Sputtering and forming device by tumbling cylinder method

A roller method and sputtering technology, which is applied in the field of rapid solidification and near-net shape processing, can solve the problems of unsuitability for industrial continuous production, difficulty in uniform deposition of molten metal, and single product preparation, so as to facilitate continuous production, convenient implementation, and The effect of simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

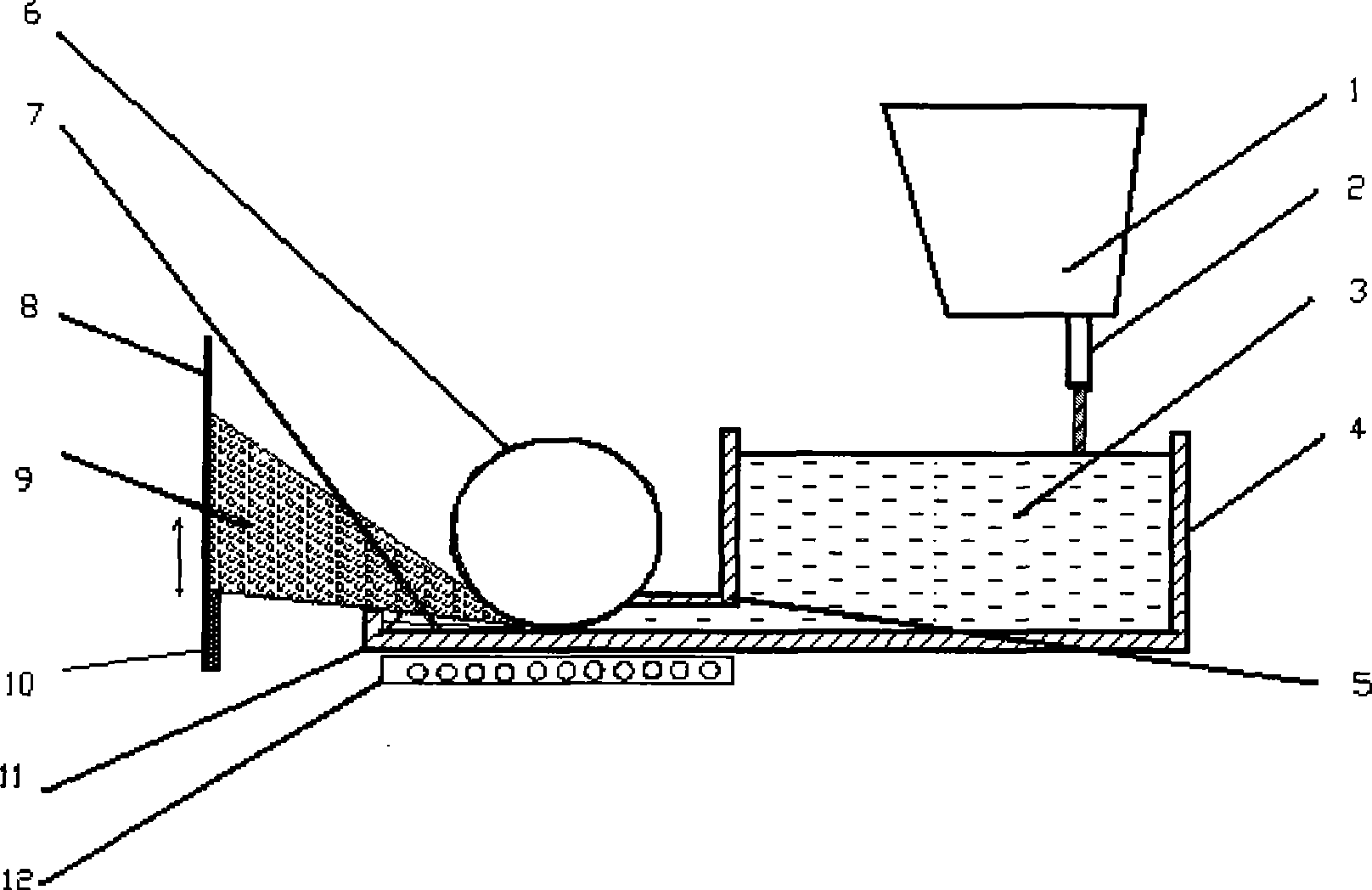

[0027] refer to figure 1 The present invention comprises: a ladle 1, a nozzle 2, a molten metal 3, a tundish 4, a deposition substrate 8, a metal droplet 9, a deposition blank 10, a molten metal drainage channel 5 is provided at the bottom of the tundish 4, and a molten metal drainage There is a high-temperature drum 6 at the exit of the channel 5, and there is a gap between the high-temperature drum 6 and the bottom plate of the molten metal drainage channel 5, and the molten metal 3 in the gap between the high-temperature drum 6 and the bottom end of the molten metal drainage channel 5 forms a liquid steel film 7, and the molten metal is drained A baffle plate 11 is provided at the front end of the bottom plate of the channel 5 , a heater 12 is provided on the lower surface of the bottom plate of the molten metal drainage channel 5 , and the deposition substrate 8 is located on the side of the tundish 4 in front of the high-temperature drum 6 .

[0028] During preparation, i...

Embodiment 2

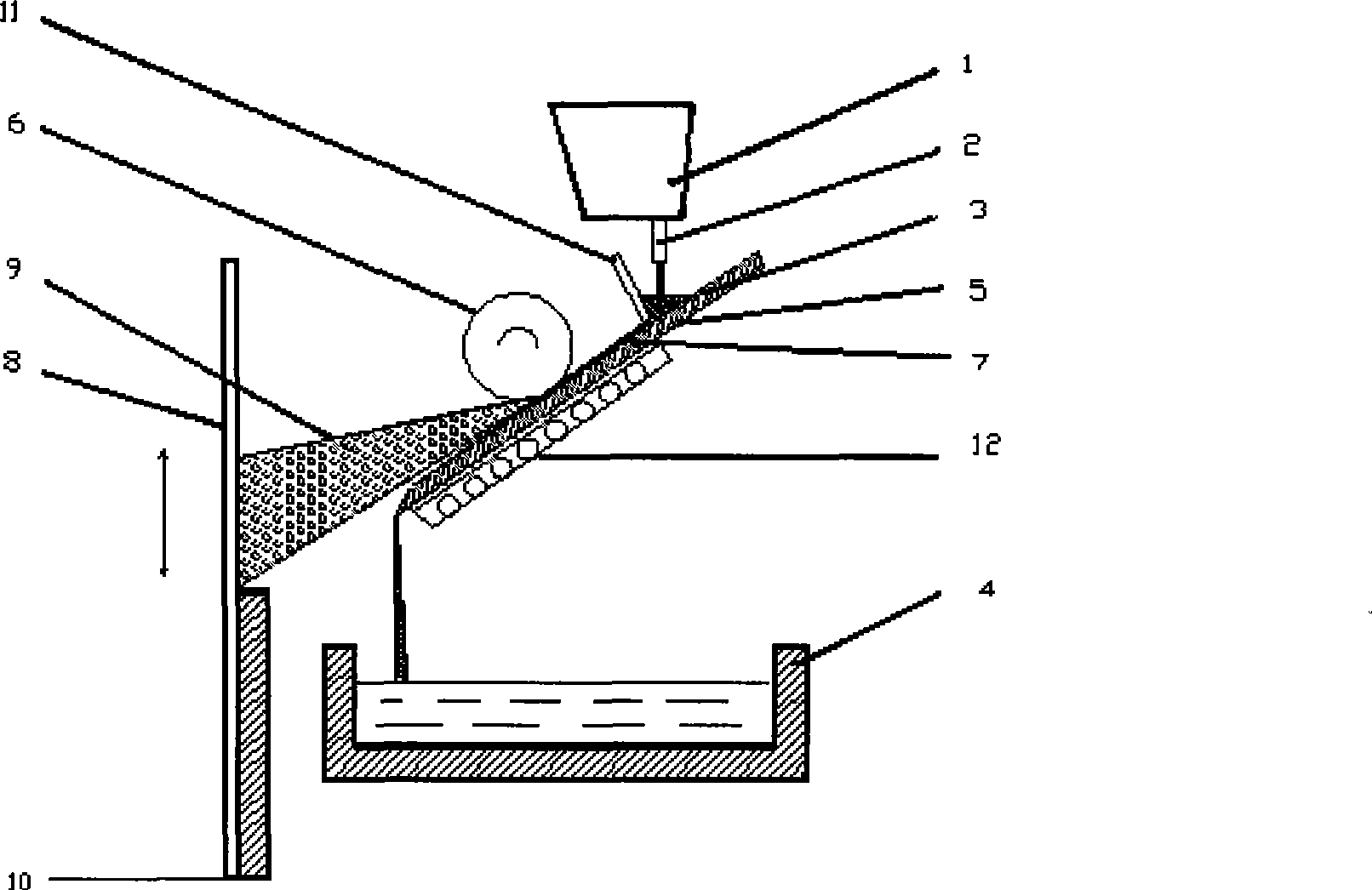

[0030] refer to figure 2 : Including: ladle 1, nozzle 2, molten metal 3, tundish 4, deposition substrate 8, metal droplet 9, deposition blank 10, below the nozzle 2 and above the tundish 4, a prefabricated liquid film is arranged obliquely Plate 13, a baffle plate 14 is arranged above the liquid film prefabricated plate 13, and the baffle plate 14 and the liquid film prefabricated plate 13 form a molten pool. A gap is left to form a liquid film 7 in the gap position of the molten metal 3. In order to prevent the liquid film 7 from solidifying during the flow process, a heater 12 is provided on the lower surface of the bottom plate of the molten metal drainage channel 5, and the deposition substrate 8 It is located on the side of the tundish 4 in front of the high-temperature drum 6 . There is a gap between the high-temperature drum 6 and the bottom plate of the drainage channel 5 of the molten metal 3 .

[0031] The molten steel 4 in the tundish of the present invention is ...

Embodiment 3

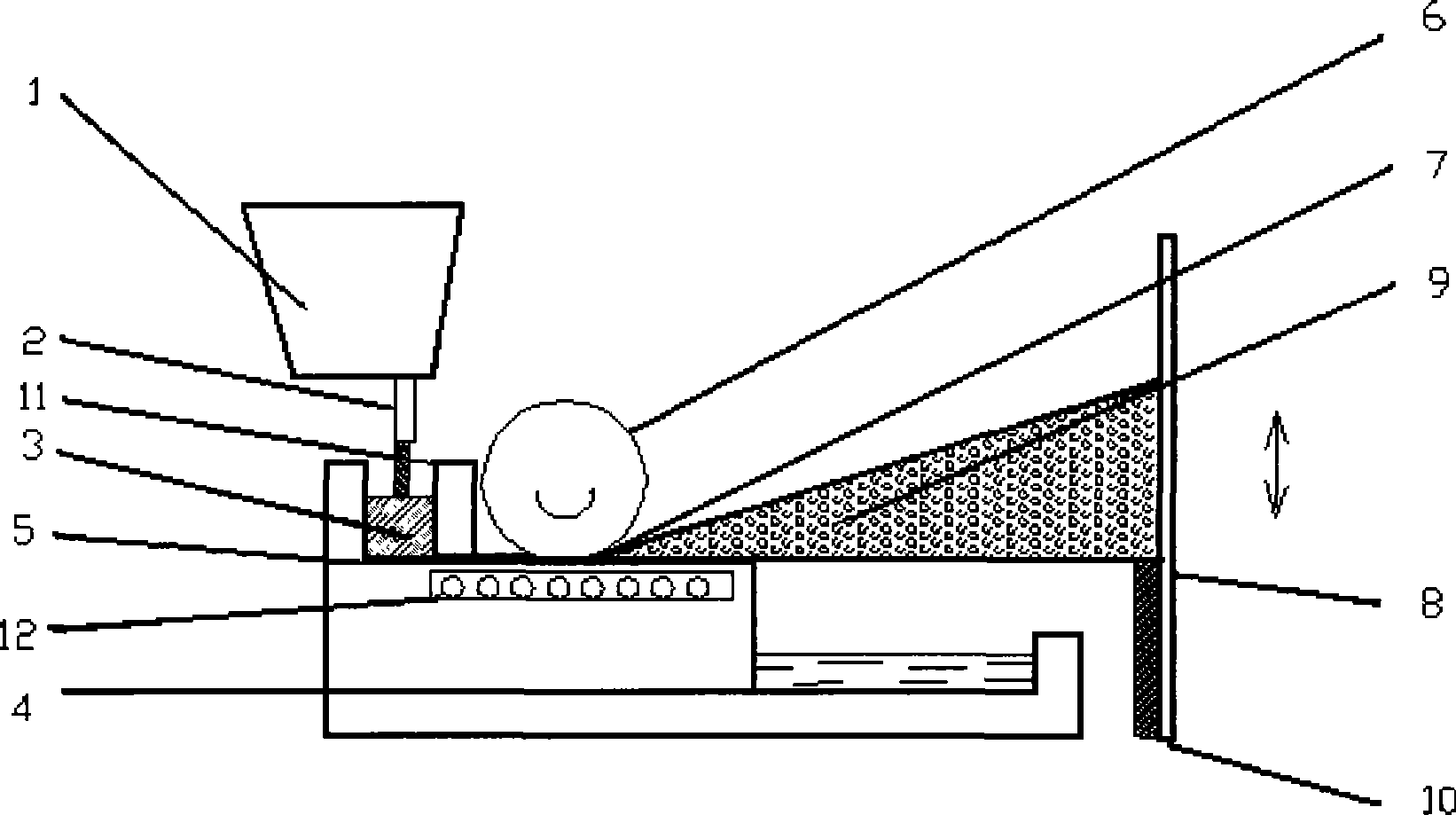

[0033] refer to image 3 : The upper end of the tundish 4 is equipped with a horizontally placed liquid film prefabricated plate 13, a baffle plate 14 is arranged above the liquid film prefabricated plate 13, there is a gap between the baffle plate 14 and the liquid film prefabricated plate 13, and a high temperature is provided in front of the baffle plate 14. Drum 6 , heater 12 is provided on the lower surface of liquid film prefabricated plate 13 located under high temperature drum 6 , and deposition substrate 8 is located on the side of tundish 4 in front of high temperature drum 6 .

[0034] image 3 It is a schematic diagram of the heater-embedded drum method sputtering forming process. The molten metal 9 of the present invention is pre-injected into the molten pool between the liquid film prefabricated plate 13 and the baffle plate 14, and a heater 12 is embedded in the bottom of the liquid film prefabricated plate 13 to prevent the molten metal 3 from solidifying. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com