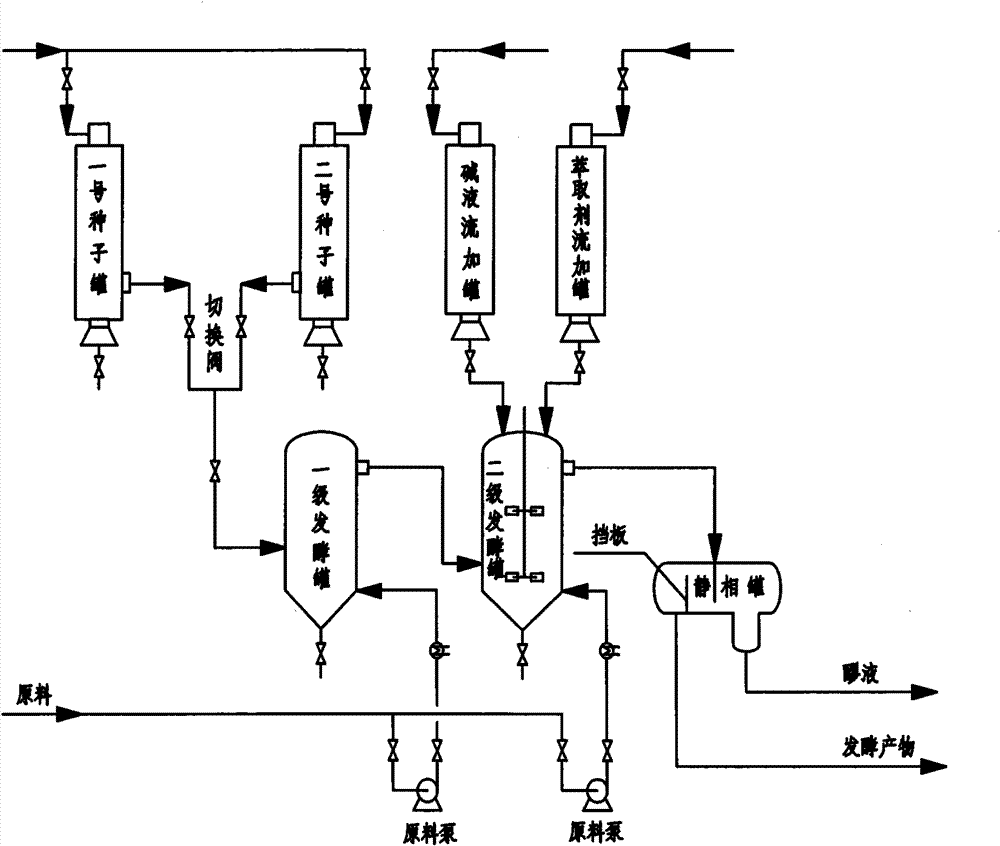

Acetone-butanol in-situ extraction continuous fermentation device and technology

A kind of acetone-butanol fermentation device technology, applied in the field of acetone-butanol in-situ extraction continuous fermentation device, can solve the problems of poor stability, difficulty in large-scale production, high equipment price, etc., and achieve the goals of reduced dosage, easy implementation, and increased output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

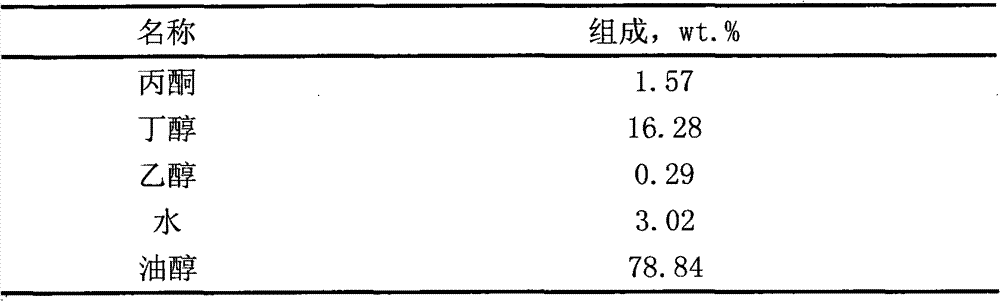

Embodiment 1

[0024] 1) with corn steep liquor as raw material, its content in the culture medium is 20g / L, and the additional nutrient is 0.3g / LCaCl 2 , 0.2g / L MgSO 4 ·7H 2 O, 0.5g / L KH 2 PO4, 0.5g / L urea; configure 0.5M NaOH to inject into the lye tank; oleyl alcohol stock solution is injected into the extractant storage tank for use. Fermentation begins with in-situ steam sterilization of the equipment.

[0025] 2) Preparation of seed liquid: with Clostridium acetobutylicun CGMCCAS1.132 as fermentation strain, (purchased from China Microorganism Preservation and Management Commission Ordinary Microorganisms Collection Center), the component of each liter of seed medium is: 40g glucose , 6g tryptone, 2g yeast extract, 2g beef extract, 3g (NH 4 ) 2 SO 4 , 0.2g MgSO 4 ·7H 2 O, 0.5g KH 2 PO 4 , 0.01g FeSO 4 ·7H 2 O, adjust pH=6.0~6.5. Inject the seed medium into the No. 1 seed fermenter, and the injection amount is 2 / 3 of the volume of the fermenter. 2 Deoxygenate for 2 to 3 ho...

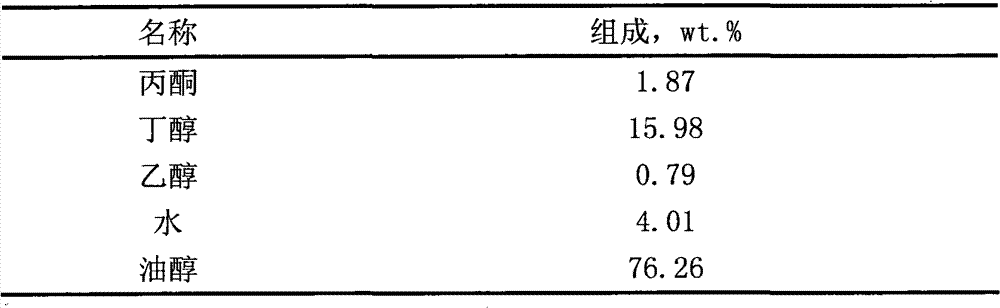

Embodiment 2

[0033] 1) with cassava pulp as raw material, its content in culture medium is 40g / L, and additional nutrient is 0.3g / LCaCl 2 , 0.2g / L MgSO 4 ·7H 2 O, 0.5g / L KH 2 PO4, 0.5g / L urea; configure 0.5M NaOH to inject into the lye tank; oleyl alcohol stock solution is injected into the extractant storage tank for use. Fermentation begins with in-situ steam sterilization of the equipment.

[0034] 2) Preparation of seed liquid: Clostridium acetobutylicunm CGMCCAS1.244 was used as the fermentation strain, (purchased from the General Microorganisms Collection Center of China Microorganism Preservation and Administration Commission).

[0035] The steps were the same as in Example 1, and the incubation temperature was set to 35°C.

[0036] 3) After 7 hours of seed liquid culture, turn on the primary fermentation tank raw material circulation pump, make the raw material enter the 2 / 3 volume of the fermentation tank, close the pump, and insert the seeds in the No. 1 seed tank into the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com