Treatment device and method for implementing total recycling of electroplating rinse water

A processing device and processing method technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of complex shape of electroplating workpiece and cannot be cleaned, achieve easy equipment maintenance and management, save rinsing water, and low one-time investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

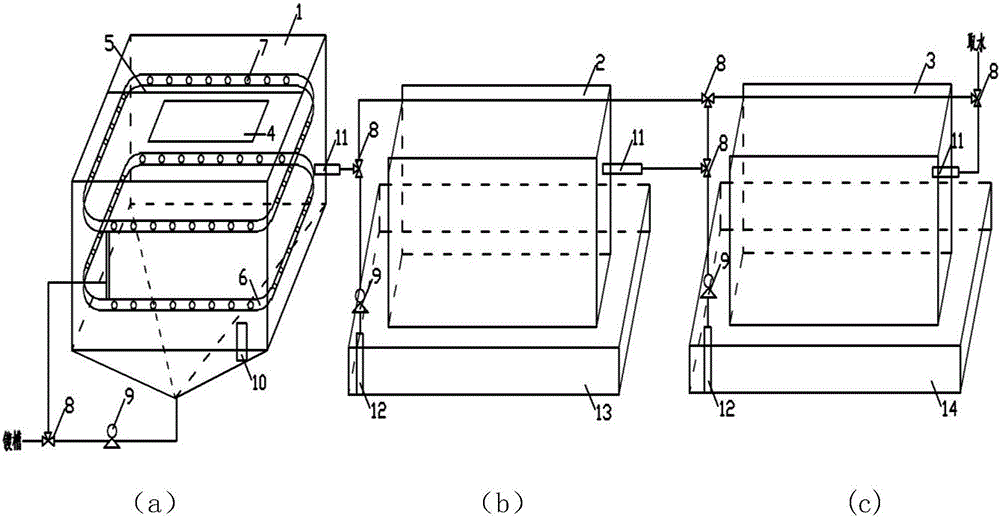

[0024] The processing device for realizing the full recovery and utilization of electroplating rinsing water of the present invention includes a spray system device (a) and two countercurrent rinsing systems (b) and (c), wherein the spray system device (a) Including water pump, spray tank, nozzle and connecting pipeline. The nozzle pipeline is fixed at the corresponding position of the spray tank. The spray tank has a corresponding water pump and three-way valve. There is a water outlet on the left side of the three-way valve, which can lead to Coating tank; the counter-current rinsing system device (b), (c) includes 2 rinsing tanks, 2 sumps, water pump, three-way valve, water outlet, water inlet and pipe network, 2 rinsing tanks are connected in series At the same time, the upper end of the three-way valve at the water inlet of the second-stage rinsing tank is provided with a water inlet to achieve water intake for supplement; the spray tank, nozzles and connecting pipelines in...

Embodiment 2

[0028] The device and method of the invention are applied to the silver plating production of a certain electroplating enterprise. Such as figure 1 As shown, the others in this embodiment are as in embodiment 1, the silver-plating DC power supply is 1000A, and the plating tank is 16M 3 , The total area of plateable parts per tank is 2000dm 2 , The electroplating time is 15 minutes, and 6000ml of plating solution is taken out of the plating tank each time. If calculated based on the uninterrupted production of 365 days a year, 24 hours a day, 210240L of plating solution from the plating tank will be recovered every year; Calculated based on the amount of plating solution contained in the rinsing water in the plating solution of 500 mg / L, 420,480 tons of water used for rinsing can be saved each year, and 420,480 tons of silver plating wastewater can be treated less annually.

Embodiment 3

[0030] The device and method of the invention are applied to nickel plating production in electroplating enterprises. Such as figure 1 As shown, the others in this embodiment are as in embodiment 1, the nickel-plating DC power supply is 1000A, and the plating tank is 6M 3 , The total area of plateable parts per tank is 667dm 2 , The electroplating time is 15 minutes, and 1000ml of plating solution is taken out of the plating tank each time. If calculated as 365 days a year, 24 hours a day, uninterrupted production, 35040L of plating solution from the plating tank will be recovered every year; Calculated based on the amount of plating solution contained in the rinsing water in the plating solution of 500mg / L, 70080 tons of water used for rinsing can be saved each year, and 70080 tons of nickel-plating wastewater can be treated less annually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com