Rapid dehydration method for low-temperature sealed interface of produced liquid in oil field central treatment station and device for implementing method

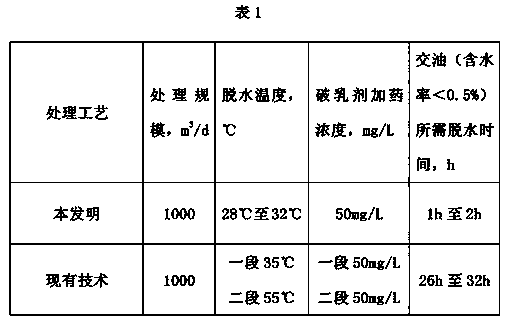

A centralized treatment and rapid dehydration technology, which is applied in the direction of hydrocarbon oil dehydration/demulsification, dehydration/demulsification by chemical methods, and only multi-stage serial refining process treatment, etc., can solve the problem of high dosing concentration of demulsifier and long dehydration time , high dehydration temperature and other issues, to achieve significant environmental benefits, reduce dosing concentration, and reduce the effect of dehydration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

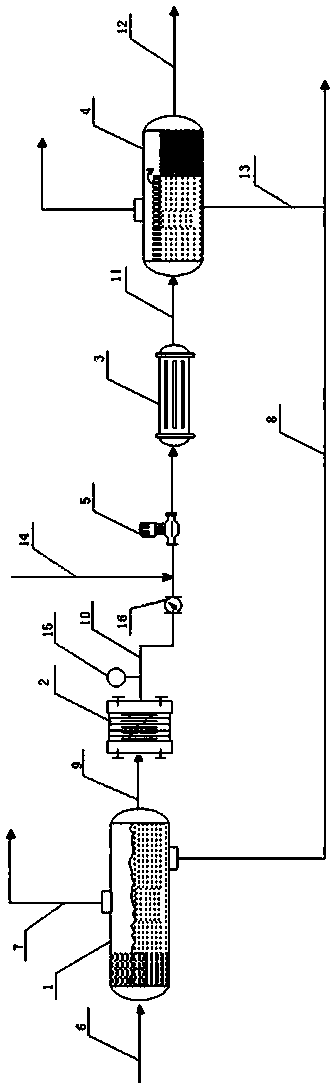

[0021] Embodiment 1: The rapid dehydration method of the low-temperature airtight interface of the oilfield centralized treatment station produced fluid is carried out according to the following method: the first step, the oilfield produced fluid enters the three-phase separator 1, and passes through the three-phase separator 1 to divide and eliminate After foaming, coalescence, vortex elimination and demist purification, dry gas, water-containing crude oil and water are obtained respectively. The dry gas is discharged from the gas outlet. Due to the density difference between water-containing crude oil and water and its own gravity, the water sinks to the three-phase separator 1 The bottom is discharged through the water outlet of the three-phase separator 1, and the water-containing crude oil floats on the top of the three-phase separator 1, and is discharged to the steam phase change heating furnace 2 through the oil outlet of the three-phase separator 1; in the second step, ...

Embodiment 2

[0024] Example 2: As an optimization of the above example, in the second step, the dehydration temperature is 28° C. to 32° C., and the mixing ratio of the demulsifier to the aqueous crude oil is 50 mg of the demulsifier per liter of aqueous crude oil.

Embodiment 3

[0025] Example 3: As an optimization of the above example, the strongly lipophilic and hydrophobic interface active material has a contact angle with oil of 3° to 5°, and a contact angle with water greater than 148°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com