Conversion unit high ammonia nitrogen acid condensate pretreatment system and conversion unit high ammonia nitrogen acid condensate pretreatment method

A high-ammonia-nitrogen acidic, conversion unit technology, applied in the field of high-ammonia nitrogen acidic condensate pretreatment system of the conversion unit, can solve the problems of increasing process complexity, ammonium salt crystallization blockage, occupying space, etc., to avoid corrosion and reduce burden , the effect of effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

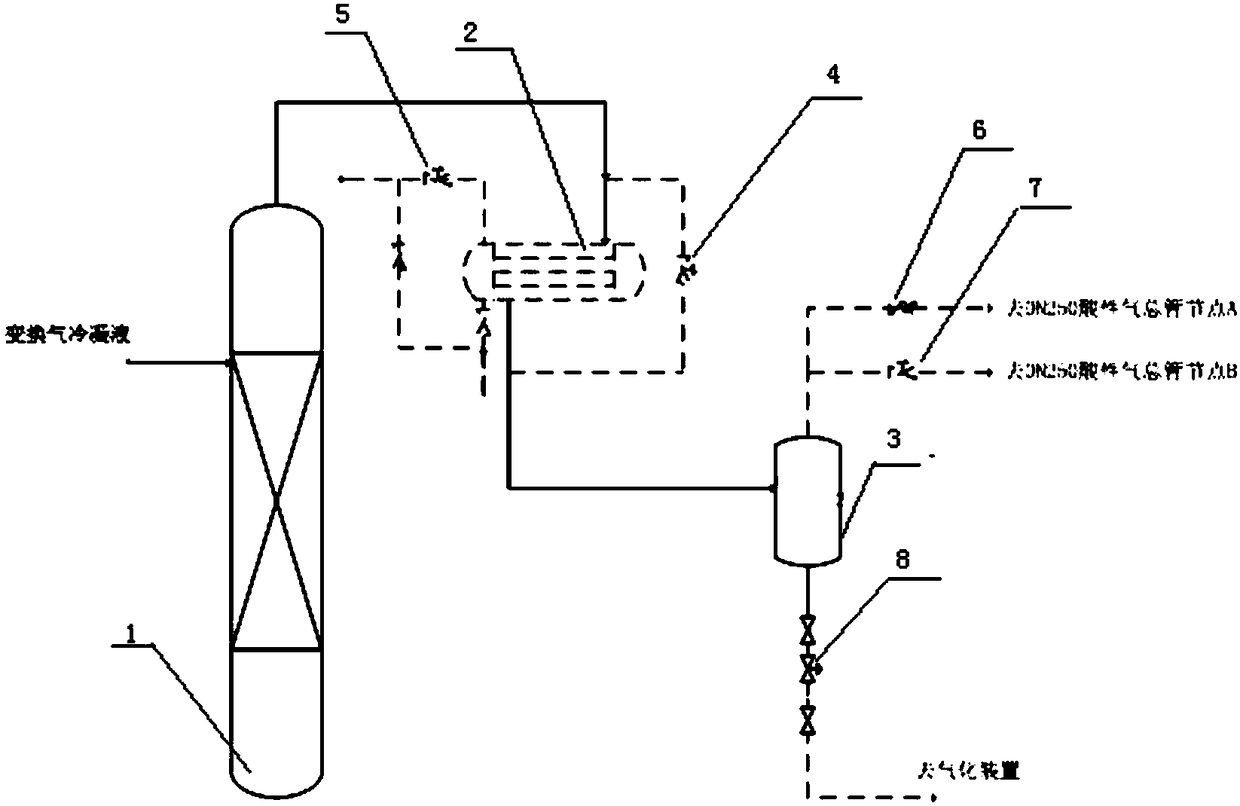

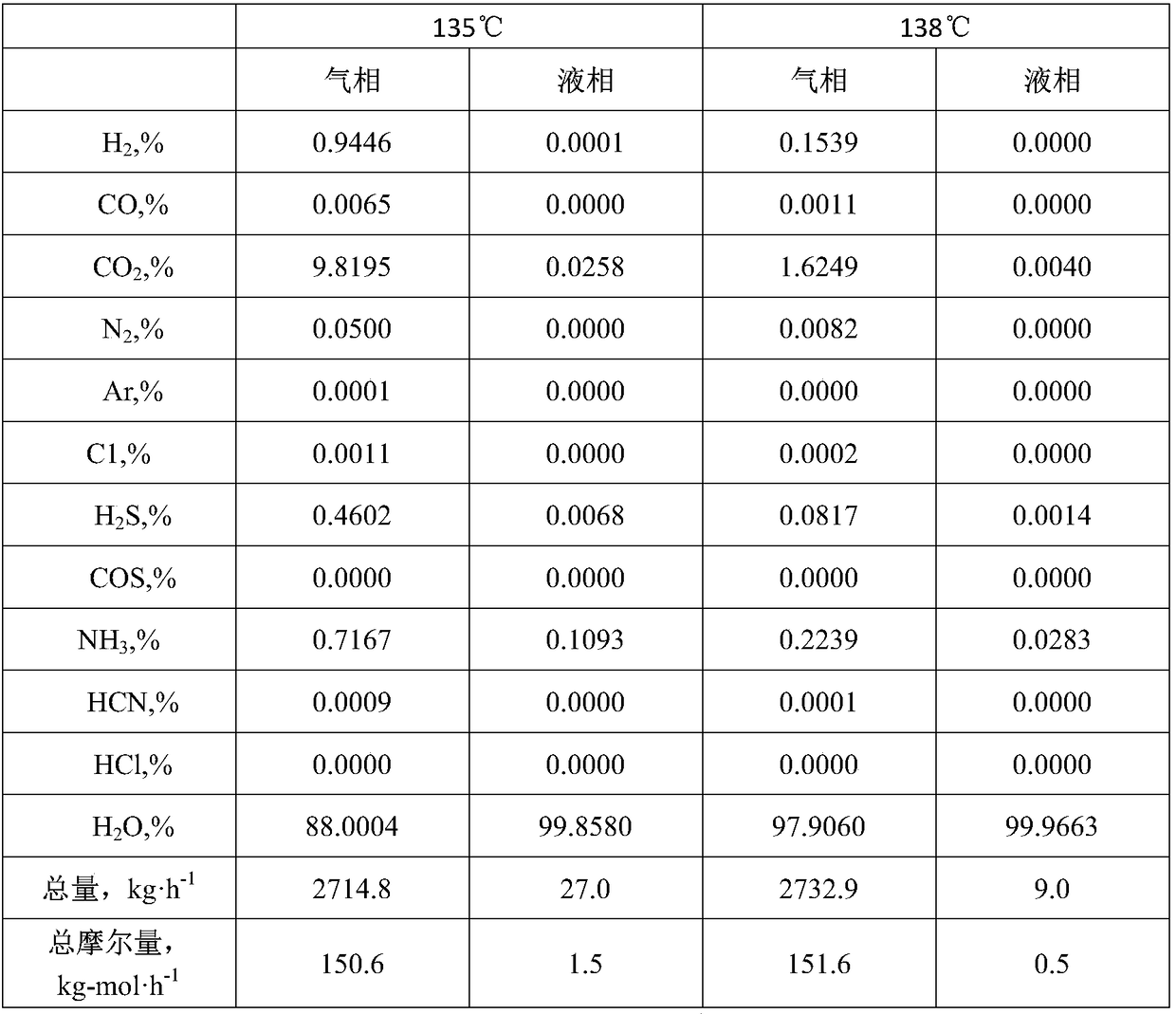

[0043] The shifted gas condensate enters the stripper from the top of the stripper 1, and the acid gas in the condensate is stripped out, and the stripping gas passes through the top of the stripper 1 and exits from the top of the stripper 1 after defoaming. Entering the pipeline connected to the heat exchanger 2, the temperature of the stripping gas at the top outlet of the stripping tower 1 is 148°C.

[0044] The stripping gas passes through the tube side of the heat exchanger 2, is cooled by the desalted water entering the shell side, and enters the separation tower together with the stripping gas passing through the bypass, and the temperature of the stripping liquid at the inlet of the separation tower is controlled at 135°C; The boiler replenishment is carried out through the shell-side desalted water inlet pipeline;

[0045] The cooled stripping liquid enters the separation tower, where the gas and liquid are separated, and the gas phase is adjusted to a gas phase press...

Embodiment 2

[0047] The shifted gas condensate enters the stripping tower from the upper part of the stripping tower, and the acid gas in the condensate is stripped out. The stripping gas passes through the top of the stripping tower after defoaming and exits from the top of the stripping tower. The pipeline connected to the heater, the temperature of the stripping gas at the top outlet of the stripping tower is 146°C.

[0048] The stripping gas passes through the tube side of the heat exchanger 2, is cooled by the desalted water entering the shell side, and enters the separation tower together with the stripping gas passing through the bypass, and the temperature of the stripping liquid at the inlet of the separation tower is controlled at 138°C; The boiler replenishment is carried out through the shell-side desalted water inlet pipeline;

[0049] The cooled stripping liquid enters the separation tower, where the gas and liquid are separated, and the gas phase is adjusted to a pressure of...

Embodiment 3

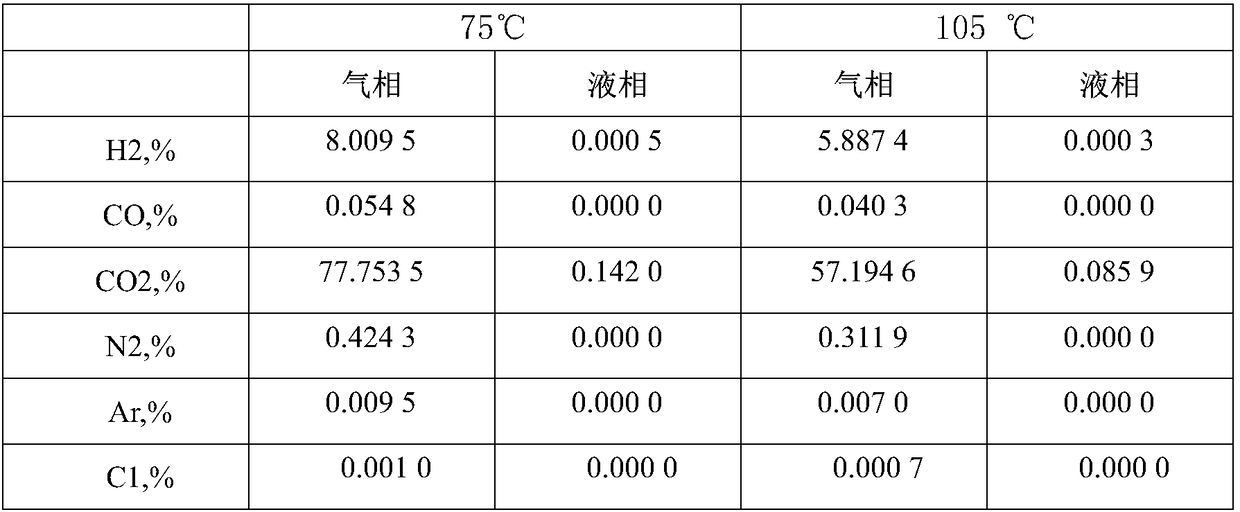

[0051] The shifted gas condensate enters the stripping tower from the upper part of the stripping tower, and the acid gas in the condensate is stripped out. The stripping gas passes through the top of the stripping tower after defoaming and exits from the top of the stripping tower. The pipeline connected to the heater, the temperature of the stripping gas at the top outlet of the stripping tower is 140°C.

[0052] The stripping gas passes through the tube side of the heat exchanger 2, is cooled by the desalted water entering the shell side, and enters the separation tower together with the stripping gas passing through the bypass, and the temperature of the stripping liquid at the inlet of the separation tower is controlled at 105°C; The boiler replenishment is carried out through the shell-side desalted water inlet pipeline;

[0053] The cooled stripping liquid enters the separation tower, where the gas and liquid are separated, and the gas phase is adjusted to a pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com