A continuous separation and purification device and method for behenic acid amide

A technology of behenic acid amide and purification method, which is applied in the direction of carboxylic acid amide separation/purification, separation method, chemical instrument and method, etc., can solve the problems of high volatility of solvent, high cost, and many processes, and achieve the goal of process equipment Simple and practical, low processing cost, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

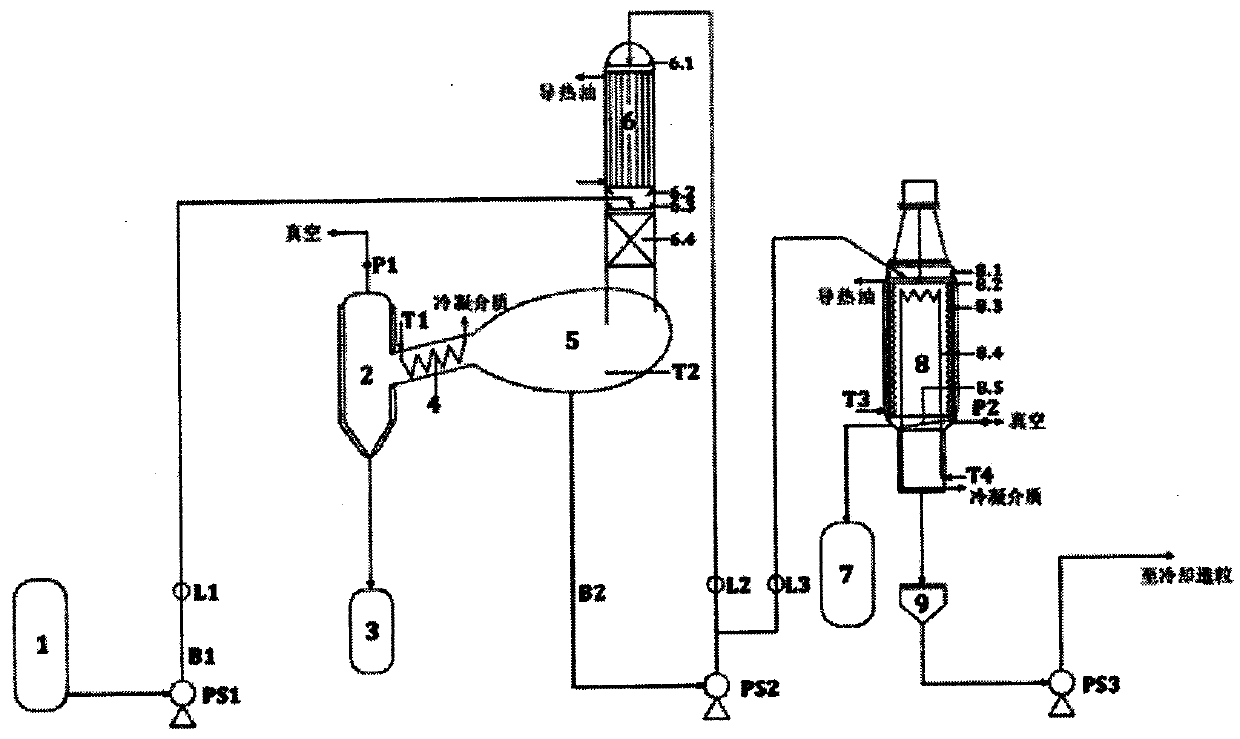

[0022] Such as figure 1 As shown, the continuous separation and purification device of behenic acid amide of the present embodiment includes a crude product storage tank 1 connected in sequence, a first-stage falling film distillation device for steaming and separating light components and for separating behenic acid The amides are distilled off and separated from the heavy components in a two-stage rotary wiped-film short-path distillation device.

[0023] The first-stage falling film distillation device includes a cooling collector 2 , a short path still 5 and a falling film heating evaporator 6 . The falling film heating evaporator 6 is sequentially provided with a distributor 6.1, a collector 6.2, a distributor 6.3 and a rectification section 6.4 from top to bottom. Tank 1 is connected to the distributor 6.3 of the falling film heating evaporator 6 through the first delivery pump PS1, and the bottom of the rectification section 6.4 of the falling film heating evaporator 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com