g KH 2 PO 4 , 0.01g FeSO 4 ·7H 2 O, adjust pH=6.0~6.5. Inject the seed culture medium into the No. 1 seed fermentation tank, the injection volume is 2 / 3 of the volume of the fermentatio...

Example Embodiment

[0032] Example 2:

[0033] 1) Using cassava pulp as raw material, the content in the medium is 40g / L, and the additional nutrients are 0.3g / LCaCl 2 , 0.2g / L MgSO 4 ·7H 2 O, 0.5g / L KH 2 PO4, 0.5g / L urea; equipped with 0.5M NaOH injection lye tank; oleyl alcohol stock solution injected into the extractant storage tank for later use. The fermentation begins to steam sterilize the equipment in situ.

[0034] 2) Preparation of seed liquid: Clostridium acetobutylicunm (CGMCCAS1.244) was used as the fermentation strain (purchased from the General Microorganism Collection Center of the China Microorganism Collection Management Committee).

[0035] The steps are the same as in Example 1, and the culture temperature is set to 35°C.

[0036] 3) After 7 hours of seed solution cultivation, turn on the raw material circulation pump of the first-level fermentation tank to make the raw materials enter 2 / 3 of the volume of the fermentation tank, turn off the pump, and connect 8% of the seeds in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com